Lessar air conditioning systems are practical and safe equipment. It is equipped with high-quality protection against voltage surges, temperature rise / fall, and a self-diagnosis system. In order for the owner to be able to identify malfunctions himself, the errors of Lessar air conditioners are displayed on the device display.

We will tell you how breakdowns of the climatic unit are identified by special codes and indicators. We will show you how you can independently determine the malfunction of the software, sensors, and other parts and mechanisms. Agree, it is important to timely identify a problem in the system so that you do not have to buy new equipment.

The article discusses common types of errors in various models of split systems of this brand, as well as ways to identify malfunctions and ways to eliminate them. The presented instructions for eliminating breakdowns and failures in the system will help to assess the complexity of the work and make a decision - to correct errors on your own or contact the workshop.

The content of the article:

- Features of the self-diagnosis work

-

Error codes in household appliances

- #1. Troubleshooting the indoor unit

- #2. Registration of external unit breakdowns

- Malfunctions in commercial air conditioners

- Conclusions and useful video on the topic

Features of the self-diagnosis work

When a breakdown, electronics failure is detected, the Lessar climate unit diagnostic system issues an error code on the front of the indoor unit panel or control panel. A malfunction code is a letter designation on the screen and a combination of LEDs that flash in a specific order.

The error indication and alphanumeric code are displayed until the malfunctioning of the system is completely eliminated.

All models of equipment of the Lessar company are subject to some breakdowns in cases of improper installation and operation. For this, each model of the air conditioner is equipped with an auto-error search function for the subsequent elimination of identified malfunctions.

If the split system does not function properly, you need to pay attention to the display. The error of the device is displayed there. Thanks to their presence, the user will be able to independently identify the cause of the malfunction and, if possible, eliminate it. In the event of a complex violation, you will need to contact the service center for help.

For self-elimination of malfunctions, it is necessary to understand in more detail the design features of the climatic equipment.

Household (wall, multisplit systems) and semi-industrial (cassette, floor-ceiling, channel, column type) systems consist of two parts, which are interconnected by a freon line - an internal and an external compressor-condenser block.

The line of the air conditioner connects the units and consists of a signal and a connecting power cable, copper tubes for the passage of freon and a drain tube for draining liquid from premises. To protect against environmental factors, the track is placed in a durable PVC tube

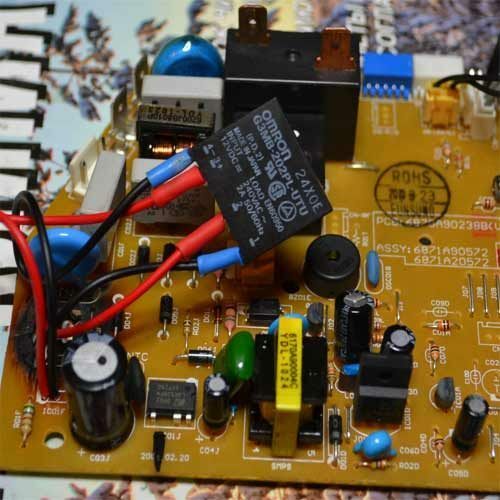

The structure of the internal evaporating unit consists of a mains cable, a front panel, filter elements, louvers, evaporator, fan, drip tray, board management.

The components of the external block of the split system are: compressor, 4-way valve, condenser temperature sensor, capillary tube, filter, control board, fan. More powerful air conditioners - 36-60 thous. BTU, - additionally equipped with high and low pressure switches, muffler, various filters, accumulator, air temperature sensor.

After familiarizing himself with the air conditioning system diagram, the user will be able to identify a breakdown, change and even repair a part or a mechanism that is out of order.

Error codes in household appliances

Before self-diagnosis of errors in the units of the Lessar company, you should check the parameters of the input voltage, the values of which should be within the normal range of +/- 10%. You should also make sure that the connection of the outdoor, indoor units is correct. If the split system is connected incorrectly, the diagnostic measures carried out will not give the correct result.

In the climatic equipment for household use, malfunctions may occur both in the inner part and in the outdoor unit.

#1. Troubleshooting the indoor unit

Consider the common mistakes that occur when operating units at home, and ways to fix them.

