Perhaps you consider yourself a connoisseur of bathing or just love it. There are many such people, and some have their own baths, but even they make mistakes. You've probably heard about the importance of ventilation - when arranging it, mistakes are made very often, especially with regard to the bastu system, which provides many options for air removal. Correct ventilation of a bastu in a Russian-type bathhouse with its high humidity gives many advantages.

After studying our article, you can choose the parts yourself and assemble the ventilation duct without assistance. The work will take a lot of time, but it will not be difficult if you know everything. We will also talk about the advantages and disadvantages of bastu ventilation.

Bastu works with a certain air circulation. Much depends on the layout of the bath - you will need to combine your own comfort and the ideal layout for ventilation. Find out more about the principle of operation of this ventilation system and its components from our article.

The content of the article:

-

Feature of ventilation bastu in the bath

- Benefits of ventilation bastu

- Disadvantages of the bastu ventilation system

- Ways to increase ventilation power

-

Installation of ventilation system bastu

- Preparation of tools and materials

- Ventilation training

- Conclusions and useful video on the topic

Feature of ventilation bastu in the bath

Bathhouses and saunas have steam rooms, and at different conditions they all need ventilation. In the steam room, the air is renewed up to several times per hour. The ventilation drawing is drawn in advance, sometimes they are chosen among standard solutions for each size.

The word "bastu" is Swedish for sauna. From him came the name of the type of ventilation. At the top, this system is closed, and at the bottom it works as a supply and exhaust system. The ventilation includes any heaters, if they can heat the air flow.

The exhaust system is located behind the wall, and its inlet has a horizontal direction, plus it is in a straight pipe. She is depicted here conditionally

A detailed ventilation scheme for bastu looks like this:

