A high and blank fence is needed to fence and protect private property. But every fence must have a way out. And very often a regular wicket is not enough, even if you do not have a car. Sometimes situations arise when you need to bring something into the yard and then you simply cannot do without a gate. Do you agree?

Of course, you can purchase a ready-made product or order the manufacture and installation of gates in a specialized company, but for saving money, we propose to build a gate with your own hands from corrugated board, especially since it is not as difficult as it seems at first sight.

Next, we will tell you what kind of gates made of corrugated board are, we will give their advantages and disadvantages, and also provide detailed instructions on how to build a gate on our own.

The content of the article:

- Types of gates made of corrugated board

-

Installation instructions for swing gates

- Stage 1 - creating a drawing of the gate

- Stage 2 - preparation of tools and materials

- Stage 3 - installation of structural supports

- Stage 4 - making the frame and installing the hinges

- Stage 5 - installation of a profiled sheet and installation of accessories

- Advantages and disadvantages of swing gates

- Conclusions and useful video on the topic

Types of gates made of corrugated board

Gate structures made of profiled sheet can be: sliding, swinging, forged and lifting. They also differ in their shape and manufacturing method. In addition, many designs can have a built-in wicket door.

Swing gates - the easiest option both in performance and in service. Even an inexperienced home craftsman can cope with the construction of such a structure.

Swing gates require a lot of space to open the leaves. This is a rather important point that must be taken into account before proceeding with their construction.

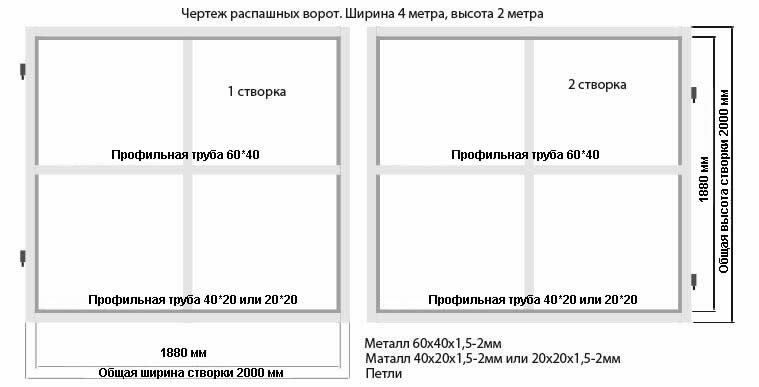

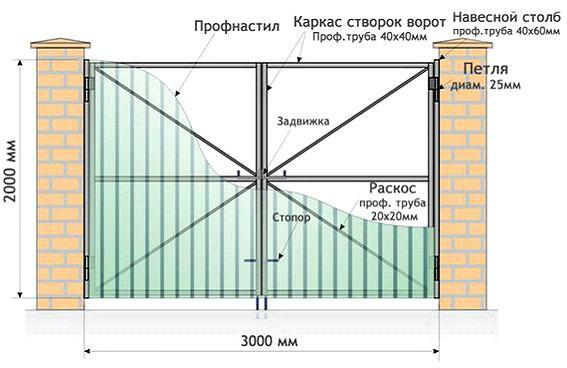

An approximate diagram of a swing gate 4 meters wide with an indication of all dimensions of the structure, the required materials and the locations of the hinges

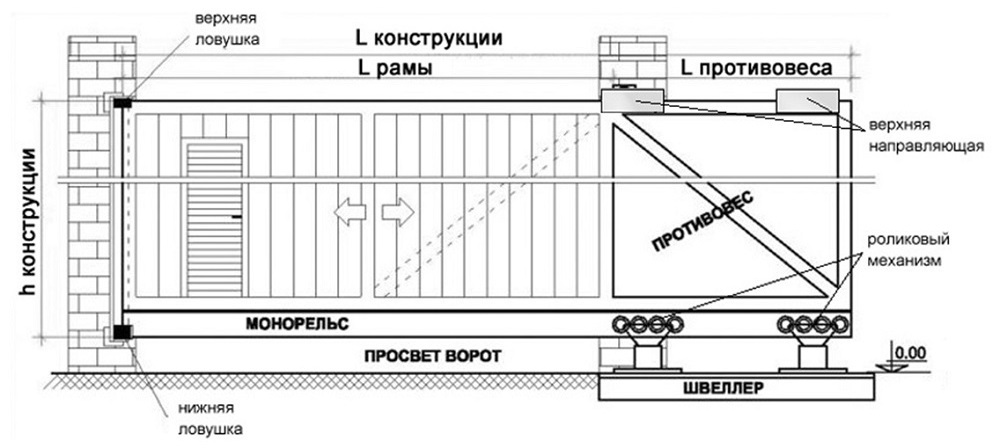

Sliding gates, perhaps, one of the most practical and aesthetic solutions for the design of an entry group in a private house or in a summer cottage. Unlike the previous version, they do not require a lot of space.

