Air conditioning equipment from Panasonic has a powerful intellectual functional content. Among the significant advantages convincing the consumer to give preference to these particular air conditioners is the self-diagnosis system. We will tell you how the errors of Panasonic air conditioners are determined by characteristic codes.

From the article presented by us, you will learn how, when a malfunction is detected, the control system informs the owners about an impending or already existing breakdown. You will understand how malfunctions are diagnosed, and then the error code is transmitted to the display of the remote control or indoor module.

Our advice will help you keep your machine in perfect condition.

The content of the article:

- What is the error code?

- Errors on the remote control of the air conditioner

- Interpretation of signals of malfunction

- Standard Care Requirements

- Conclusions and useful video on the topic

What is the error code?

Panasonic air conditioners have a good set of functions and many automatically controlled systems. This can be fine air purification, ionization of the atmosphere, destruction of dangerous microorganisms, etc.

Automation turns off the air conditioner when it needs repair or cleaning. New models of Panasonic air conditioners have an advanced self-diagnosis system. Based on its results, the control system detects a malfunction and reports its cause on the control panel.

The error code is a flashing number-letter designation on the panel of the air conditioner or the module of the multi-split system. If an error code lights up on the air conditioner display, you need to find out what it means

In the event of a serious breakdown, the entire operation of the equipment can be blocked. If the failure does not affect the operation of the system, the error message will continue to flash during operation. If air conditioner or split system detects two or more breakdowns, first a high priority fault is indicated, then all the others.

When a flashing signal appears, you need to immediately figure out the reasons for the failure. There may be several malfunctions, but the most serious one will be displayed most actively.

However, a running air conditioner with a blinking error is not a reason to continue operating the system. Ignoring the sensor signal will exacerbate the problem and, as a result, lead to more serious repairs, entailing high costs.

Therefore, when a blinking signal appears, you need to figure out the causes of the failure as soon as possible and call a repairman for repair or, if you have the necessary experience and skills, solve the problem yourself.

If an emergency occurs, the self-diagnosis system of the air conditioner will stop the operation of the equipment and display an error code on the display. If an error code appears, you must immediately take measures to clean or repair the device.

Also under the cover hiding the air conditioner buttons there is a Check button, with which you can see all errors in the system by scrolling up and down arrows. To reset critical errors, you must eliminate them, after which they will disappear from the display on their own. Errors are also cleared after a power reset.

Errors on the remote control of the air conditioner

In different models of air conditioners, different methods can be implemented for reading the error codes issued by the system. However, the timer indicator on the indoor unit will always flash. Let's take a look at how to determine the error code.

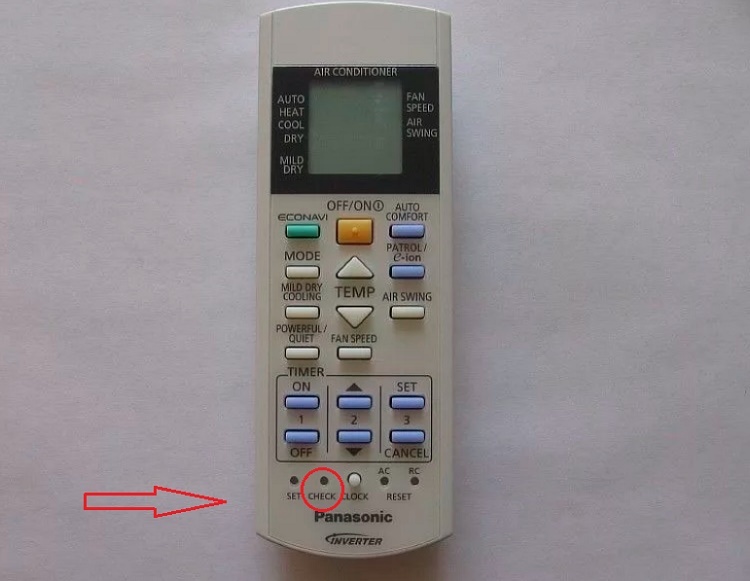

There is a “check” button on the remote control

If the control panel has a “check” button, to read errors, press and hold it for about 5 seconds. After that, the display on the screen will change from temperature values to existing error codes.

