Poultry - can provide seven eggs and delicious dietary meat, but this is subject to proper maintenance. With the approach of cold weather, in order to maintain a healthy livestock, care must be taken to maintain a comfortable microclimate in the poultry house. Even if you did not have time to prepare in the summer, high-quality ventilation in the chicken coop in the winter with your own hands is quite real.

But how to arrange it correctly, how to take care of every little thing and not miss important details? Now we will try to tell you about this in detail.

The content of the article:

- Types of ventilation for the chicken coop

-

Natural ventilation of the chicken coop

- Natural exhaust ventilation of the chicken coop

- Arrangement of supply and exhaust ventilation

-

Forced ventilation of the chicken coop

- Fans and how they are located

- The simplest ventilation

-

Choice of materials and accessories

- Air ducts - features of choice

- Nuances of arrangement in winter

- Conclusions and useful video on the topic

Types of ventilation for the chicken coop

Air exchange of the poultry house can be organized in one or several ways. People often confuse systems for different reasons, therefore, initially, you should figure out what and what refers to, so that later you do not get confused in decoding schemes and definitions.

The choice of the scheme is based on the number of chickens, the density of their location in the winter, the volume of the room, the possibility of arranging a particular structure in a particular building

So, ventilation is divided according to:

- way of air circulation - natural (based on physical laws of nature) and artificial (also, compulsory, organized with the help of various devices that require energy consumption, in particular, fans);

- purpose - exhaust, supply, supply and exhaust;

- location - zonal or general exchange.

Immediately it is necessary to make a reservation that regardless of the premises or buildings in which the ventilation system, equipment, devices and materials used in its construction, as well as diagrams, can be the same.

But each variety has its own pros and cons. Therefore, taking them into account, it is necessary to select a ventilation network for the conditions of its operation.

Let's consider different options in more detail, but first, let's take a look at what requirements are imposed in this case.

Natural ventilation of the chicken coop

As mentioned above, this method works on the basis of physical laws. Warm air always rushes up, and cold, on the contrary, down.

By varieties it is divided into:

- Unorganized - with the implementation of the air exchange process through the window and cracks.

- Organized - the air is removed and flows in through special channel structures.

The system cannot be based only on the removal of air, how much air has left, so much must enter. That is, the influx of air masses must appear from somewhere.

Many houses do not have any design for improved ventilation. For ventilation, vents and doors are used. However, this method is not effective and even if it does not create health problems for chickens, it certainly reduces egg production.

In chicken coops, these are cracks in the structure, a window pane, a door, and so on. However, if the chicken coop is overhauled, the standard inflow will not be enough, as well as the output of the spent masses. There is stuffiness in the room. Therefore, further we will discuss precisely the organized version.

The problem is solved by inserting valve-type duct exhaust and supply devices into the roof / walls of the house. Exhaust, according to the logic of physical laws, are always installed above the intake.

To organize a natural air exchange system, ventilation duct structures are designed vertically.

The main difference between natural draft and forced draft is that this ventilation can be arranged in any chicken coop in winter, since the scheme does not implies electricity and complex processes of arrangement, which also makes it cheaper both from the installation and from the operational point vision.

But there are also disadvantages. It is completely dependent on the climatic conditions outside. That is, when the outside air temperature exceeds that in the room, the draft occurs in the opposite direction, and again, in standing weather, the air exchange is minimal.

In small coops with active birds, natural ventilation is usually sufficient. In addition, many birds are active even in cold weather, which allows them to stay warm and walk outside. However, some breeds of chickens are indoors almost all the time during the cold season and need additional heating.

This does not really matter in small poultry houses, the available circulation is usually sufficient, but in the case of large poultry farms, it is recommended to use a forced scheme.

Natural exhaust ventilation of the chicken coop

Exhaust ventilation can be installed without additional supply structures, but at the same time it must be organized. Air outlet occurs through equipped channel openings in the wall or in the roof of the room. A suitable chicken coop area is approximately 10 square meters.

