Gas water heaters are reliable water heaters, however, like other devices, they have wearing parts. Therefore, there are times when the water stops heating up. If the reason for this is a leaky membrane for a gas column, then it is not necessary to invite a master for repair. You can make the replacement yourself, do you agree? But what is needed for this and where to start?

In this article, we will analyze in detail the process of replacing the membrane and the features of repair work for different generations of columns. But first, let's get acquainted with the device of the water block, which will have to be dismantled and disassembled in order to get to the membrane. We will provide instructions for replacing with visual photos, useful recommendations and videos with an example of replacing the diaphragm of various speakers.

The content of the article:

-

Purpose and structure of the water unit

- Water reducer device

- The principle of operation and the meaning of the regulator

- Reasons for the failure of the diaphragm

-

Diaphragm failure detection

- Diagnostics of the cause of automatic shutdown of the column

- Checking the correct connection of communications

- How does a membrane malfunction appear externally?

- Selecting a membrane to replace

-

Detailed instructions for replacement

- Stage # 1 - preparatory work

- Stage # 2 - step by step description of membrane replacement

- Stage # 3 - we put things in order in the entire water block

- Replacing the membrane of old type columns

- Features of membrane replacement in new models

- Is it possible to get by with a diaphragm repair?

- Conclusions and useful video on the topic

Purpose and structure of the water unit

The diaphragm is an important detail in gas regulation. To understand its purpose and principle of operation, you should study in detail the device of the column water block, the structural element of which it is. This knowledge will help when replacing the membrane, because in order to get to it, you have to dismantle the entire unit and disassemble it.

We also recommend getting to know the general geyser deviceto make it easier to find a water block in its design. But first things first.

Water reducer device

One of the units of almost any gas heat exchanger is a water reducer (water unit - VU, water regulator). It is designed to regulate the uniform supply of water and gas. Practically designed form of the regulator (in common parlance - "frogs") contributes to the compact placement of the unit in the column case. A technically simple device works automatically.

The functions of the gearbox are as follows:

- starting and stopping the work of the gas column when opening / closing the tap;

- regulation of water and gas supply;

- protection of the column from overheating in case of insufficient water pressure.

The design of the gearbox is well thought out and not visually complicated. The body is made of brass, polyamide (containing fiberglass), silumin or plastic.

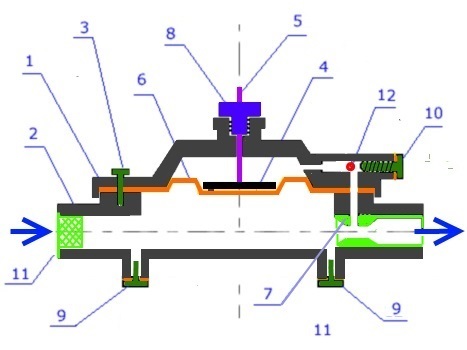

Details of the water unit: cover (1) and base (2), screwed together; plate (4); a stem that opens / closes the gas valve (5); membrane (6); venturi fitting (7); gland nut (8); water outlets (9); adjusting screw (10); mounting screws (3); mesh filter (11); retarder ball (12)

The principle of operation and the meaning of the regulator

The hollow cavity of the gearbox, divided in two by a membrane, is filled with water. Water enters the cavity from the water supply. From the bottom, passing through the fitting Venturi, it enters the upper compartment through the overflow opening. However, the water coming from the water supply to the lower part always presses on the membrane with the force of the water pressure in pipeline, and in the upper part, the pressure force changes, depending on whether the water flow through heat exchanger.

The fact is that in pipelines with narrowed sections, the pressure of the flowing fluid in the narrow place decreases. When opening the tap and passing water through the fitting Venturi, the pressure in front of the local constriction (nozzle) of the choke rises.

