One way or another, you are faced with the issue of economy and power of household appliances. Whether it is at the stage of the first repair or when replacing outdated equipment. It is useful to calculate the gas consumption or the need for it before buying a stove or boiler, choosing a gas meter, and possibly replacing it. If you have questions about gas charges, if the search for new equipment is a matter of the coming weeks for you, an accurate method for determining gas consumption and formulas for calculating will make your life easier.

Gas prices are gradually increasing and appliances are becoming more powerful, so it doesn't hurt to come up with your own cost optimization strategy. Our article will help you with this. You will not be able to find out about the real level of gas consumption in your home from conversations with neighbors, you need accurate information.

The content of the article:

- Natural gas consumption at home

- Gas calculation for heating, hot water supply, stove

-

Fuel meters

- Measurement methods used in gas flow meters

- How is gas pressure determined?

- Conclusions and useful video on the topic

Natural gas consumption at home

The owners of all apartments and houses, many enterprises need to calculate the volume of consumed gas. The data on the need for fuel resources are included in the projects of individual houses and their parts. To pay with real numbers, use gas meters.

The level of consumption depends on the equipment, building insulation, season. In apartments without centralized heating and hot water supply, the load goes to the water heating boiler. The device consumes up to 3-8 times more gas than a stove.

Gas water heaters (boilers, boilers) are wall-mounted and floor-mounted: they are used simultaneously for heating and water heating, and less functional models are mainly only for heating

The maximum consumption of the stove depends on the number of burners and the power of each of them:

- reduced - less than 0.6 kW;

- common - about 1.7 kW;

- increased - more than 2.6 kW.

According to another classification, low power for burners corresponds to 0.21-1.05 kW, normal - 1.05-2.09, increased - 2.09-3.14, and high - more than 3.14 kW.

A typical modern stove uses at least 40 liters of gas per hour when switched on. Usually, the stove consumes about 4 m³ per month for 1 tenant, and the consumer will see about the same figure if he uses a meter. Compressed gas in cylinders is much less required in terms of volume. A family of 3 people will have a capacity of 50 liters for about 3 months.

In an apartment with a 4-burner stove and without a water heater, you can install a G1.6 meter. A device with a standard size G2.5 is used if there is also a boiler. To measure gas consumption, large gas meters are also installed, on G4, G6, G10 and G16. The meter with the G4 parameter will cope with the calculation of the gas consumption of 2 stoves.

Water heaters are 1- and 2-circuit. For a boiler with 2 branches and a powerful gas stove, it makes sense to put 2 counters. One reason is that household gas meters are not good at handling large differences in equipment power. A weak stove at minimum speed uses many times less fuel than a water heater at maximum.

The classic stove has 1 large burner, 2 medium and 1 small, using the largest is the most economical

Subscribers without meters pay for the volume, based on consumption per 1 inhabitant, multiplied by their number, and consumption per 1 m², multiplied by the heated area. The standards are in effect all year round - they have laid down the average indicator for different periods.

Rate for 1 person:

- Gas consumption for cooking and heating water using a stove in the presence of centralized hot water supply (DHW) and central heating is about 10 m³ / month per person.

- The use of only one stove without a boiler, centralized hot water supply and heating - about 11 m³ / month per person.

- Using a stove and a water heater without centralized heating and hot water supply - about 23 m³ / month per person.

- Water heating by a water heater - about 13 m³ / month per person.

In different regions, the exact flow rates do not match. Individual heating with a water heater costs about 7 m³ / m² for heated living quarters and about 26 m³ / m² for technical ones.

On the notice from the meter installation company, you can see how different the consumption figures with and without a gas meter are.

Dependence in gas consumption was indicated in SNiP 2.04.08-87. The proportions and indicators are different there:

- stove, central hot water supply - 660 thous. kcal per person per year;

- there is a stove, no hot water supply - 1100 thous. kcal per person per year;

- there is a stove, a water heater and no hot water supply - 1900 thous. kcal per person per year.

The consumption according to the standards is influenced by the area, the number of residents, the level of amenities with household communications, the presence of livestock and its livestock.

The parameters are differentiated based on the year of construction (before 1985 and after), the attraction of energy-saving measures, including the insulation of facades and other external walls.

For more information on gas consumption rates per person, see this materiale.

Gas calculation for heating, hot water supply, stove

The required amount of fuel for heating the premises is determined by the square or the cubic capacity of the room. In the case of rooms with a height of 3 meters or less, it is sufficient to determine the area. For 1 sq. a meter of such premises will require an average of 100 watts.

In the southern regions of the country, the specific parameter per 1 m² is reduced to 80 W, in the conditions of the far north, it is increased to 200 W per m². The water heater is selected with a margin above the maximum load.

With the volumetric method of counting, from 30 to 40 W is taken per cubic meter, with a decrease in the number for the southern regions. All methods work well in winter, but the indicators for 1 m² decrease as the difference between the outside temperature and room temperature drops from 40 degrees to 10.