The positive qualities of this option include the simplicity of the arrangement, very good air circulation, the possibility of increasing efficiency by adding some elements.

However, there are also disadvantages. You will not be able to regulate the supply and exhaust air in this way, the cold will penetrate into the room and, of course, this system is suitable for very small poultry houses.

The system is the simplest to manufacture, it functions due to the difference in temperature conditions inside and outside the room. You just need to take care of the presence of the hood.

The role of the inflow will be performed by a door and / or a window. Of course, the control is manual. The hood will be located under the very ceiling, but not closer than 15 cm to it and on the wall opposite to the self-organized inflow, or it will be located in the roof structure. We are considering option 1, as it is easier to organize in winter.

Supply air enters through cracks in structures, as well as doors and a window. With correct calculations, polluted air will escape quite efficiently.

You will need a 90 ° angle elbow0 and a pipe with a diameter of 110 mm. Through the knee, we bring the structure into the drilled hole to the street and then install an insulated vertical section with an elevation above the level of the roof by 1-1.5 m.

The joints at the location of the corner element should be foamed with polyurethane foam, and the pipe itself should be fixed on the outer wall with clamps. Be sure to put a deflector on the outer head of the pipe.

Arrangement of supply and exhaust ventilation

So, you have a room of about 12 square meters. This system suits you as the most optimal one for small poultry houses. Let's consider the simplest assembly option.

Stage 1 – ventilation design

Before installing ventilation, you need to think carefully about everything, draw a diagram of the future design, decide on the place where the pipeline will exit, develop dimensional nuances, taking into account the dimensions of your chicken coop and its constructive features.

You can lead both pipes through the roof, as in the diagram below, or through the walls. Installation is possible at any time of the year.

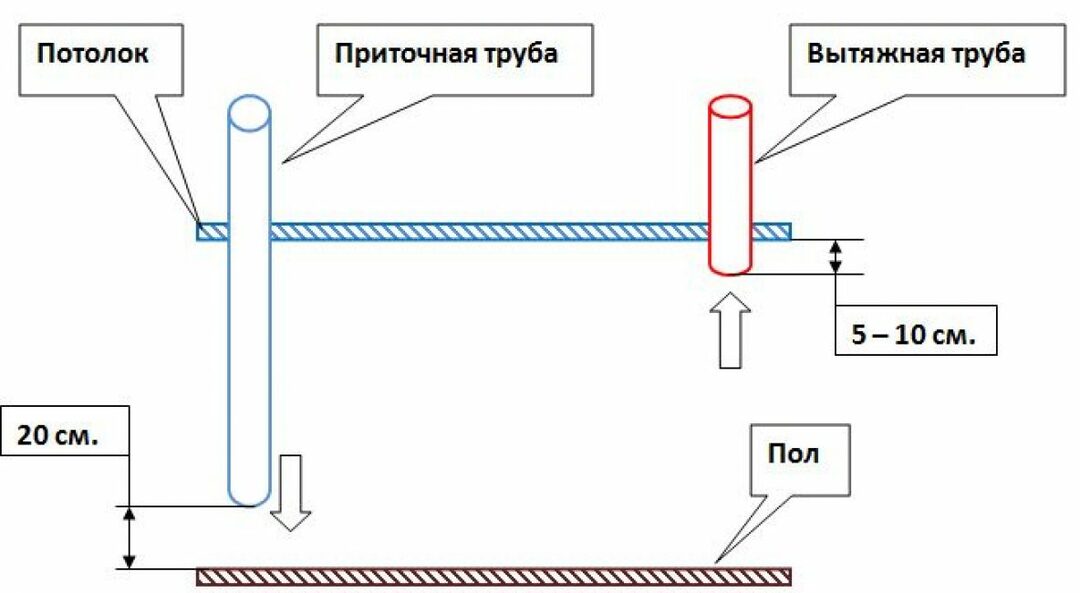

If it is not possible to bring the pipes into the wall, which is easier to do in winter, the pipes are placed immediately vertically without elbows and taken out through the roof. In this case, the chimney is installed above the perch 20 cm from the ceiling and 1.5 m above the roof. The supply air is mounted 20 cm from the floor and rises 30-40 centimeters above the roof. It can be fitted with a damper for mechanical adjustment of the air flow.

