A powerful gas boiler installed in a cottage can easily solve the problem of heating and supplying the house with hot water. But the amount of heated liquid for hygienic and household needs is limited and does not always suit the owners. To compensate for its deficit, a BKN is installed - an indirect heating boiler for a gas boiler.

Let us consider the features and functional capabilities of the storage unit, and also find out how best to use it in tandem with a gas boiler so that the result is as effective as possible.

The content of the article:

- Distinctive features of the indirect heating boiler

-

Gas heating equipment + BKN

- Wiring diagram for 1-circuit boiler

- Two applications with a 2-circuit boiler

- How to make a strapping without errors?

- Conclusions and useful video on the topic

Distinctive features of the indirect heating boiler

A boiler is a large barrel, the main function of which is storage. It comes in various sizes and shapes, but this does not change its purpose. Without a boiler, a problem may arise when using, for example, two showers or a shower and a kitchen tap at once.

If a household 2-circuit boiler with a capacity of 24-28 kW produces only 12-13 l / min per flow, and for one shower room requires 15-17 l / min, then when you turn on any additional tap, there will be a deficit water supply. The boiler simply does not have enough working capacity to provide several points with hot water.

If a large storage tank is installed in the house, even with several simultaneously turned on water points, everyone will be provided with hot water

All storage boilers can be divided into 2 broad categories:

- direct heating, creating a supply of hot water using a heating element - for example, an electric heating element;

- indirect heating, heating water with a hot heat carrier.

There are other types of boilers - for example, conventional storage water heaters. But only volumetric accumulators can indirectly receive energy and heat water.

BKN, unlike volatile equipment operating on electric, gas or solid fuel, uses the heat generated by the boiler. Simply put, it does not require additional energy to function.

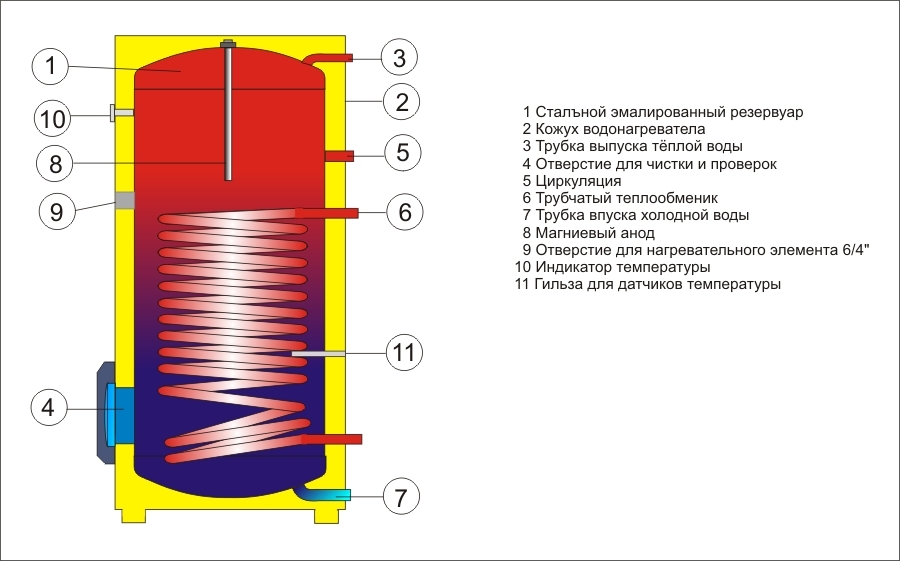

BKN design. Inside the tank there is a coil - a steel, brass or copper tubular heat exchanger that acts as a heating element. The heat inside the tank is stored like a thermos

The storage device easily fits into the DHW system, and does not cause problems during operation.

Users see many advantages in using BKN:

- the unit does not require electrical power and benefits from the economic side;

- hot water is always "ready", no need to skip cold water and wait for it to heat up;

- several water distribution points can work freely;

- stable water temperature not falling during consumption.

There are also disadvantages: the high cost of the unit and additional space in the boiler room.

