Installing a pump for a stable water supply to the house requires the connection of additional fittings. A check valve for the pump is installed in the water supply system or on the suction pipe lowered into the well - a small but useful device.

Do you want to equip the pumping system with check valves yourself, but do not know how to do it correctly and which valve is suitable for these purposes?

We will help you understand the issue - in this material we suggest that you familiarize yourself with the design, the principle of operation of the check valve, and the main varieties. We will also provide step-by-step instructions for installing it.

The content of the article:

- Purpose and principle of operation of the valve

- Types of back-locking devices

- Borehole pump check valves

-

Types of pipe check valves

- Classification # 1 - by type of locking element

- Classification # 2 - by type of attachment

- Classification # 3 - by material of manufacture

- Recommendations for the installation of such a valve

- Conclusions and useful video on the topic

Purpose and principle of operation of the valve

A check valve, like any device for a water supply system, is installed in order to protect the network from any changes in flow parameters. Simply put, that water is supplied constantly, without stops and breaks, in the right volume.

A narrower purpose of the valve is to organize the movement of water in one direction and prevent its return movement.

Manufacturers of pumping stations equip the kits with a valve, and if this element of shut-off valves is not available, then they insist on its mandatory purchase

The tasks that the installation of such a valve on the pumping line solves:

- stabilizes pressure and the pressure of water when moving from a well or well;

- organizes the supply of water in the right direction - from the source to the consumer;

- keeps the line constantly filled;

- protects equipment from pressure surges, force majeure situations and unscheduled repairs.

The principle of operation depends on the type and design of the valve. Let's consider it using the example of a device designed for tapping into a pipe.

The simplest model for plumbing, made of brass and stainless spring steel. Connection method - coupling, thread - internal. Designed for temperatures up to +110 ˚С

The main structural elements of the check valve are two working parts: saddle and shut-off element. A spring is used to return the shut-off element to its primary position.

The principle of the check valve is simple. When the liquid flows in a forward direction, from the source to the internal networks, the valve disc moves inside the body, opening a gap for water. If there is a movement of the liquid in the opposite direction, the shut-off element is tightly pressed against the seat and completely closes the flow area.