Stage 2 - preparation of materials and tools

It is best to do this in advance, so that later in the middle of the installation you will not be faced with the fact that you cannot find this or that part in stores.

You will need the following materials:

- pipes 2 pcs. - length 2 m, diameter 20 cm. It is best to choose with a round cross section, as they create the most favorable circulation;

- insulation for pipes. Anyone suitable for outdoor installation can be used. It is also advised to equip a box around the pipe so that the insulation fits snugly. But if this is not possible, just fix the material tightly;

- knee - 900;

- clamps or other devices with which you can fix the pipe itself;

- deflector;

- ventilation grilles 2 pcs.;

- polyurethane foam.

The set of tools required depends on individual factors. The main thing is that you can easily make 2 round holes in the walls of your chicken coop and screw something on both the grilles and the pipe itself.

You will definitely need a hacksaw for metal or a grinder, self-tapping screws (the purpose depends on the material of the structure), a drill or a hammer drill.

Stage 3 - we install the chimney

The air duct, which will remove the exhaust air from the room, is installed above the perch under the very ceiling, but not closer than 15 cm to it.

To begin with, we make a hole of a suitable diameter and through it we bring a pipe of the required length with a corner element onto the street.

Be careful and mark in advance the location of the future hole before making it. Act strictly according to the scheme you have drawn up

The outlet of the chimney behind the roof is usually 120-170 cm.

On the street side, in the knee, experienced chicken owners advise making a small through hole. Its diameter should be about 5 mm and it will serve to drain condensate.

A deflector is installed on the pipe head.

Stage 4 - install the supply pipe

It should be placed on the opposite wall. To do this, we also pre-mark the location of the future pipe and drill a hole in the wall. Output to the street is carried out through the knee.

If your holes do not turn out perfectly straight, there is nothing terrible in this. The main thing is that the pipe can go out through the wall. The slots can be repaired by laying something around the pipe and blowing in the gaps with polyurethane foam.

The inlet pipe for the poultry house is installed at least 30 cm from the floor and at least 50 cm from the exhaust height.

It should be noted that with a gable roof of the chicken coop, it should not be higher than the horizon of the roof visor, and with a flat roof with a slope, it should be 30-40 cm from the visor.

Stage 5 - fixation of pipes

In general, each pipe should be fixed immediately after installation. They must be securely fixed. This will help prevent them from falling. For this, clamps are used, some kind of homemade design, or you can even use suspensions that are used when installing a drywall frame.

Someone makes only 1 attachment point closer to the roof near the rafters, but if there is an opportunity it is better to play it safe and make 2-3 in different places, directly in the wall of the chicken coop.

Supply and exhaust ventilation through the walls must necessarily be well fixed to the external structures of the building. In addition, it is very important to insulate the pipes in order to avoid the formation of condensation and ice within them, as well as to well seal all openings in the outlet.

Ventilation grilles are installed on the inner sections of the pipes, and deflectors are installed on the tops on the street side. Dampers will help to avoid clogging of pipes and the ingress of sediments into them.

Stage 6 - pipe insulation

First of all, the slots and holes around the pipes should be blown out with polyurethane foam. For pipe insulation a huge number of different methods are used.

Various materials are used to insulate ventilation pipes. Someone wraps them with a “reflector”, someone blows them out like a casing with foam, but the most convenient option is ready-made thermal insulation in the form of casings

A very interesting method of pipe insulation is the pipe-in-pipe principle. In order to implement the idea, a larger diameter pipe is taken.

It should be worn over the one prepared for ventilation. Further, a heater is hammered into a pipe of a larger diameter, very tightly.

A pipe with "sandwich insulation" is a rather expensive option. However, if the chicken coop contains valuable breeds of chickens or you just want to make such a structure, regardless of the non-budget option, it will last a long time and will be quite reliable in its role.

