Many errors of Vertex air conditioners are determined using the self-diagnosis function, which displays fault codes on the unit display. In case of a sudden malfunction of the split system, you should not immediately call the service center and call the repairman.

Knowing the error codes will help you quickly navigate the situation and fix the problem yourself. Having figured out the problem and restoring the operation of the equipment, you can save the family budget from unnecessary expenses. After all, the service technician will present an invoice even for the call.

The content of the article:

-

Error coding for Vertex air conditioners

- Split systems Triton, Cockatoo, Crab 21 (9 + 12)

- Split system Crizzly-18U1CF

- Fan coil units VFC

- Conclusions and useful video on the topic

Error coding for Vertex air conditioners

The vast majority of Vertex brand air conditioners have the ability to self-diagnose breakdowns. In the event of a malfunction, the system monitors and analyzes the operation of all units and parts, detects an error and displays information about it on the display of the unit or smartphone, informs about the cause of the breakdown by signals indicators.

They start blinking in a periodically repeating series of flashes. The display shows an error code in numeric or alphanumeric encryption.

The list of errors generated by Vertex air conditioning systems is rather modest. These can be found in the instructions supplied with the respective models. Manufacturers send detailed information about error codes to trusted service centers.

Vertex air conditioners are assembled on the basis of equipment of well-known brands, which ones, you can find out from the manufacturer or authorized service centers, where you can contact for missing information.

The user manuals also provide a list of the most common damages and advice on how to fix them. Each model of the Vertex air conditioner has its own error codes, which will be discussed below.

Split systems Triton, Cockatoo, Crab 21 (9 + 12)

E1 - the indicator blinks once - the temperature sensor in the room is damaged.

The room air temperature sensor (thermistor) sets the operating mode of the compressor.

Actions: disconnect the device from the power supply, check the connection of the temperature sensor to the board. If the connection is broken, you must try to reconnect the sensor and turn on the device. If there is no result, a check of the part is necessary.

Based on the readings of the outdoor temperature sensor, the system turns off when the temperature drops below the set minimum

The main indicator of the health of a thermistor is its resistance. An ohmmeter or multimeter is used to measure it. According to the diagram in the technical documentation, the correspondence of the measured resistance to room temperature is checked. If the thermal sensor is defective, it is replaced.

E2 - the indicator blinks 2 times - the sensor for fixing the temperature of the pipe inside the room is damaged. The actions are similar to those described above.

Non-separable fan motor of the indoor unit in a plastic case. The electric motor of the outdoor unit is housed in a metal shell and can be disassembled for repair

E6 - the indicator blinks 6 times - the fan motor of the indoor unit is damaged.

Possible reasons for stopping the fan motor.

- Defect in electrical wiring or loose wire connection terminals. Repair operations: eliminate the defect in the electrical wires or reinforce the connection clamps.

- Blower motor burned out. It should be dismantled and a new engine installed.

If a malfunction occurs due to wear of the bearings and the electric motor, they are replaced with parts of the corresponding nomenclature.

Split system Crizzly-18U1CF

Messages on the display about malfunctions in the operation of the indoor unit.

E1 - interruption of communication.

The connection between indoor and outdoor units has disappeared inverter system. In other air conditioners, such an error is not noted, since they have only one-way communication between the units.

Possible reasons for the lack of communication:

- the power supply is disconnected;

- there is no connection between the blocks (as an option, the wires are confused);

- terminal blocks and control board are not provided with communication;

- blown fuses;

- breakdowns in the electronics of the control board.

Consecutive steps to find damage.

- Check the correctness of the connection of the wires of the blocks according to the terminal numbers.

- By dialing, they are looking for a possible wire break.

- Blown fuses are detected visually or with a multimeter when the power is off. If a blown fuse is found, they look for the cause of its blown in the control board. Most likely, there are faulty parts, in particular the unit responsible for communication.