Due to an increase in the flow rate in a narrow place, the pressure decreases both in the choke and in the upper cavity of the frog. This is similar to flattening the end of the garden hose. With a difference in the diameters of the choke nozzle (0.3 cm) and the main chamber (2 cm), the pressure drop reaches 1 atmosphere. This is enough for the diaphragm to bend upwards and press on the plastic plate, which is rigidly fixed on the stem axis. The stem presses against the gas valve with force, causing the valve to open and gas flows to the gas burner.

When the membrane rises, water from the upper compartment begins to come out through bypass the channel where the steel retarder ball is located. The ball, moving to the right, partially blocks the channel, so the gas is switched on and supplied to the burner smoothly. Smoothness is adjusted with an adjusting screw.

The venturi nozzle is located in the outlet (on the right side of the frog). This is a local constriction that provides a pressure drop when the valve is opened. Clogged fitting must be cleaned

When the hot water tap (HW) is closed, the water flow stops and the pressure in the nozzle Venturi compared to the pressure in the cavity under the membrane. Due to the action of the springs, the stem with the disc is displaced downward, and the diaphragm returns to the middle position.

The gas valve closes automatically. The gas valve is turned off quickly, since the ball moves to the upper cavity (to the left) by the reverse flow of water in the culvert and ceases to impede the flow of liquid. We recommend that you look at the information on what to do if gas valve does not work.

If the flow rate of hot water is less than 2-3 l / min, the required pressure drop does not arise, and the springs do not allow the stem to open the gas valve at all or is sufficient for full heating of the water. Also, the necessary pressure difference does not arise if the integrity of the membrane is violated.

Water regulator based on the nozzle principle Venturi, is a safety device, since it allows you to turn on the water heater only when a sufficient water flow is flowing through the heat exchanger. Thus, the reducer automatically protects the gas water heater from overheating.

The overflow hole connects the venturi nozzle and the upper cavity of the frog. This hole must be left open when installing the diaphragm in order for the gearbox to work properly.

Reasons for the failure of the diaphragm

Membranes are consumables with a service life of 5-8 years (on average). The elasticity of the material decreases over time. As a result of the action of alternating stresses, each material working in bending over time develops fatigue - the formation and accumulation of damage. If the membranes work in an enhanced mode, when the gas column is often used a lot, fatigue occurs earlier. Microcracks appear in the body of the diaphragm, then breakouts are formed.

The scale that forms inside the frog also contributes to the rapid wear of the diaphragm. Another reason is the use of clandestine diaphragms. Often such products are made of low-quality rubber.

Therefore, information on how to properly replace the membrane in a household gas water heater, if it fails, it will come in handy. With such knowledge, you can repair the water unit on your own, without involving specialists for this.

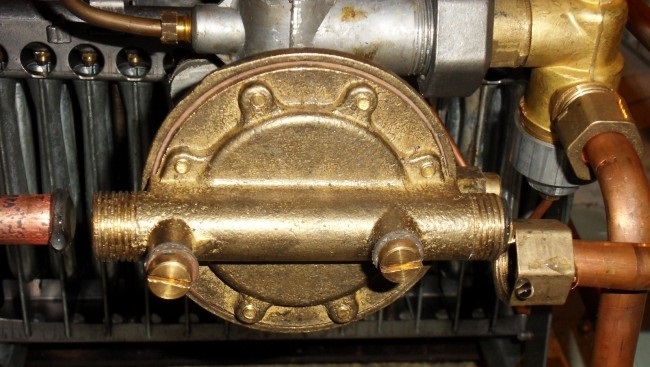

This is what the water reducer looks like when removed. As a result of the groove of the gland on the stem and its nut, scale has formed, which is removed during the process of replacing the diaphragm.

Diaphragm failure detection

The operation of the gas water heater may deteriorate gradually or stop immediately. The malfunction does not always lie in the wear of the rubber heart of the water block. Sometimes the cause is foreign. Therefore, before proceeding with a screwdriver or a key to the insides of the unit, it is more rational to diagnose it.

Diagnostics of the cause of automatic shutdown of the column

Column failure can occur for various reasons. Therefore, if a column malfunction is detected, you should not immediately take on the dismantling and disassembly of the water unit.