However, pipe insulation can also be carried out with a homemade casing. Usually, this is a wooden structure. hammered out of boards. The sectional shape does not play a special role here.

Warming is carried out either at the stage of pipe installation, or after installation, depending on the chosen method.

Forced ventilation of the chicken coop

Forced ventilation is all the same channel sweeps of the supply and exhaust types, however, to increase air exchange, a fan is used and, if necessary, or at will, additional devices, such how filters, heaters, humidifiers and so on.

When arranging mechanical air exchange, the schemes for arranging ventilation shafts may be different. The only thing is that a fan is always involved in artificial air exchange, or even several, depending on the calculated scheme

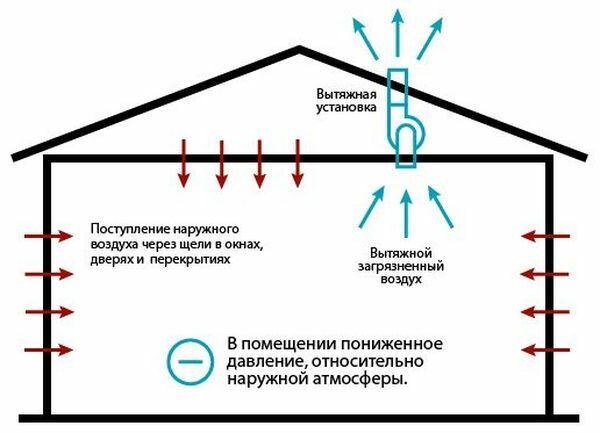

The functionality of this type of ventilation is based on the difference in pressure readings between the outside and inside the house.

It can be conditionally divided into:

- Working with reduced pressure, that is, with vacuum (exhaust). This is when air leaves the house creating a vacuum and passively sucking in the outside.

- Functioning at overpressure, which is often found in the systems of old poultry farms (supply). This is when the air is injected in excess quantities and undergoes various processes before these - heating, cleaning, and so on.

- Performing air exchange at equal pressure, when equipped with ventilation devices and a supply, and an exhaust (combined).

- Forced ventilation has many advantages. In particular, this is the possibility of high-quality air exchange in any quadrature, with any density of birds (which is important in winter) and in any weather outside.

At the same time, you can equip a more accurate adjustment of air exchange to your engineering calculations, thanks to the selection of equipment power.

Grilles can be installed on the fans, or various filters can be added. They help trap dust, dirt, gases and even pathogens from their species.

Cons, of course, are present. Among them are more expensive equipment, complicated installation, however, if you understand the scheme, any person can handle it - the cost of paying for electricity, labor for maintaining the system.

Fans and how they are located

The first definition you will come across when installing an artificial ventilation system is a fan.

The main varieties of this unit used in the arrangement of the air duct system:

- Axial - the most common type, characterized by high efficiency and the simplest structural assembly.

- Diagonal - the device is somewhat similar to axial ones, but their main difference is that they send the air flow in a diagonal direction, which significantly reduces their noise during operation.

- Diametric - have upward curved blades. They have high aerodynamic capabilities and, as a rule, are rarely used for chicken coops.

- Direct-flow - they do not have "wings", for this they are also called bladeless. Their advantage is the ability to pump large volumes of oxygen and accurate flow direction.

- Direct-flow turbines pump air through specially designed frames. Such devices pump large volumes of oxygen and allow the flow to be directed in the desired direction.

You will also hear concepts such as channel and roof fans. But everything is simple here. Ducted ducts are installed in air ducts, and roof-type ones in roof structures.

Duct-type fans can be used to remove waste masses (exhaust), to supply fresh air (supply), and in addition, they can be combined, performing simultaneously both exhaust and supply functions (reversible)

Unfortunately, it is best to provide an artificial type of ventilation in the summer, and even better - at the stage of building design. Moreover, it will require the arrangement of holes in the main walls and electrical wiring. Although simple schemes in standing, maximum "dry" winter weather are quite feasible to perform.

