Built-in household appliances are a part of our daily life. And it became popular due to the fact that it saves the area of the working area, it looks much more attractive than outdated stand-alone equipment, and according to technical data it often overtakes his.

Ovens, which are so beloved by housewives for the opportunity to prepare tasty and healthy dishes, have not spared innovations either. Let's consider how to connect a built-in gas oven in order to comply with the installation standards and not harm the equipment. In fact, this is no more difficult than installing a traditional stand-alone stove, but some of the nuances are very important - we will dwell on them separately.

The content of the article:

- What do you need to know before installation?

- Preparation: power supply and ventilation

- Tips for choosing a gas hose

-

Gas oven installation instructions

- Stage # 1 - unpacking and studying the instructions

- Stage # 2 - preparing a niche for installation

- Stage # 3 - connection and testing

- Conclusions and useful video on the topic

What do you need to know before installation?

Even if you are well versed in the regulatory documents and can independently carry out all the installation work, the final point in the connection process will be set by a gas service employee.

It is he who will check the connections for the likelihood of leakage, make sure that the connection is correct and that the oven is working properly, and then issue a permit.

It is better to time the call of the representative of Gorgaz or Oblgaz to the end of the installation work. We do not recommend starting to use the oven without an official conclusion.

During preparation and installation, we advise you to strictly follow the manufacturer's recommendations set forth in the instructions and regulatory requirements. SNiP 42-01-2002acting instead of SNiP 2.04.08-87.

Remember that following the instructions is the safety of your family, so take any measures related to the installation of gas equipment seriously.

Here are a few rules that will help you both take into account the standards and carry out work on connecting the gas built-in oven so that it becomes comfortable for use in the future:

- The shorter the distance from the oven to the gas pipe, the better. The length of the hose should not exceed 4 m, ideally 1.5-2 m.

- The oven is connected to the pipe only with a flexible hose - a hose that complies with GOST standards.

- The auto ignition system requires a power connection. A separate socket with grounding and a 16A RCD is required.

- To ensure air exchange in the required volume, good ventilation is necessary - it may be necessary to install forced ventilation.

- To prevent gas from penetrating into living quarters, it is necessary to make all connections airtight.

Sooner or later you will have to deal with replacing the gas hose, a shut-off valve or some parts of the oven, therefore, in advance, provide free access to all significant gas supply nodes.

Often, to decorate the work surface, a tightly glued one-piece tabletop is used, sometimes very heavy. In this case, the socket and the connection to the gas pipe should be located immediately behind the oven, in an open place or masked by a cabinet.

It is undesirable for the electrical wiring and water supply to be in close proximity to a gas pipe or piping - the distance between them should not be less than 20 cm.

Preparation: power supply and ventilation

Not a single gasman will sign an inspection report if he is not convinced of the good operation of the ventilation shaft. and a properly installed outlet, therefore, we recommend solving air exchange and power supply issues in advance.

An outlet or a separate outlet for the electric cable is required if your gas oven is equipped with a fan, electric grill, electric ignition and is equipped with an electronic control panel

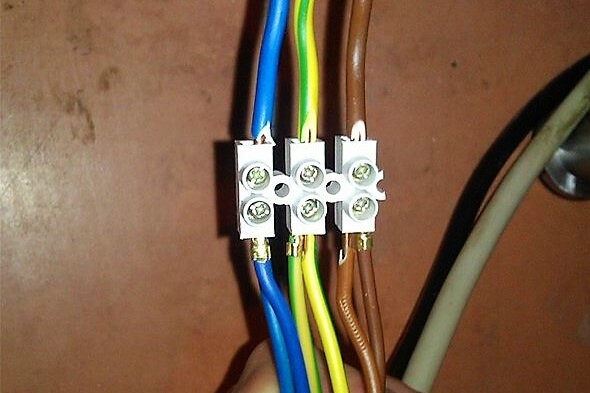

All gas ovens can be divided into two categories: with and without power cable. If the power cable comes off the rear of the unit, it needs a socket. If not, you can find the terminals for installing the wire under the cover of the junction box - in the same place, on the rear panel.

The wire does not have to end with a plug. There is another way of connection - connecting the cores directly or through the terminals. It is important to correctly connect and insulate each wiring.

When connecting a gas or electric oven, do not use extension cords, filters for multiple outlets, tees. The same rule applies here - the shorter the cord and the fewer connections, the better.

The oven belongs to powerful household equipment, therefore it requires the installation of a separate RCD by 16 A. If you are simultaneously replacing the wiring and assembling the electrical panel, then be sure to leave one place for it on the Din-rail in the group of kitchen appliances.

