Are you using a gas water heater as a water heater, but all of a sudden it started emitting a strange pop when you turned it on? Unfortunately, any equipment is not eternal and breakdowns happen at the most unexpected moment. But a number of simple faults can be eliminated on their own. You decided to try to fix the column with your own hands, without waiting for the arrival of the master, right? But do not know why the gas water heater turns on with a clap and where to look for the source of the problem?

We will help you figure it out - this article discusses the most likely causes of cotton in older and newer models of gas water heaters. The material is supplemented with visual photos and video recommendations for troubleshooting and troubleshooting.

The content of the article:

-

Why is cotton most common?

- Reason # 1 - poor cravings

- Reason # 2 - batteries are dead

- Reason # 3 - nozzle contamination

- Reason # 4 - clogged burner holes

- Reason # 5 - poor gas quality

- Reason # 6 - casing deformation

- Features of the repair of old models

-

Troubleshooting new hardware

- Column microswitch breakage

- Flow sensor malfunction

- Working candle offset

- Incorrect operation of the ignition retarder

- If the equipment is still noisy?

- Conclusions and useful video on the topic

Why is cotton most common?

When turned on, cotton most often occurs in columns of the old design, where there is a constantly burning wick. In the columns of the new generation, where the gas is automatically ignited, a malfunction occurs, but not so often.

So, a clap is heard due to the late ignition of gas in the burner, which has time to accumulate in large quantities. Therefore, when the gas finally ignites from the flame of the wick or from the spark of the ignition device, a loud bang is heard by the user. But such a situation is extremely dangerous if left unattended - over timeazo- the air mixture, before it ignites, will begin to fill part of the chimney, which is fraught with non-weak explosion.

A serviceable column of any configuration should turn on without flames and pops, softly and quickly.

There are common causes of power-on pop that you can diagnose and quickly fix on your own.

Let's consider the most common reasons for such a nuisance in columns of all types:

- malfunction of the ignition retarder;

- insufficient supply of fresh air to the room;

- insufficient or no draft (in the chimney).

For columns with a wick, the most common breakdown is when the flame is in the wrong position in the ignition wick element.

For models with automatic ignition, the reason may be:

- incorrect position of the candle;

- malfunction microswitch;

- discharged power supply in the control unit.

Let's consider in more detail the main causes of cotton and the specifics of determining the source of the problem.

Reason # 1 - poor cravings

Combustion products are discharged through the chimney. This happens quickly, but if steam or carbon dioxide does not have time to cool down, they can fall back into the column and provoke contamination of the air and gas mixture. We also recommend that you familiarize yourself with the reasons and ways to eliminate reverse thrust in the chimney.

In the presence of weak traction, the column often ignites with certain pops. Once you identify the cause of poor traction and eliminate it, excess noise will cease to bother

To check the draft, there is a special hole in the upper part of certain columns and boilers - a control hole. It is located on the casing. The check can be done simply: bring your hand to this hole, you should feel the pull. You can also use a match. Adequate thrust is determined by the deflection of the flame tongue from the vertical.

A similar operation can be performed using a hatch with which the chimneys of gas boilers are equipped. If necessary, through the same hatch, you can clean and remove debris.

You can check the channel for the presence of debris using an ordinary mirror. It is stirred through the hatch inside the channel. If a gap is visible, then the channel is clear. And if there is no draft, then in this case the help of specialists will be required, who will remove the accumulated soot, which has become the reason for the narrowing of the pipe diameter.

Also, the reason for insufficient or lack of draft can be poor ventilation, when there is no air flow into the room. Safety measures indicate that it is possible to use a gas water heater if the room is ventilated (open window, window on ventilation). Also, in this situation, the installation will help inlet valve into the wall or installation valves for plastic windows.

Reason # 2 - batteries are dead

If the batteries in a column with an automatic ignition system are dead, then a pop will appear when the water is turned on. The lack of electricity for the instantaneous generation of a spark provokes a crackling sound that is continuous. At this moment, the fuel accumulates in the working area, and when a spark occurs, there is a loud pop.

Dead batteries provoke a problem with the emergence of serious popping and popping when turning on the column. Therefore, the batteries must be replaced in a timely manner.

