Technologies related to the extraction, transportation and processing of natural gas are developing at a rapid pace. And many people today are hearing the abbreviations LNG (LPG) and LPG (LNG). Almost every other day natural gas fuel is mentioned in the news in one context or another.

But, you must agree, in order to have a clear understanding of what is happening, it is important to first understand how the gas is liquefied, why it is done and what benefits it gives or does not give. And there are a lot of nuances in this matter.

Large high-tech factories are being built to liquefy gaseous hydrocarbons. Next, we will carefully understand: what is all this for and how it happens.

The content of the article:

-

Why do they liquefy natural gas?

- Economy and transport safety

- Use in various fields

-

LPG and LNG production technologies

- Gas preparation

- Basic liquefaction process

- Transport and storage

- Liquefied Hydrogen Prospects

- Conclusions and useful video on the topic

Why do they liquefy natural gas?

Blue fuel is extracted from the bowels of the earth in the form of a mixture of methane, ethane, propane, butane, helium, nitrogen, hydrogen sulfide and other gases, as well as their various derivatives.

Some of them are used in the chemical industry, and some are burned in boilers or turbines to generate heat and electricity. Plus, a certain amount of the mined is used as gas engine fuel.

Calculations of gas workers show that if blue fuel needs to be delivered at a distance of 2500 km or more, then in liquefied form it is often more profitable to do this than by pipeline

The main reason for the liquefaction of natural gas is to facilitate its transportation over long distances. If the consumer and the gas fuel production well are located on land close to each other, then it is easier and more profitable to lay a pipe between them. But in some cases, the construction of a highway is too expensive and problematic due to geographic nuances. Therefore, they resort to various technologies for obtaining LNG or LPG in liquid form.

Economy and transport safety

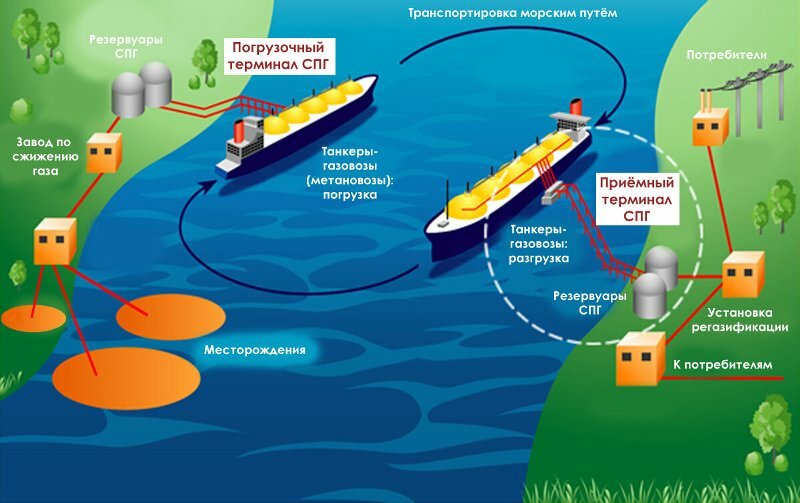

After the gas has been liquefied, it is already pumped in the form of a liquid into special containers for transportation by sea, river, road and / or rail. At the same time, liquefaction is technologically quite costly from an energy point of view of the process.

At different factories, this takes up to 25% of the initial volume of fuel. That is, to generate the energy required by the technology, it is necessary to burn up to 1 ton of LNG for every three tons of it in finished form. But natural gas is now in great demand, everything pays off.

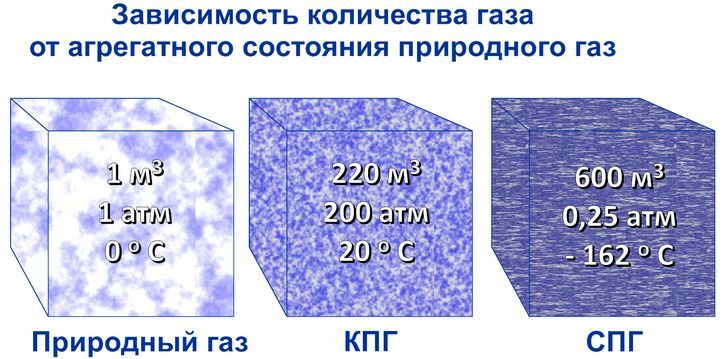

In liquefied form, methane (propane-butane) occupies 500-600 times less volume than in gaseous state

As long as natural gas is in a liquid state, it is non-flammable and non-explosive. Only after evaporation in the course of regasification, the obtained gas mixture turns out to be suitable for combustion in boilers and hobs. Therefore, if LNG or LPG is used as a hydrocarbon fuel, then they must be regasified.

Use in various fields

Most often, the terms "liquefied gas" and "liquefied gas" are mentioned in the context of the transportation of a hydrocarbon energy carrier. That is, at first, blue fuel is extracted, and then it is converted into LPG or LNG. Then the resulting liquid is transported and then returned to the gaseous state for one or another application.

LPG (liquefied petroleum gas) is 95% or more of a propane-butane mixture, and LNG (liquefied natural gas) is 85–95% of methane. These are similar and at the same time radically different types of fuel.