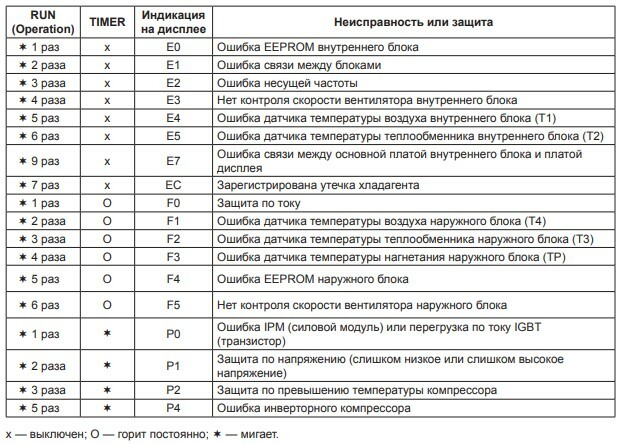

In the event of a malfunction of any unit in technology, an alphanumeric value appears on the display, on on the basis of which the user can understand the cause of the violation and correct the existing errors in the work systems

It is not recommended to independently solve problems with the air conditioning system when a burning smell appears. You should not try to repair it yourself if the internal electric circuit breaker is often triggered, heating the cable or outlet to which the unit is connected, the occurrence of uncharacteristic noises and squeaks, water ingress premises.

In all these cases, immediately disconnect the device from the power supply and contact the service center for help.

Internal volatile memory (software EEPROM) error - E0, the indicator lights up 1 time.

The microcircuit works only in the "read" mode, which can be reprogrammed by supplying a pulse current.

Breakdown reasons:

- violations of equipment installation technology;

- malfunctions of the board.

Remedies:

- disconnect the unit from the power supply system;

- start the device in 2-3 minutes;

- make sure that the air conditioner is working correctly;

- if the code reappears, replace the control board.

Incorrect communication between blocks - E1, flashes 2 times. This error occurs when there is no response from the indoor unit more than three times in a row for about two minutes.

Causes:

- insufficient quality power cord;

- the wires are not connected correctly;

- the board is out of order.

Remedies:

- turn off for 2 minutes, then turn on the device again;

- when the code reappears, check the presence of voltage between the red and black terminals on the outdoor unit;

- in the absence of voltage, diagnose the connection of wires to the interior of the split system;

- check the chokes and replace if necessary.

If the error occurs again, you must completely replace the outdoor unit board.

If the E1 code appears on the screen again, you will need to replace the board in the indoor unit. Thanks to this action, the connection between the structures of the system will be completely restored.

Carrier frequency error - E2, the indicator lights up 3 times.

Causes:

- poorly executed device installation;

- the board is broken.

Remedies:

- re-enable the system after a few minutes;

- if the problem persists, the boards in the two blocks will need to be replaced.

There is no fan speed control - E3, The indication is highlighted 4 times. The problem manifests itself in the case when its speed gradually decreases and is less than 300 rpm.

Causes:

- broken wire connections;

- the motor is broken or the fan impeller is jammed;

- the control system does not work.

Remedies:

- carry out a diagnostic reconnection of the unit to the network;

- de-energize the device and check the correct movement of the impeller;

- make sure that the wires are connected correctly between the fan and the board;

- check the presence of voltage at the terminals of the part;

- if absent, replace the board.

If the current flows, it means that the fan is out of order: it will need to be replaced with a new one.

To check the operation of the fan, it is necessary to turn on the climatic equipment and select the maximum speed of the diagnosed part. After starting it up, within 12-15 seconds, measure the voltage at terminals 1 and 2. If less than 100 V, the problem is a broken board that needs to be replaced.

Broken air flow t ° sensor - E4, Beep 5 times. Broken wire or short circuit of the heat exchanger t ° sensor - E5, 6 times. Errors E4 and E5 are issued in case of voltage surges above or below the standard values - 0.06-4.94 V.

Causes:

- breakdown of the mechanism;

- part connected incorrectly.

Remedies:

- check the correctness of the sensor connection using a voltmeter;

- check the obtained data on resistance with tabular ones;

- if the indicators do not match, replace the spare part;

- otherwise, change the board.

Communication problem between display boards and indoor unit - E7, Flickers 9 times.

Causes:

- rupture of wire connections in the electronic system;

- wrong connection;

- breakage of boards.

Remedies:

- check the integrity of the wires and the correctness of their connection to the boards;

- check the operation of the multimeter control boards one by one;

- replace them if necessary.

A coolant leak is detected - EC, the light signal is issued 7 times.