To read the error, find the “check” button on the remote control. In order to activate it, you need to press and hold for a few seconds

We direct the remote control to the indoor module of the air conditioner and use the “up” and “down” buttons to scroll through the error log. At the moment when the required error is displayed on the display, the air conditioner module will emit a sound. It is necessary to flip through the journal completely from the first code to the last.

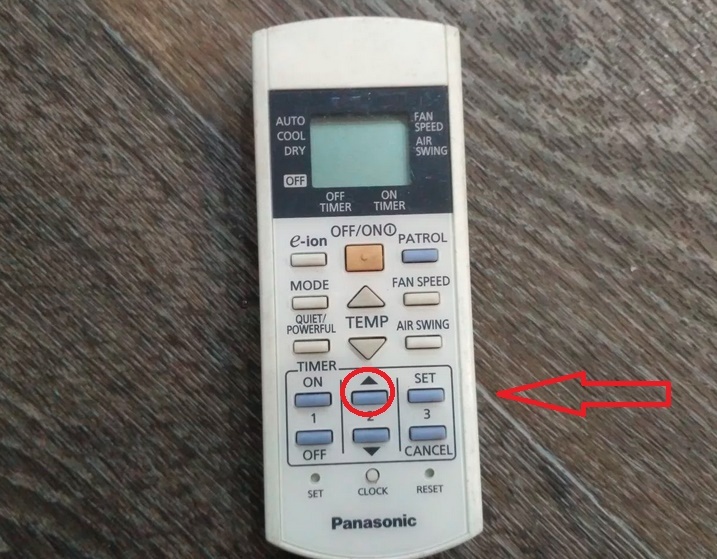

There is no “check” button on the remote control

If there is no “check” button on the remote control, press and hold the “up” timer setting button for 5 seconds. After that, the console goes into error codes mode.

Next, briefly press the same button and leaf through the errors. At the moment of indication, the indoor unit will also make a sound. It is necessary to completely flip through the entire error log, as there may be several of them.

If there is no “check” button on the remote, press the timer up key and wait for the error code programmed by the manufacturer to appear on the display

In both cases, after a minute, the control panel will return to the normal temperature display mode.

On the display panel

This is the standard way to find errors on newer air conditioners. There is an indicator panel on the indoor unit, on which the error code is displayed. The owner of the air conditioner is only required to look at this code and find what it means. In multi-split systems, it is necessary to check the presence of errors on all indoor units.

Interpretation of signals of malfunction

Let's take a look at what error codes for Panasonic air conditioners exist and how to find a malfunction using the code.

H00. There are no problems in the operation of the device.

H11. There is no communication between the external and internal modules or a malfunction of the control boards. If this error appeared immediately after installing the air conditioner, then there were errors in the line. Perhaps there is a cliff somewhere. For diagnostics, you can check all the connections suitable for the boards - it is possible that somewhere on the line there is a bad contact.

A defective control board can cause any error to appear on the display.

If the error appears after several years of using the air conditioner, then it's time to change the board. You need to find out which board is out of order - the indoor or outdoor unit. If an error occurs, the fan of the indoor unit may continue to run.

H12. The total capacity of the internal modules does not match the capacity of the external one. This error appears only in multi-splits. The signal appears 1.5 minutes after switching on.

There may be 3 options:

- the refrigerating capacity of indoor units is incorrectly calculated;

- the number of internal modules is incorrectly selected - the external unit cannot cope;

- error H11 appears on one of the units, then H12 appears on the other (wrong number of indoor units).

H14. The problem with the air sensor - the sensor records the room temperature above + 46 ° C or below -56 ° C. This means there is an open circuit or a short circuit in the sensor.

H15. Compressor temperature sensor problems. The same problems as with the temperature sensor - either the circuit broke in some part or a short circuit occurred.

H16. Low current consumption is detected by the external module.

A drop in consumption can occur for several reasons:

- not enough freon (low pressure);

- current transformer defect (it is necessary to solder or replace the board);

- breakdown of the power IPM module.

H17. Similar to H14, but in relation to the outdoor unit - breakdown of the temperature sensor on the suction tube in the compressor. There was either an open circuit or a short circuit on the sensor.

H19. When an error occurs, the indoor unit motor is jammed: when the actual motor speed of the unit does not match the speed set by the processor.