Among the existing variety of color and design solutions, everyone will be able to find a suitable gate option, both in terms of cost and design.

Schematic representation of sliding gates with the designation of the main structural elements. It remains only to apply the required dimensions and you can start construction

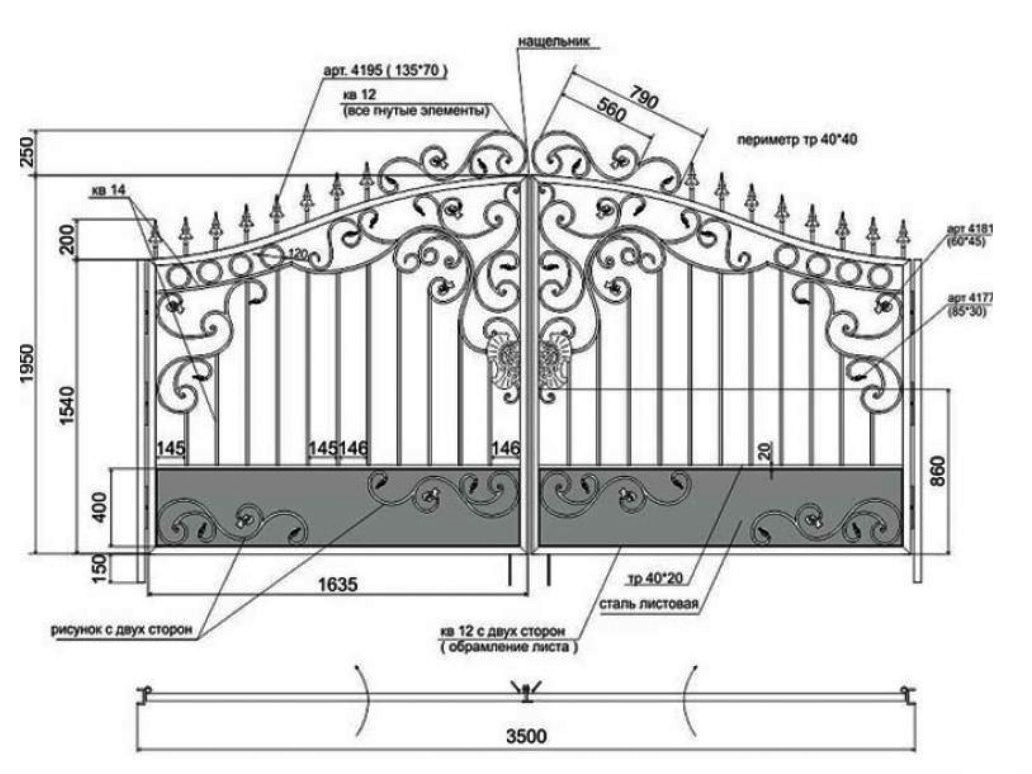

Forged gates - can be both swing and retractable. Their only difference from the usual ones is that they are decorated with forging elements.

But, it is worth noting that such an addition to conventional corrugated doors can be quite expensive, so it is better to plan your budget in advance.

Decor made of forged elements is one of the best ways to decorate the surface of the gate, because every owner dreams that his yard would be the most beautiful and memorable

One of the options for decorating gates from corrugated board is to decorate them with curly forging elements. This method allows you to give the gate a more noble appearance even without preliminary dismantling.

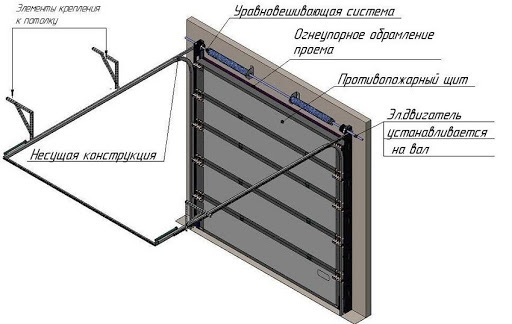

Lifting structures, according to many users, the most convenient of the above. They can be sectional and lift-and-turn.

It is the second option that is more popular. With the help of a lever-hinge mechanism, the door leaf rises completely to the garage ceiling, freeing up space for vehicle entry / exit.

