South Korean gas boilers of the Master Gas Seoul brand are structurally complex functional devices with rich technical equipment. Compact units are literally crammed with devices that ensure the stable operation of the equipment and automate the process. All components of the system are important and interconnected, but any of them can fail.

To find out about the occurrence and cause of the malfunction, the error codes of the Master Gas boiler will help. The alphanumeric combinations that appear on the display will tell you where the violation has occurred, will allow you to quickly decide what should be done to eliminate it. It is extremely important not to waste time when restoring the unit to work. Do you agree?

We will tell you how the boiler malfunctions are coded by the manufacturer. We will show you what steps are to be taken to correct the situation. From the article presented by us, you will find out what repairs are needed to restore the unit and which of the shortcomings in the work can be eliminated with your own hands.

The content of the article:

- Briefly about the device and functional systems

-

Decoding codes and how to deal with failures

- Factory encoded irregularities and errors

- Boiler malfunctions without error code

- Conclusions and useful video on the topic

Briefly about the device and functional systems

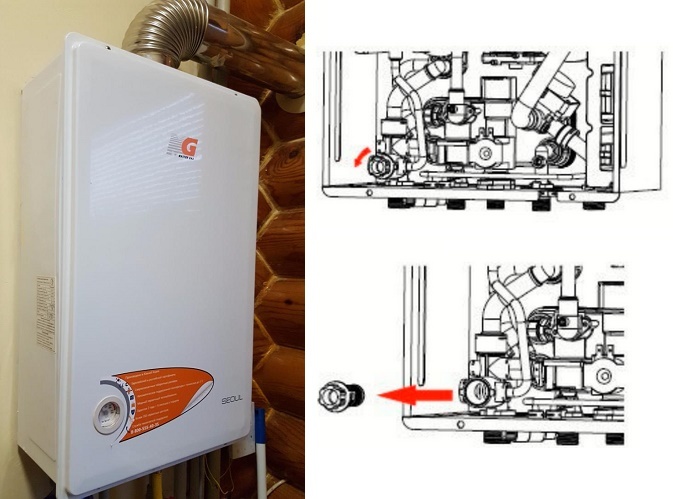

Founded in the Republic of Kazakhstan, Daesung Celtic Enersys Co. Ltd. " offers the Russian consumer a line of wall-mounted gas boilers serving facilities ranging from 110 to 210 m². Two-circuit units from South Korea with the Master Gas Seoul logo and the following letter designation from 11 to 21 are adapted to the domestic operating conditions.