It is not always easy to find the cause of the breakdown even by the code: you will have to use the manual detailed by the manufacturer in the instructions for the product offered for sale

There can be several reasons for the errors:

- problems directly with the motor of the indoor unit;

- the connectors of the wires of the engine of the indoor unit have been disconnected;

- problems with the indoor module board.

H21. There is a problem with the drain pan float in the indoor unit. The signal indicates that the sensor is open. You need to check the logic of the sensor and see the resistance on the pump motor windings, which should be about 200 ohms. Drainage can also become clogged - drain needs flushing or blowing.

H23. Problems with the base # 1 sensor for the heat exchanger surface temperature in the indoor unit. The processor detects the fact of an abnormal temperature of the heat exchanger above + 80 ° C or below -40 ° C. You need to look for either an open circuit or a short circuit on the sensor.

H24. Problems similar to H23 with optional # 2 heat exchanger surface temperature sensor in the indoor unit.

H25. There are problems with the ionization unit. The port is on when the E-Ion is off. There may be a problem with the E-Ion board or the indoor module board.

H26. Practical tip, for some reason the air ionizer is out of order.

H27. There is a problem with the outdoor air sensor. The processor records the outdoor temperature above + 150 ° C or below -40 ° C. The cause of the failure may be an open circuit or a short circuit on the sensor.

H28. Problems with the sensor # 1 of the surface temperature of the heat exchanger of the outdoor unit. The processor records the temperature on the heat exchanger surface above + 110 ° C or below -60 ° C.

Open circuit and short circuit of sensors are the most common causes of breakdowns. You need to call a professional for repair

The cause of the malfunction is either a short circuit of the sensor, or an open circuit.

H30. Problems with the temperature sensor on the discharge pipe in compressor. The processor records temperature readings above + 200 ° C or below -16 ° C. An open circuit in this temperature sensor is detected when the condensing temperature is 6 degrees higher than the discharge temperature. The reason may be an open circuit or a short circuit on the sensor.

H33. An inter-unit connection error appears when there is a mismatch in the voltage in the data transmission line between the internal and external modules. There is a problem with the power supply lines of the outdoor and / or indoor units.

H34. An error has occurred in the temperature sensor installed in the heat sink of the power module. The processor records the temperature from the heat exchanger plates of the outdoor unit above + 80 ° C or below -43 ° C. There was either an open circuit or a short circuit of the sensor.

H35. Drain pump problem or drain blockage. The drain line needs to be cleaned / blown out. Then check the sensor logic and the resistance in the pump motor windings (should be about 200 ohms).

H36. There is a problem with the temperature sensor in the gas pipe of the outdoor unit in warm mode. The processor records the temperature above + 149 ° C or below -45 ° C. You need to check the circuit or sensor for a short circuit.

H37. There is a problem with the liquid pipe temperature sensor in the outdoor unit in cold mode.

Both the external and internal units need to be checked for errors, since they work interconnected. Often, the failure of one automatically entails a breakdown of the other.

Either an open circuit has occurred, or a short circuit has occurred on the sensor.

H38. Inconsistency between the brand codes of the indoor unit and the outdoor unit.

H39. The indoor unit freezes in standby mode. Occurs due to abnormal temperature of the unit evaporator. This indication appears simultaneously on all units, except for the unit on which the evaporator freezes. The last block displays the error code F17.

The problem is due to the fact that:

- the solenoid valve of the outdoor unit is out of order;

- the freon lines and control wires are confused.

H41. Incorrect commutation of wires and freon lines.

H 50. Fan motor defective. Or there is a problem with the indoor unit board.

H51. The nozzle is clogged.

H52. The limit switch has failed. Or there is a problem with the indoor unit board.

H58. A malfunction is detected in the PatrolSensor unit.

H64. A malfunction is noted in the high pressure sensor installed in the external module. The high pressure sensor remains open for one minute when the compressor is stopped. The failure can be caused by the failure of the sensor itself, damaged / broken wires or problems with connectors on the board.

