Shut-off valves play an important role in the correct operation of pipelines. Elements such as valves, taps, gate valves and others make it possible to tightly shut off the movement of liquids and gases through pipes, if necessary. One of the most popular types of valves used in household networks is a 3/8 ball valve.

The content of the article:

- What is a 3/8 ball valve

-

Classification of 3/8 ball valves

- In the direction of the pipe

- By modification of handles

- By ball valve size

- Through the bore of the ball device

- By connection method

- By the design of the ball

-

What you need to consider when choosing 3/8 inch ball valves

- Stuffing box of ball valves

- Handle attachment

- Rules for the operation of a ball valve 3/8 inch

What is a 3/8 ball valve

All locking devices and the ball model, including, consist of three parts:

- cylindrical body;

- ball with a slot or hole (through) - located inside the body;

- a stem, which is attached to the ball on one side, and on the other to the lever.

The latter serves as a rotary device. By turning it one way or the other, the inner space of the ball valve can be closed or opened.

This is how a ball valve should work. With its help, it is impossible to regulate liquid or gas flows inside the pipeline (throttle them). If, due to lack of knowledge or other reasons, this is done, the fittings quickly fail. It is not difficult to determine what caused the defect. Such ball valves are not covered under warranty repair.

The stem goes through the body, but the lever is outside of it. In order not to be mistaken with the adjustment, in the factory, the assembly of these parts is carried out in such a way that if the latter is located along the valve body, then this means that it is open. Liquid or gas can move inside it. If the arrangement is transverse, then the ball valve is closed.

The ball type of shut-off valves was invented a long time ago. But it was not possible to use it due to the poor quality of the seals. Today, there are several high-quality sealing materials that are used in the construction of ball valves:

- synthetic rubber of nitrile butadiene type (NBR);

- teflon.

The first is black, the second is either white or yellowish. Be sure to add lubricants to the seals that increase the performance of materials. A commonly used option is graphite.