The need for heating a room of one size or another is determined before installing a boiler or a "warm water floor" system, which can also be operated from a gas boiler.

The maximum gas consumption by the boiler is calculated by the formula V = Q / (q × efficiency / 100), where:

- V - fuel volume, m³;

- Q is the power of the heating system and heat loss, kW;

- q is the lowest specific calorific value of fuel, kW / m³ (average 9.2);

- Efficiency is the efficiency of a gas boiler, usually 96%.

Using the same, but modified formula, you can calculate the maximum consumption of the stove, including per unit of time.

When measuring the consumption of liquefied gas (LPG), instead of the lowest specific calorific value, the specific heat of combustion is substituted. It differs for different mixtures, and for propane-butane it is equal to 46 MJ per kg. The efficiency of a gas boiler when using LPG is reduced from 96 to 88%.

The amount of fuel for individual hot water supply is determined according to the needs for 1 person. Information is available in the documentation on water consumption, but you can calculate it yourself. For a family of 4, 1 heating of 80 liters per day is enough, from +10 to +75 ° C.

The required power is determined by the formula Q = c × m × Δt, wherein:

- Q is actually the required power, in kW;

- c - heat capacity of water, 4183 kJ / kg × ° C;

- m - water consumption, kg;

- Δt is the difference between the start and end temperatures, usually 65 ° C.

They save on fuel through system and external methods. Condensation plates, indirect heating boilers with a timer are beneficial. Automation with a change in the temperature in the room from a comfortable one to + 10... + 15 ° C during absence will help. External savings options include home insulation and underfloor heating.

Each square meter of the outer wall can save up to 80% of gas, and in total, about 15% of the heat goes through the walls - 4 times more than through the roof of a private house

You can save gas when using the stove using the following methods:

- "Do not release" the flame from under the bottom of the containers;

- close kettles and pots with lids;

- use only maximum heat for boiling;

- heat food in large portions.

Gas consumption is also determined before roofing work, in fusion burners. A 50-liter cylinder with a propane-air mixture will last 10.8 hours, because the consumption will be approximately 2 kg / h. For 1 m² of coverage you will need 0.2 kg in spring and autumn and 0.3-0.4 kg in winter.

We also suggest reading our other articles, where we talked in detail about how to correctly calculate the gas consumption for heating a house:

- Gas consumption of a floor-standing boiler.

- Calculation of gas consumption for heating the house.

Fuel meters

The meter measures the amount of gas at different conditions of temperature and pressure and with the presence of a special technique brings the result obtained to an indicator that will be under standard conditions (SS) - +20 ° C and 101 kPa.

Fuel volume for SU is determined by the formula Vc = V × (p × Tc / pc × T × K), where

- V is the gas volume;

- p is the density;

- T is the thermodynamic temperature;

- K - coefficient of fuel compressibility.

Values with the letter "c" - indicators for standard conditions, without - for workers.

In everyday life, membrane, rotary and ultrasonic meters are used, at large enterprises - turbine and vortex - these are the most popular types of gas meters. In gas factories, volume is determined primarily by varying pressure variations in the constrictions, often between 2 flange connections in close proximity. The counters differ in their working characteristics.

The image shows a classic membrane meter (diaphragm, chamber), in the compartments of which there are membranes moving from the movement of the gas and determining its volume

Diaphragm flow meters give the minimum error in calculations and consume little electricity. The devices give readings over a wide range, but with a low ultimate pressure - up to 0.5 bar. In everyday life, the meter shows itself in the best possible way, since the calibration interval reaches 10 years with a high reliability of the device. The design reacts poorly to mechanical contamination of the gas and is generally very cumbersome.

Rotary, or rotary, the models do not depend on the power supply, suitable for small industrial facilities, but they are less convenient. With a small area for installation and high accuracy in conditions of sudden pressure drops, they are noisy and often fail. They are "afraid" of pneumatic impacts and pollution.

Ultrasonic meters are small in size, vary significantly in the complexity of the structure. Acoustic gas meters are valued for their reliability and ease of installation. Some devices contain non-volatile memory. Meters for standard sizes G1.6 and G2.5 are relatively expensive.

Turbine devices used to measure the amount of household and corrosive gases, multicomponent compositions. Counters are widely used in gas pipelines and chemical plants. Turbine devices record large amounts of gas at pressures up to 10 MPa, differ significantly in size and working DN. These are universal instruments for measuring the flow of natural gas in industry.