The leakage problem is fixed when the system is triggered three times in case of not maintaining the temperature set by the user for four seconds

Causes:

- freon leaked out;

- the temperature sensor is malfunctioning;

- malfunction of the board;

- lack of sufficient air exchange in the outer part of the structure;

- contamination of the heat exchanger of the outdoor unit;

- hall of the track.

Remedies:

- restarting the system after a while;

- in cooling mode, you should check the actual t ° of the air masses entering the room;

- when warm air enters, it is necessary to check the presence of a working fluid in the system and the pressure level;

- inspect the outer part of the split system for contamination, remove them if necessary;

- if cool air escapes from the device, it will also be necessary to diagnose the temperature sensor according to the scheme, as with code E4;

- if the part is intact, the control board must be replaced.

Overcurrent error - F0, signals 1 time.

The microprocessor receives a signal that the compressor has exceeded the consumption of electricity and after 2-3 seconds the protection is triggered and an error occurs. This allows you to prevent the fire of the device, fusion of contacts, failure of the compressor.

Causes:

- short circuit between turns;

- short circuit;

- making mistakes when charging refrigerant, especially in winter;

- jamming of the compressor.

Remedies:

- release access to the compressor;

- if, when the equipment is turned on in cooling mode, the unit does not start, it is necessary to ring it and check the connecting circuits;

- eliminate the short circuit in the wires;

- if a short circuit is detected, it will be necessary to change the compressor;

- in the absence of a short circuit, check the serviceability of the sensor, the power module and completely replace the board;

- if high pressure in the system persists, it is necessary to clean the heat exchangers from dust and dirt.

After the actions taken, you must turn on the air conditioner again and check if the error code appears again. A repeated problem - the detection of strong vibration, high pressure on the lines indicate a jammed compressor block. If it is impossible to restore it, it should be replaced.

If the pressure remains high, the air conditioner will need to be refilled.

#2. Registration of external unit breakdowns

Air temp sensor problem - F1, the indicator blinks 2 times, the timer is constantly on.

Heat exchanger temperature sensor error - F2, lights up 3 times, the timer is constantly on.

Short circuit / breakage of compressor discharge t ° sensor - F3, Flashes 4 times, the timer is highlighted.

Diagnosis of problems F1, F2, F3 is carried out in the same way as in the case of errors with the temperature sensors of the indoor unit.

Reconciliation of values should be carried out in accordance with the presented table of dependences of the resistances of temperature sensors. It presents the t ° range from -20 to +42 ° C and the standard resistance values in kΩ

EEPROM error - F4, The indication lights up 5 times, while the timer does not turn off. In this case, the main processor does not receive a signal from the memory chip. The elimination of the breakdown is carried out, as in the internal part of the split system, by replacing the board.

Fan speed control failure - F5, the indication lights up 6 times, the timer is on. It is triggered when the number of revolutions decreases less than 300 per minute.

Causes:

- connection error of wired connections;

- the motor does not work, the fan impeller;

- replacement of a broken board is required.

Remedies:

- Repair of a fan with a built-in microcircuit. When the climatic equipment is in standby mode and connected to the mains, measure the voltage between pins 1 and 3, 4 and 3 of the mechanism. If the value obtained does not fall within the range indicated in the table, the board will need to be replaced.

- Diagnostics of the fan of WZDK36-38G-W, WZDK40-38G-W-1 models with a control chip on the board. To test the node's functionality, it must be connected to the network. If the mechanism works, a board replacement will be required. If the fan does not turn on, you need to check the resistance of the windings on each pair of pins.

The considered methods will completely eliminate the error and restore the correct operation of the device.

| № | Wire color | Voltage, V | Signal |

| 1 | Red | 280-380 | Vs / Vm |

| 2 | – | – | – |

| 3 | Black | 0 | GND |

| 4 | White | 14-17,5 | Vcc |

| 5 | Yellow | 0-5,6 | Vsp |

| 6 | Blue | 14-17,5 | Fg |

Power module error and inverter module protection - P0, breakdown indicator and timer light up 1 time. The code appears when the voltage is over or under voltage, which the power module sends to the compressor.

A digital tester must be used to take measurements. If different values are obtained for different pairs, the fan is out of order and will need to be replaced. If the values are the same, a new board should be installed

Causes:

- incorrect connection;

- breakdown of the fan in the external device of the split system;

- failure compressor;

- malfunction of the main board;

- breakdown of the power module.

