Have you come across household appliances that have worked for many years without failures? We are sure not. Refrigerators, air conditioners, microwave ovens require periodic attention ...

Moreover, you should not be upset if you need to repair the Neva gas water heater. After all, it can be done quickly, and there will be no problems with spare parts. How exactly to identify and eliminate malfunctions, our article tells.

We will introduce you to the design features of Neva equipment used in heating water for hygienic and sanitary consumption. The useful information provided by us will help to accurately find the cause of the breakdown. Guided by our advice, you can easily restore the performance of the column.

The content of the article:

- Design and principle of operation of PGV "Neva"

-

Most common malfunctions

- Problems due to lack of power supply

- Damage to the gas-water unit

- When the solenoid valve needs to be replaced

- Incorrect burner operation

- Sensors and electrical circuit or why the burner goes out

- Conclusions and useful video on the topic

Design and principle of operation of PGV "Neva"

In a series of flowing gas water heaters (PGW) of the Neva trademark, there are many models and modifications. Today the most popular are NEVA-4510M, NEVA-4511, NEVA 4513M with electric ignition.

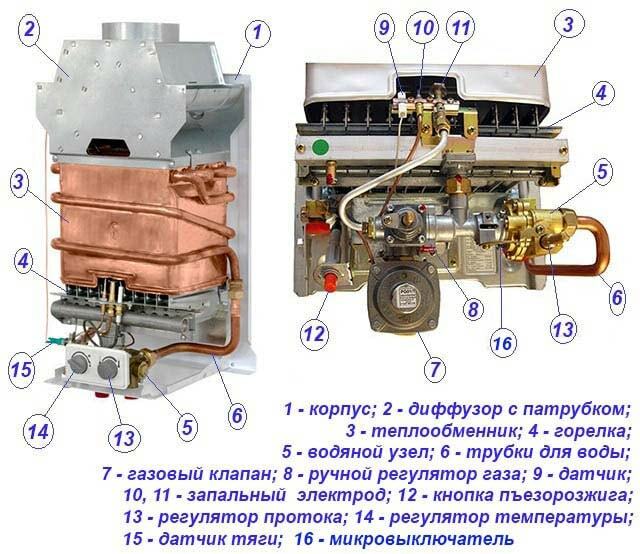

They are manufactured at the factories of the domestic company BaltGaz Group in accordance with GOST 31856-2012 and include:

- metal case;

- gas path;

- water circuit;

- burner;

- combustion path;

- security system;

- control system;

- adjustment block.

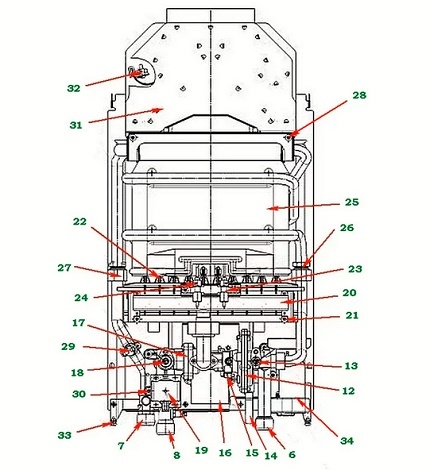

The listed nodes consist of many elements, some of which are shown in the diagram below.

Main positions: 6, 7, 8 - pipes for water supply, hot water supply and gas pipes; 12 - water block; 13 - water flow control valve; 15 - microswitch; 16 - control unit, 17 - gas unit; 18 - gas flow control valve; 19 - electromagnetic gas valve; 20 - burner; 23 - candle; 24 - flame combustion sensor; 25 - heat exchanger; 29 and 32 - overheating and traction sensors; 34 ¬ battery compartment

The water circuit begins with a pipe connected to the cold water pipeline and is pumped in with a hot water supply pipe. This includes the water block, which plays a key role in electric ignition. It consists of a lower and upper chamber, between which there is an elastic membrane.

When the tap is turned on, the flow of cold water rushes to the heat exchanger, but along the way it passes the lower chamber and completely fills it. Under water pressure gas column membrane bends and presses against the poppet valve of the stem located in the upper chamber.

The stem of the water block extends through the hole and acts on the coaxially located stem of the gas block. This, in turn, acts on a mechanical gas valve, the disc of which is retracted and allows a passage of gas, which instantly fills the burner manifold.