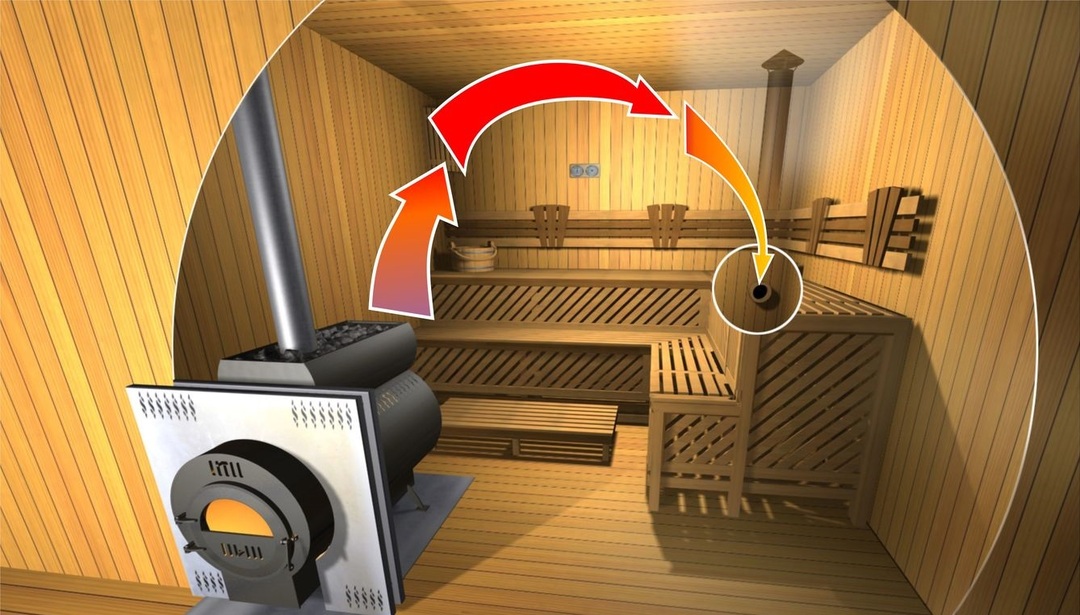

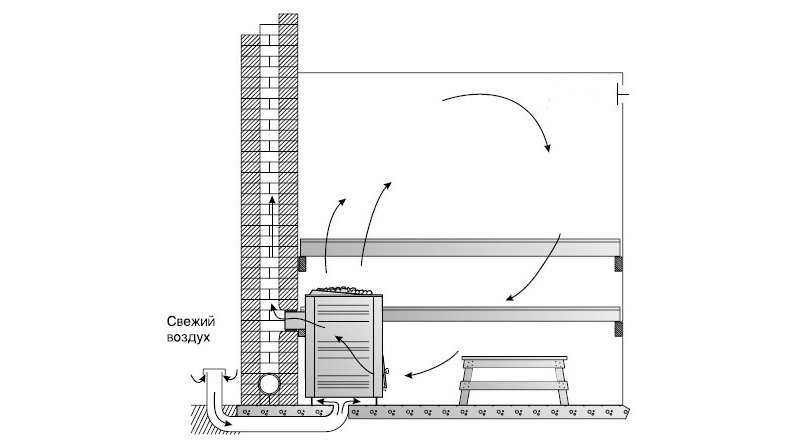

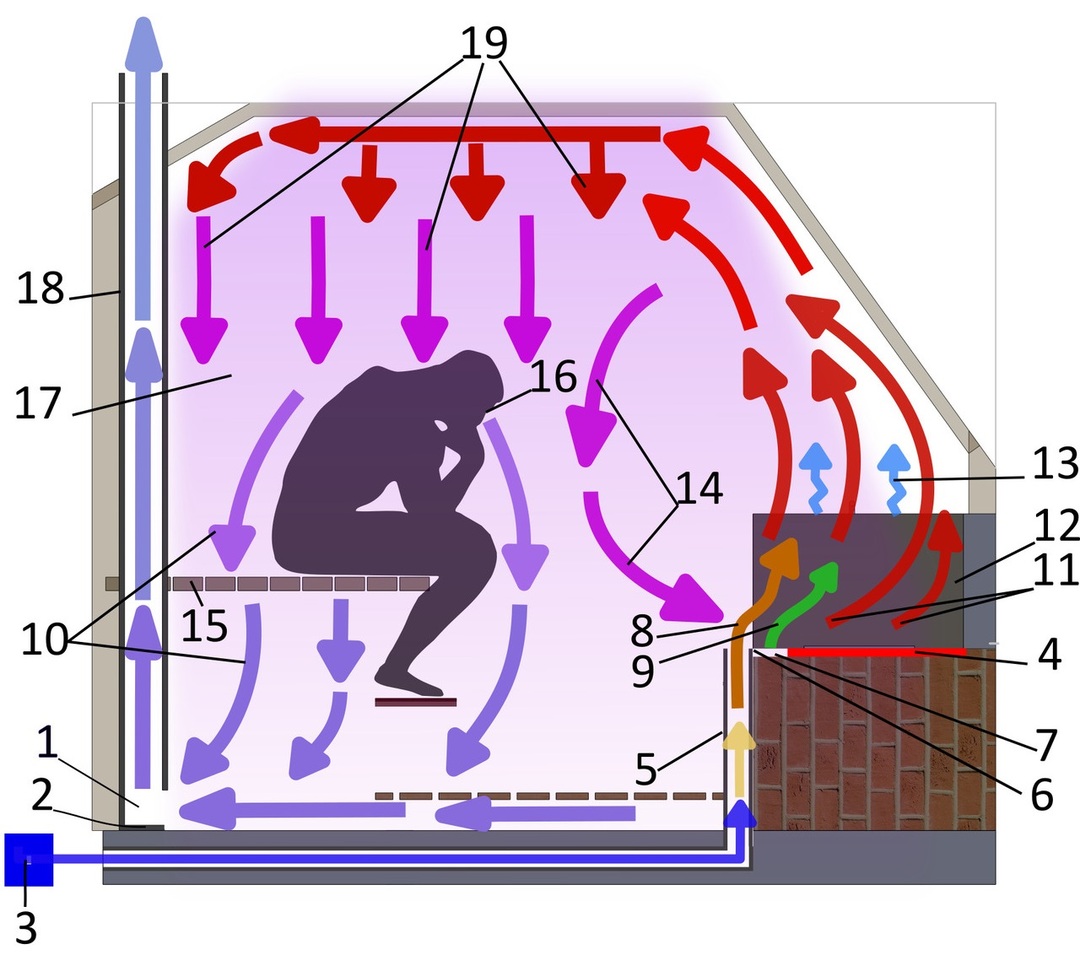

- Air through the supply channel enters the steam room from the street. In the classic and most common version, this is exactly what happens.

- The inflow enters the room at the place under the stove (in the floor or at the bottom of the wall) and heats up from it.

- Warm air goes up and mixes with the steam. Under the ceiling, it gradually cools down and begins to descend. Steam, saturated with microscopic water droplets, moves in the same way.