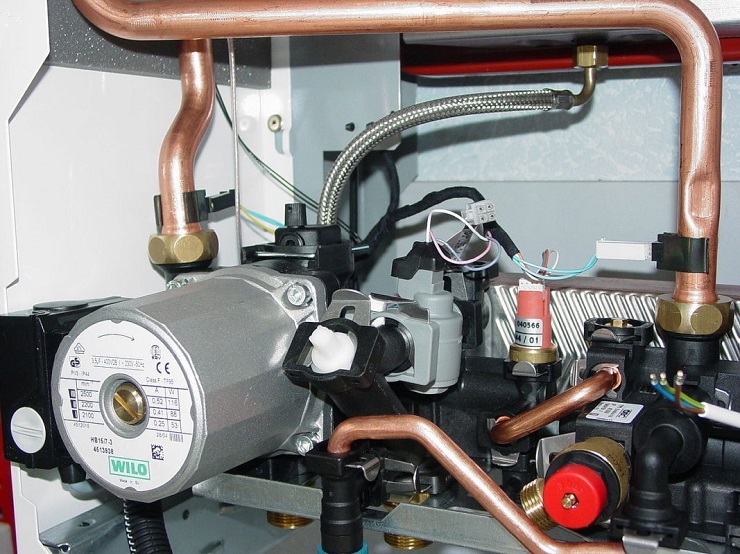

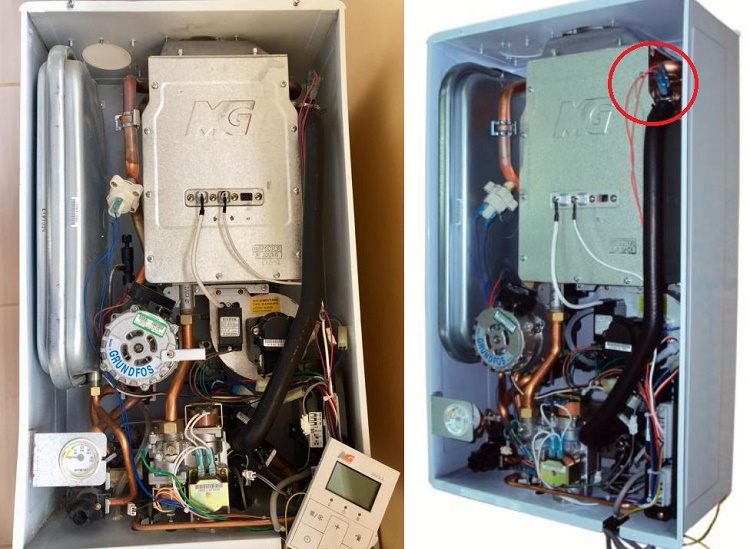

In fact, they represent a thoroughly thought out and carefully equipped mini-boiler room. It has its own protection systems, stimulating the movement of the heated medium, removing air locks and combustion products, and other devices.

Image gallery

Photo from

In the domestic market, boilers of the South Korean brand Master Gas Seoul are represented mainly by wall-mounted models serving two circuits: heating and hot water supply

Gas boilers MG are essentially a mini-boiler room equipped with volatile devices and protection systems

The Master Gas boiler is fixed to the load-bearing wall with anchors. According to the diagram attached to the product, communications are connected to it, the chimney must be installed

Gas heat generators with the Master Gas logo are controlled either from an electronic panel or from a panel programmed by the manufacturer. The manufacturer does not recommend reprogramming the remote control

High quality components from renowned companies are used in the assembly of gas boilers. The assembly itself is also great

To restore the performance of Korean gas boilers, you can easily find or order spare parts. However, they cannot be called cheap.

The boilers of the popular South Korean brand are adapted to our difficult operating conditions. The units are equipped with all types of protective systems

Despite the presence of multi-level protection, measures should be taken to exclude situations dangerous for the boiler. For example, use a voltage regulator in the wiring diagram

Boilers of South Korean production Master Gas Seoul

Electrodependent technical filling

Fastening the boiler to the load-bearing wall

Gas boiler control options

Gas unit accessories

Spare parts for the repair of gas boilers

Supply of communications for a gas boiler

Boiler operation in tandem with a voltage stabilizer

Despite the high quality of the assembly, as well as the scrupulous selection of units and parts, from time to time something of them becomes unusable. Disruptions in work occur due to trivial wear and tear, the end of the working life, etc. Unfortunately in the list of common reasons also includes the incorrect attitude of the owners to the complex technical equipment.

In addition, the units process gas to generate heat. And this type of fuel is extremely toxic, and therefore breakdowns should be taken seriously. Any violation can entail undesirable threatening consequences, which are better prevented at the initial stages.

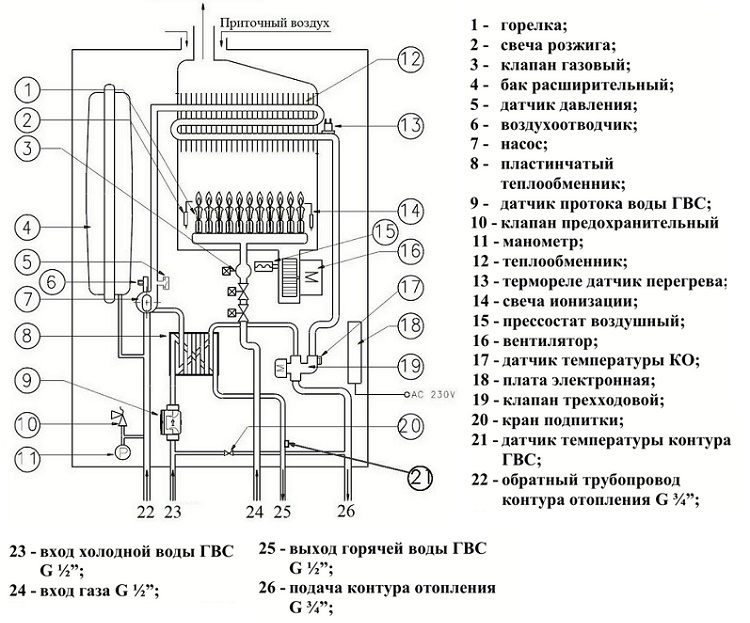

Before proceeding with the decoding of codes signaling malfunctions, you should carefully familiarize yourself with the design features, device and components of the gas boiler

The important components responsible for the operation of the wall-mounted boiler model include:

- Burner block. Located in the combustion chamber. Consists of a burner and a manifold with gas injectors. Responsible for the preparation of a gas-air mixture, more precisely, for mixing blue fuel with air in the proportions required for normal combustion.