The column is automatically turned off in the following cases:

- there is no draft in the chimney;

- the heat exchanger overheats;

- the flame does not ignite above the gas burner;

- the membrane does not work properly.

Other reasons for the attenuation of the column, we gave in following material.

In modern household heat exchangers equipped with digital displays, the main control board displays an error code expressed in numbers on the screen. He will tell the master what to check first.

This is not the case in older devices. To an ordinary user, the error code will say little. Therefore, the search for the cause of the breakdown should be guided by a tried-and-true method - the method of verification and elimination.

Checking the correct connection of communications

So, first you need to make sure that there is water in the water supply network of the house, the gas at the inlet is not blocked, the valves supplying water and gas to the column are open in operating mode, and the batteries have not sat down.

The problem of the inoperability of the gas water heater may well be trivial batteries - if they sat down or the contacts are oxidized, then the gas water heater will not turn on

That is, you need to find out if the column has disconnected for reasons beyond its control.

- Check the water pressure in the water supply system, and in the chimney - the presence of natural draft. To turn the membrane into operation, the water flow must be at least 2-3 liters per minute. About the reasons for a weak pressure we spoke here.

- Strip the contacts on the power compartment, replace batteries.

- Imported units are sensitive to how the phase is located in the outlets. Reverse the position of the plug in the outlet.

- Check fuses.

- If a sump is installed on the cold water inlet pipe, check if the filter is clogged. You should also check the mesh installed on the mixer tap. Clean if dirty.

- Check for a spark on the ignition electrodes with the hot water mixer on. In units with a closed chamber, the clicking of the discharges is heard from the outside. The presence of a spark means that the membrane is being triggered.

After making sure that the reasons for the failure of the GC lie within the system, proceed to further diagnostics.

How does a membrane malfunction appear externally?

In some HK models, the stem, including the column, is brought out above the body, so the movement of the stem can be observed. If the stem does not move or does not fully extend, then the diaphragm and poppet should be checked for integrity. On some models, stem movement can be seen when the shroud is removed.

If, after cleaning the filter mesh, the gas burner does not fire, but ignites only when the hot water tap is fully opened or at the same time opening several such taps connected to the main gas pipeline, which means that it will be necessary to replace the old diaphragm of the gas column with new.

By installing a strainer on the inlet, you will protect the elastic gasket from accelerated destruction. Silicone membranes, which withstand many times higher tensile and bending stresses than rubber parts, are especially sensitive to mechanical abrasion

During normal operation of the membrane, the tongues of flame rise 3-5 cm and are located exactly above the edges of the burner. Otherwise, especially if cleaning the nozzle did not help (if ignition is carried out from the wick), a leaky diaphragm may be the culprit. It is also the most probable reason if no characteristic clicks are heard when the speaker is ignited from the batteries.

A red high flame can be a signal that the gas is not suitable. If a blue flame, burning sluggishly, gives first hot, then rapidly cooling water, then we have one more symptom of "membrane ailment".

The reducer must be disassembled even if water leaks from the water block. This malfunction can be caused by scale, wear of the gasket on the screw sleeve of the stem, failure of the diaphragm itself or the plastic parts of the combined diaphragm.

Selecting a membrane to replace

Diaphragms are made of elastic material - black rubber or silicone. They can be solid or composite, for example, the product can be rubber-metal or come complete with plastic parts. Most often, diaphragms have a simple circular shape. But there are models of gas water heaters, the diaphragms of the reducers of which are distinguished by a complex, "bizarre" configuration.

You are in luck if the speaker is domestic and there are “native” membranes on sale. It is even more fortunate if the part you need is made of silicone, which means it will last longer (about 10 years). But it is also likely that you will have to purchase a "native" diaphragm through dealers, an online store. You may have to get a complete repair kit or a new frog. It all depends on the model of the gas heat exchanger - not all reducers have the same operating principle.

The “figure eight” diaphragm for the Ariston Fast GIWH column reducers has a shape that is difficult to replicate. It is more practical to have such a membrane in reserve.