One of the main factors in determining this problem can be considered the presence of a characteristic crackling, which indicates that the ignition was not carried out. You can fix the problem with a simple replacement of batteries.

Reason # 3 - nozzle contamination

Semi-automatic models equipped with piezo ignition, have a system of forming a flame from a wick.

If the jet gets clogged or starts to work incorrectly, the intensity of combustion of the wick becomes minimal - insufficient for timely ignition. To fix this problem, the jet just needs to be cleaned.

Cleaning the jet is done carefully, since damage to this element will require its replacement, and this is a rather time-consuming procedure

Cleaning the jet is a simple process. After removing the cover, the holes are simply cleaned with a thin and soft wire. You also need to check the position of this element. If necessary, move it a little closer to the burner.

Reason # 4 - clogged burner holes

If the holes of the main burner are clogged, in addition to the fact that there will be a cotton when turned on, significant noises will be heard during operation. In order to fix this problem, you need to disassemble part of the column. The burner is cleaned with a soft brush (debris will be visible). It is not necessary to unscrew the jets from the frame, but it is also recommended to clean their holes.

You can clean the gas column burner immediately after removing the casing, using a thin and flexible copper or aluminum wire. But cleaning must be done with extreme care.

Reason # 5 - poor gas quality

Often, the cause of cotton is gas, which in its composition contains a significant amount of additional impurities. Due to the presence of such impurities, it flashes loudly - this noise is similar to cotton.

To make sure that the reason really lies in the quality of the gas, you just need to ask your neighbors about the existence of the same problem. With poor fuel quality, a similar situation will be present for all residents of the house.

Reason # 6 - casing deformation

Heat (heating and cooling) can deform the casing. This problem occurs frequently. If the deformation occurs inward, then the spark plug can pierce the body.

If deformation is detected, the concave part will need to be bent slightly.

The cause of a pop when turned on may be a deformation of the casing or poor gas quality. In the first case, the situation can be corrected on your own, and in the second, you can contact the gas service

Features of the repair of old models

First of all, you need to determine why the gas water heater pops and makes noise when the water is turned on, and if everything the above shortcomings have already been eliminated, but cotton is still preserved, then you need to check the functional product condition.

Let's start by looking at simple pieces of equipment with wicks that are used to ignite a combustible mixture.

In such models, loud clap noise often occurs if the design parameters do not correspond to the flame contours. Timely ignition of the burner does not occur if the size of the fire is small or too large. The cause of this problem is considered to be mechanical clogging of the nozzle holes. Metered gas supply is formed through these holes.

Old models of gas water heaters break down. The cause of cotton when turned on is most often a clogged nozzle, burner or lack of traction.

To eliminate the malfunction, you will have to take the following actions:

- The main casing is dismantled in order to free full access to all internal components of the column.

- The block where the gas and air is supplied (many manufacturers use this structure) must be disconnected from the pipe system.

- This is followed by cleaning the jet. The most commonly used metal wire is soft type. It can be copper or aluminum. The procedure is carried out carefully, so that the calibrated hole is not damaged.

- Reassembly is carried out in reverse order, with particular attention to the integrity of the threaded connections and seals.

The jets can become clogged in the main burner. With such a blockage, the inclusion is also carried out with cotton. When disassembling the device, you need to remember that some components and elements, for example, gaskets, valves, thermocouple, differ in low strength, so they need to be handled extremely delicately.

Troubleshooting new hardware

Various problems can also arise in new equipment. Most often they manifest themselves in the operation of the flow sensor, in the operation of a candle or in the power system. Let's take a closer look at the listed problems.