- Spark plug. Located to the left of the burner. When activated, it generates a spark that ignites the gas-air mixture.

- Circulation pump. It stimulates the movement of the coolant along the circuits located inside the boiler and "pushes" after heating to the outlet to the heating system and the hot water supply pipe.

- Expansion tank. It takes the volume of the coolant formed when the water is heated. Thus, it eliminates excess pressure that could lead to depressurization of the circuits.

- Air vent. The device for automatic venting of air locks from closed pipeline systems contributes to the creation of a stable head without excess and pressure drops.

- Temperature and DHW flow sensors. Used to automate the process. The first one fixes the upper and lower heating limits to send a command to turn on / off the burner. The second gives a signal to switch to the supply of sanitary water at the moment the tap is opened.

- Heating temperature sensor. Reacts to changes in the temperature of the coolant. Automates the heating procedure.

- Gas valve. Regulates the supply of gas to the combustion chamber through the gas manifold nozzles. Blocks the fuel supply to the burner in the event of a dangerous situation.

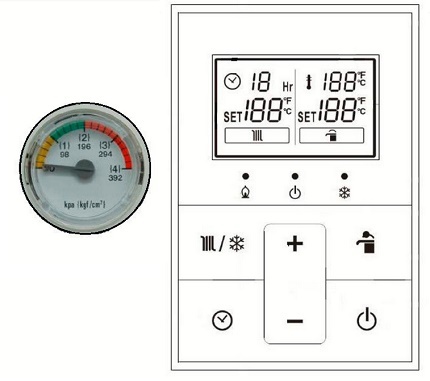

- Pressure sensor. Controls the pressure of water, gives commands to shutdown the unit in case of pressure drop or excess.

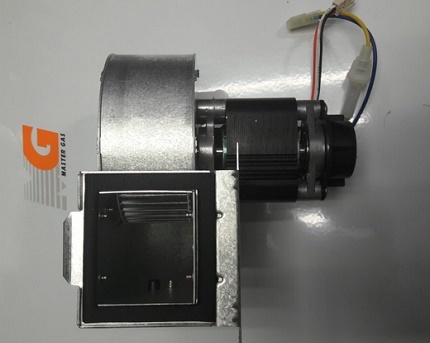

- Fan. Stimulates the withdrawal of gaseous fuel processing products into the chimney. The air pressure switch is responsible for the operation of the fan itself, which, in the absence of traction, stops the boiler.

- Ionization candle. Fixes the presence of a flame when the burner is running. If the fire goes out for any reason, this device will give a command to stop the gas supply.

Each of the listed devices performs its own front of work. In addition to them, there is also an important group that prevents the occurrence of dangerous situations. These include a safety valve, a thermal relay that excludes overheating of heat exchangers, and other equally important parts and system units.

Decoding codes and how to deal with failures

We note right away that serious violations in the operation of the heating gas unit must be eliminated by employees of the organization with which a contract for the maintenance of gas equipment has been concluded.

All actions of amateurs inside the "mini-boiler room" are strictly prohibited. Simply put, if you need to remove the casing from the gas boiler to fix the problem, you should not "climb" there yourself.

Image gallery

Photo from

The manufacturer warns that any manipulations for cleaning and caring for the Master Gas gas boiler should be carried out after disconnecting the unit from the mains.

All repair operations, for the production of which it is necessary to dismantle the casing, must be carried out by craftsmen from the service company with which a service contract has been concluded

The replacement of system units and parts of the gas boiler must be carried out by a certified repairer, trained and qualified.

If a representative of the company servicing the equipment records the fact of independent intervention in the structure, the warranty will be canceled.

Gas boiler care Master Gas

Boiler with front panel removed

Replacement of system assemblies and parts

The result of self-intervention

However, the owners need to know what happened to their device in order to decide whether to call the master or the problem is solved by a banal cleaning of the soot-clogged device. Let's consider what errors the manufacturer has coded and what to do if the code appears on the electronic scoreboard.

Factory encoded irregularities and errors

Error A2. This is a signal about a malfunction of the fan.

There are three reasons for the failure:

- The device is not receiving power. It is necessary to check the wiring, which is equipped with the fan, and connections. It is possible that contact is simply broken somewhere.

- The fan is out of order. It doesn't matter if it worked its way or broke down for another reason, the fan will have to be replaced. If it "flew" during the warranty period, then the gas workers must supply a new one.

- Fuse blown. With this device, everything is extremely simple. It must be changed immediately.

Regardless of the type of breakdown, the boiler will be stopped by a pressure switch. Indeed, due to the inoperability of the fan, caustic poisonous smoke can enter the premises. The owners need to turn off the boiler and call the master from the service center.

