Any buildings, both residential and industrial, must undergo periodic ventilation checks. This is necessary to maintain an optimal indoor climate. Let's see why it is important to follow the rules and frequency of checking the efficiency of ventilation systems regularly and on time.

After all, you must agree that following certain documentary requirements means not only obtaining permits and passing the commission, but also preserving the health of people in the room. How this works, what are the verification times - we will talk about this and many other things later.

The content of the article:

- Purpose of the ventilation system

- The purpose of checking ventilation systems

-

Types of checks and their purpose

- Ventilation check frequency

- Who checks the ventilation efficiency?

- How to extend the service life of ventilation?

- Conclusions and useful video on the topic

Purpose of the ventilation system

First, it's worth finding out what ventilation systemand how its effectiveness is tested.

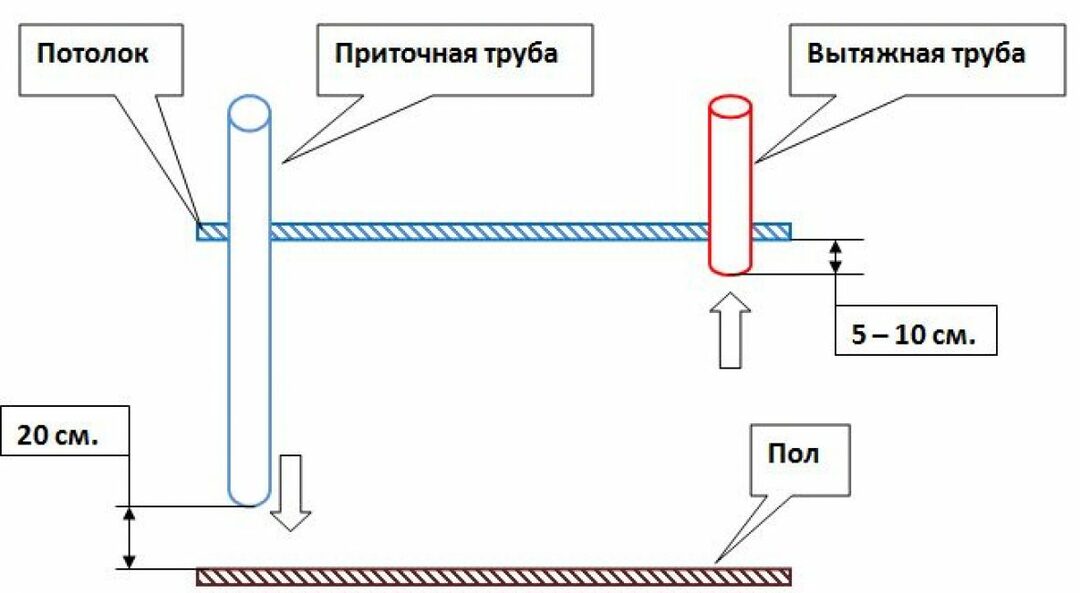

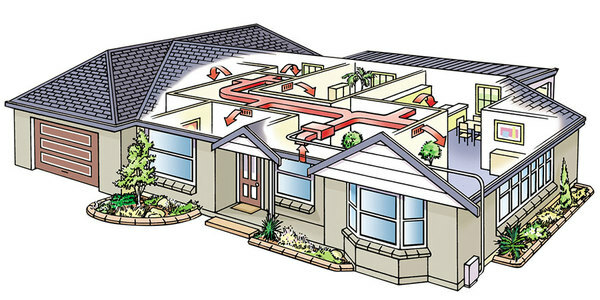

A ventilation system is a set of equipment that circulates and renews air in a room, while maintaining a certain microclimate. Sometimes this process is accompanied by filtration, humidification, air heating.

The process of air movement through the ventilation system is shown on the example of a residential building. The room is provided with clean air with proper ventilation

Such a process of constant air exchange provides a person with the necessary conditions for a favorable life, good health. A certain temperature, required humidity, air purity are maintained.