There are no big difficulties with ventilation either. Usually it is provided by open vents and valves for ventilation on one side and ventilation ducts and shafts on the other. Productive cooker hood welcomed, since during cooking it is she who cleans the air from vapors and combustion products.

A burnt lunch in the oven is an unpleasant event, but the negative from it increases if, in the absence of good ventilation, households or neighbors begin to panic due to a huge amount of black smoke

If the hood does not cope or the ventilation does not meet the requirements, then into the opening of the shaft or a plastic channel leading to the same shaft, a fan is installed, forcibly removing the waste air out.

Tips for choosing a gas hose

Simple in essence and not requiring special skill, but a very crucial moment is the connection of a gas oven to a pipe that supplies fuel to an apartment or house. It is important here to choose the right hose and connect it tightly to the oven and pipe.

If you are not confident in your abilities, it is better to entrust the connection to a Gorgaz employee. He will install the wiring, and immediately check it for serviceability, and the connections for tightness

Calling the master, you can ask what gas hose better to choose.

Today in stores you can find products that are different in material of manufacture:

- inexpensive rubber-fabric liners with a service life of up to 5 years;

- rubber hoses in a metal braid, reliable and ready for installation;

- two-layer reinforced PVC hoses;

- bellows tubes.

They may also offer an oxygen hose - it seems to be strong and reliable, but do not agree. These products have already been banned for use for a number of reasons, and one of them is relevant specifically for the kitchen. The material of the hose is destroyed when grease enters, and this is the probability of a gas leak with all tragic consequences.

A few tips for choosing:

Image gallery

Photo from

When choosing a hose, check the certification and compliance with GOST. Take only those products that are equipped with factory nut-threaded ends, and be sure to pay attention to their integrity

Don't buy cheap Chinese products from online stores. They look beautiful, but in fact, brittle hoses will not last long, and replacing them, taking into account the built-in design of the equipment, is sometimes very laborious

Do not confuse gas connections with other products such as water. Gas fittings are easily recognizable by the yellow color of the braid, yellow markings or stripes

There is no need to buy a long line "with a margin" or a short length that barely reaches the connection points. The hose should be free, slightly sagging, without tension

Certificates and high quality

Expensive products last longer

Yellow marking of gas lines

Choose the right hose length

Do not forget to buy a dielectric for the gas pipe and a shut-off valve along with the hose - if it is not already installed. Please note that in order to install the valve, you will have to shut off the line, that is, call a gas worker.

Gas oven installation instructions

The entire installation process can be divided into 3 parts: the 1st is the continuation of the preparation, the second is the direct installation of the built-in oven, the 3rd is the connection of the oven to the gas supply line. Let's sort everything out on the shelves so that there are as few questions as possible on the topic of how to properly install and connect the oven to the gas in the living room.

Stage # 1 - unpacking and studying the instructions

The first stage is neglected by many, although the serviceability of equipment is one of the conditions for its correct functioning in the future.

To make sure that the oven is ready for installation, unpack it and check from all sides, namely:

- The front side, on which the control panel and the oven door are located, should not have any scratches, cracks, dents or stains. It is not recommended to remove the protective film before the end of installation.

- The back wall, where on the parts visible or hidden under the covers are elements for connecting the unit to electricity and gas.

- Internal surfaces located behind the door.

- Protruding elements - mechanical knobs for power adjustment and setting modes, door handle.

Then take the data sheet and check the complete set: baking trays, grates, grill equipment, installation and fixing kit.

The installation kit consists of a pair of rails and several self-tapping screws with washers. Do not be surprised - for the installation of modern technology, a large number of fasteners are not required.