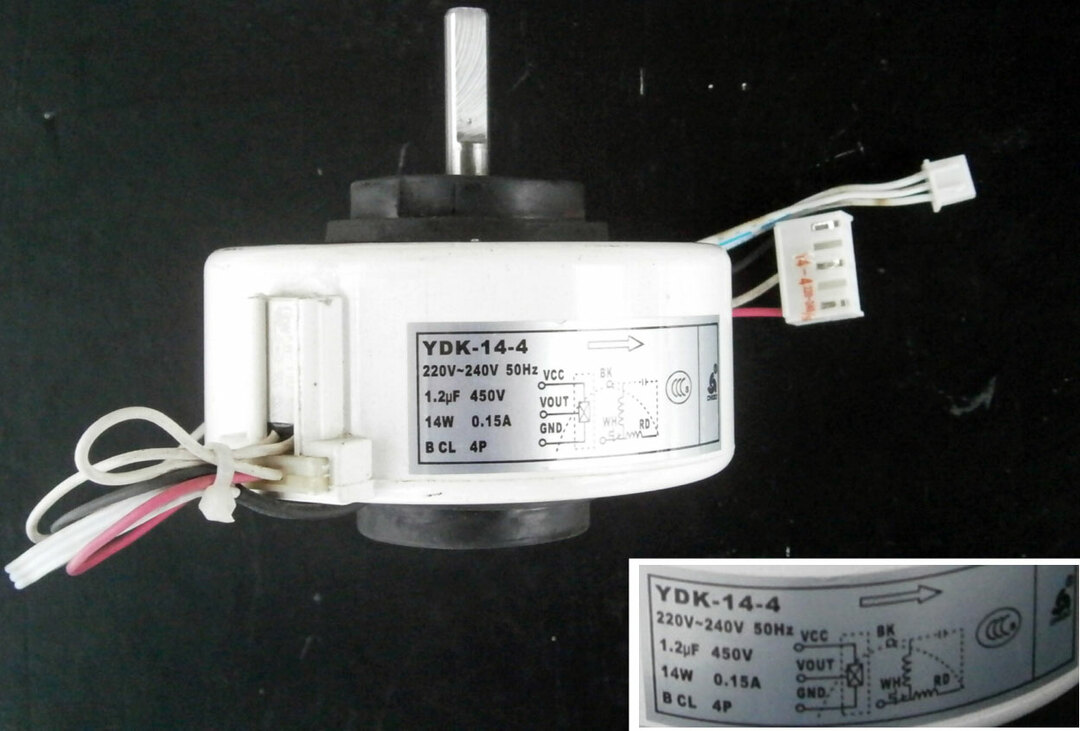

H97. The motor of the external unit is stuck: the actual speed of the motor does not match the one set by the processor.

The reason for the failure lies in:

- breakdown of the motor of the external unit;

- breakage of the board of the indoor module;

- in problems with the wire connectors (they need to measure the voltage).

H98. The protection of the indoor unit against excessive pressure or overheating of the unit in heat mode has been triggered. When the temperature of the heat exchanger in the indoor module rises to + 52 ° C, the protection is activated, and at a temperature of + 65 ° C, the compressor stops completely. The compressor restarts after the temperature has dropped.

The problem may appear due to:

- insufficient removal of heat from the heat exchanger;

- contamination of the heat exchanger;

- incorrect readings of the sensor installed in the heat exchanger;

- warming up the indoor unit during start-up to heat.

H99. In the operating mode, the evaporator of the indoor unit freezes. The speed limitation is activated when the temperature in the indoor unit drops to + 8 ° C. The compressor stops at 0 ° C and then restarts after the temperature rises. The limitation is lifted when the temperature rises to + 13 ° C.

The air conditioner needs regular cleaning. Clogging of the track leads to unnecessarily rapid wear of the compressor and engine, the replacement of which will require a considerable amount of money

The problem can happen due to:

- refrigerant leaks or insufficient topping up;

- clogged capillary tube;

- the appearance of moisture in the refrigeration circuit.

F11. This error indicates that the 4-way valve responsible for the cold / heat changeover is incorrect. The reason may be defects in its mechanism or in the solenoid coil of the valve.

F17. Freezing of the indoor module in standby mode is detected. The indicator is triggered exactly on the block on which freezing occurs.

The cause may be a malfunction of the solenoid valve (leakage) of the corresponding circuit of the outdoor unit. Also, incorrect data from the indoor unit heat exchanger sensor can lead to an error indication.