E2 - the sensor for measuring the room temperature is damaged. The troubleshooting steps are described above.

E3- malfunction of the temperature measurement sensor in the tube. Actions are common for all sensors.

E4 - breakdown of the protection of the external unit.

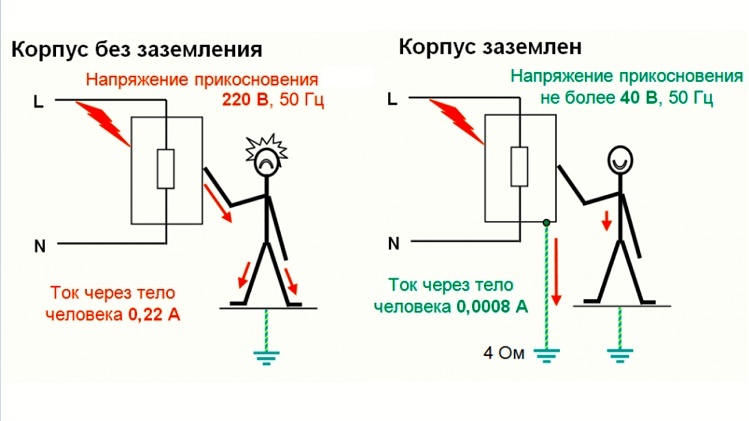

De-energize the installation. Call a qualified engineer with a permit for special electrical work from the service center of the Vertex technician. According to the current PUE, the air conditioner case must be zeroed. Connection of the air conditioning unit is only allowed to earthed euro sockets.

In the absence of protective grounding, there is a high probability of electric shock if it breaks down on the air conditioner case.

It is recommended to install protective devices on the power line to the air conditioner that disconnect the system from the power supply. When choosing and installing circuit breakers, the following rules are followed: rated current circuit breaker must be higher than the current consumed by the air conditioner, and the rated current in the wiring must be higher than the current in the machine.

E8- icing or overheating.

In case of icing on the condenser, evaporator, air conditioner pipes, frost may appear. In this case, the system is de-energized and a specialist from the service department is called. Further operation can completely damage the device.

The reason for the freezing of the indoor unit may be:

- loss of heat dissipation due to accumulation of dirt on the fan, evaporator or cleaning filter.

- continuous operation of the SCR as a result of a breakdown of the control unit, damage to the sensor that monitors glaciation;

- a decrease in the level of refrigerant due to a leak or over time - it is necessary to regularly monitor its amount and, if necessary, replenish stocks;

- malfunction of the thermostatic valve - only a specialist from an authorized service center can handle its replacement.

Freezing can also occur if the capillary tube is damaged or clogged. In this case, the defective area is changed or the capillary is blown through with a jet of air under pressure.

On the outdoor unit, ice forms during operation in the heating schedule when the outdoor air tо is below the set level, in the absence of the defrost function. Icing is possible in the event of a breakdown of the temperature sensor, control board, contamination of the heat exchanger

Superheat is determined by the difference between the boiling point of the refrigerant liquid and the temperature of the vapor after the evaporator. The overheating value for a specific model is indicated in the air conditioner documentation. Usually overheating is determined from 5-7O WITH.

Overheating indicates an excess of refrigerant in the system - freon, its amount must be reduced.

In all cases, the air conditioner must be turned off.

Next, let's analyze the indicator signals about malfunctions in the operation of the outdoor unit.

Flashes 4 times in 6 seconds - protection against low pressure in the system.

Freon type, filling rate, maximum pressure are selected from the factory information on the unit nameplate or look in the model instructions

Reasons for low discharge pressure:

- small amount of coolant;

- broken compressor valves;

- insufficient suction pressure;

- blowing off the condenser with low temperature air.

Troubleshooting procedure.

- Refill refrigerant or repair refrigerant leaks.

- Replace compressor valves.

- Adjust the suction pressure.

- Increase to air mixture directed to the condenser.