At the same time, when the rod moves, the microswitch plate is triggered, closing the electrical circuit.

Electricity is drawn from batteries located in the battery compartment and supplies power to the unit control, which supplies electrical voltage to the spark plug and opens the electromagnetic valve. Spark discharges are generated between the burner head and the spark plug electrode, igniting the burner.

The heat generated by the combustion of gas is transferred to a heat exchanger tube through which water flows. As a result, a few minutes after turning on the tap, hot water flows out of it. When the tap is turned off, the reverse processes take place, and the burner goes out.

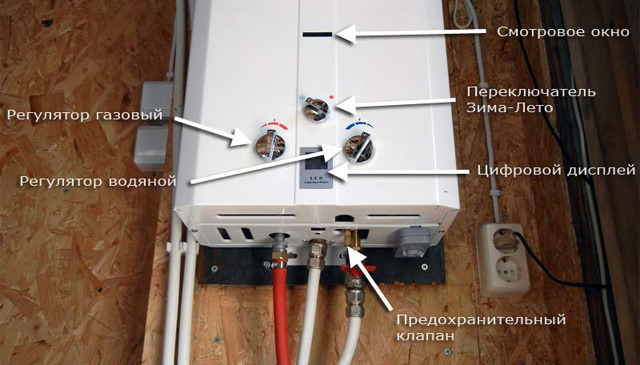

On the front side of the cladding there are adjustment knobs, as well as a display that shows the water temperature at the water intake point

Gas is one of the ecologically cleanest types of fuel, but its combustion also releases carbon dioxide, water vapor, and nitrogen. Through the flue gas pipe and gas boiler chimney they are removed from the combustion chamber to the outside. The removal of combustion products is possible only if there is adequate draft in the chimney.

To monitor the operation of the column and ensure its safe operation, the following sensors are included in the design:

- the presence of a flame;

- the presence of traction;

- water temperature.

Thanks to these components, gas flows to the burner only when the tap is on and there is water in the water supply. If the burner goes out for some reason, the gas supply is immediately interrupted.

The automatic shutdown of the water heater is caused by the lack of proper draft in the chimney, an increase in the water temperature at the water intake point to 90 ° C. If the pressure in the water circuit reaches a critical value of 1000 kPa, the emergency valve is triggered and excess water is drained.

Modern models are equipped not only with knobs for adjusting the flow of water and gas, but also with a knob "Winter / Summer", which is set to the desired position depending on the season

Now that you have become familiar with the device and design of the Neva gas water heater, you can proceed to the next chapter of the article, in which we list the most common malfunctions, their causes and methods elimination.

Please note that the manufacturer recommends that for maintenance and repair work related to disassembling the gas-water unit, call the service center employees, with whom contract signed for the supply of gaseous fuel and equipment maintenance.

Most common malfunctions

Malfunctions of certain units are indicated by the following problems when using a water heater:

- the burner does not ignite;

- the burner does not go out;

- the column turns off spontaneously;

- insufficient water heating;

- overheating of water.

Let's see how it looks in practice. You turn on the faucet in the kitchen or bathroom, expecting hot water to run out of it. But contrary to expectations, the burner does not ignite. Another situation: the column starts to work normally, but soon turns off, although you did not turn off the tap with water.

We wanted to wash our hands and almost burned ourselves, because boiling water was running from the tap. Or on the contrary: they are going to take a shower, and the water is barely warm. A very unpleasant moment: you turned off the water, and the burner continues to burn.

These problems can have completely different reasons. Sometimes they lie on the surface, as is the case with dead batteries. But often you have to perform one complex operation after another in order to get to the bottom of it.

In older models, such as the Neva-3802, a manual piezo ignition is used; to start it, you need to press two buttons simultaneously

The work of home craftsmen is hampered by the lack of experience, professional tools and thorough understanding principles of operation of the gas column. Therefore, when starting diagnostics and repairs, it is worth weighing all the pros and cons, guided by the principle of “do no harm”.

Problems due to lack of power supply

The fuel for the Neva water heaters is gas; nevertheless, they cannot work without electricity. The control unit, glow plug, solenoid valve and other components of the apparatus need a stable power supply. It is powered by two LR20 alkaline batteries located in a separate, easily accessible compartment.

For the uninterrupted operation of a gas water heater with electric ignition, it is advisable to have at least two LR20 or CR20 batteries in stock

If there is no electricity, when you turn on the tap with water, a spark discharge will not occur or it will be weak and the column will not turn on.