The system for the geometry of the location can be of several types. Let's talk about the types of forced briefly and later in more detail about some specific schemes.

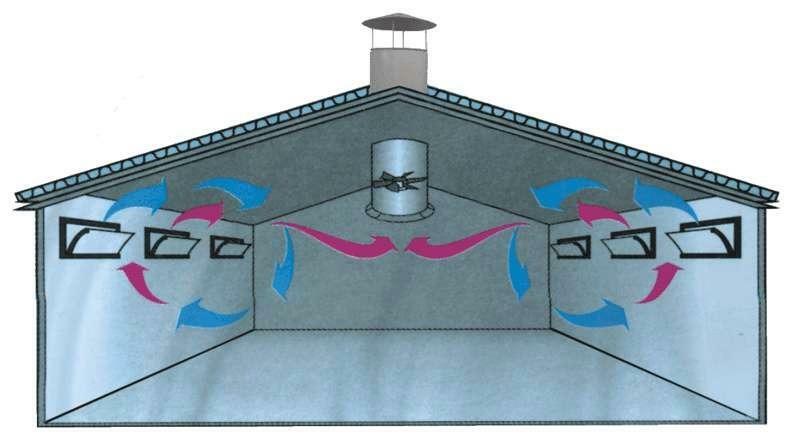

Roof ventilation - when the exhaust ventilation ducts are equipped in the roof ceilings or in the end area of the room, and the exhaust ducts are in the walls and in the roof (there may be one option).

Roof or mine ventilation is good in moderate and cold climatic conditions. In addition, it is she who is preferred to use in monoblock poultry houses. In winter, it helps to reduce the risk of air entering the chicken bedding from outside.

Cross ventilation refers to the placement of fans on a single side of the house to extract exhaust air. And the inflow comes from the opposite side through valves. It is imperative to have an automatic control station that allows you to control and set the high-speed fan rotation mode. Devices are usually low power.

This option is installed in poultry houses with several floors, but it is not popular, since all fans have to be used in winter. to achieve optimal microclimate indicators, otherwise “dead” zones are created, and in summer such arrangement does not allow proper ventilation premises.

The longitudinal one is similar to the transverse one in principle, however, the fans are installed on the end area of the room when air exchange is required along the building. Units of higher power are used here than in the transverse one.

Tunnel ventilation differs from the longitudinal arrangement of louvers on the wall opposite to the fans. In other words, the air in it moves like a tunnel. The basis of the system's functionality is convection cooling of air masses, which is formed due to the high speed of the flow moving at the level of the birds.

The basis of the system's functionality is convection cooling of air masses, which is formed due to the high flow rate moving at the level of the birds.

There are many schemes, you just need to make a choice and take into account that it is best to think about ventilation of a large-sized poultry house during its development, that is, design, excluding the simplest options.

In the meantime, we will consider only the simplest, because other species settle in large poultry farms.

The simplest ventilation

Do not think that all the schemes are complicated. For small chicken coops, the simplest options can be used. The main thing is that they can provide air exchange with a calculation of 6 m3 for each kg of the weight of the chickens available. Of course, it is not necessary to carry out approximately, ideally accurate calculations.