- So that the air does not circulate in the steam room and the excess of carbon dioxide does not harm visitors, it should be removed outside.

- The natural exhaust method works: the air, after sinking to the floor, begins to go into the lower opening of the vertical pipe. The difference in pressure leads to its suction and movement along the channel upward and further out into the street. The pipe also heats up and raises the temperature of the air, which contributes to its rise.

- Before getting outside, the air passes from the vertical pipe to the horizontally located tee, which is higher. One end of this part goes into the street, and the other - into the room. The second should cover the plug. It is removed for normal ventilation and to reduce heat.

- Another and more efficient option is when there is no horizontal movement in the exhaust system, and its vertical pipe exits through the roof. A bastu of this type also has a tee - shorter and with vertical rather than horizontal placement.

Bastu works without fans / blowers and only due to natural air movement.

Discharge of air into the stove directly in the steam room increases the ventilation several times, but the temperature will drop rapidly

The outside opening of the exhaust duct should be the end of the pipe, not a flat passage. Remember power sauna stove. The higher it is, the more important is the turn of the air in the bastu pipes. The thrust is weakened by the change in movement.

Due to their high power, in the instructions for quick-burning stoves, it is suggested to make a strictly vertical exhaust duct with an outlet through the roof. Keep this in mind. Due to the design with a twist and a powerful stove, the tree will begin to rot, and it will become difficult to control humidity.

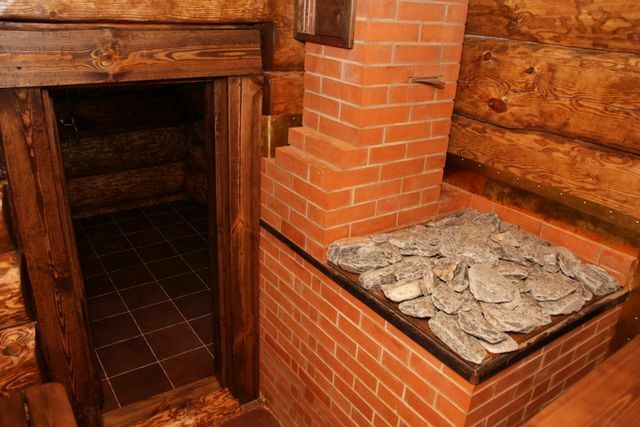

The stove can be located in an open place or behind a partition, then the incoming air will come out above it. Sometimes there is only a stove in the steam room, from which the air is heated, and the stove remains insulated.

Outgoing air enters the chimney at a low height above the floor or falls under it and enters the duct, the opening of which is also below the floor. Sometimes the cooled air goes under the seat of the shelf, where it enters the pipe. In some baths, the channel is hidden in a box, in a wall or behind it.

The exhaust part of the bastu is placed closer to the corner, and if the stove also has an angular arrangement, then the pipe is placed diagonally opposite.

Do not raise the exhaust duct inlet above your knees - it will be too cool below. In Russian baths, high humidity is maintained, therefore, sometimes it is necessary to install a control valve on the hole. They reduce the outflow of air if there is not enough moisture in the bath.

An ideal solution for air circulation: in the image 1 - the opening of the exhaust duct, 2 - the floor, 3 - the air from the outside, 4 - the heated surface of the oven, 5 - continuation after the inlet channel, 6 - horizontal edge of the furnace, 7 - place for aromatic substances, 8 - heated air, 9 - evaporating aromas, 10 - high density exhaust air, 11 - convective currents, 12 - tank - humidifier, 13 - humidity and steam, 14 - air, which is sucked in by convective currents, 15 - shelves, 16 - breathing zone, 17 - steam cake, 18 - chimney through the ceiling, 19 - steam-air mixture

Bastu ventilation is suitable for simple steam rooms and combined with a sink. The pipes are suitable in stainless steel or galvanized steel.

Sometimes they take channels for the drainage system and insert into each other, but they are more suitable air ducts.

Benefits of ventilation bastu

The main plus of circulation with a closed upper part of the room is that the air warms up more evenly. Objects in such a steam room also heat up better.

Other advantages of air exchange according to the bastu principle:

- fresh air for heating comes from the street;

- pleasant smell in the steam room;

- no additional ventilation devices are needed;

- more health benefits;

- facilitated bath care;

- large comfort zone in the steam room.