The volume of the storage tank is selected based on the number of people permanently living in the house. The smallest boilers are designed for 2 consumers, so when choosing, you can start from a volume of 50 liters

According to all characteristics, BKN is suitable for use in tandem with gas boiler. Moreover, it is one of the best solutions for equipping a hot water preparation system for a private house with a large number of residents.

But boilers are different, so we will consider both acceptable options and those where problems may arise.

Gas heating equipment + BKN

At a summer cottage, it is not necessary to install a complex communications system for a summer vacation, while for a permanent residence cottage it is simply necessary. There is no need to think about whether you need an additional boiler for a gas boiler - of course, it will turn out to be a very useful acquisition that significantly increases the comfort of living in the house.

We will review the basic schemes for connecting the BKN in order to prevent errors that are possible during self-installation of equipment.

Wiring diagram for 1-circuit boiler

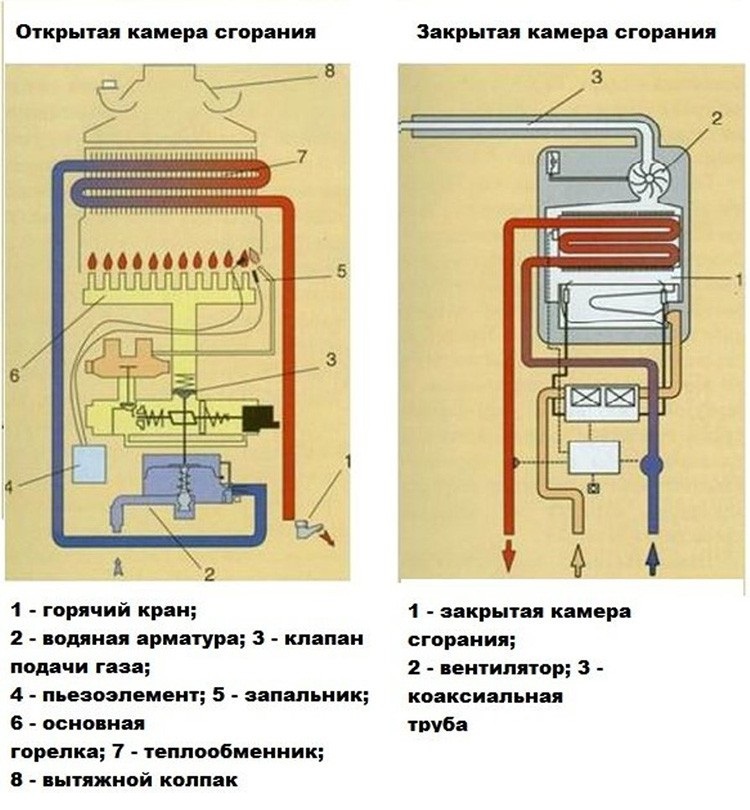

Single-circuit units perform one of the functions declared by the manufacturer: either they provide heating of water for hot water supply, or they heat the house - and the second option is used much more often in everyday life.

The combined solution - 1-circuit gas boiler + BKN - is one of the best for a small cottage.

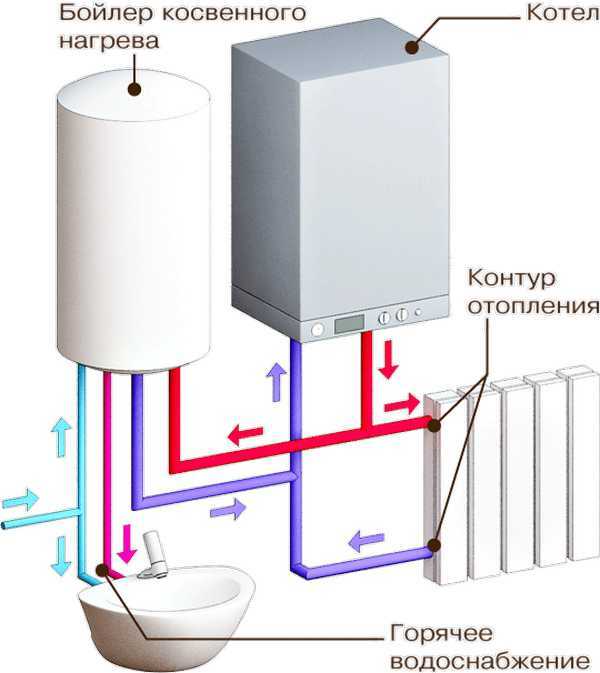

Scheme of connecting the BKN to a gas boiler. Heating of water for heating and hot water supply occurs synchronously, after which it is distributed along two branches - to the heating radiators and the boiler