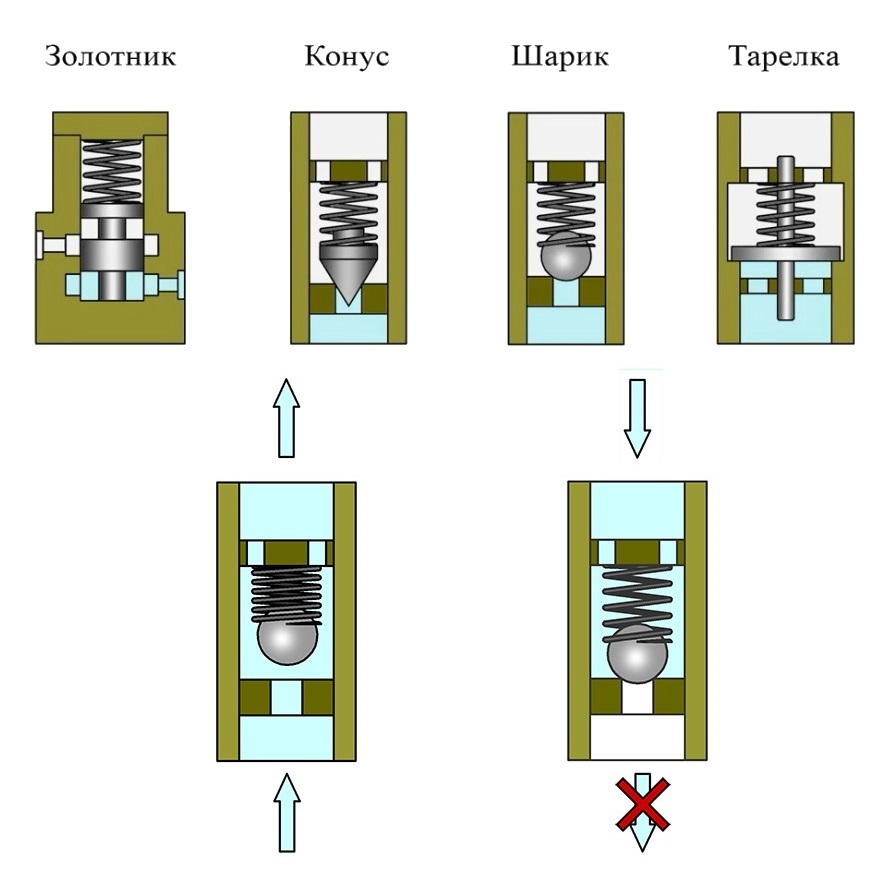

The shut-off element has several versions: a cylindrical spool, a cone, a ball, a plate. Accurate seat hitting on reverse travel provides additional guides

Without back-stop valves, when the pump is turned off, the liquid, according to the laws of hydrodynamics, would go back into the well or well.

Types of back-locking devices

At the place of installation, all check valves intended for pumping equipment are divided into two categories:

- for mounting on the suction pipe of a surface pump or through an adapter to a submersible pump;

- for installation on a pipeline.

The former prevent the reverse movement of water and ensure the filling of the system in a constant mode, the latter regulate water pressure.

We recommend installing both types of check valves, since the functions of the devices are different. The valve on the suction hose additionally protects the pump from dry running, prevents air congestion, that is, it is responsible for the pump's serviceability. Even if the equipment is originally equipped with the option of protection against "dry running", thanks to the check valve, you do not have to constantly fill with water.

Installing such a valve at the suction point is a must. But to stabilize the pressure in the system, a similar device is mounted in front of the pumping station or in front of the hydraulic tank, if it is located separately

The valves, which are installed on the pipe in the house wiring, prevent the liquid from returning to the outside - to the pump or well. They maintain the required water pressure and regulate the pressure. The main function of pipe models is considered to be the protection of pumping and plumbing equipment from sudden pressure surges and water hammer.

Borehole pump check valves

Check valves installed on the suction line are called bottom valves. They are used in a set of pumping stations to prevent water from draining from the network back into the well and to maintain the pressure at the desired level.

Models differ in design. Usually spring-loaded valves are used, less often - flap valves. If in spring the main working elements are the spring and the disc that blocks the flow, then in the casement ones there are 1-2 flaps that open under the pressure of the liquid.

The method of connecting the device to a pipe or hose also varies. More often used products with clutch fastening method, less often - with flanged.

A popular type of valve for submersible pumps is a spring device with a coupling method of attachment. Installation is made on the HDPE pipe using a threaded connection

To prevent the valve from clogging and the sediment from the bottom of the source does not move further - to the pumping equipment, a filter with a fine mesh is installed under it.

Types of pipe check valves

Depending on the installation conditions and the characteristics of the water supply system, valves are installed that differ in design, size, material and method of fastening. Some are designed for small diameter pipes and domestic use, others for centralized water supply.

Consider the main classifications of water check valves.

Classification # 1 - by type of locking element

The overlapping part of the valve inside the body is available in various configurations.

According to the locking element, the following types of devices are distinguished:

- Lifting, in which the shutter device moves up / down depending on the presence or absence of water pressure in the pipe. A spring is responsible for the dynamics, and a spool acts as a shutter.

- Swivel, also equipped with a spool - flap or "petal". When the pump is turned on, it leans back and clears the path for the liquid, when turned off, it slams shut, blocking the section.

- Bivalveblocking the path of the water flow with two connecting flaps.

The movement of the closure element is parallel, perpendicular to the axis or at an angle, therefore manufacturers recommend that some devices be installed only on horizontal pipes, others - and on vertical.

For domestic use, it is advisable to purchase spring valves, which are characterized by a simple design and ease of installation. If you decide equip yourself pumping system with back-shut-off valves, we recommend just such a model.