European companies manufacture water heaters with membranes that are difficult to fake. In the worst case, if spare parts for "foreign cars" are not supplied, you will have to buy a new column or invent and craft something from the means at hand. There are universal diaphragms that fit a wide range of models.

If you have to wait for a suitable membrane for the column to be shipped and the diaphragm of the column is not complex, you can make a part yourself for temporary replacement. Rubber 1.5-2 mm thick is suitable, for example, from thick dielectric gloves or an old car camera.

Using the old product as a template, cut out a new gasket. The bypass and screw holes are punched out of a thin-walled metal tube. The diameters of the bypass opening of the lid and the diaphragm should be equal so that the flow of water between the cavities of the frog is not impeded.

Detailed instructions for replacement

Next, let's take a look at how to properly replace the diaphragm. But before starting work, it is important to remember that working with gas equipment belongs to the class of increased danger. Therefore, a qualified technician should repair the column.

You should not overestimate your skills and strengths - if in doubt, you need to contact the gas service. It is also imperative to contact gas workers if you smell gas in the room, because if you ignore safety measures the column may explode.

Stage # 1 - preparatory work

First of all, they block the flow of gas and cold water to the column. Before starting work, it is imperative to turn off the gas, even if it is not planned to inspect the gas part of the equipment. The water unit is connected to the gas unit, "hitting" which you can get in big trouble.

Water is drained from the system, for which a tap is opened, which receives hot water from the column. If several hot water taps are connected to it, open the one located below the device. Then the maximum amount of water will drain from the system. To drain the remaining water, a basin is placed under the water regulator.

The fact that the membrane for replacement needs to be purchased ahead of time can not be mentioned. It is also best to purchase gaskets to seal the stem and flare nuts on both ports. You can purchase a complete repair kit.

It is best to replace with a silicone membrane. Not for all modifications of geysers, this is easy to find right away. Often you have to take the option from the availability that suits your speaker model

Tools are prepared for work: screwdrivers, wrenches or gas wrenches, pliers. Fine-grained sandpaper may come in handy. It is also worth stocking up on rags, a means for dissolving rust (frog screws often turn sour).

To open access to the water unit, the column case is opened. Removing the cover is usually easy - it takes a short time to find and unscrew the fastening screws.

It is also not difficult to find a water regulator - this is the first block on the way of cold water entering the column.

The GK Neva water regulator is located under the gas block. From the left, cold water enters the gearbox through the inlet. Through the right outlet pipe from the frog, water enters the heat exchanger

Stage # 2 - step by step description of membrane replacement

You can get an idea of the process of replacing a worn-out membrane in a gas column using the example of the Neva household flow-through heat exchanger.

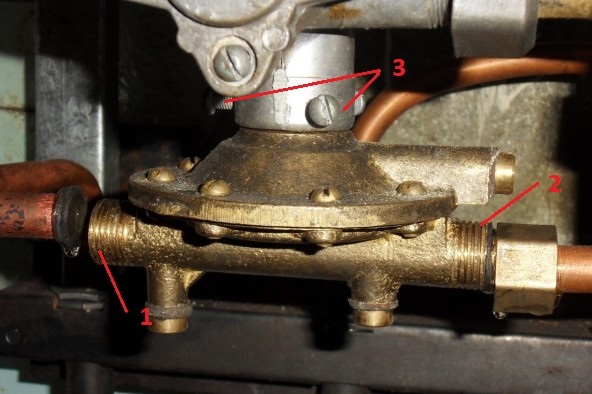

Unscrewing the union nut of the outlet pipe with a wrench, as well as unscrewing the screws connecting the water block to the gas block, hold the frog with your hand

Next, consider the process of dismantling the water unit:

- Armed with a wrench, first unscrew the union nut of the inlet pipe on the left side of the gearbox. We remove the tube so as not to interfere with further actions.

- Holding the frog with your hand, unscrew the nut of the outlet pipe. Let the water drain.