If the error was caused by improper installation, you will have to go through the entire system again.

If the error appears immediately after the first start of the system, then when installation of the air conditioner the freon lines and control wires were mixed up.

F90. The error appears when the compressor speed is no longer synchronized with the signal from the processor.

The signal will appear:

- when the compressor windings break (each winding under normal conditions should have a resistance of about one Ohm);

- if there is a difference in the resistance of the windings;

- if there is a malfunction in the inverter circuit of the outdoor unit board.

To eliminate the malfunction, you need to measure the resistance and voltage.

F91. The error indicates an incorrect operation of the refrigeration circuit or a low pressure protection is triggered in it.

A malfunction occurs when:

- there is no freon;

- faulty three-way valve on the outdoor unit.

F93. The signal indicates a discrepancy between the actual compressor capacity and the controller control signals. In other words, when its speed does not coincide with the control signals of the controller. In this case, the system stops.

The error is fixed when the compressor windings are broken or because of the open circuit of the inverter of the outdoor module board. To measure the resistance on the compressor windings, you need a multimeter

F94. Protection is triggered due to excessively high discharge pressure. It is necessary to check the operation of the refrigeration circuit.

F95. In cooling mode, outdoor unit high pressure protection has been triggered. The problem may occur in the refrigeration circuit or due to overheating of the heat exchanger of the outdoor unit.

F96. Overheating of the power module is detected, and in multisystems, the compressor thermo-tablet has opened.

Possible reasons for the error triggering:

- contamination of the heat exchanger of the outdoor unit;

- contamination of the refrigeration circuit;

- power module defect;

- compressor breakdown.

F97. A high discharge temperature in the compressor is detected, and the compressor overheats. The error may self-zero after 20 minutes of uninterrupted operation. One symptom of an error is frequent stopping of the plug-in for no apparent reason.

The causes of the problem may be:

- underfueling;

- compressor discharge tube sensor data error;

- turn-to-turn circuit in the compressor windings;

- breakdown of the fan of the outdoor unit.

F98. The protection for the consumed total current has triggered. An inadequately high current consumption by the external module in operating mode is detected. The cause of the error must be looked for in the contamination of the refrigeration circuit or in the contamination of the heat exchanger of the outdoor unit.

You need to clean the heat exchanger regularly, without waiting for breakdowns. The frequency of cleaning is indicated by the equipment manufacturer in the technical documents attached to the product.

The error may appear when the voltage drops in the power supply when the air conditioner is turned on or during operation.

F99. This is the DC protection error signal. Possible reasons for the error:

- jamming of the compressor;

- breakage of the transistor module;

- defect of the current sensor installed in the PCB of the outdoor unit;

- the resistance in the compressor windings has dropped below normal. It is necessary to measure the resistance in the compressor windings and in the transistor module.

In order to figure out what this or that error of Panasonic air conditioners shows, you need to download a service manual for a specific model from the network and look in the error section.

Standard Care Requirements

The instructions for air conditioners of this brand necessarily describe the procedures for their care. This part of the documentation should be studied especially carefully, since following these instructions will help to reduce the number of breakdowns.

It is imperative to regularly clean parts of the air conditioner to avoid damage to it.

Malfunctions in Panasonic air conditioners can require costly repairs and even the purchase of expensive spare parts to restore the unit's functionality. Therefore, regular maintenance according to the manufacturer's requirements is especially important for the technology.

Most of the care procedures do not require much knowledge and do not take a lot of time, but to perform some will require disassembly of blocks, so it is better to seek the help of a wizard from a certified service center.

Conclusions and useful video on the topic

You can watch how the Panasonic air conditioner is cleaned in this video:

How to check the indoor module for errors is clearly shown in the following video:

Intelligent systems of Panasonic air conditioners are able to promptly notify the owner of the climatic device about a malfunction that has occurred in the bowels of the unit. Information on decryption can be found in the passport or video review.

Having found out the error code, a person can make a decision - to correct the situation on his own (for example, to clean the drainage) or call a foreman for a more complex repair.

Tell us about how you identified a violation in the operation of the climate system of the Panasonic brand by the code. Share the nuances of diagnosing and troubleshooting the problem you know. Leave comments, please, in the block below, post a photo and ask questions on controversial and interesting points.