Each building, regardless of its purpose, is equipped with supply and exhaust ventilation. At low air speed, dampness, mold, and unpleasant odors appear. Over time, the destruction of the load-bearing elements begins, the service life of the structure decreases, and various engineering communications fail.

In order for the system to work without interruptions, moisture does not penetrate into the channels, nodes for the passage of ventilation exhaust shafts are installed. Air intake and exhaust points are located at the highest places. Often a roof is chosen for their installation. But what are these nodes and how to install them correctly?

We will talk about this in detail in our article - we will consider the types of nodes, the features of their use, the technology for removing ventilation through the roof. This information will help to avoid mistakes that are made by inexperienced users when choosing elements, installing them, which leads to the appearance of serious defects, disruption of the entire system.

The content of the article:

-

Features of ventilation passage units

- Structural elements of the pass-through unit

- Typical versions of penetrations

- Recommendations for the selection of penetration

-

Rules and features of the installation of the passage assembly

- Option # 1 - ventilation outlet on a solid roof

- Option # 2 - performing work on a soft roof

- Conclusions and useful video on the topic

Features of ventilation passage units

Exhaust ventilation in a private house and a small public building can be represented by a complex, branched air duct system. They can be combined into common channels or brought out independently.

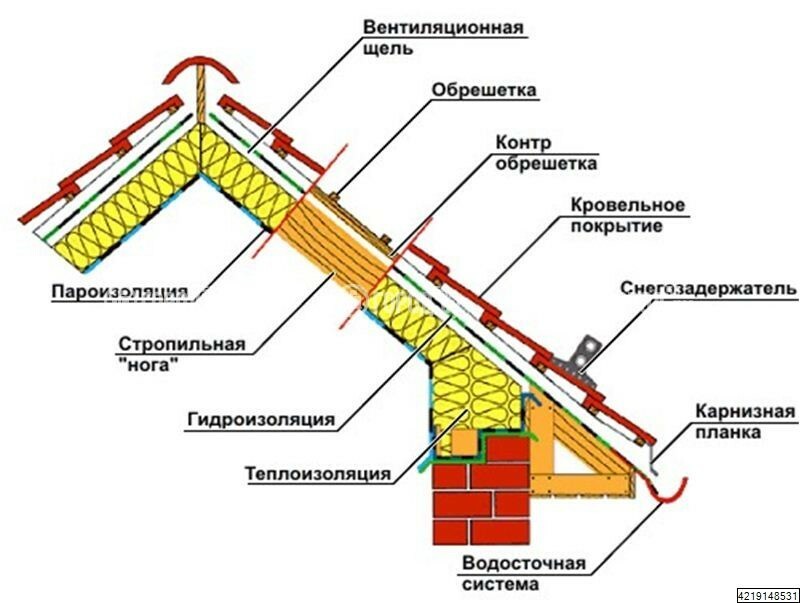

To allow the exhaust air to leave the building without hindrance, a through hole must be made in the roof. Such a passage needs insulation, high-quality sealing, and other arrangement measures.

In the presence of defects in the process of passage of exhaust ventilation through the roof, it becomes possible for melt, rainwater to penetrate under the insulating material, the formation of cold areas. As a result, wooden, metal elements of the roofing cake are destroyed, the coating deteriorates much earlier than the allotted time.

It is also equally important to eliminate the likelihood condensation. Moisture droplets appear as a result of temperature differences between warm, humid air in the inner part of the room, and the outer part of the duct, the open part of the roof, cooled by the street air.

All exhaust ventilation ducts must have access to the street. This allows the exhaust air to be easily discharged from the room.

Installation of ventilation shafts passage nodes allows you to solve such problems. They help to remove waste air masses without disturbing the roofing system.

Structural elements of the pass-through unit

Structurally, the passage assembly consists of the following elements:

- roof openingsexactly matching the ventilation duct;

- section of the ductequipped with insulation;

- the lower part, in which the sealing casing is located - its task is to create a platform around the hole, hermetically connected to the roofing.