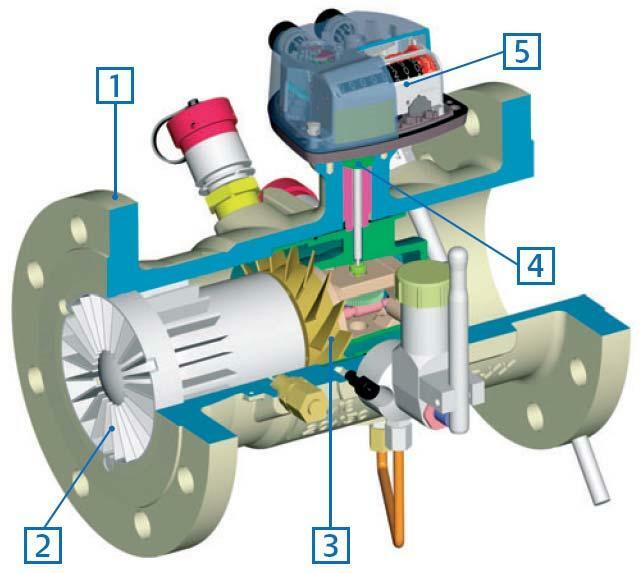

A turbine meter is a fragment of a pipe: in Figure 1 - housing, 2 - gas flow straightener, 3 - measuring mechanism with a turbine, 4 - magnetic coupling for transferring rotation to the counting mechanism, 5 - counting mechanism

Vortex measure the volume of natural or inert gases. In terms of the measurement range, they have an advantage over other models. They catch the slightest movements in the gas mixture and determine large quantities of gas per diameter. The efficiency of a vortex flow meter is directly proportional to the fuel flow rate.

Measurement methods used in gas flow meters

Fuel consumption is calculated direct and indirect methods.

In the case of direct gas, the gas fills and exits the measuring chambers. The volume passed correlates with the filling-emptying cycles. Counting in membrane, rotary and drum counters works according to the described principle.

Indirect gas meters operate with velocity and known cross-sectional area. The counting method can be mechanical or other, related to the characteristics of the counter. In mechanics, impellers, impellers, balancing elements are used.

The indirect method of counting has other methods:

- vortex detection;

- measuring the pressure difference across the orifice device;

- calculation of heat transfer from a heated body;

- measurement of velocity head;

- counting based on the movement of ultrasound.

The correctness of indirect methods depends on the correspondence of the speed in the direction and in the section. Flow preparation means help: turbulators, condensers and flow straighteners. Devices come separately or as meter elements.

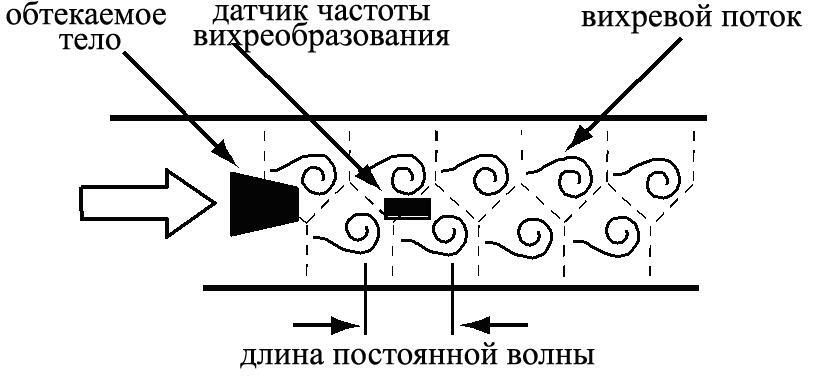

The principle of operation of the vortex gas meter: the streamlined body has a balancing element, due to which the vortices alternately pass then on the right, then on the left - the sensor will not fix anything if the gas velocity drops to a value at which the vortices do not formed

The devices can determine the speed difference over the cross section simultaneously with the speed of gas movement and thus reduce the error. The latter often occurs due to stagnation of fuel at the walls. Read more about direct and indirect methods for determining gas flow rate. Further.

How is gas pressure determined?

The pressure is measured in a direct way using pressure gauges or by adding the values of atmospheric (Pb) and overpressure (Pi). Pb is measured at the location of the transducer P and if the latter is in a closed space and there is a boost or vacuum in it.

Pressure gauges measure the pressure and indirectly the gas velocity, which helps to determine the amount of fuel consumed, as well as calculate the benefit from the meter

The pressure tapping port for vertical and horizontal pipes is placed radially. On a transverse pipeline, it is located in the upper half of the section.

In flow meters without a specified hole, sampling is carried out in front of the meter, at a distance of 1 to 3 pipeline diameters, with a reference point from the gas meter inlet flange.

Conclusions and useful video on the topic

Estimated gas consumption by the boiler at a certain power:

Large gas consumption when using gas equipment for a car:

Simple ways to reduce fuel consumption in an apartment / house:

Time has shown that it is better to have one or more meters in your apartment. Only with large volumes of consumption and a high price of gas meters becomes a profitable payment for the standards. In domestic conditions, flow meters with rotors and membranes, smart counting are used to measure gas consumption.

For commercial purposes, turbine, vortex and levitation are used. For the most accurate measurements in laboratory conditions, drum models are installed. It is not enough to have a gas meter, sometimes you need to count yourself. The estimated amount of gas for current and planned needs should be determined by formulas or together with an invited specialist.

Write comments on the topic of the article. Tell us if you had to determine the gas consumption yourself, and if so, for what purpose did you do it. Ask questions in the form below the article.