The heating process takes place according to the following scheme:

- cold water enters the boiler, where it is heated to the required temperature (for example, + 80 ° С) with a gas burner;

- the heated coolant enters the heating circuit - to the radiators - and to the heat exchanger storage water heater, i.e. boiler;

- due to the increase in the temperature of the heat exchanger, the water in the boiler heats up and when the taps are turned on, it flows to the consumer.

When implementing this scheme of a gas 1-circuit boiler with an indirect boiler, technical data is of primary importance - the power and flow rate of the coolant.

On average, the water in the boiler, if it has not previously functioned, heats up from zero to an acceptable temperature in 5-15 minutes, that is, the wait will not last long. Usually the unit is in working order, so there is always access to heated water.

Let's analyze the features of the piping of the devices in question.

To begin with, you need to choose the most convenient place for installation - most often it is a boiler room, a separate non-residential premises. It is better to place the units at a close distance from each other - this way the heating process is faster, and less materials are consumed.

Floor-standing installation assumes such an installation in which the distance to the nearest obstacles or devices would be at least 0.5 m - this will be required for maintenance or inspection of the unit

The strapping takes place from two sides: loading and water supply.

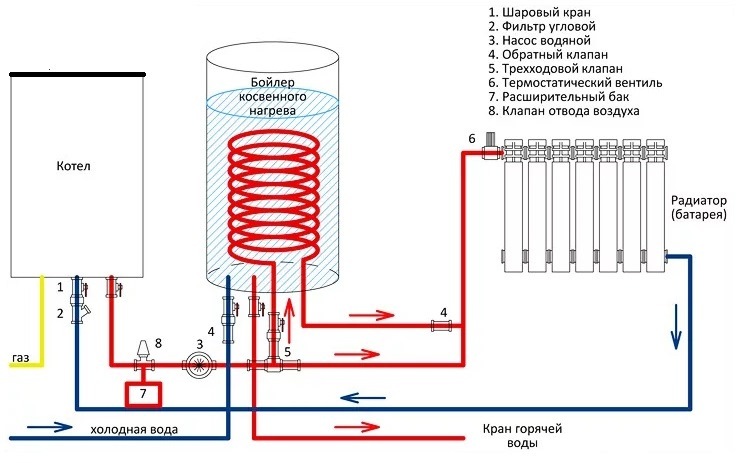

It is recommended to install at the outlet of the boiler membrane expansion tankto compensate for thermal expansion and stabilize system performance. All circuits must be equipped with ball valves and check valves that regulate the direction of the coolant flows.

It will not be superfluous to install filters - water is supplied to the system differently, and during an accident sand or other debris can get in, which can contaminate the coolant and disable equipment.