The main element of such a unit is considered to be penetration - ventilation devices that ensure the functionality of the unit.

Transits are made from different materials. Elastic models are made of durable rubber and other flexible materials. They easily tolerate the negative effects of atmospheric phenomena, are resistant to harsh ultraviolet radiation, changes in humidity and temperature. The main advantage of the product is the presence of a flexible sleeve that allows you to change its shape.

Ventilation passages can be made of different materials. However, the most popular are elastic structures. They can be used on different types of roofs

Rubber penetrations are used on roofs with different slopes. The sleeve height is different in different models. The greater the slope of the roof, the more the sleeve should be at the penetration.

Plastic products have excellent performance characteristics. They are distinguished by a long service life, resistance to low temperatures, ultraviolet radiation, and humidity. For different types of roofs, penetrations of various configurations are available.

On the roof there can be several nodes of the passage, which ensure the release of exhaust air from bathrooms, kitchens, basements, and other systems. If the area of the cottage is small, there may be one passage node.

Typical versions of penetrations

Relatively recently, there were very few options for the execution of the nodes of the passage. The elements were made in the form of sections of air ducts with a square, circular cross-section. Mounting washers were welded to them, the structure had additional reinforcement due to the presence of stiffeners.

The passage unit must ensure the unhindered passage of air, tightness, thermal insulation of the joints, while not preventing precipitation from the roof

The nodes of the passage were installed in reinforced concrete mounting sleeves - special support structures. The glasses were fixed to the roof during the construction of the building and were equipped with a horizontal platform that allowed supporting elements to be installed on surfaces with any slope.

Thanks to the development of private housing construction, there are many more varieties of passage nodes that differ in characteristics and operating conditions.

Today manufacturers offer:

- spark-proof modelsused in exhaust ventilation of enterprises that work with flammable gases;

- products with valveequipped with a condensate collection ring;

- models without valve.

By choosing a duct without a valve, designed for an exhaust ventilation shaft, the homeowner gets the simplest device. It will be the optimal solution for a constantly running system that does not require periodic adjustments.

The valve is required, if necessary, to close the access for cold air - during the period when the exhaust ventilation is not working.

Passage assemblies equipped with valves differ in different types of control:

- manual - relevant for stably operating systems that do not require constant adjustments, and is implemented using a cable, a counterweight, which allow you to regulate the rate of air exchange in the house;

- automatic - is carried out with the help of an electric drive, if necessary, frequent changes in the operating modes of the exhaust ventilation.

The devices can be additionally equipped with a condensate collection ring.

A wide range of exhaust ventilation duct assemblies allows you to choose a product that will be externally combined with the roof design. Different models are equipped with connecting platforms with different reliefs, which greatly simplifies installation

Today in construction, walkway components made of polymers or metal are used. Plastic Models significantly facilitate installation work, reduce maintenance costs.

Using metal productsHowever, homeowners sometimes experience noise generated by air currents.

Recommendations for the selection of penetration

The selection of the passage unit is carried out depending on the type of air ducts used when installing the exhaust ventilation.

By form they are:

- square;

- round;

- oval;

- rectangular.

The models also differ in section size. To ensure waterproofing, the devices are equipped with connecting platforms, which are installed before the roof is covered. For example, when installing the passage assembly on a roof made of metal tiles, foil paper is necessarily used, all holes are filled with sealant.

When choosing a passage node, you should dwell on products of a domestic manufacturer, as well as on imported models adapted for use in the climatic conditions of your region.

The selection of the passage unit is carried out at the design stage in accordance with the design requirements of the exhaust ventilation system, the features of its operation

Selected models are equipped with insulated valves, excluding the possibility of icing. This ensures uninterrupted operation of the automation during severe frosts.

As a preventive measure, the passageway assembly should be regularly inspected to prevent:

- the presence of mechanical debris inside the valve;

- difficulty in rotating moving elements;

- no gap between the valve and the body, the distance between them is less than 2 mm;

- violation of the integrity of seals, linings;

- the appearance of cracks, other mechanical damage in the inner, outer parts.

In the presence of the above violations, the passage assembly must be replaced.