LPG from propane-butane is mainly used as:

- gas engine fuel;

- fuel for pumping autonomous heating systems into gasholders;

- liquids for refueling lighters and gas cylinders with a capacity of 200 ml to 50 liters.

LNG is usually produced exclusively for long distance transportation. If for storage of LPG there is enough capacity that can withstand a pressure of several atmospheres, then for liquefied methane, special cryogenic tanks are required.

LNG storage equipment is highly technological and takes up a lot of space. It is not profitable to use such fuel in passenger cars due to the high cost of cylinders. LNG trucks in the form of single experimental models are already driving on the roads, but in the passenger car segment this "liquid" fuel is unlikely to find widespread use in the near future.

Liquefied methane as a fuel is now increasingly used in operation:

- railway locomotives;

- sea vessels;

- river transport.

In addition to being used as an energy carrier, LPG and LNG are also used directly in liquid form in gas and petrochemical plants. Various plastics and other hydrocarbon-based materials are made from them.

LPG and LNG production technologies

To convert methane from a gaseous state to a liquid, it must be cooled to -163 ° C. And propane-butane liquefies already at -40 °WITH. Accordingly, technologies and costs are very different in both cases.

One liter of LNG equals approximately 1.38 cubic meters. m of original natural gas (this figure depends on temperature and pressure), a decrease in volume - about 620 times

The following technologies from different companies are used to liquefy natural gas:

- AP-SMR (AP-X, AP-C3MR);

- Optimized Cascade;

- DMR;

- PRICO;

- MFC;

- GTL, etc.

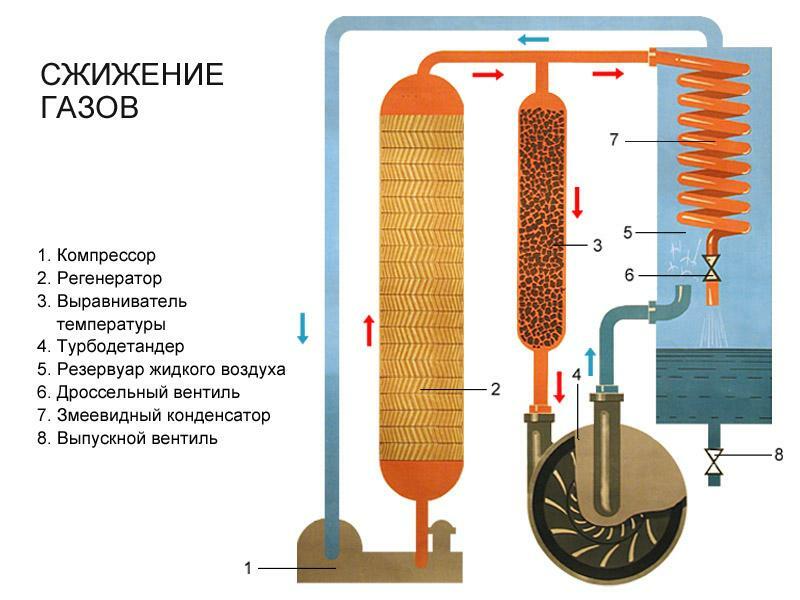

All of them are based on the processes of compression and / or heat exchange. The liquefaction operation takes place in the plant in several stages, during which the gas is gradually compressed and cooled to the temperature of transition to the liquid phase.

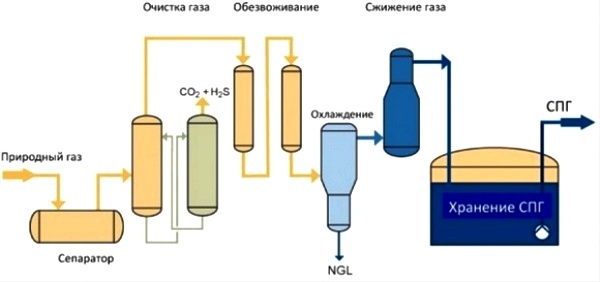

Gas preparation

Before starting to liquefy raw natural gas, water, helium, hydrogen, nitrogen, sulfur compounds and other impurities must be removed from it. For this, the adsorption technology of deep purification of the gas mixture by passing it through molecular sieves is usually used.

Then the second stage of preparation of the feedstock takes place, during which heavy hydrocarbons are removed. As a result, only ethane and methane (or propane and butane) with an impurity volume of less than 5% remain in the gas, so that this fraction can begin to be cooled and liquefied.

Primary preparation with the removal of all unnecessary from natural gas is carried out in order to protect refrigeration equipment from the aggressive effects of water, carbon dioxide, sulfur compounds, etc.

Fractionation allows you to get rid of harmful impurities and release only the main gas for subsequent liquefaction. At a pressure of 1 atm, the temperature of transition to the liquid state for methane is -163 ° C, for ethane -88 ° C, for propane -42 ° C, and for butane -0.5 ° C.

It is these temperature differences that explain the reason why they separate into fractions and only then liquefy the gas supplied to the plant. There is no single liquefaction technology for all types of gaseous hydrocarbon compounds. Each of them has to build and use its own technological line.