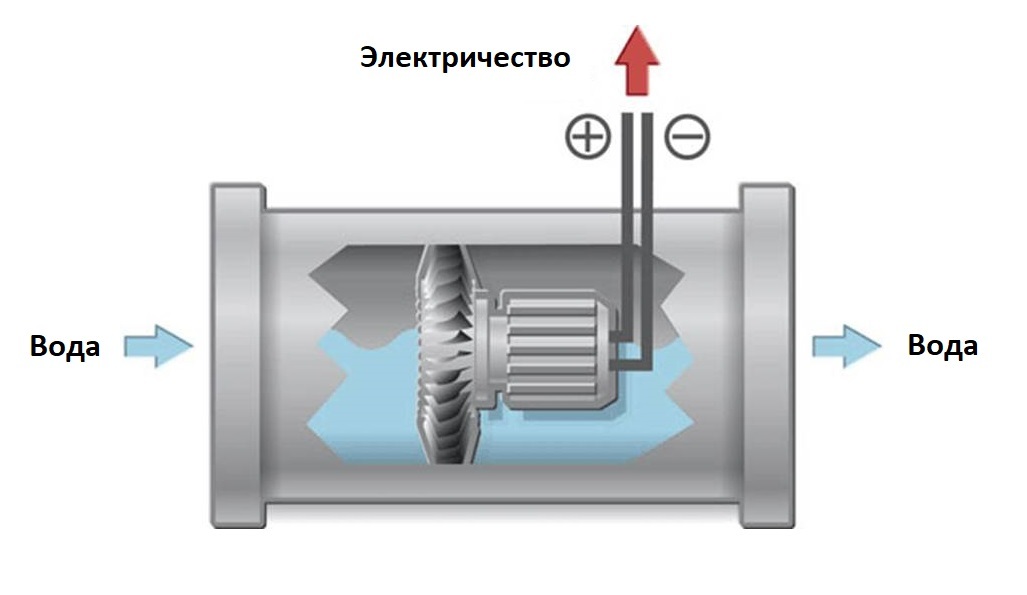

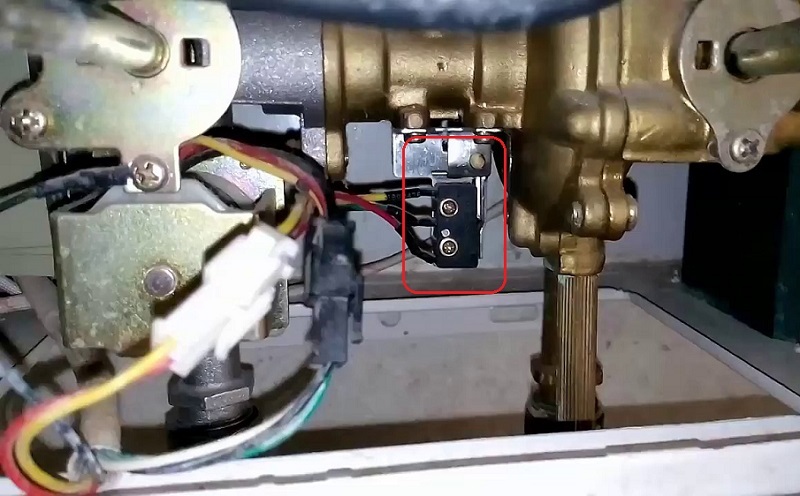

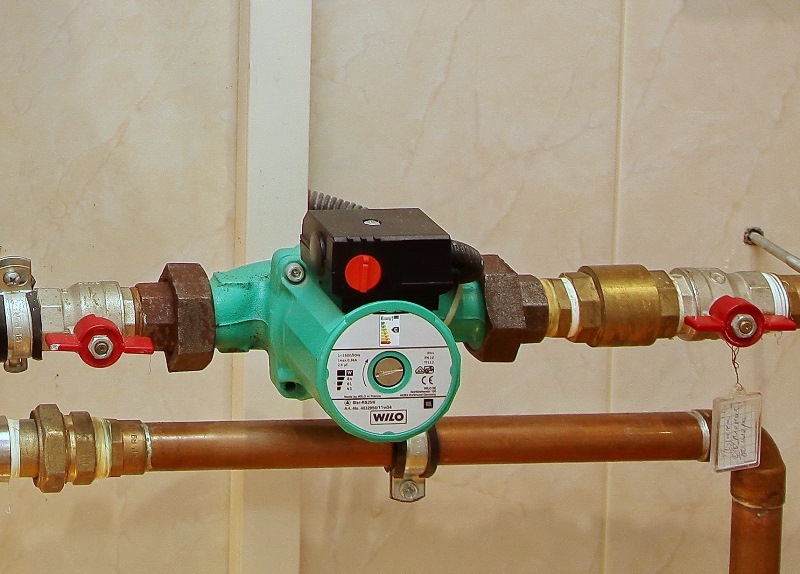

An obligatory element is a circular pump that supplies water at the required pressure. It is mounted on a pipe between the boiler and the boiler, and it is controlled in one of the ways: either a storage thermostat, or a temperature sensor in the boiler

Stop valves are installed on both sides of the pump. The same tap is at the inlet of cold water to the boiler.