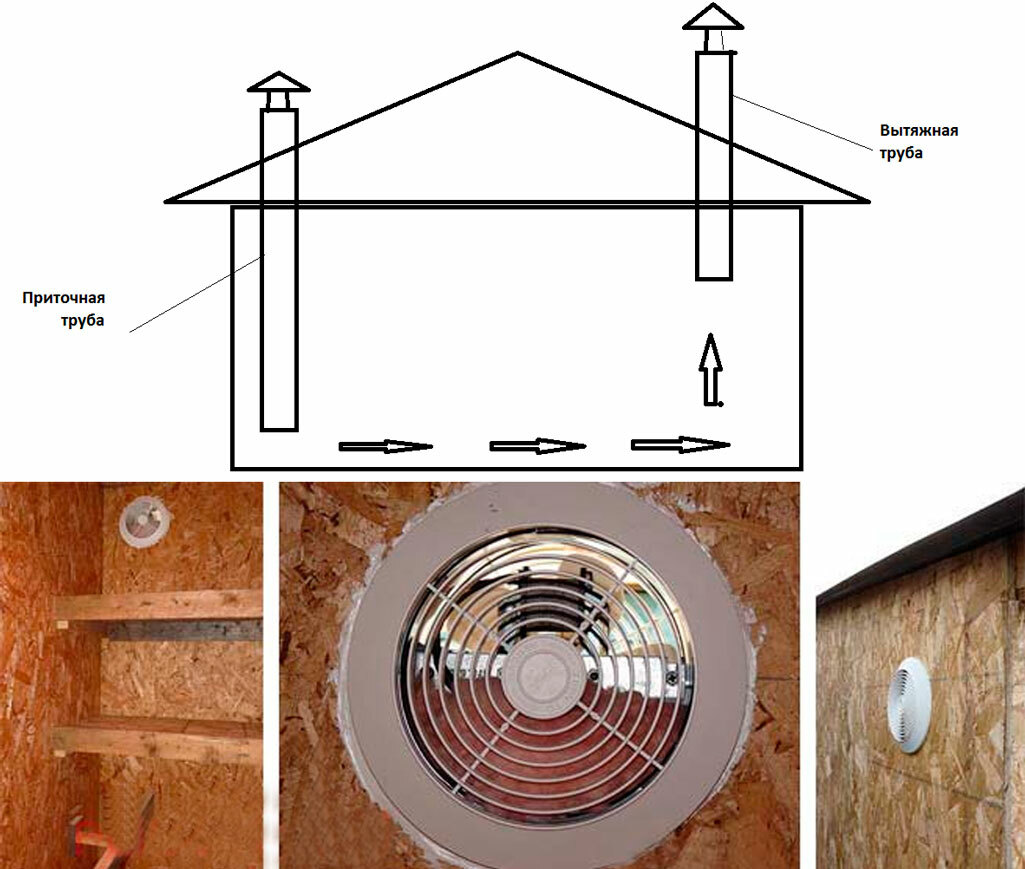

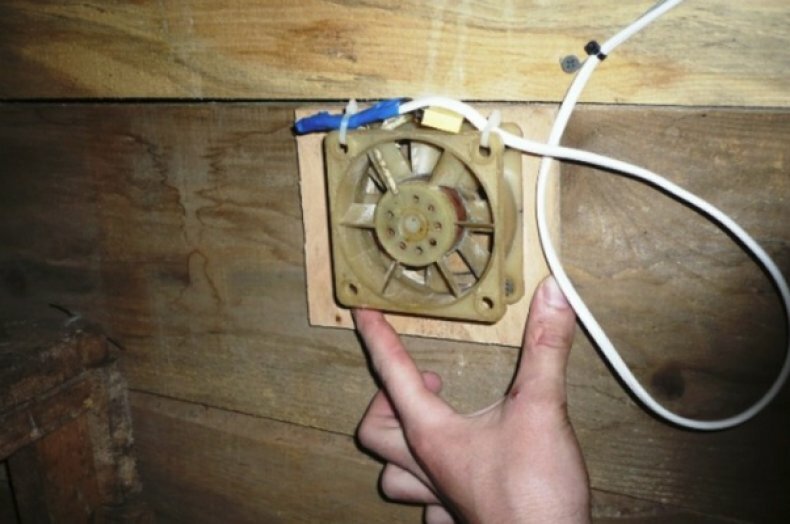

The principle of building a duct system is the same as in the case of natural supply and exhaust ventilation. All are also installed two opposite pipes at different levels. The only thing in the design is a fan.

The installation location of the fan depends on the selected model - in the supply or exhaust pipe. However, in small rooms, the device is placed in a window or wall openings, and sometimes in a window.