The ventilation system based on the bast principle has three options for the operation of the exhaust duct. With the plug and the bottom valve open, it will become much drier and the steam room will receive fresh air through the exhaust section.

With the lid closed and the valve open in the steam room, the pressure will decrease and excess moisture will leave - this is the operating mode. Without a plug and with a closed gate under the horizontal exhaust pipe, the steam room becomes cooler and fresher.

Disadvantages of the bastu ventilation system

Disadvantages manifest themselves in different ways, depending on the situation. Wood-fired stoves emit carbon monoxide, so you can enter the steam room only after complete combustion. During this time, the supply part of the bastu system will noticeably cool the room and the stove. You will have to heat with a large amount of firewood, which is even worse, more expensive and inconvenient in time.

The consumption of raw materials after kindling can be reduced with any ventilation, not necessarily of the bastu type. It is enough to cork it.

One of the strengths of bastu is that the air does not look for cracks, but combined with waterlogging from an unsuccessfully chosen ventilation pattern, mold appears because of this

In Russian baths, it is customary to add water to hot stones. More humid air burns more strongly, and with ventilation bastu it sinks onto the bathhouse attendants almost without losing temperature, especially if the air outlet is placed under the shelf. We'll have to open the window more often.

Weaknesses of such ventilation:

- Low power. The exhaust part copes worse with air exhaust compared to top ventilation, ash pan, mechanical systems.

- You cannot put a filter under the stove, it will melt.

- On a calm day, the thrust decreases.

- Strong gusts of wind lead to drafts, cold at floor level.

The main disadvantage of the bastu is its relatively low power.

Ways to increase ventilation power

Power is increased in several ways. If the ash pan of the stove is in the steam room, then it should be surrounded by an elevation. The air near the stove will heat up, then make a semicircle along the upper half of the steam room and, already heavier and cooler, will first descend on the opposite side. Due to the difference in height and draft in the ash pan, cold air will enter the furnace (combustion chamber) of the furnace, from where it will exit through the chimney.

Most often, the ash pan is located in the recreation room, and the closed part of the furnace is sent to the steam room. Then, under the floor of the steam room, you can place a pipe for intake of exhaust air, with a hole at the wall farthest from the rest room. Place the opposite end of this exhaust duct under the ash pan in the break room. The draft of the stove will remove air from the building much faster than the chimney in a steam room.

A window at the head: in the winter it is opened and the humidity is reduced, it is also used to give fresh air to the steaming one or to reduce the temperature of the heat

The bastu exhaust duct should still be left for additional ventilation. Just below the junction of the vertical and horizontal pipes should be gate to deactivate traction. Close it so that air can only be evacuated through the ash pan of the furnace.

In the case of a chimney with a horizontal outlet, the influence of external air is manifested. Its streams go down the roof slopes and weaken the traction. In winter, there is another problem. A gust of wind begins to mix the cold outside air with the warm air from the outlet. The two streams swirl and further weaken the suction channel.

Consider the size of the slopes. If possible, make a street conclusion from the side of the tong, where there are no overhangs. It is worth protecting from the cold wind in winter at the design stage of the bath itself. Protect the side under the outer outlet from the side with a building or some kind of heap.

Do not forget about the straight-line version with an outlet through the ceiling and roof.

Installation of ventilation system bastu

We will do everything with our own hands, and before assembling the ventilation in the bath, we proceed step by step: we choose the material, the elements of the bastu, we collect them to the level of the ceiling.

Taking into account all the nuances, it makes sense to try a system with a branch into a pipe going through the roof. First, we choose the material. Stainless steel parts will last twice as long - up to 50 years, but galvanized steel can withstand pressure, bending and many other types of stress better.

Preparation of tools and materials

We choose the number of parts based on the height of the building. Above the roof, the pipe must be raised by more than a meter, and the bottom must be placed just above the floor or under the bench seats.

A set with short insulated pipes, a tee, a TsAGI deflector, a retractable gate and everything made of stainless steel is a good choice, but not ideal

Let's dwell on the following set for the exhaust ventilation part:

- 3 or 4 pipes 1.25 m in length, with a cross section of 110 mm;

- 2 channels of the same length, with a section of 180 mm;

- tee with cover;

- globular turbo deflector;

- adapter from 110 mm to 180;

- gate.

The elements will be assembled into one another. We will make sandwiches with insulation from pipes of different widths - at the level of the attic and the roof. We connect the adapter to the channel approximately at the level of the ceiling. It is better to take a gate with a rotary damper, and not a retractable one. It will be more convenient this way.