A tee with a drain valve is installed on the boiler branch pipe, and shut-off valves on both pipes so that the unit can always be cut off from the boiler for cleaning or other maintenance. An air vent must be placed on the supply, in front of the shut-off valve.

The best option is to connect using a three-way thermostatic valve, which organizes the coolant outlet from the boiler and dividing it into two streams - into the boiler and the heating sector. It can be used to regulate the temperature: if heating up to + 80-90 ° С is suitable for radiators, then for warm floors it is better to limit yourself to + 45 ° С.

If there is no three-way valve, then two circulation pump, one of which serves the BKN, the other is intended for the heating branch.

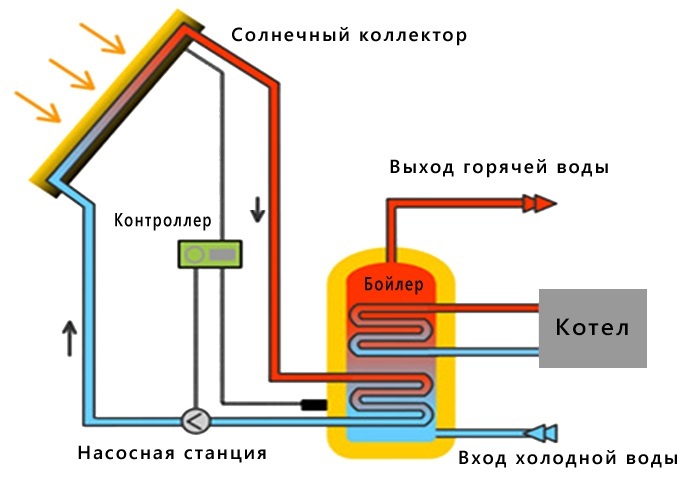

Diagram of connecting the boiler to the solar system. Interaction with a solar collector requires the arrangement of a separate closed loop with a heat exchanger and temperature sensors

Sometimes circuits with heat carrier recirculation are used - for example, to constantly maintain a heated towel rail in "working" condition. The heated water circulates in a closed loop, preventing the pipe from cooling down. A circulation pump is an obligatory element, and a check valve is not needed. The disadvantage of such a system in the summer is energy overrun.

With the transition of the gas boiler to the "summer mode", the heating circuit is simply cut off - the gas burner heats the coolant for the boiler. But there is another way out - just turn off the gas boiler and use only the boiler. This is possible if the drive is additionally equipped with an autonomous heating source - a heating element.

Two applications with a 2-circuit boiler

Owners of gas heating equipment are also interested in how it works indirect heating boiler with a 2-circuit gas boiler. Experts believe that the interaction of the units is possible, but the result depends on the connection scheme: with one of them, they are simply not designed to work with each other.

Integration of the boiler into the DHW circuit

First, consider the option when the boiler is integrated into the DHW circuit. From a hydraulic point of view, everything looks right. A three-contact mechanical thermostat, placed in the boiler body, closes the pump power supply circuit when the temperature drops.

That, in turn, begins to pump water, which circulates along a circuit between two heat exchangers: it is heated from a gas burner, and then moves into the BKN coil.

Simply put, both devices perform their functions: the boiler stops heating and starts heating the water for DHW, and the boiler tries to heat the contents of its "Storage"

The problem arises precisely because of the inconsistency of the temperature parameters. Suppose that initially the boiler filling temperature is + 15˚С, and the recommended water heating temperature in the boiler is + 60˚С - the automatic limiter no longer allows.

The difference between the two preset parameters of 45˚ is significant, therefore the heat exchange in the boiler is quite intense. But the temperature begins to rise, and when it reaches + 40˚С, the difference is already much smaller - only 20˚. Accordingly, the heat exchange slows down.

Do not forget that water continues to circulate between the two devices. The gas burner of the boiler begins to receive not a 15-degree coolant from the cold water system, as recommended by the manufacturer, but 40- and then 50-degree heated liquid from the boiler.