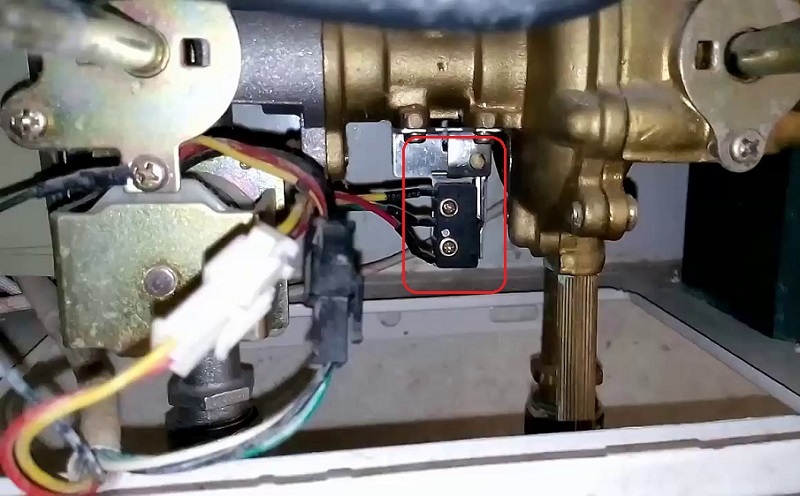

Column microswitch breakage

Often the problem of the appearance of a loud pop during ignition is an insufficient discharge of the batteries, which provokes the lack of the possibility of instantaneous igniting gas-air mixture.

The power supply is connected to the control unit by means of special microswitches, which are responsible for the occurrence of a signal to activate ignition when opening the hot water tap. If the signal arrives late, this is the cause of the problem. Such a malfunction occurs most often due to oxidized contacts. Renovate microswitch impossible, it will need to be replaced.

If the microswitch breaks down, repairs will not work, since this system will have to be completely replaced

Flow sensor malfunction

Often the problem with popping is in the flow sensor. It is located in the input circuit. A signal is sent to the controller of the control unit about the presence of liquid in the pipe. The data will instantly activate the ignition system. Intensive use of this element creates an increased risk of breakdowns. For example, contact groups can be oxidized.

Such sensors are most often manufactured in non-collapsible execution, therefore, in the event of a problem, they cannot be repaired, you need to replace it.

Working candle offset

The problem may be with the candle. After applying voltage, it provokes the formation of an electric spark. Modern candles are made in such a way that they can last for a long time. Element breakdowns are rare, but they do happen.

The most common displacement of the igniter is relative to the nominal position. It can occur as a result of excessive heating and cooling. Such processes are associated with a change in the size of individual structural elements. As a result of adjusting the position of the candle, the spark parameters become normal, extraneous noise completely disappears.

Incorrect operation of the ignition retarder

Incorrect operation of the ignition retarder is considered a rare breakdown. When disassembling a column, you need to remove the water regulator. On its cover there is an opening of the bypass channel, in this hole the ball is located. The adjusting screw determines the position of the ball.

If, when shaking the lid, you hear the sound of a moving ball, then there is no need to manipulate this part further. If there is no knocking, then you can stir the ball with the help of copper or aluminum thin wire, through the opening of the passage channel, which is located in the cover of the regulator.

Most often, the retarder is a metal or plastic ball that blocks off a portion of the bypass in the water regulator. In most column designs, this moderator is located in the tide of the water regulator cover.

As a last resort, you will have to resort to the procedure for parsing the element. It must be said right away that the outer screw does not affect the position of the ball in any way. The inner screw must be removed very carefully. First, you should remember its initial position, and also clearly determine the number of revolutions by which this screw is screwed in. This will allow for the subsequent assembly to maintain the required position of the element (ball).

After carrying out repair work, it is imperative to check all connections in order to completely exclude leaks of both water and gas. All connections must be treated with a sealant, ensuring tightness. Then you can put the cover back in place and use the column as usual.

If the equipment is still noisy?

If, after the manipulations done, the geyser is still lit with cotton when the water is turned on, then it is better to stop further independent research. In such situations, you will have to seek help from qualified specialists.

They will make competent diagnostics of the equipment, will be able to clearly establish what is the cause of the cotton and, based on the data obtained, will be able to provide you with options for solving the problem.

In certain cases, self-repair is impossible, then cooperation with qualified specialists will be a rational solution.

Conclusions and useful video on the topic

Search for the reasons why the gas water heater turns on with a clap and how to eliminate them in the following video:

There are many reasons for extraneous sounds when you turn on the speaker. Most you can diagnose yourself and try to fix the problem yourself. If you still could not determine the cause of the breakdown, then the only solution in this situation will be to contact a gas equipment repair specialist.

Would you like to tell another user about your experience in finding the cause of the geyser cotton? Or do you still have questions that we did not pay attention to in this material? Ask them in the comments section - our experts will try to help you. Share your experience, take part in discussions - the contact form is located below.