Basic liquefaction process

The basis for converting a gas into a liquid state is a refrigeration cycle, during which heat is transferred by one or another refrigerant from a low-temperature environment to a higher one. This process is multistage and requires powerful compressors for expansion / contraction of the heat carrier and heat exchangers.

Compression technologies are high-tech, energy-intensive and costly, but in one cycle they allow gas to be compressed 5-12 times at once

The following are used as a refrigerant at different stages of liquefaction:

- propane;

- methane;

- ethane;

- nitrogen;

- water (sea and purified);

- air.

For example, for the primary cooling of natural gas at Novatek's Yamal LNG, a cool arctic air, which allows you to lower the temperature of the feedstock with minimal cost immediately up to +10 ° С. And in the hot summer months, instead of it, it is envisaged to use sea water from the Arctic Ocean, which, regardless of the time of the year, at a depth of constant 3-4 ° С.

At the same time, nitrogen obtained directly from the air is used as the final refrigerant in Yamal. As a result, the Arctic provides everything necessary for LNG production - from the source natural gas to the working agents used in the liquefaction process.

Propane is liquefied according to a scheme similar to methane. Only the cooling temperatures are much lower - minus 42 ° C versus minus 163 ° C. Therefore liquefaction gas for gas tanks costs several times cheaper, but the produced propane-butane LPG itself is less in demand on the market.

Transport and storage

Almost the entire volume of LNG is transported by large-size sea-going LNG carriers from one coast to the other. Transportation by land is limited by the need to maintain the temperature of the "liquid blue fuel" at values of about -160 ° С, otherwise methane begins to turn into a gas state and becomes explosive.

For the transportation of LPG, cylinders of 5-50 liters with an internal pressure of up to 1.5-2 MPa and larger tank containers designed for 5-17 MPa are used

The pressure in the LNG container is close to atmospheric. However, if the temperature of liquid methane rises above -160 ° C, then it will begin to turn from liquid to gas. As a result, the pressure in the container will begin to rise, which is a serious hazard. Therefore, LNG carriers are equipped with installations for maintaining low temperatures and a thick layer of heat insulator.

LPG is regasified into gas directly in the gasholder. Regasification of LNG is carried out in special industrial plants without oxygen access. Physically, liquid methane at positive temperatures gradually turns into gas. However, if this happens directly in air outside special conditions, then such a process will lead to an explosion.

After natural gas in the form of LNG is liquefied at the plant, it is transported, and then again at the plant (only regasification) is converted back into a gaseous state for further use.

Liquefied Hydrogen Prospects

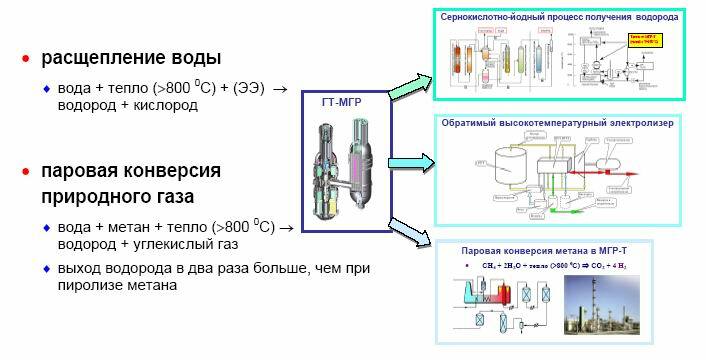

In addition to direct liquefaction and use in this form, it is also possible to obtain another energy carrier from natural gas - hydrogen. Methane is CH4, propane C3H8, and butane C4H10.

The hydrogen component is present in all these fossil fuels, you just need to isolate it.

The main advantages of hydrogen are environmental friendliness and widespread occurrence in nature, however, the high cost of its liquefaction and losses due to constant evaporation practically negate these advantages.

To transfer hydrogen from a gas state to a liquid, it must be cooled to -253 ° C. For this, multistage refrigeration systems and compression / expansion units are used. So far, such technologies are too expensive, but work is underway to make them cheaper.

We also recommend reading our other article, where we described in detail how to make a hydrogen generator for your home with your own hands. More details - go link.

Also, unlike LPG and LNG, liquefied hydrogen is much more explosive. The slightest leak of it in combination with oxygen gives a gas-air mixture, which is ignited by the slightest spark. And storage of liquid hydrogen is possible only in special cryogenic containers. There are still too many disadvantages to hydrogen fuel.

Conclusions and useful video on the topic

How liquefied gas is produced and why it is liquefied:

Everything about liquefied gases:

There are several technologies for liquefying gases. They are their own for methane, and their own for propane-butane. At the same time, it is cheaper to get LPG, and it is easier and safer to transport / store. The production of methane LNG is a more costly and complex process. Plus, its regasification requires specialized equipment. At the same time, methane is more in demand on the market today, therefore it is liquefied in much larger volumes.

Do you have any clarifying questions or your expert opinion on the subject of gas liquefaction? Perhaps you have something to add to the above. Feel free to ask and / or comment on the article in the block below.