Also, when choosing a passage unit, it is important to distinguish devices for exhaust ventilation from devices for chimneys. The ventilation system is used to discharge exhaust air masses, but through the chimney hot combustion products are removed, therefore such a passage unit needs additional fire protection.

Rules and features of the installation of the passage assembly

When planning an independent installation of the passage assembly, it is important to consider rules for its construction, take into account a number of nuances and ensure during installation:

- tightness - the connecting flange must adhere tightly to the surface to prevent moisture from entering the inner layers of the roof;

- no barriers to rain, melt water - it is especially important in the off-season, during thaws, when the moisture remaining in the cracks freezes at night, expanding the gaps, violating the integrity of the coating, the general tightness of the roof;

- thermal insulation of the structure - which will avoid the formation of condensation, which will gradually destroy the rafters and other elements of the roofing system.

On the top of the passage assembly is located deflector. It prevents birds, small debris and moisture from entering the exhaust duct.

Most of the deflectors have approximately the same appearance. For those wishing to stand out, manufacturers offer unique designs.

In some models of the passage units intended for exhaust ventilation ducts, the deflector is made in the form of a wide valve that protects the air duct

The choice of installation technology for the passage assembly depends on the characteristics of the roofing material, the angle of inclination, and other technical characteristics of the roof. All actions during the installation process are aimed at creating a hole corresponding to the size of the air duct, sealing it, and insulating it.

The general installation procedure involves the following steps:

- Surface marking - the diameter of the hole is made a couple of centimeters larger than the duct. To do this, you can take a piece of pipe or make a template that repeats the shape of the exhaust duct. Having attached the duct to the roof, it is necessary to circle it with a small margin.

- Hole creation - the passage is equipped using a technology corresponding to the type of roofing material. For example, when forming a hole from corrugated board, a grinder is not used. With an electric drill, holes are drilled around the perimeter, which are subsequently connected with scissors for metal, a hacksaw.

- Trimming insulation layers - this is done carefully so as not to disrupt the configuration of the roofing cake. The passage is inserted into the resulting hole, insulated.

- Pinning a node - the installed unit is securely fixed on the roof surface.

One feature is that experts do not recommend using a grinder to create a hole in a roofing material such as corrugated board, since sparks appear in the process. The fire burns through the micro-holes in the coating. They are not immediately visible, however, over time, corrosion appears in the damaged areas.

If your roofing material is able to withstand the effects of sparks and you plan to make a hole for the outlet of the ventilation duct using angle grinders, we recommend that you familiarize yourself with the rules safe operation of the grinder.

Option # 1 - ventilation outlet on a solid roof

Most often, developers choose metal tiles for roof finishing. Therefore, we will analyze the technology of installing penetration using this material as an example.

It is recommended to install the unit for exhaust ventilation on a solid roof after the installation of ventilation, installation of roofing

First executed roof marking: the exhaust outlet must be located between the rafters. The ventilation shaft is often installed at the horizontal joint of two sheets of roofing material. The top sheet will cover the pass point plate, and the bottom sheet will pass under the plate.

First, the location of the penetration is determined from the inside. It is easy to outline it by drilling a hole in the metal. From the outside, it is necessary to mark the place of the proposed hole with a marker. For this, a template is used, which is included in the set of the passage assembly.

After marking, you can proceed to creating a hole. For work, you can use manual or electric metal scissors. After the hole in the metal tile is created, it is transferred to the inner layers of the roof.

At the end of the work, the installation site is cleaned of small debris, sawdust, and thoroughly degreased. In the places of the planned attachment, holes are drilled for self-tapping screws.