- Using a screwdriver, unscrew the three screws connecting the water and gas blocks. It is not necessary to completely unscrew the fasteners, it is enough to free the stem. We remove the gearbox.

Now we unscrew the screws that secure the cover and the base of the unit (8 screws). If the bolts are acidic, use WD-40. We open the cavity of the block, remove the damaged membrane.

We inspect the condition of removable parts - plates, stem and bushings, filter mesh, fitting. If necessary, we clean the cavity and other surfaces of the frog and its parts from scale or rust. We replace unusable or install old parts in the appropriate places.

It is important not to forget to check the condition of the retarder ball. It is enough to shake the lid like a rattle and listen if the rolling steel ball is knocking.

We install the membrane, not forgetting to accurately align the hole of the rubber part with the hole of the bypass channel. If the channel is blocked, then water will not flow into the upper cavity. The water pressure on the bottom of the gasket will keep it in a curved position, the gas will be open by the stem even when there is no water flow.

We return the cover to its place, install and thread the fastening screws crosswise (one against the other). After making sure that everything was done correctly, tighten all the screws in the same sequence.

Then we install the assembled block:

- We mount the gearbox in reverse order. It is advisable to install new half-inch diameter gaskets on the pipes.

- We check the quality of the connection by opening the hot water tap. If no leaks are observed when the tap is open, turn off the water and check for leaks under pressure. Then we turn on the gas supply. By applying soap solution to the gas connections, we check for gas leaks.

- If no leaks are found, we check the column in all operating modes.

After making sure that everything is done correctly, the column is working, we mount the removed case cover.

Dismantle the gearbox in the sequence indicated by the numbers, twisting all the connections in turn. And only after completing this stage, you can carefully remove the water block. Its installation after replacement should be carried out in the reverse order.

Stage # 3 - we put things in order in the entire water block

So that it does not happen that you replaced the gearbox gasket, and after a few days you will need disassemble the water heater to eliminate another malfunction, it is more rational to stay and do prevention.

While the reducer is removed, in addition to replacing the diaphragm, it is necessary to check the ease of movement of the stem. The stocks of the water and gas assemblies interact.

Leaks can cause the gear stem to scale or sour. It must be cleaned, polished with 240 grit sandpaper, lubricated with mineral oil, for example, lithol. The stroke should be smooth and light.

It will not be superfluous to inspect the stem bushing and oil seals to prevent leaks. The seal on the stem bushing needs to be changed periodically. In order to change the seal, unscrew the nut, remove the sleeve. If there is scale, clean it off. Replacing the seal, assemble the assembly in the reverse order. The stem seal should be changed every three years.

You should also check the nozzle for cleanliness. Venturi (Union). Even a small amount of pollution has a strong effect on the functioning of the frog. You can clean the fitting with a thin wooden stick. The O-rings on the Venturi may need to be replaced.

Then it is advisable to check the following elements:

- Check the operation of the magnetic switch button. If the button is operational, and the burner does not light up due to the lack of gas supply, the reason may lie in the tongue of the switch. It can be squeezed slightly to ensure a snug fit.

- Replace the unusable filter mesh or install a new one if it was missing before.

A routine inspection of the water unit should be carried out at least once a year. Equally, do not forget about cleaning and regular maintenance all structural elements of the gas column.

Replacing the membrane of old type columns

There is no stagnation in technology, the design of modern gas water heaters and old water heaters (GVA, L, WPA) are different. Therefore, there are nuances in replacing the gasket. The following description is for OIG-56.

Columns KGI-56 are originally from the Soviet Union. They have been produced at the Iskra plant since 1956. But they can still be found in working kitchens.

To replace a worn out or stretched diaphragm in KGI-56, a number of actions are performed sequentially:

- Having unscrewed the nut, remove the burner located above the gas block, set it aside.

- Dismantle the gas block by disconnecting it from the gas pipe and loosening the three screws that connect it to the water block. Unscrewing the union nut, hold the gas block by hand.