The tee with a strictly vertical assembly will be inside the building. The deflector will help to draw air more intensively, and it works from the wind. The turbo deflector spins and increases traction almost always, even in light winds.

Ventilation training

We begin to connect the parts of the exhaust part of the system. We take the gate and put it into a pipe with a cross section of 110 mm. We place the elements on a solid surface and fasten them with thirteen self-tapping screws from 3 or 4 sides - we use a screwdriver. The gate will be at a comfortable height for control.

At an accessible distance from the floor, but at the top of the steam room, you need to place a tee with a cover. With a strictly straight direction of the pipe, the part is fixed vertically.

We take a 110 mm pipe and cut off a fragment for insertion between the gate and the tee, less than half a meter is enough. The length of the intermediate segment depends on the height of the ceiling more than all other parameters. We measure the steam room vertically. Usually it is 2.1-2.4 meters. Then we insert the cut fragment into the gate and drill it. Then we attach a tee to the intermediate part. We work with a screwdriver.

Galvanizing for air ducts is quite pliable, so an element can be brought inside another without much effort, and a slight curvature can be quickly leveled

We start each element in the previous one and gently press it. Next we take a straight pipe, again 110 mm wide, but not full length, but the remainder after the previously cut fragment. We insert it into the tee through the hole in the ceiling, fasten it inside the steam room. We strengthen all connections starting from the bottom of the exhaust system with tape in order to achieve normal density. We do the same with subsequent ones.

In the attic, insert a sandwich made of pipes of 110 and 180 mm. If necessary, we cut these channels. We place the insulation with a sandwich, and not openly - to protect it from adverse factors. Among the insulation materials, we choose either mineral / glass wool, or foamed based on polymers.

We select the thickness of the insulation, fix it with glue, fix it with tape or adhesive foil over as large an area as possible. We install a 180 mm pipe on the insulation, and the sandwich is ready.

Then we put the adapter from 110 mm to 180 mm into the finished part of the exhaust structure, fix it. We insert the insulated part into the transition element, fasten it with self-tapping screws and seal it with tape. We make another sandwich - part of the system that will be above the roof.

Cut out a hole in the roof. If the roof is made of corrugated sheet, then we make a hole without outside help. We drill points around the circumference to fit the width of the pipe and squeeze out the unnecessary middle. We insert another one of the same into the previously installed sandwich. We go to the attic and fix it there with hardware and tape.

Among the deflectors, a spherical turbo deflector is most suitable, it is up to four times more effective, is not subject to blowing, holds traction well, it can be installed without experience

We install a master flush on the roof. We process its edges with sealant and fasten with large self-tapping screws. Place the turbo deflector on the top of the last pipe. We process the joints with tape, including on the master flush and in front of the deflector. The main stage of work ends here.

We decorate the pipe inside the steam room. To hide the scotch tape, small dents and irregularities, we put on sheathing with imitation of wood or brickwork. We screw a wooden handle to the tee cover.

Thanks to the Dutch oven, the steam room heats up quickly and cools down more slowly, which is good for the bastu system, while less bearing capacity is required from the foundation

For better draft of the incoming air in the supply part of the system, it should be done with a pipe, but only one void between the brickwork will also cope with the task. The gap is left at least 5 cm.

Ideally, the air is supplied so that it comes out exactly under the stove and vertically. Then drafts in strong winds will be less noticeable. The air supply point is fenced off with a small podium about two bricks high. Often they put one row with an edge. The air supply from the street will be regulated by a rectangular butterfly valve.

We also recommend reading our other article, where we talked in detail about the best schemes for organizing ventilation in a bath. More details - go to link.

Conclusions and useful video on the topic

Bastu ventilation drawing with a transition from a vertical exhaust duct to a horizontal one:

Three interesting nuances in the installation of a ventilation system:

How best to do ventilation bastu, examples of errors, and what they lead to:

Now you know what ventilation is and how you can improve the circulation in the bath, make it more comfortable. We told how the ventilation system works, how it works, and also walked through the main options for its installation. Even if you did not understand the device of the bath before, you now know the main thing about its ventilation and you will be able to assemble a new bastu system or improve the old one.

Write comments if you collected ventilation for the bath or thought to do it. Tell us about your steam room. Perhaps you are just planning to build a bathhouse and do not know where to start arranging ventilation? Ask your questions in the form below the article.