If the necessary requirements are not observed in the room, this can seriously affect human health and can lead to the following consequences:

- due to poor air exchange, carbon dioxide will begin to accumulate in the room. This phenomenon can cause a person to fatigue quickly, light suffocation, weakness, headaches and other unpleasant consequences. Therefore, the air must constantly circulate and be replaced by new air;

- malfunctioning ventilation can lead to the formation of high humidity. This phenomenon provokes the formation of mold and the reproduction of insects. For example, mold spores are bad for the human body;

- airborne contamination can accumulate. These include dust, animal hair, any harmful substances of chemical origin, etc. All of this ends up in the lungs and can harm human health. Therefore, it is very important to carry out regular system cleaning;

- Excessive noise may occur due to improper operation of the ventilation system, which can interfere with work in an office, medical institutions. This occurs when the fan or motor does not work properly, as well as in the absence of sound insulation of the ventilation system;

- problems in the operation of the ventilation system can significantly affect the loss of heat in the operated room. Heated air can escape through the ventilation system and significantly increase heating costs;

- contaminated ventilation can cause an unpleasant odor from the inside. This phenomenon is also possible with increased humidity in the room, due to the spread of fungus and mold on the inner surfaces of the system.

Checking the efficiency of the ventilation system is an analysis of conformity of air exchange accepted standards in the project or sanitary and hygienic standards.

Trust the verification of the efficiency of the ventilation system only to professionals who will carefully approach this process from all sides.

This is an important process that should be done regularly. Not only in order to obtain certain permits, but also to preserve the health of people.

The need for such a check is to provide a person with clean, high-quality air. This applies to all businesses. If a poor-quality ventilation system turns out to be in an industrial organization, then there is a possibility of accumulation of poisonous or explosive substances in the air.

This can lead to serious destructive processes. Therefore, you should take the ventilation system seriously and involve only professionals for this work.

The purpose of checking ventilation systems

The fundamental goal of checking the ventilation system is to identify violations in its operation, possible breakdowns, defects. The analysis of the ventilation performance shows how well it copes with the given load and whether the building is well provided with the removal of internal and supply of external air. In addition to faults, it identifies possible errors in calculations at the design stage.

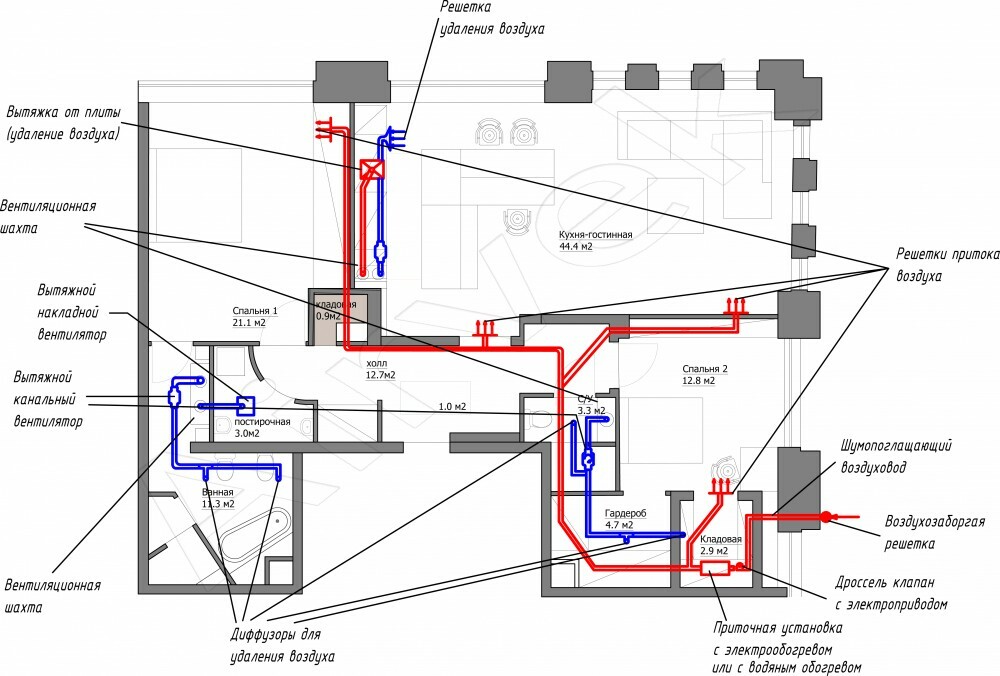

It is almost impossible to do this work on your own. A quality check requires special equipment, knowledge and experience. For example, industrial ventilation systems are complex structures interwoven with high-tech electronics and mechanics, consisting of many parts.