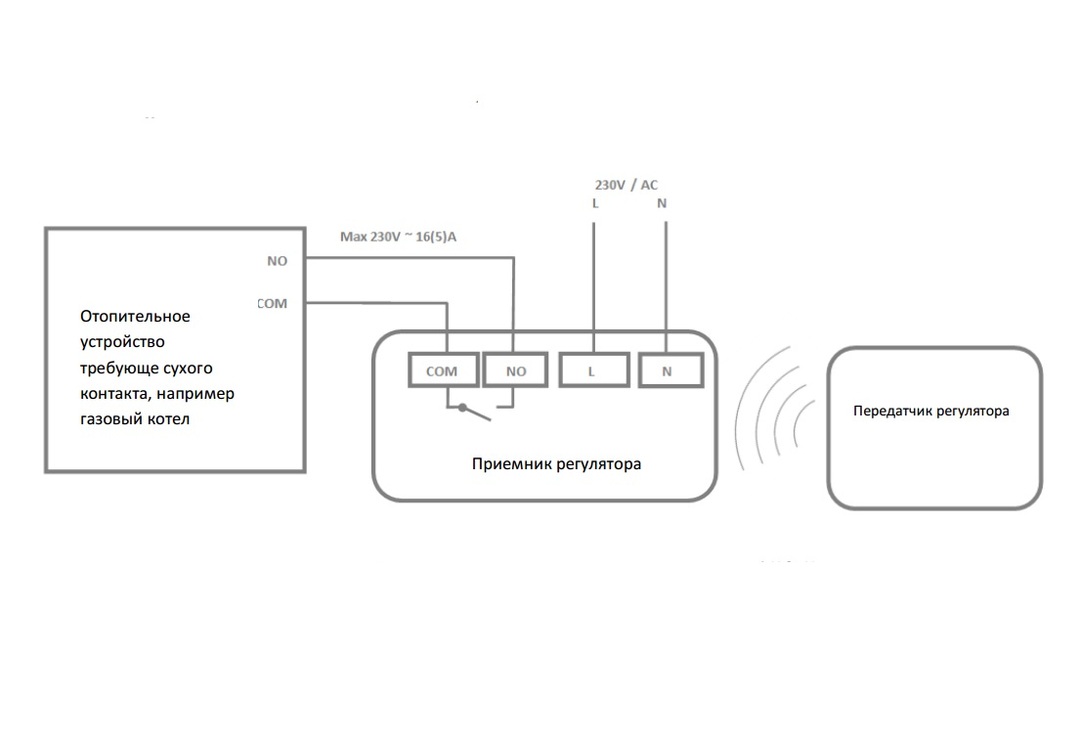

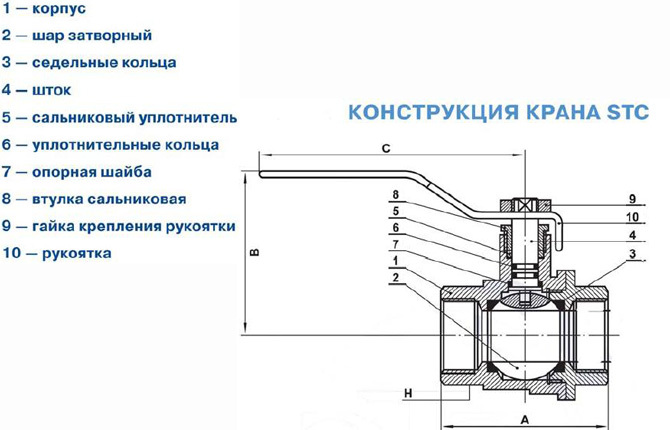

Structural diagram of ball valves

Classification of 3/8 ball valves

There are several characteristics by which 3/8 ball valves are classified. The first one is based on the material of manufacture. There are three groups here:

- steel;

- cast iron;

- brass.

Manufacturers offer ball valves that include polypropylene parts. This is a combined option.

For the domestic pipe network, 3/8 brass ball valves are considered the best. They are made according to the technology of volumetric hot pressing. The starting material is one hundred percent pure or lead-containing brass.

Most models are coated with a galvanized layer, which increases the life of the ball product. It is silvery in color. Therefore, it is necessary to pay attention to the inner surfaces of the tap pipes. If they are yellow, then the element is made of brass. You can rub the surface of the case with sandpaper. If yellowness appears, then it is brass.

Today on the market you can find 3/8 ball valves from ZAM. It is a zinc-aluminum alloy. Worst case for plumbing. They fail quickly. The reason is zinc corrosion. They can be distinguished from brass ball valves by their specific gravity. They are lighter.

In the direction of the pipe

The classification is based on the direction of the pipe line, which can be straight or branched. In the first case, a ball valve connects two pipes laid along one axis. In the second, sections of the network are connected at an angle - usually at right angles.

Angle ball valve 3/8 is rarely used here. It is better to install a standard straight-line, and connect the pipes through an elbow or tee.

By modification of handles

There are also two varieties here:

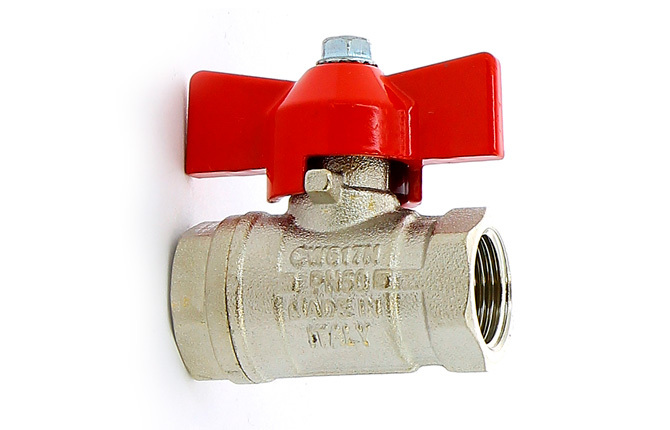

- butterflies installed on small cranes;

- levers for reinforcement of large cross-section.

The second design allows it to withstand heavy loads. In this case, it is easier to open the pipeline with a lever.

Ball device butterfly handle

By ball valve size

Ball valves are dimensioned in inches. For example, 1 inch is 25.4 mm. Correspondingly, 3/8 inch is 9.5 mm. But there are other common dimensional parameters. Each ball valve is selected for the diameter of the pipe to which it is connected.

Through the bore of the ball device

There are also two positions here:

- full bore;

- partly through passage.

In the first, the passage opening of the valve coincides with the opening of the pipe. Therefore, the permeability of liquid or gas through the pipeline is almost one hundred percent. The shut-off valves do not create resistance.