As a result, the temperature of the liquid instantly flies up to + 60˚С, the sensor is triggered, the burner is turned off, since it is programmed for parameters that are safe for consumers.

In the boiler, the water begins to cool down - the sensor turns on again, and the circulation process resumes. And so it is constantly. This leads to the fact that the water in the boiler does not reach the desired temperature, but remains not hot enough, which is not suitable for domestic hot water use.

The process of interaction between the two units could take place if the boiler burner heated the coolant to + 80˚C, but this is prohibited by the instructions to protect users from burns.

Another reason not to use the BKN and the DHW circuit of a gas boiler in steam lies in the impossibility of heating the water in the boiler to a temperature exceeding + 60˚С. This is due to sanitary standards.

Approximately once a week, the apparatus is filled with hot water at about 70-75 ° C, so that the legionella bacteria, whose colonies resemble mucus, do not multiply in the tank. A large number of bacteria in the water leads to the development of allergies and other diseases

It can be concluded that for just two, but significant reasons, the scheme for combining a gas boiler and a BKN through a hot water supply circuit is recognized as ineffective and unsafe. If you already have a double-circuit boiler, just use it for its intended purpose: use one circuit for the heating system, the second for DHW.

BKN interaction with the heating circuit

The second option is the interaction of the BKN with the heating circuit. The technical solution works great if the capacity of the gas boiler is not enough, and this is the only effective way to connect the BKN to a 2-circuit boiler.

We do not touch the DHW circuit, but use only the branch responsible for heating - that is, going to the radiators and the "warm floor" system. The pipe leading to the boiler must be connected immediately under the boiler, after the tap

With electronic control, you need to set the boiler to heat water + 70 ° C - just such coolant will enter the boiler, where further temperature adjustment will take place. The thermostat located in the boiler will turn on the pump when the temperature drops, and when the required value is reached, turn it off.

With mechanical control of a gas boiler, everything happens differently. The second thermostat - boiler is connected to the boiler thermostat, and then the first device can be controlled by the second one. For example, if you set the temperature to + 80 ° C on the second, then the first, worker, will require heating the water to + 80 ° C, regardless of what temperature is set on it.

When the water in the boiler heats up to the desired temperature, the second thermostat breaks the circuit, and the first, located on the boiler, becomes the "master" again. If at this moment the temperature is set to + 40 ° C, then it will drop to 40.

How to make a strapping without errors?

In order for both units - both the gas boiler and the BKN - to work flawlessly and throughout the entire service life, it is important to correctly perform strapping, that is, set the security group and other items.

Image gallery

Photo from

The accumulator is necessary so that the boiler does not suffer from the thermal expansion of the water at the moment when it reaches its heating peak. Tanks for heating and hot water systems are different - keep this in mind when buying

It is installed immediately at the outlet to ensure complete drainage of water from the heat exchanger for maintenance or repair work.

When the unit is started for the first time, air is removed from the system using an air vent. In the future, the crane will be useful for putting the boiler into operation after a downtime

The main merit of the circulation pump is the immediate supply of heated sanitary water to the consumer in the taps - there is no need to wait for it to heat up

Expansion tank for boiler

Drain valve for service

Air vent to remove air pockets

Hot water circulation pump

When installing coarse filters, be sure to check its location - there is an arrow on the body indicating the direction of water movement.

Such a filter cannot be installed vertically, since as a result, coarse particles accumulate in the pipe, and not in the filter itself. Cleaning can only be carried out by flushing under pressure - this way you can stain the entire boiler room.

The expansion tank must not be installed separately, but between the boiler and the check valve, otherwise it will be useless and will not perform its functions.

Conclusions and useful video on the topic

How to make a piping for a 1-circuit boiler with a BKN:

On the nuances of connecting an indirect heating boiler:

Connecting a gas boiler to a BKN in practice:

We recommend involving specialists in the installation and connection of the boiler, so as not to collide in the future with heating or DHW problems only due to improper piping or the absence of important elements in system. Do not forget about the manufacturer's instructions, which often indicate the nuances of the unit's operation with a particular device.