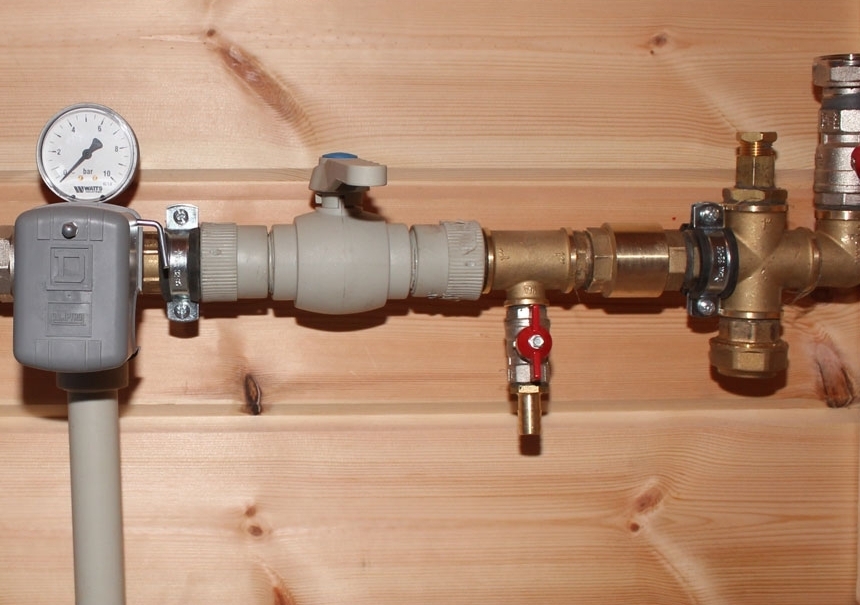

A sample of a spring valve installed in the piping of the boiler and preventing water hammer. A pumping station is connected to the system, pumping water from the well.

The spring valve design consists of the following elements:

- brass body (steel, polymer), consisting of two parts - base and cover with a seat;

- disc element with a rubber seal that abuts against the seat;

- stock, performing the functions of centering and holder;

- spring to return the shut-off element to its initial state.

Valves such as rotary valves are almost never used in domestic water supply, but they are often used for industrial pipelines, the diameter of which reaches 0.5 and even 1.5 m.

Classification # 2 - by type of attachment

Tie-in into the pipe is made in various ways, which are chosen depending on the pipe material and installation conditions.

Four types of valves are recognized as the most acceptable:

- flanged;

- interflanged;

- coupling;

- welded.

In systems associated with pumping stations, it is advisable to use a clutch type with a spring mechanism and simple installation. But in more "serious" networks, for example, for equipment for supplying water to an apartment building, all of the above types are successfully used.

Image gallery

Photo from

Flanged valves are named after the fastening elements - flanges. They are large and heavy and are made of steel or cast iron. Main field of application is the supply of liquids or gases on an industrial scale

Wafer devices are mounted without flanges. They are often used in pneumatic and hydraulic systems that experience water hammer. To mitigate the impact, they are mounted together with damping shock absorbers

Threaded couplings are the most convenient valves for installation in a household network. The fastening is provided by two threaded transitions, the diameter of which is measured in inches. Products with metal closures are considered more reliable than with plastic ones.

They are found under the name "welding-welding". The cut-in into the pipe takes place in a collapsible state, for the convenience of connection, a clamp-clamp (monolithic bracket) is used. Manufacturing material - stainless steel AISI 304 and AISI 316, possible diameter - 0.25-1 m

Flanged Cast Iron Industrial Models

Butterfly Valves

Coupling devices for tapping into a domestic pipeline

Welded models

If you decide to install a check valve in your home pumping network, you should stop at the coupling model. Devices can be purchased in specialized stores at a price of 40 to 600 rubles. The size of the products is 1ˮ, 1 / 2ˮ, 3 / 4ˮ.

Classification # 3 - by material of manufacture

Valve bodies are made of materials that reliably protect the internal mechanism, do not deform from the effects of the external environment and the liquid flowing through the pipes.

The check valve on the pipe is:

- steel;

- cast iron;

- bronze;

- brass;

- plastic.

Products installed near centrifugal pumps in the heating system must be metal, since plastic is not intended for hot water.