The second is a special solution if it is necessary to limit the volume of flow of liquid or gas. Partially passages are divided into two subgroups:

- standard bore. They have a ball hole one size smaller than a pipe. Throughput capacity - 70-90%;

- partial bores. The hole in the ball is smaller than the pipe diameter. Low permeability of the node - 40-70%.

By connection method

This refers to the connection to the pipeline. The classification includes 4 positions:

- coupling, they are also threaded;

- flanged;

- welded;

- combined - one end can be welded, the other threaded and other combinations.

The first option has a tapered or cylindrical thread. Typically, such ball valves are installed on pipe sections with a diameter of not more than 50 mm. The thread can be external or internal.

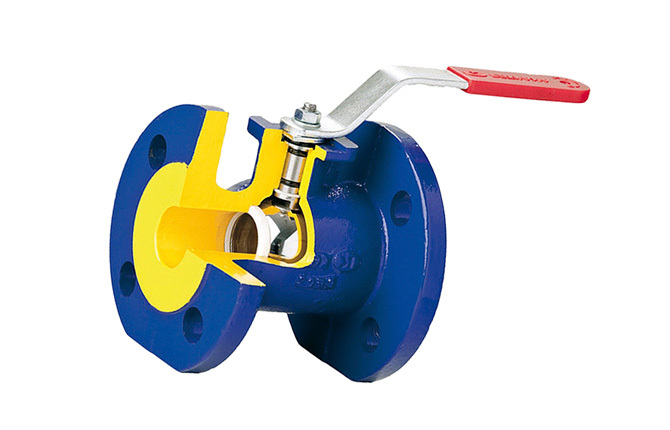

Flanged are mounted only on pipe lines with a diameter of more than 50 mm. Collapsible and non-collapsible flanges are used. This type of ball valves is installed in those rooms where it is impossible to carry out welding work. Or where it is necessary to carry out frequent repairs of the site, its dismantling.

The third category includes both steel and plastic cranes. A distinctive feature is the most tight connection with pipes. Typically, the installation of such cranes is carried out on the external sections of the pipeline.

Flanged ball design

By the design of the ball

There are also 2 positions here:

- The ball is floating. The design got its name due to the fact that the ball is not tightly connected to the stem - two parts can move relative to each other. The offset is small. The ball inside the tap works like this - the internal water pressure presses the first one against the seal, which creates a high tightness of the structure. In the open state, the tightness is not important.

- Ball in supports. Supports in the form of protrusions are added to the structure. There are two of them - lower and upper. The purpose is to enter the saddles (seats) and secure the ball tightly inside the body. This design reduces the effort required on the lever to open or close the pipeline. But the complexity of the device increases its cost.

The ball is electroplated, which is based on chromium. It is applied to either an aluminum or nickel substrate. If the substrate is not applied, the service life of the coating is significantly reduced.

Several manufacturers offer 3/8 ball valves with a Teflon-lined plug. On the one hand, friction is reduced. On the other hand, Teflon is a fragile material. And since solid particles move in the pipelines, they quickly disable it, which leads to depressurization of the ball valve.

What you need to consider when choosing 3/8 inch ball valves

The most important parameter is the pipe diameter. It is clear that the two diameters (device and pipe) must match.

The second selection criterion is the material from which the ball device is made. Stainless steel is stronger, more durable, but they are expensive. In this regard, brass have shown themselves perfectly in household pipe systems. But we must take into account what brand of brass they are made of. If it is LS59-2, then you can safely buy the device.

The ball is usually made of stainless steel, but not always. When choosing a 3/8 ball valve, you must familiarize yourself with the product labeling. It is available on all devices, regardless of the manufacturer. Usually two parameters are specified:

- bore diameter, denoted as Dn;

- the pressure of the working medium, which the valve must withstand, is denoted by - Pn.

Serious manufacturers indicate their logo. But the absence of this mark is not an indicator of poor quality.

It is important to pay attention to the pressure. If you buy a 3/8 ball valve and install it in an engineering system in which the pressure of the flowing medium, then there is a high probability that with low pressure the device after a while will cease to hold load. He will start to siphon.

Ball valve marking

Stuffing box of ball valves

The unit ensures the tightness of the device to the external environment. Preference is more often given to designs with an external clamping nut. She has an external thread.

The maintainability of the product depends on the stuffing box. There are 3/8 ball valves non-collapsible and collapsible. The first are classified as non-repairable. If they leak, they are replaced with new ones. The latter can be repaired.