Lack of power supply can be caused by the discharge of batteries, oxidation of the contacts of the battery compartment, or an open circuit.

With incomplete discharge, the batteries can power the display, but their power will not be enough for more power-intensive operations. Therefore, if you see that the display is working properly and displays temperature data, nevertheless clean the contacts of the battery compartment and replace the batteries with new ones, similar or lithium CR20.

The battery compartment is located at the bottom of the device and is accessible without removing the cover, be sure to observe the polarity when installing the batteries

The battery compartment cover is located at the bottom of the case and is accessible without disassembling the device. That is, you can clean the contacts and replace the batteries yourself. Elimination of the causes of underheating of water.

If, with new batteries, the column still does not turn on, it is necessary to check for scale in the heat exchanger pipes.

The formation of scale on the inner surfaces of the pipe interferes with the normal passage of water, which can lead to the shutdown of the column. Also, a thick precipitate of magnesium and calcium salts significantly reduces thermal conductivity, the apparatus cannot ensure the heat output declared in the accompanying documentation, which leads to insufficient heating water.

For descaling, use ordinary citric acid diluted with warm water, the amount of solution should correspond to the volume of the heat exchanger, you can also use table vinegar

As a reminder, the instruction manual states that clean gas water heater and its heat exchanger is needed every 12 months. With intensive operation of the column and using hard water, scale builds up faster, so extra cleaning may be required.

To do this, you need to remove the casing and remove the heat exchanger. Before disassembly, close the taps on the gas and water inlet pipes. Remove the gas and water adjustment knobs by pulling them towards you. Some models have screws under the handles that can be removed with a screwdriver. Also, unscrew the screws that fix the casing to the bracket from below on both sides.

Open the wires connecting the water temperature sensor and the control unit with the display. Remove the cover by pulling it towards you and sliding it up. Looking ahead, we note that after the repair, the casing is installed in the reverse order.

So, the casing was removed and now it is necessary to remove the heat exchanger. Unscrew the plug located under the water unit and drain the remaining water from the heat exchanger. Disconnect the column pipes from the cold and hot water pipes, remove the old gaskets. Unscrew the two screws and remove the metal plate securing the top of the heat exchanger.

Remove the heat exchanger and place in a container with a hot solution of dish detergent or regular laundry soap. After 15 minutes, remove the soot from the grate and other surfaces with a soft brush. Rinse the grate and other surfaces under a strong jet of water.

To remove scale from pipes, a warm solution of citric acid is prepared at the rate of 100 grams per 1 liter of water heated to 40 ° C. The resulting solution is poured into a heat exchanger tube and drained after 15 minutes. The pipe is flushed with water. Repeat the procedure if necessary.

When installing the heat exchanger in place, the detachable joints are sealed with new gaskets. Do not overtighten the connections so as not to pinch the gasket. Otherwise, its transmitted edge may end up in the pipe in the path of the water flow, which will cause unpleasant noises. Installing gaskets at an angle will lead to similar consequences.

Damage to the gas-water unit

If the power supply is provided, the heat exchanger is clean, but the water heater does not turn on, you will have to disassemble the gas-water unit to determine the condition of the diaphragm and stem.

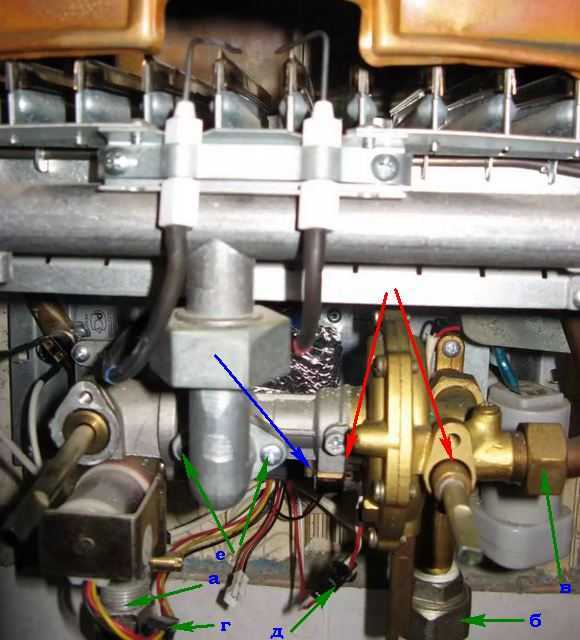

The sequence of dismantling the gas-water unit of the column with an indication of the detachable connections that require sealing with elastic gaskets to avoid water leaks. The course of action is listed in alphabetical order

We repeat that for repair work gas and water supply taps must be closed. The water unit is dismantled together with the gas unit.