The fan is an important component of the gas heat generator. Its duty is to remove products from the processing of blue fuel in order to obtain thermal energy.

Error A3. Pump failure warning.

If the pump stops working, the heated coolant will not go to heating devices, and hot sanitary water to mixers. The standard consequence of error A3 is the shutdown of the Master Gas boiler by the thermostat. For a blocked unit, you will need to buy a new pump.

The most economical and humane option for a breakdown for the owners is a violation in the wiring. If a wire is pinched somewhere or a contact has moved away, the master will quickly fix and start the equipment.

If the pump is in good working order and the wiring is not damaged, which can be found out by checking, and the thermostat turns off the operation of the boiler, then the reason is not at all in the pump. This means that the thermostat itself requires replacement.

The circulation pump from Grundfos almost never comes out of a standing position. All his problems are most often associated with electrical circuit disturbances.

Error A4. Boiler blocking by triggered thermostat.

Thermostat is a protective device that reacts to overheating of the heat exchanger. Most often, the temperature rise in Master Gas boilers and the A4 error "popping up" on the display occurs due to a pump breakdown. If the circulation of the coolant does not occur, the boiler continues to heat it. As a result, the water in the heat exchanger boils and the unit is blocked.

Note that overheating occurs not only due to pump breakdown. Often it occurs due to slow movement in pipes "overgrown" with mineral deposits. The owner of the autonomous system can clean the heating himself, but it is better for the master to remove the "growths" from the heat exchanger.

The thermostat blocks the unit in case of overheating of the heating medium or sanitary water. If heating is performed in normal mode, and the relay turns off the boiler, then it will have to be changed

It should be remembered that the performance of cleaning is not included in the list of warranty obligations of the manufacturer of the technical product. They are carried out at the expense of the owners, therefore it is better to prevent the deposition of sediment on the walls of the pipes. To do this, you need to try not to change the coolant in the system unnecessarily.

Error A5. Coolant pressure drop.

If the error code A5 appears on the electronic board or on the display of the control unit of the Master Gas boiler, it means that there is a sharp decreased pressure.

This violation also has three reasons:

- Airlock. Often they appear when the heating is filled with a coolant, less often when the water boils and the thermostat does not work. Air locks can be removed by the user himself by bleeding through Mayevsky cranes near the batteries. It is necessary to start bleeding to the device farthest from the boiler.

- The heating pressure sensor has broken. If bleeding air from the radiators did not help, you will have to change the coolant pressure sensor.

- Lost connection between sensor and electronic board. To identify the exact cause and location of the break in the connection circuit, it is necessary to check all contacts and wiring between the control board and the sensor.

In short, if you blew air out of the batteries, and it did not help, turn off the boiler and call the service department.

The pressure sensor records the excess of the standard values in the system and transmits information to the control board, which turns off the boiler. Timely blocking of work protects the unit from depressurization of units, increases its working life

Error A6. Ignition does not work.

There are plenty of reasons for this error, most of them are associated with the deposition of combustion products on the candle or with a violation of the electrical wiring:

- Burner block clogged. It is required to clean the burner and gas nozzles from carbon deposits and soot. For cleaning, the burner with the manifold is removed from the gas chamber and brushed. The carbon deposits from the ionization and ignition candles are cleaned off with fine sandpaper. Then they wipe everything with a damp cloth and clean the internal channels with a brush.

- The ignition plug does not work. It may either be faulty itself, or the wiring connected to it may be damaged. If the electrode of the candle is simply covered with carbon, it must be cleaned, the device itself must be wiped and degreased.

- The ionization plug does not work. There are two solutions: either the catfish "flew" or the wiring has gone somewhere.

- The ignition transformer does not work. The situation is like with candles: it is broken by itself and requires replacement, or somewhere there is no contact in the electrical circuit.

- Gas supply interrupted. This is the most serious and dangerous of the causes of error A6. Requires a mandatory appeal to gas workers, unless, of course, you yourself have not forgotten to open the gas valve at the inlet of the gas pipeline to the boiler.

In case of interruptions in the gas supply to the burner, contacting the gas company is mandatory for those whose boilers are supplied with main gas.

And the owners of autonomous systems must first check the pressure in gasholder or cylinders. Now, if everything is in order with the gas source, you need to call the masters from the service company.

It is the responsibility of the flame ionization plug to register the combustion process in the combustion chamber. If it detects extinction, the operation of the boiler will be immediately stopped, and the gas supply will be interrupted.

Error A7. Damage to the gas valve.