The system is equipped with a switch. Moreover, it is best not to connect it to the lighting, as many do, in order to be able to control the system at any time. In principle, it is enough to turn on the fan for only 3-4 hours a day.

Additionally, on request, the system is equipped with humidity and temperature sensors. This provides the simplest automation of the process.

And of course, don't forget to equip the vertical heads ventilation ducts deflectors. This is mandatory for any type of ventilation arrangement.

Choice of materials and accessories

In the schemes of mechanical ventilation of different types, various devices may be present, with a purpose that is not always clear to an ordinary farmer.

Let's take a look at some of them.

- Filters. Devices that trap debris and / or harmful air impurities entering from the street side. Or they also help to clean the air coming out of the chicken coop.

- Heating elements. Everything is clear here. These are devices that contribute to the possibility of increasing the temperature regime in the poultry house in a mechanical way.

- Recuperator - mixes the air, outside and out of the room, forming a homogeneous warm mass.

- Noise absorption - devices or structures that help to get rid of the noise produced by the fans or to reduce them. Typically installed in large farms and factories.

- Auto control system - manages all automated processes.

These are just the main basic elements that are most often used for ventilation of rooms with chickens and other poultry.

At very large enterprises, other high-tech devices may also be present.

The automatic control system is comfortable to use for any farmer. It is from it that control and operation of all ventilation equipment, lighting and heating of the poultry house takes place.

As for the choice of materials, then it is necessary to approach the solution of the issue responsibly, since the durability of your structure and the frequency of repairs depend on their quality.

Air ducts - features of choice

It is very important to choose the right air ducts.

The main selection criteria include:

- tightness and strength;

- the possibility of arranging thermal insulation and, preferably, noise insulation;

- absolutely smooth internal structure.

Air ducts can be plastic or metal.

Metal pipes made of galvanized or stainless steel are quite strong and durable in operation. But they are usually used for large objects.

It is not at all necessary to run around the shops in search of some special pipes. Standard plumbing pipes and sets of elements are suitable for the implementation of conventional schemes.

As for plastic pipes, their budget and ease of installation are advantageous precisely for arranging poultry houses. They are made from durable polypropylene mass.

They do not rust, look quite aesthetically pleasing and, in addition, provide good air flow and better sound insulation compared to metal ones.

You can read more about the types of ventilation ducts and the features of their installation in this material.

Nuances of arrangement in winter

In winter, depending on the weather, almost any method of air exchange in the house can be arranged. Including, it is possible to arrange both ventilation in the hen house in winter according to the scheme without electricity, and with its use.

The main thing is that when using a power tool and when installing electrical wiring on forced systems, observe safety precautions for working in a humid environment. And besides, when removing roof-type structures, be careful in high-rise works.

In addition, it is very important to locate chickens somewhere during installation so that they do not breathe dust during the installation of holes for devices and do not freeze from drafts.

When planning a ventilation system, it is very important to consider that supply ventilation is a cooler. The exhaust and supply pipes are placed as far apart as possible, usually on opposite surfaces.

To avoid the formation of ice due to condensation, pipes must be insulated with special casings or henchmen means and in some cases, install channels for condensate drainage through a specially provided hose

Another very important nuance - do not forget to periodically check the draft and inspect / clean the entire ventilation system.

In addition, not a single, even the most effective ventilation will cope if you do not clean the chicken coop of droppings as needed and change the litter to a fresh one.

Conclusions and useful video on the topic

Video # 1. One of the options for arranging ventilation for the chicken coop:

Video number 2. Ventilation in a hen house made of plastic pipes:

Thus, we examined different schemes for effective winter ventilation in the chicken coop with our own hands. Some of them are available for arrangement in any case, others should be chosen based on design possibilities of installation in a specific building and precisely during the cold season, everything is here individually. But you can certainly install simple natural exhaust / inflow mechanisms.

Have you ever encountered the arrangement of ventilation in a chicken coop? Please tell our readers how ventilation works in your house. Share your experience or ask questions of interest on the topic in the comments.