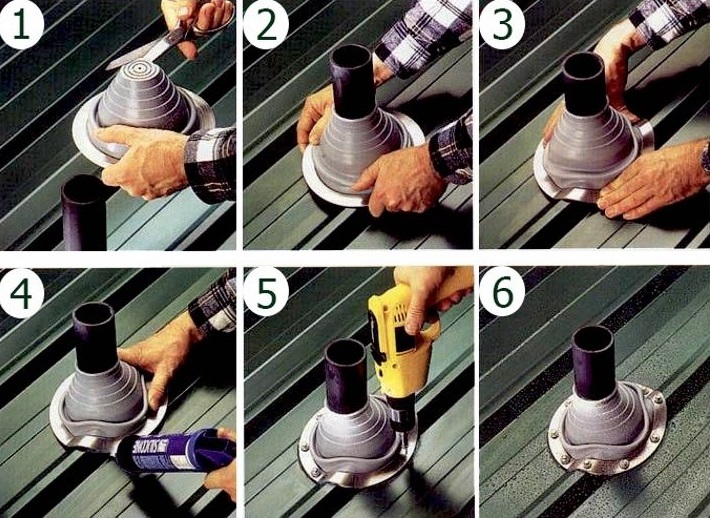

Next comes the turn installation of penetration. At first mounted seal - the sealing element is applied to the attachment point, carefully crimped in accordance with the relief of the roof. Its lower part is treated with the sealant included in the kit, strongly pressed against the prepared hole. Excess sealant is squeezed out from under the gum and applied to the joints.

Then on top of the sealing gum putpass-through element, fixed with self-tapping screws. The final stage is installation of an exhaust ventilation pipe, its connection with the channels running in the house. The outer part of the canal is equipped with drippers, deflectors, umbrellas that provide protection.

The order of installation of the penetration: 1) prepare the passage element; 2) install it on the outgoing duct pipe; 3) crimp the penetration thoroughly in accordance with the topography of the roof; 4) attach to the surface with a sealant, press well around the perimeter; 5) secure with self-tapping screws; 6) fill all joints with sealant

To ensure the smooth operation of the exhaust ventilation in winter, it is important to take care of thermal insulation. The presence of insulation will eliminate the likelihood of condensate formation, freezing of the pipe. We have provided installation nuances and recommendations for choosing a ventilation pipe for the roof in this material.

Option # 2 - performing work on a soft roof

The technology of mounting the outlet unit for exhaust ventilation on a soft roof is carried out in the same way. Many experts note that the installation is somewhat easier due to the lack of a relief of artificial roofing material. During the arrangement of the unit, you do not have to accurately repeat all the bends of the coating, it is enough to tightly attach the elements to the surface, and provide high-quality insulation.

A professional approach, strict adherence to instructions during the installation work - all this will help to create an ideal do-it-yourself exhaust ventilation system

In the process of installation work, special attention should be paid to the tightness of joints, seams. They are carefully processed. If water finds a loophole in the structure, it will cause damage. Even when moisture does not penetrate all layers of the roofing structure, it freezes in the cracks, expanding them to a significant size. By treating all elements with a sealant, it is easy to reduce the risks of leaks, to ensure a long service life of the roof.

If you decide to install the passage assembly on your own, we recommend that you also familiarize yourself with high pipe fixing options in the roof and the main mistakes that are most often made by inexperienced installers.

Conclusions and useful video on the topic

The point of outlet of the exhaust ventilation duct to the roof creates the risk of leaks, violation of the tightness of the roof structure. Therefore, it is important to choose the right equipment for arranging the passage assembly, follow the instructions during installation work. The videos below will help you determine the optimal model, prevent mistakes in the process of installing the passage unit.

Professionals will share the secrets of a competent choice of roof penetration. After viewing, you can easily decide on a model for metal tiles or corrugated board with any profile, as well as a product for soft materials:

The video tells in detail about the stages of working with metal tiles. It is interesting that the penetration is installed at the junction of the sheets:

Installation of several units for exhaust ventilation on a flat roof.

From the proposed material, it becomes clear that there are no particular difficulties when removing ventilation ducts to the roof. Most of the necessary tools are in the arsenal of every home craftsman, and manufacturers offer complete set of gangways, equip craftsmen with fasteners, and high-quality sealant.

If you already have experience in removing exhaust ventilation to the roof, share it in the comments. If you are just planning to carry out work, or you have questions, ask our experts and other site visitors - the feedback block is located below.