This is how a ventilation system looks like in industrial production - it consists of many air ducts and other structural elements. Do not risk checking such complex structures yourself.

It will be difficult to analyze such a system without a highly qualified specialist. The intervention of a licensed organization will be required.

The process of checking ventilation equipment is quite laborious, but it is necessary for any building equipped with ventilation - industrial buildings, medical organizations, residential apartments, shops, office premises.

Types of checks and their purpose

Performance analysis can be done in several ways. Instrumental methods for checking the efficiency of ventilation systems are considered the main ones, since they are the most highly accurate.

Such measurements can be carried out in any of the following ways or, if necessary, in a complex:

- An instrumental method for measuring the parameters of the level of carbon dioxide and other conditions of the air environment. It is carried out in the operated premises and outside. It consists in checking the quantity and quality of gas elements in the air

- Instrumental method for measuring the components contained in the air. For example, aerosol study of the airspace in the room used, which determines the level of contamination of the space with small particles.

- Aerodynamic testing is a method that also refers to instrumental testing.

Aerodynamic tests include checking the following main characteristics: air pressure and ambient air pressure in the room; air flow temperature in the room; the duration of the movement of the anemometer in the area of the measured area.

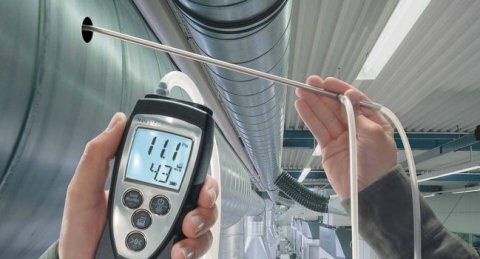

The specialist carries out instrumental verification of the ventilation efficiency using high-tech equipment. This method is much more effective than conducting an independent check without special devices.

Air quality measurements must be carried out strictly in certain openings. If the location was determined incorrectly, then an error in measurements and calculations appears. Trust this work to trusted specialists.

Including there is a method for checking the effectiveness of ventilation without the use of special devices. The quality of the ventilation system can be checked with a piece of paper. The paper should be attracted by the air and maintain its position on the ventilation grill.

Remember that methods of checking ventilation systems without the use of high-precision instruments are not effective, and often show an erroneous result.

If it does not fall for a long time, then the ventilation work can be considered satisfactory. But this method is not effective in comparison with any instrumental one.

In addition, in large industries, it and other alternative methods of checking ventilation are not used.

Ventilation check frequency

Finally, we got to the most interesting and important thing - the frequency of checking the ventilation system. These terms vary depending on the purpose for which the premises are used.

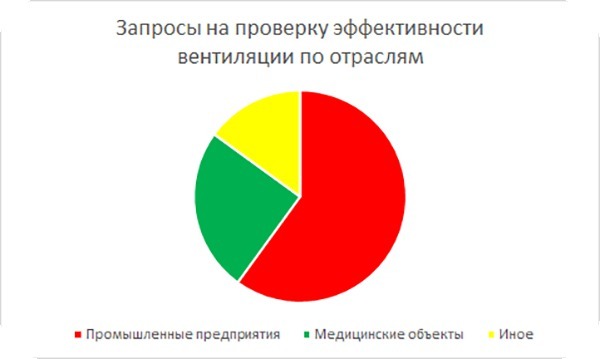

Regular and timely inquiries to check the operation of ventilation systems are the key to the successful operation of any enterprise and the health of its employees

There are fundamental acts that determine the frequency, nature and essence of assessing the effectiveness of ventilation systems:

- Federal Law No. 52 - a document that regulates the issues of sanitary and epidemiological welfare of citizens;

- GOSTs – 12.4.021-75, 12.3.018-79, 12.1.005-88. They define the test methodology, parameters of ventilation systems and other issues.