- Unscrew the bolts securing the water block housing cover. Remove the cover.

- Replace the worn out part, insert the screws (to facilitate subsequent screwing in), put the gear cover back in place. The screws are first screwed on, doing it in pairs-opposite, then tightened in the same order.

- Mount the gas block, then the burner.

Be sure to substitute the bowl, because when removing the gearbox cover, water will flow.

Features of membrane replacement in new models

Water nodes of modern speakers work on the same principle. The main differences between the new designs of instantaneous water heaters are saturation with control units, control units, touch screens, and wires.

Some fasteners have changed. For example, now the screws are tightened and unscrewed with special screwdrivers with an asterisk. The innovations affected both the shape of the frogs and their connection with the gas block.

On the devices Amina, Selena, Milla, Ross (in the folk way - Chinese), it is better to entrust the replacement of the frog gasket to specialists, since it is necessary to dismantle the gas part along with the water

On brand In the Bosch and Junkers columns, the water node is located at the bottom right. To remove it, you need punite the terminal of the thrust sensor located in front of the VU.

After shutting off the water supply to the column and opening the hot water tap, remove the bracket with a screwdriver, which presses the pipe going from the VU to the heat exchanger. Pulling the pipe slightly to the right of the water unit, they wait for the water from the system to pour out through the tap, after which the pipe is drained completely. After that, use a key to unscrew the nut that secures the water block to the water supply.

Brackets - a new type of fastening for the structural elements of the water block of Bosch and Jurkers speakers, pry in and release with a screwdriver

Unscrew the VU fastening screws with a Phillips screwdriver. They are located at the bottom of the structure. There is no need to unscrew them completely. After that, the water block is at the disposal of the owner. It can be inspected, cleaned, consumables can be replaced (the coarse filter mesh can be cleaned without removing the VU).

There are much more consumables in such a frog than in the gearbox of the Neva Group of Companies. Firstly, the water block itself is made of plastic, the mounting screws are screwed directly into the plastic (without brass inserts). The connection is not designed for multiple assembly-disassembly cycles. If there is a leakage along the rod of the VU, you will need to replace the cover completely (the maximum period of operation is 2-3 years).

Secondly, in addition to the functions described above, it additionally regulates the amount of water flowing through the column, therefore, a stable liquid temperature is maintained at the outlet from the hot water tap.

In a Bosch water heater, the silicone membrane is a convex cap of a complex design that cannot be cut out of flat rubber. Only to buy, moreover, my own

To regulate the water flow, the lower part of the frog is equipped with additional overflow channels, crane-axle box, mechanical regulator of water flow. If the brass valve-axle box is acidic, it is replaced with a new one. The diaphragm for replacement will need to be purchased "native". All spare parts brand water heaters are expensive. It happens that it will be cheaper pick up and buy a new columnthan to find the desired node and wait for its delivery and installation.

Is it possible to get by with a diaphragm repair?

Home craftsmen could not miss the opportunity to try to repair the leaky rubber part.

Practitioners have tried the following methods:

- applying patches using various adhesives;

- filling the surface of the diaphragm with silicone sealant;

- silicone compound application Pentelast.

Experience has shown that such measures will not help for a long time, perhaps only for a day or two, since the membrane is working in a tense mode. A new failure of it can aggravate the situation. Therefore, you should not resort to gluing and patching the gasket.

Conclusions and useful video on the topic

How to replace the diaphragm in the Bosch column, see the following video:

Features of replacing the diaphragm in the water block of the "Neva" column:

Replacing the membrane is quite within the power of home craftsmen. The article provides detailed instructions, following which beginners can understand the principle of the water reducer, as well as replace the membrane in common speaker models with their own hands. If you doubt your own abilities, then it is better to call a wizard to diagnose the breakdown and eliminate it.

Want to share your own membrane replacement experience with other users? Tell us about the difficulties you faced in the process, add unique photos, your experience will be interesting to many beginners. Write your recommendations for replacing the membrane and disassembling / assembling the water assembly - the comment form is located below.