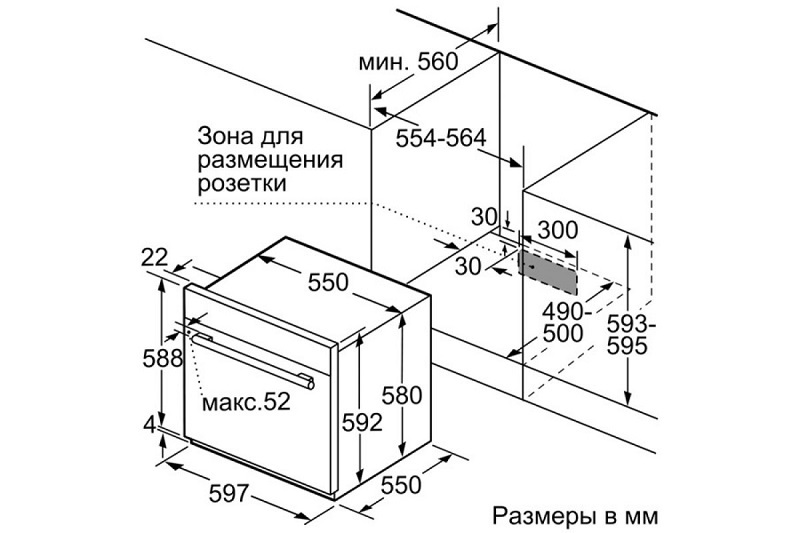

Installation instructions are drawings, diagrams and operating procedures, presented in the form of a list. We recommend that you study the drawings even when ordering a kitchen set, so that there are no discrepancies in size.

After making sure that everything is in order and in place, you can start connecting the hose, wires and installing the cabinet body in a niche - usually these activities take place simultaneously.

Stage # 2 - preparing a niche for installation

The dimensions of the ovens are standard, like the kitchen sets, but care must be taken that the dimensions of the prepared niche and the cabinet match. To do this, the oven is inserted into a niche - it should fit tightly, but with a small gap for attaching to the guides.

To ensure air circulation in the lower panel, under the oven, cut out a small section, the width of which is equal to the width of the unit, and the height is about 10 mm. For the same purpose, a small gap is left between the wall and the rear wall of the device.

According to the drawing, the oven is installed either directly on the bottom of the niche, or on rails fixed on the sides or on the top panel - according to the manufacturer's recommendation. The final touch is to secure the case with self-tapping screws, so that during operation it does not lose stability.

The electrical wire and hose are connected even before the case is finally fixed.

Stage # 3 - connection and testing

Tools and materials may be required:

- screwdriver;

- gas wrench;

- adjustable wrench;

- fum tape;

- soap solution.

According to the norms for oven installation a separate pipe branch with an installed valve is required to cut off the gas supply in case of repair or accident. The liner is connected through a dielectric insert that provides additional protection.

How to install the dielectric correctly - in the photo gallery:

Image gallery

Photo from

It is a threaded metal piece with a rubber insert. A dielectric or insulator is installed on a gas pipeline to protect against electric current that can get into the pipeline from a faulty power line or ground loop

One of the most suitable locations is directly under the shut-off valve. From a variety of models - with internal and external threads, different diameters - you need to choose the one that matches the thread and dimensions of the gas pipe and connection

First you need to fix the insulating piece to the gas pipe. Fum tape is used to seal the connection, and for reliability, the dielectric already put on the thread is tightened with a gas wrench. But don't overdo it and drag the connection

In the last turn, attach the eyeliner - a rubber hose in a metal or polymer braid. It is also screwed on the thread and carefully tightened with a gas wrench or pliers.

Step 1 - buying a dielectric for gas

Step 2 - choosing a location

Step 3 - mounting the dielectric onto the pipe

Step 4 - connecting the piping

At the other end, the hose is connected to the oven. Please note that the length of the hose must be sufficient for a free connection at a time when the unit is not yet inserted into the niche - that is, the connection must be long enough. This is one of the features of the installation of built-in appliances.

Testing is carried out in the old "old-fashioned" way: the compound is covered with a soapy solution and gas is supplied. If there are no bubbles at the junction, then the connection was successful.

The called representative of the gas service will record the fact of connection, and to check the concentration of gas in the air, he uses a gas analyzer - an electronic device that quickly detects a leak

Otherwise, you will have to do a more thorough sealing of the joint or still wait for the master and entrust him with this work. After connecting the gas, you can switch the electrical wires or simply insert the plug of the cabinet into a pre-installed socket.

The last step is installing the already connected oven in the cabinet, tightening the fasteners and one more, final testing.

Conclusions and useful video on the topic

Video # 1. Tips from a user who has connected the oven by himself:

Video # 2. Installation recommendations from the manufacturer Hansa:

Video # 3. About connection order:

And the last recommendation: be sure to pair with a gas service representative. If the connection passes "by" Gorgaz and an accident occurs, resulting in damage to health or damage to property, you face considerable fines.

Sanctions are also possible during the next scheduled inspection - if the installation of new connected equipment is not recorded and not documented. Follow the law and your safety is guaranteed!

Please write comments, ask questions and post photos on the topic of the article in the form below. Tell us about your own experience in connecting a gas oven. It is possible that the technological subtleties of the process known to you will be very useful to site visitors.