Such gates practically do not take up space in the garage / yard, provide good thermal insulation of the room and are more resistant to burglary due to the integrity of the structure.

An approximate diagram of the location of the main structural elements of the overhead door made of corrugated board. The size will depend on the available space.

Installation instructions for swing gates

Above, we have given several popular schemes for gates made of corrugated board. Swing gates are an affordable and easiest option that even a beginner can handle.

The only caveat is that they take up quite a lot of space on the site. If there is enough space, then you can safely get down to work.

Stage 1 - creating a drawing of the gate

As a rule, swing gates made of profiled sheet have dimensions of 3-4 meters in width and from 2.2 meters in height. It should be borne in mind that in front of their location, there must be at least 2 meters of free space for the unhindered opening of the doors.

In addition, swing gates can be made in several variations: with one or two leaves, with or without a wicket. It is better to give preference to the second option, since single-leaf structures require a lot of space for opening and have a large windage.

An approximate diagram of a gate made of corrugated board with fastening on previously laid pillars with the designation of the main structural elements, their sizes

If there is not a lot of space on the site, then it is better to give preference to swing gates with a built-in wicket.

When starting to create a construction drawing, consider:

- The location of the wicket and its dimensions.

- The number of supports and their height, taking into account the digging depth.

- Dimensions of each sash.

- Places of attachment of hinges, lock and internal latches.

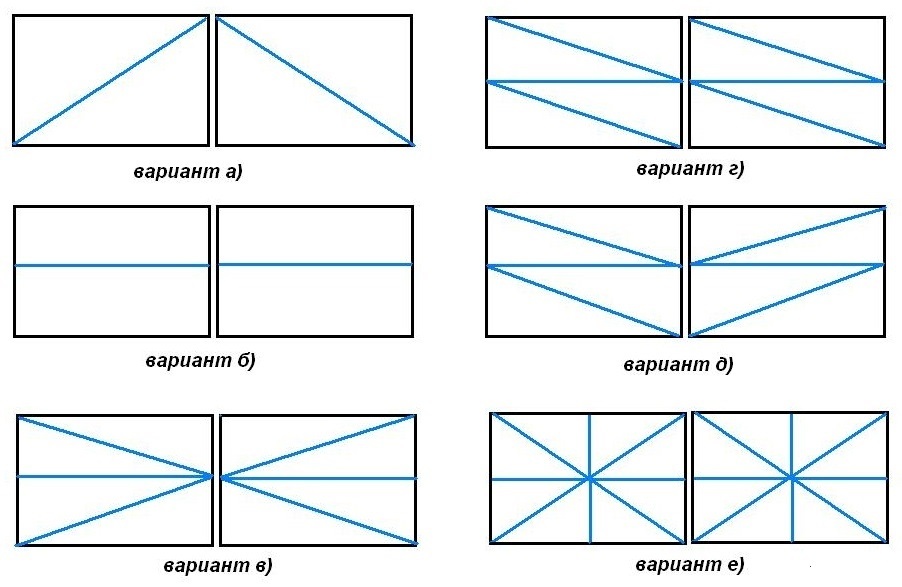

To extend the service life of the structure, professionals recommend strengthening the gate in one of the following ways: weld corners for structural rigidity, make a frame inside the frame or above it, or install jumpers.

The figure shows six options for installing jumpers on the gate. Option "e" is considered the most optimal, since all corners, hinges, latches and lock are reinforced in it

Stage 2 - preparation of tools and materials

Based on the drawing prepared by you with the application of all sizes of the future gates, you have to prepare:

- corrugated board (it is advisable to purchase a brand not lower than C18);

- hollow metal pipe for support pillars, cross-section not lower than 60 * 60 mm;

- pipe for the base - it is better to take 40 * 40 mm;

- pipe for strengthening the base - 20 * 20 mm;

- plates for fastening reinforcement under the lock;

- self-tapping screws;

- clamps, hinges, lock;

- concrete solution for the installation of supports;

- primer and paint.

In addition to these materials, you will need for work: a level, a tape measure, a grinder, a screwdriver, a welding machine, a shovel, metal scissors, brushes.

Stage 3 - installation of structural supports

The installation of corrugated sheeting doors begins with the installation of support pillars. To do this, you will need to dig a depression about 1/3 of the length of the support. And the larger the diameter of the support, the larger the diameter of the recess will be needed.

At the bottom of the recess, it is necessary to pour a layer of crushed stone with sand 15-30 cm thick. This is done to ensure an unobstructed outflow of water from the base of the support post.