Sample of brass OK, universal for use. It is installed on both metal and plastic pipes. The product does not rust the bends, does not change technical characteristics over time

Cast iron valves are characterized by high weight and roughness of the material. But they are not used for the equipment of autonomous home networks, but are installed only for industrial operation on large-diameter pipes.

Devices from plastic lightweight and inexpensive, installation is very quick. But they cannot be applied to serious home water systems.

Polymer products are suitable for polypropylene pipes in networks with a low water pressure - for example, for watering a vegetable garden or pumping water into a bath

The internal parts - the seat, plugs, stem - of the valves are made of polymers, stainless steel or aluminum. They are durable and resistant to corrosion. The active element, the spring, is made from a special spring steelwith increased service life.

In valves installed on centralized lines and industrial facilities that can withstand heavy loads, plastic or rubber seals.

Recommendations for the installation of such a valve

Consider one of the options for installing a check valve - on a submersible pump "Aquarius". The device is connected directly to the pump. As soon as the unit stops working, the valve shuts off the water so that it does not drain back down. Due to this, the line is constantly filled with liquid.

The procedure for connecting the bottom check valve:

Image gallery

Photo from

If the pump is not supplied with OK, it must be purchased separately. The valve must match the diameter of the adapters. It is better to choose a metal part - from brass or steel

First screw in the male double-threaded connection fitting 1ˮ. Sealing is done with linen strands or fum tape

Take a product with a 1ˮ thread, check the direction of movement of the water flow along the arrow and screw it to the adapter. Flax thread or fum tape is also pre-wound on the thread of the fitting.

The flexible irrigation hose is connected with a plastic sleeve that is screwed into the valve's female thread. Inside the coupling there is a seal that seals the joint

Step # 1 - preparing the check valve

Step # 2 - attaching the adapter

Step # 3 - installing the valve

If the check valve does not have an arrow indicating the movement of water, you can try to purge it. The valve is screwed to the pump with the side from which it is freely blown.

There are several rules regarding the location of the valve inside the well. If it is installed on the pipe of a surface pump, then the distance to the bottom should be at least 0.5 m. The manufacturer indicates the exact parameters in the technical passport. Also observe the distance to the water surface - not less than 0.3 m.

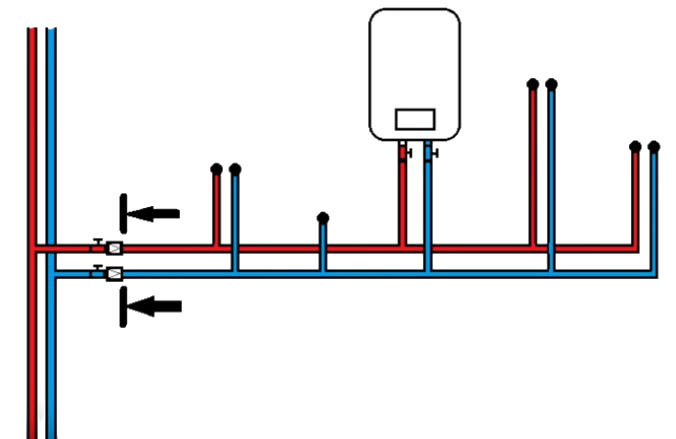

If the check valve is installed in the water supply system, powered by a pump, inside the house, then the main thing is to choose the right place. Usually two devices are installed - separately on the hot and cold water line

We recommend that you observe the following order: at the entrance you should install ball valve, then a strainer, followed by a counter, and only then a check valve.

Some metering devices are equipped with built-in valves, but they are not very reliable, so it is better to play it safe and install a separate device.

Conclusions and useful video on the topic

Recommendations for the selection and installation of a check valve for a submersible pump:

More about the design and purpose:

About the nuances of installing the valve in the following video:

It is not worth talking about the need to install check valves - this device is mandatory for the stable operation of the water supply system. It is also used with submersible, and with surface pumpsto prolong the life of the equipment and prevent the system from accidents.

Experienced in installing a check valve? Or would you like to ask our experts or more experienced users for advice? Ask your questions, share your own opinion in the comment block below this article.