The gas and water connections are turned off, the nut of the heat exchanger pipe is unscrewed, the wires connecting the solenoid valve with the control unit and the wires of the microswitch open.

Unscrew the screws connecting the gas-water unit and the burner manifold pipe. This assembly can now be removed and placed on the table for further disassembly.

Having unscrewed a few screws, the gas block is separated from the water block and set aside. Further, they work only with a water block. Unscrew the screws located around the perimeter. The block is divided into two parts, between which the membrane is located.

The membrane is removed and inspected. Most often, it is because of its sprains or breakouts that it is not possible to turn on the column. During reassembly, a new diaphragm is placed in a standard seat. The stem is installed in such a way as to ensure its translational movement, without jamming.

When the solenoid valve needs to be replaced

If the solenoid valve fails, gas does not enter the system and the column does not turn on. The valve is removed from the device, but not disconnected from the control unit.

By simulating the supply of water to the system by moving the microswitch pusher, the ability of the valve to retract and hold the stem is determined, opening the gas passage to the burner. If the valve does not work, it is replaced. To do this, disconnect the wires, remove the water-gas unit, unscrew the fastening screws, remove the old valve and install a new one in its place.

Incorrect burner operation

The displacement of the spark plug electrode or the formation of carbon deposits on it leads to the absence or weakening of the ignition spark and, as a result, to the failure of the column to turn on. Also, due to problems with the spark plug electrode, the gas concentration in the combustion chamber may increase. For this reason, ignition is accompanied by a loud bang.

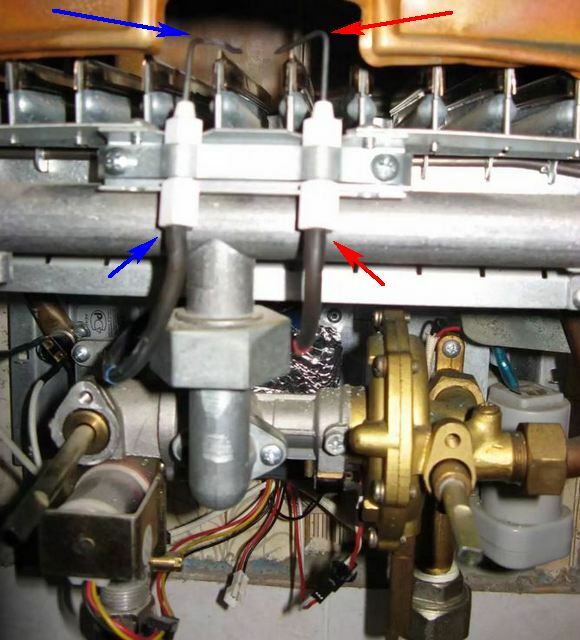

Arrows indicate the most problematic areas of the water heater burner, including the glow plug electrodes, which need to be cleaned of soot, and the electrical wiring connectors.

It is enough to clean the electrode with sandpaper and return it to its original place for the spark to “work” and the extraneous noise to disappear.

When the burner becomes clogged, its flame weakens and begins to smoke. As a result, the water does not heat up to the intended temperature. Before cleaning, the burner is removed, for which the wires of the ionization sensor and the glow plug are disconnected, unscrewed manifold nut and two screws, the manifold is removed, two more screws are unscrewed and the unit is disconnected burners.

The surfaces of the parts are cleaned with a brush. A brush of a suitable size is used to clean the internal channels. After removing the dust, wash the parts with dishwashing detergent, rinse and, after drying, put in place. The flame of a clean, functional burner is blue.

Sensors and electrical circuit or why the burner goes out

As it was said in the chapter on the device of the water heater, the security system includes three sensors that are connected in series in a single electrical circuit.

It is enough to fail one of them to open the electrical circuit and turn off the column.

The ionization sensor installed on the burner, as well as the glow plug, is equipped with an electrode that can become dirty or change its position, and then not "see" the flame. With such a malfunction, the water heater starts working normally, but after a few minutes the burner goes out, since the solenoid valve shuts off the gas.