Flashes 3 times in 5 seconds - protection against high pressure in the installation.

High discharge pressure occurs due to:

- excess freon in the system;

- high temperature of the air entering the condenser;

- the presence of foreign gases in the pipes that are not subject to condensation;

- the effect of excess heat on the evaporator;

- condenser contamination;

- damage to the condenser fan motor;

- spinning the condenser fan belt.

Trouble-shooting.

- Remove excess refrigerant.

- Reduce the air temperature at the condenser.

- Purge foreign gases from the system.

- Reduce the thermal effect on the evaporator.

- Clean the condenser from dirt

- The elimination of the malfunction of the electric motor was described above.

- Install a new fan belt.

Flashes 9 times in 11 seconds - protection of voltage phases.

In a three-phase air conditioner, protection is triggered against incorrect connection of phases or the disappearance of one of them. In order to prevent emergencies, the correct connection and phase sequence are checked, if necessary, protective devices are installed.

Flashes 7 times in 9 seconds - voltage drop protection.

The air conditioner turns off when the voltage in the network is critical. Voltage fluctuations can be caused by various reasons: heavy load, accident, bad electrical wiring, etc. In this case, replacing the wiring or installing voltage stabilizer.

When buying a stabilizer for an air conditioner, it is recommended to check if it has overvoltage protection. The best choice is an inverter stabilizer with many protective functions

Flashes 5 times in 7 seconds - a sensor for measuring the external temperature.

Flashes 2 times in 4 seconds - overheating sensor.

Flashes once in 3 seconds - defrost sensor.

Actions to eliminate errors in these cases were discussed above.

Flashes 8 times in 10 seconds - protection against power outages.

The restart function is available in almost all air conditioners. The air conditioner turns on after the power is supplied in the same mode in which it worked before the power outage.

Information about the detected breakdowns is automatically entered into the electronic error log of the vertex air conditioner.

Fan coil units VFC

F0 - the cooling indicator is flashing - the ambient temperature sensor is open or short-circuited.

Actions: disconnect the device from the power supply, check the connection of the temperature sensor to the board. If the connection is broken, you must try to reconnect and turn on the device. If there is no result, a check or replacement of the sensor is necessary.

Heavily contaminated outdoor units of air conditioners will help to clean professional masters, armed with modern equipment and cleaning agents

F1 - the cooling indicator is blinking - the temperature sensor of the evaporator made of copper base and aluminum fins is open or short-circuited. Switch off the device, check the connection between the sensor and the control board. If the wire is disconnected, restore the connection and turn on the device for testing. If the problem persists, the sensor needs to be replaced.

C5 - the fan coil indicator is flashing. Protection tripping due to incorrect setting of jumpers. After the system is de-energized, the correct installation of the jumpers is checked.

H6 - the operation indicator is flashing. The engine is not responding. After de-energizing chiller-fan coil systems, it is turned on again and the error correction is checked. If there is no result, contact the service center.

Given the lack of information on error codes for Vertex air conditioners, you should stock up on a magazine and prepare in advance for a sudden failure in the operation of the purchased equipment.

It is advisable to ask the manufacturer or an authorized service center for a complete list of air conditioner errors, their coding and recommendations for elimination. This information will help with self-repair or useful for monitoring the actions of a representative of a workshop accredited by the manufacturer to carry out repair operations.

Conclusions and useful video on the topic

The first video shows in detail the process of filling the air conditioner with freon after eliminating the refrigerant leak:

The second video clearly demonstrates professional cleaning and testing of the split system in full, including the internal and external units:

Long-term trouble-free operation of the split system will be ensured by proper operation and regular maintenance: cleaning the filters every two to three weeks, protection against voltage surges.

Do you want to tell how you yourself determined the cause of the breakdown by the error code? Do you have personal experience in troubleshooting? Please write your comments in the block below, ask questions, post photos on the topic of the article.