Further, supports are installed in the prepared holes. They should be positioned clearly vertically, since even the slightest tilt will lead to a skew of the entire structure.

After checking the correctness of the installation, the supports are fixed with reinforcement or bricks and only then they are poured with concrete mortar. Fixation is necessary so that, after pouring the concrete, the supports do not tilt.

In order to avoid water getting inside the supporting pillars, you can concrete them from the inside, or close the upper part with a special metal plate.

The supports faced with brick will look beautiful, but the width of the supports must be taken into account in advance - even at the stage of drawing up the drawing

Stage 4 - making the frame and installing the hinges

First you need a pipe cut with a grinder into blanks, clean them of dirt and lay out the prepared fragments in accordance with the drawing of the future gate. Further, using a welding machine, the workpieces are connected to each other.

After the frame is completely welded, it is reinforced, if required. After complete cooling of the welding seams, they are thoroughly cleaned.

The upper parts of the frame must be welded at an angle of 45 degrees. This will help prevent water from entering the structure. The lower parts of the structure can be butt welded

Then the frame must be completely degreased, thoroughly primed and painted, paying special attention to the joints of the parts.

When the frame is completely ready, hinges are welded to it and to the support posts - three on each side. They are installed, stepping back from the top / bottom edge 25-30 cm.

Never done welding? We recommend that you familiarize yourself with nuances of electric welding for beginners.

If you want to open the gate in both directions, then the hinges must be butt welded to the support post, and if in one direction, the loop is placed on the frame. To prevent the sash from hitting the fence when opening, a limiter can be installed next to it.

Stage 5 - installation of a profiled sheet and installation of accessories

At the next stage, using metal scissors, the corrugated board is cut and attached to the gate frame.

The professional sheet is attached to the frame from one or both sides. This is done with rivets or self-tapping screws. The second option is preferable

For reliable fastening, the profiled sheet should be fixed along the lower waves through one to the horizontal beams of the frame, and the sheets are attached to the vertical beams in increments of 15 to 25 cm. Please note that 1 sq. M. the gate must have at least 6 screws.

If the frame has been reinforced, then the profile sheet must also be attached to the vertical or horizontal jumpers.

The last thing left is to install the lock.

One of three types is commonly used:

- Mortise. Cuts directly into the plane of the pipe.

- Overhead. It is installed on the transverse lintel of the sash and requires additional reinforcement with a metal plate.

- Hinged. If you plan to use this option, then you should weld the loops for the lock at the stage of welding the frame.

It is recommended to use special locks for mounting in a metal profile for doors made of profiled sheets. It is better to give preference to models with an opening mechanism with a rotating element from the inside and a key outside. It is better not to save on locks and purchase products from well-established manufacturers.

Usually the handle and the lock are installed at a height of about 90 cm from the ground, but this distance can vary depending on the height of the owner - the main thing is to open the gate conveniently.

In addition to the lock, it is also recommended to install the lower retainer for the gate leaves. It helps to additionally secure the lower part of the gate from gusts of wind

Advantages and disadvantages of swing gates

Above, we talked in detail about how to independently design and install swing double-leaf gates from a professional sheet.

The most important advantage of swing gates is that no special knowledge or skills are required for their design and installation. Even a construction beginner can handle this.

This version of the gate has become very popular among residents of the private sector and here's why:

- affordable cost of materials;

- ease of installation;

- attractive appearance;

- ease of care;

- long service life;

- possibility automation installations.

Despite the large number of advantages, corrugated gates have some disadvantages: they require a lot of free space for opening; due to their large area, they are exposed to significant wind loads.

Do you need a gate with a wicket and do not know which material to choose for this? Our next article discusses types of gates with a wicket, their advantages and disadvantages.

Conclusions and useful video on the topic

Detailed video instructions for installing a gate with a wicket with your own hands:

Another option for the manufacture and installation of gates from a profiled sheet, as well as a fence and a wicket:

As you can see, there is nothing complicated in the independent manufacture of gates from corrugated board. All that is required is the minimum skills in working with a power tool, the desire to make the gate yourself and some free time.

With a little effort, you can independently make a gate that will become the hallmark of your site and protect the house from unwanted guests.

Have you ever had to independently manufacture and install gates from a profiled sheet? Tell us which design option you preferred, were there any difficulties during the work and how did you cope with them? For clarity, you can attach a photo of the gate of your own manufacture in the discussion of the article, as well as ask questions of interest to our experts.