When disassembling the burner, unscrew the screws securing the clamping plate that holds the flame detector and glow plugs

The flame sensor electrode is also cleaned with emery paper, after which it is positioned to “see” the flame.

The geyser with the Neva logo goes out also due to an improperly equipped chimney or its clogging. With poor draft, the removal of combustion products becomes impossible. To prevent the accumulation of harmful substances in the room, the corresponding sensor is triggered and the column is turned off.

When the water temperature reaches 90 degrees, the overheating sensor reacts and the column stops working urgently. The reason usually lies in the improper regulation of the gas and water supply, or in the insufficient pressure of the water supply network.

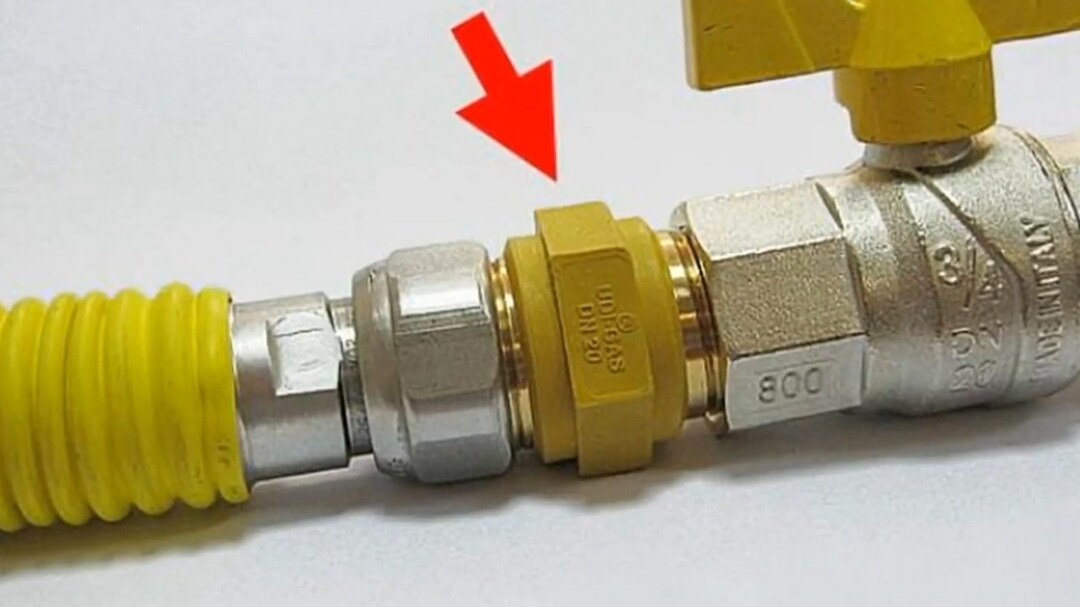

The model range includes devices operating on liquefied gas. The gas cylinder is connected to the water heater through a reducer, which can also cause malfunctions

Sometimes it is enough to turn the gas control knob towards the minimum or increase the water flow to stop the column shutdowns. You also need to set the "winter / summer" knob to the appropriate position in time.

Operability gas water heater sensors and the continuity of the electrical circuit is checked with a multimeter. If the sensors are in good working order, the electrical resistance is close to zero. An error code also signals a breakdown of the overheating sensor - instead of the usual water temperature readings, the letters "EE" are displayed on the display.

If there is no device for measuring resistance, the check is carried out by installing jumpers to close the circuit and turn on the column. If, with this connection, the column works normally, then the sensor under test is defective and must be replaced.

It must be remembered that installing jumpers is only a diagnostic method, not a repair method. It is forbidden to use a column with jumpers instead of sensors.

Conclusions and useful video on the topic

The video demonstrates the process of replacing the batteries of the Neva water heater:

The video is devoted to typical malfunctions of gas flowing water heaters:

Geysers Neva are unpretentious in maintenance and maintainable. Disassembly and assembly requires a minimum set of tools.

The technical documentation supplied with the product provides clear instructions for troubleshooting and repairs. Replacement of individual parts and assemblies is possible. Spare parts are available in the chain stores of the manufacturer BaltGaz Group and from its dealers.

Do you want to share your own experience in restoring the performance of a Neva gas column? Do you have useful information on the topic that might be useful to your site visitors? Please write your comments in the block below, post a photo, ask questions.