Remedies:

- first check the correct connection of the compressor with the board;

- inspect the power module, measure the resistance between P and terminals U, V, W, N, as well as N and U, V, W (should equal MΩ - infinity), replace it if necessary;

- a similar action must be carried out with the control board of the outdoor unit;

- check if the fan is broken, and replace it in case of failure;

- measure the resistance of the compressor winding and compare with the table.

Protection against voltage surges in the system - P1, the error indicator and timer flash 2 times. Triggers at critical low and high values.

Causes:

- Electricity problems;

- interference in the air exchange system;

- freon leak;

- board operation error.

Remedies:

- check the presence of power in the system;

- if the parameters do not match, turn off the device;

- check the integrity of the wires and the correctness of their connection;

- measure the voltage between terminals P and N on the power module and, if the standard values do not comply, replace it.

You will also need to additionally inspect the chokes and replace them in case of breakdown.

If after the measures taken, the error in the P0 code could not be eliminated, it will be necessary to replace the main board of the external structure of the split system

Compressor block overheating protection - P2, the error indicator and timer blinks 3 times.

Causes:

- Electricity problems;

- blocking of air exchange;

- coolant leak;

- board error.

Remedies:

- diagnose the air exchange of the indoor and outdoor units, clean the heat exchangers if there is dust on them;

- disconnect the device from the mains;

- after 10-15 minutes measure the temperature of the compressor;

- check the correctness of its connection, as well as overload protection;

- inspect the hydraulic circuit;

- check the resistance at the terminals of the protection unit, which should normally tend to 0;

- when receiving large readings, you will need to replace it;

- If the compressor is working properly, the reason for receiving a P2 error is a board malfunction, which will need to be replaced in the outdoor unit.

Compressor starting problem - P4, The indicator and timer will light up 5 times. The error is determined by checking the communication signals, voltage, the number of revolutions of the compressor shaft.

Causes:

- incorrect connection of the node;

- malfunction of the power module;

- compressor breakdown;

- the main control board is out of order.

Remedies:

- check the correctness and quality of the wiring between the board and the compressor;

- inspect the power module IPM, and in case of a malfunction, replace it;

- if, after checking the resistance of the compressor winding, the indicators do not correspond to the norm, replace the unit.

If the error is displayed again, the control board will need to be replaced.

After the performed actions, the compressor is installed in the place allocated for it, the complete assembly of the external unit is performed, after which the system is launched and its diagnostics

If error codes E, F are displayed, you must immediately disconnect the device from the mains and eliminate the cause of the malfunction yourself or contact the service center. In the event of a P code fault, the unit will start immediately after restoring the parameters. If the air conditioner does not restart, you will need to check for errors and eliminate them.

Malfunctions in commercial air conditioners

In addition to errors in household appliances, in semi-industrial cassette systems, most of the errors are identical, however, there are other types of malfunctions.

For example, models LS-HE12BCOA2 / LU-HE12UOA2, LS-HE18BCOA2 / LU-HE18UOA2 have the following additional codes:

- overflow of the condensate container - EE;

- violation of communication between the main and additional units of the system - E8;

- other errors (for multiple blocks) - E9;

- protection tripping in case of low pressure - P6;

- power module error - P7;

- high temperature protection of the evaporator - J0;

- high temperature condenser protection - J1;

- PFC module protection - J3;

- communication failure between the compressor and control chips - J4;

- high pressure protection - J5;

- low pressure protection - J6;

- AC input voltage protection - J8.

When using the unit at low temperatures, the letter code LC may occasionally appear on the screen.