- SNiP and joint ventures, in which the main properties and quality of air for various enterprises are spelled out - 3.05.01-85, SP 1.1.1058-01;

- recommendations R NOSTROY 2.15.3-2011 testing and adjustment of ventilation;

- fundamental European standards EN - 15251 and 13779, which indicate the rates of air exchange and categories air mass;

- inter-branch PB, MU for the control of industrial ventilation systems.

Legal acts, norms and GOSTs, which are presented above, indicate that the quality control of ventilation systems should be checked at a certain frequency.

Now let's move on to the specific deadlines, for whom and which ones are set:

- industrial structures with the release of various poisonous, explosive, radioactive components must be checked once a month. This applies to buildings working with hazardous substances of 1 and 2 classes. In some cases, separate deadlines are set for such hazardous establishments;

- the following structures must be inspected annually: if the enterprise uses equipment that consumes natural gas; enterprises of classes A, B, C that use ventilation equipment; if the walls of the ventilation equipment ducts are thin and they are in contact with hazardous air environments; used by supply and exhaust ventilation system.

- Inspection must be carried out every 3 years if the building uses a natural and artificial ventilation system.

The importance of adhering to the rules of regular inspection has been mentioned several times in the text. For the long-term operation of the building and the quality work of the employees, this is a necessity.

But such terms have been set for structures, provided that the commissioning and installation work was carried out in compliance with all requirements and technologies.

The frequency of requests from various organizations can be seen in this figure. The main thing is that requests for checking the effectiveness of ventilation occur regularly.

If the complex of these construction measures was not carried out properly, then during the first year of operation, an inspection should be carried out earlier than in due time.

In the course of work, the tightness could be broken, as a result of poor installation, damage and defects could occur. To avoid an emergency, in the first year, you should analyze the operation of the ventilation in advance and monitor the effectiveness of the ventilation to ensure the quality of its operation.

Who checks the ventilation efficiency?

Who to contact for help in checking the efficiency of the ventilation system is written in the regulatory documents. Let's take a closer look at what these or those records mean.

If it is noted in the regulatory documents that the inspection is carried out by the licensed organization, then it will be required the admission of this organization is a confirmation of permission to carry out the necessary work in compliance with standards.

If the documents say about the need for accreditation, then an accredited laboratory is required to check the ventilation equipment.

If there are no specific instructions, then often for many objects it is suitable to carry out work by an individual entrepreneur.

How to extend the service life of ventilation?

There are several tips on how to increase the life of the ventilation system and increase the economy in using this design.

Here are some rules to help you with this:

- if you use electronic adjustment of the fan speed, this allows you to save 20-30% of electricity;

- the ventilation system must not always be operated at full capacity. To avoid a quick failure, consult a specialist on this issue;

- the use of an EC motor in the ventilation system reduces energy consumption by 50%. These motors are specially designed for ventilation systems;

- usage recuperator. This is a device that heats air, the so-called heat exchanger. Due to it, you can warm up the room during the cold period, saving money for heating;

- Provide your ventilation system with filtration of the supply air. This will significantly reduce the level of its pollution. If we neglect additional cleaning, then the clogged surfaces of the heaters will reduce the level of heat transfer by 10-20%.

Just imagine, applying these recommendations, you can achieve tremendous savings, which will have a positive effect on your enterprise.

If these tricks are applied at the very beginning, it will not only extend the life of the ventilation equipment, but also save your money.

Some of these tips will provide your employees with a good working environment.

And what could be more important for industrial production, office buildings than high labor productivity?

Conclusions and useful video on the topic

This video will help you familiarize yourself with how the ventilation system works:

The need to regularly check ventilation systems will be discussed in the following video:

Clean and fresh air in the building is possible! Follow all the listed rules and recommendations for the correct operation of the ventilation system.

This will have a positive effect on your company in the form of satisfied, healthy and efficient employees, compliance with all safety rules and order with documentation.

If you have questions on the topic of the article or can add valuable information to the material, please leave your comments, share your experience, ask questions in the block below.