Maintainability makes the valves vulnerable to pressure inside the pipes. In their design, the stem is inserted from the outside and only a union nut holds it in the body. Chances are high that it will be knocked out under the pressure of the environment. It is better to purchase ball valves 3/8, in which the stem from the inside holds the collar.

The sealing elements also affect the long life of the valves. Today, more and more manufacturers use Teflon as the best sealing material. But it is expensive, therefore it affects the cost. To lower it, unscrupulous manufacturers resort to tricks:

- reduce the thickness of the gaskets;

- use Teflon from secondary raw materials, of low quality.

Another point is to properly crimp the Teflon seat rings around the ball. If the ball inside the body rotates freely, it means that the compression was carried out incorrectly. Such a ball valve will start to leak.

If, on the contrary, the valve opens and closes tightly, then after a while, due to the frictional force, the seal will become thin - this will lead to a loss of sealing.

Handle attachment

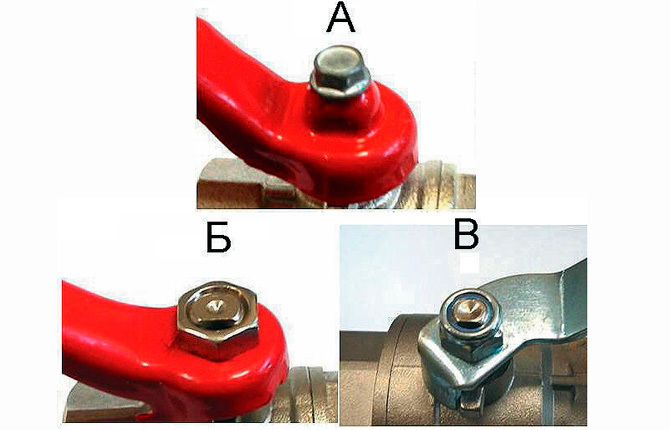

Good fastening extends the life of 3/8 ball valves. Take a look at the photo below.

Handle attachment methods

Option "B" is ideal in this case. A polymer gasket is put on the stem. It is installed in an interference fit - its diameter is less than the diameter of the stem head. A nut screwed on top will never unscrew under any load.

Option “A” is a mounting screw that is screwed into a hole made from the end of the stem. This is the most unfortunate option, because the screw will loosen all the time. Internal threads will thinner over time and will no longer hold the fastener.

Option “B” is an ordinary nut, which will be unscrewed under the influence of pipeline vibration. It will have to be tightened up periodically. Here it is important to accurately catch the twist effort. If the nut weakly tightens the handle, the latter during operation will create serious loads on the stem, which can lead to its breakage.

Rules for the operation of a ball valve 3/8 inch

Any stop valves, if properly installed and operated, will last longer than the warranty period. This also applies to the ball valve 3/8. Since domestic pipe engineering systems use various media, mostly untreated, it is highly likely that valves of this type will quickly fail. Therefore, it is recommended:

- Install a 3/8 mini ball strainer in front of the tap to retain abrasive particles. The latter thin the seals, which leads to depressurization of the structure.

- If it is a threaded model, then the threads on the pipe and the valve must be the same. This applies not only to the diameter, but also to the height, the distance between the turns.

- If it is impossible to turn the handle, do not artificially add length to it in order to increase the effort. Any mechanical overload on the stem will cause it to break.

Ball valves 3/8 over time begin to work incorrectly: they leak, it is impossible to turn the handle, they let the medium moving through the pipes pass when closing, and so on. If a non-repairable ball model is installed, then it will have to be replaced with a new one. If it is repairable, it is worth understanding its repair, which basically boils down to replacing the gaskets.

When the coating of the ball has become unusable: rust, dents, cracks, traces of abrasive particles, then there is no point in repairing such a ball device. Better to replace.

The 3/8 ball valve is an important part of the pipeline. It is installed in plumbing, heating circuit and others. In order for a product to last a long time, it is worth considering its material, seals, manufacturer and technical characteristics.

Have you ever chosen or used a ball valve? Share your experience in the comments. Bookmark the article, repost it on social networks.

We also recommend watching selected videos on our topic.

How to Choose the Best Ball Valve?

Ball valves and valves markings - what do the icons, numbers and letters mean?

Sources:

- https://aw-therm.com.ua/osobennosti-vybora-sharovyh-kranov

- https://santehstandart.com/poleznye-materialy/kran-sharovyy-3-8