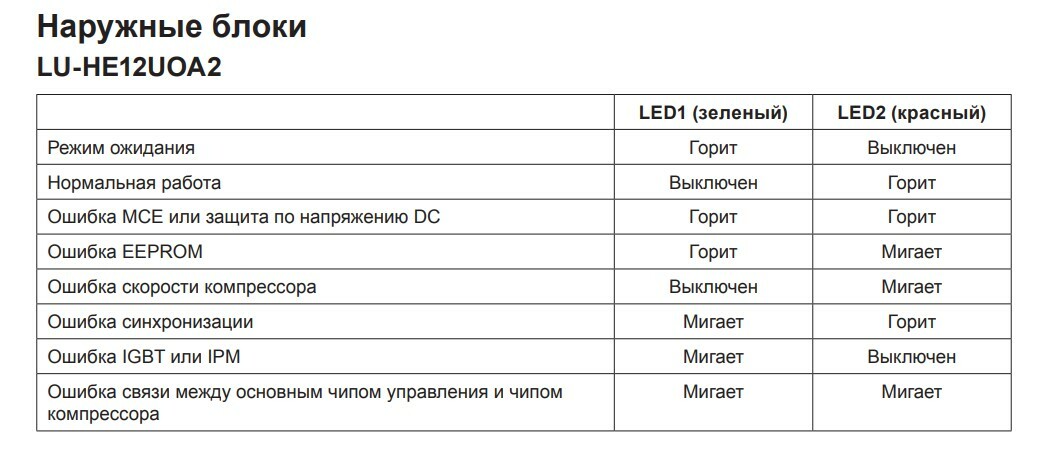

Also, in the outdoor units of these split systems, there may be errors that are displayed by illuminating the indicators. The table shows typical malfunctions for the outdoor unit model LU-HE12UOA2

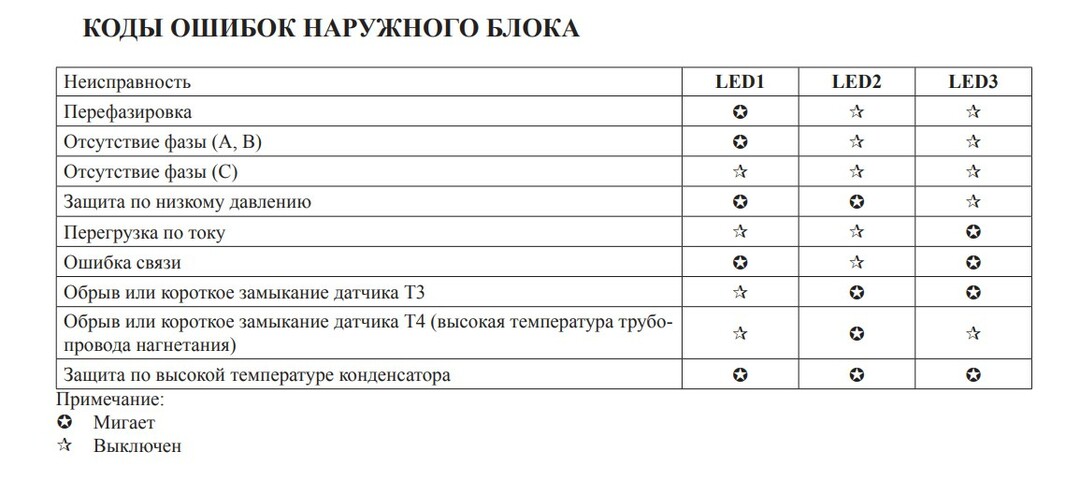

In the models of the Business series LS / LU-H18 / 24BEA2, LS / LU-H36 / 41/48 / 60BEA4, the following errors of the internal design of the system are encountered:

| № | Code | Error name |

| 1 | E2 | Air temperature sensor malfunction |

| 2 | E3 | Breakage of the pipe t ° sensor |

| 3 | E4 | Failure of the condenser t ° sensor |

| 4 | E5 | Condenser drain pump t ° sensor |

| 5 | E6 | Outdoor unit operation error |

| 6 | E7 | Failure in the EEPROM microprocessor |

| 7 | E8 | Condensate tank overflow |

External unit error codes are displayed by LED1, LED2 and LED3 indicators.

Each type of malfunction is identified by visual inspection: indicators can flash several times or stay on continuously

Elimination of problems in the operation of commercial air conditioners should be performed according to similar algorithms discussed in the section on solving errors in household units.

Conclusions and useful video on the topic

An example of the correct operation of a Lessar device:

The location of the main units and parts of the air conditioner for debugging them in case of errors, considered on the example of the Rational model range:

To eliminate any malfunction in a household, semi-industrial Lessar air conditioner, it is necessary to study in detail the design features of the system blocks. The hydraulic and electrical circuits specified in the technical instructions will allow self-diagnostics of the device, as well as independently repair broken parts and microcircuits.

In the block below you can leave a comment, ask a question and place a photo on the topic of the article. Here you can talk about your own experience in identifying violations by code and fixing the problem yourself. Please share some useful information that may be useful to the readers of the site.