Disruptions to the functionality of the gas valve are traditionally associated with:

- With a break in the modulator coil. There is nothing you can do about it, you will have to change the valve completely.

- With damage to the electrical circuit. You need to check all the contacts and wires for a poor connection or a break in the conductor.

For check gas valve for operability, one of the wires is disconnected from the modulator coil. If, after reconnecting, the blinking A7 on the display has not disappeared, get ready to buy a new device and replace it.

The gas valve is needed to regulate the characteristics of the fuel flow. If it is unsuitable for further use, it is replaced.

Error A8. Flame not extinguished after turning off the burner.

If, after stopping the heating process, a small non-extinguishing flame remains in the combustion chamber, it means that the gas valve has become unusable. Simply put, the diaphragm located inside the valve is damaged. It is not possible to change it. You need to buy a new valve.

Error A9. Anti-freeze mode.

The system is designed for continuous operation during the cold period, even if the boiler itself is turned off. When the temperature of the coolant falls below the limit declared by the manufacturer, it starts the burner so that it maintains a minimum temperature background. When the temperature drops to + 5 ° С, in addition to the burner, the automatics will also start the circulation pump.

If the boiler shows A9, you need to set up and start this mode again. Each owner can do this himself, without calling the master.

AA error. The temperature sensor of the heating circuit has been triggered.

If the temperature sensor installed in the heating circuit has triggered and transmitted a signal from the thermostat to block the boiler, it means that the water in it has warmed up above + 95 ° C and is about to boil.

The appearance of an AA error on the display of the Master Gas Seoul device is facilitated by:

- Overlapped communication cranes. It is necessary to check if you forgot to open the path for the movement of the coolant, make-up and supply of water before turning on the unit.

- Clogged filter. After turning off the boiler, it is necessary to test the heating filter. If it is clogged with mineral sediment, the coolant does not move because of it. Clean and rinse thoroughly in running water.

- Breakdown of the pump. It is required to replace the device that stimulates the flow of water in a closed system.

- Inoperative three-way valve. It is necessary to replace the device that distributes the flows for heating and the DHW line.

- Broken flow sensor. The appliance that records incorrect readings in the domestic hot water circuit must be replaced.

If the situation is not promptly corrected and the causes are not eliminated, then the consequences can be the most deplorable: from a violation of the tightness of the pipes to the irrevocable breakdown of the unit.

In order not to constantly remove the heating circuit filter for cleaning, it is necessary not to create conditions for the appearance of sediment in the system. The easiest way is not to drain or fill the circuit without real need.

Error Ab. Damage to the heating circuit temperature sensor.

If the temperature sensor that records the readings of the coolant is faulty, the device itself or the electrical connections that supply it with energy should be checked for operability.

They check it in the same way as a gas valve - disconnect one of the contacts when the boiler is off. The appearance of this error on the display after starting the boiler indicates that it is not about it, but about the wiring. By testing all contacts and wires, damage is found and repaired.

Error Ac. Damage to the DHW temperature sensor.

The reasons and their search are carried out in the same way as all these measures are done with a sensor that registers the temperature in the heating circuit. If this error appears when the wire is disconnected, then the sensor itself is intact. Consequently, it did not work due to an open circuit in the electrical circuit.

Temperature sensors register the upper and lower limit of the temperature of the heated medium (heating medium or sanitary water). If the user-defined settings are reached, the boiler is started or stopped.

Error Ae. Malfunction of the air pressure switch.

There are three main reasons for the failure of the pressure switch:

- Clogged channels. Moreover, you need to check both the chimney and the air supply pipe to the closed combustion chamber. In the case of using a coaxial chimney, only it is checked. If detected, the paths of air supply and removal of processed products by the gas boiler should be immediately cleaned.

- Violation of electrical wiring. It is possible that one of the contacts is loose or the wire is damaged.

- Breakdown of the pressure switch itself. If, at a pressure drop of 130 Pa, the device contacts do not close, then it is itself faulty. We'll have to change.

However, in addition to the errors listed above, there are also irregularities in the operation of South Korean boilers, for which codes have not been developed and adopted. Meanwhile, it is very useful to know about them.

Boiler malfunctions without error code

If your Master Gas boiler refuses to turn on, no error code will appear on the display of the remote control or on the electronic board. In this case, it is necessary to check whether the equipment is connected to the mains, whether the socket or the power supply cable is damaged.

If error codes are not displayed on the control panel or on the electronic board, then one of these control devices is faulty. Most often this happens due to the ingress of water.

After making sure that everything is in order with the power supply, but the boiler still does not turn on, proceed to inspect the electronic board. It is possible that water got on it. To dry, it is best to use a hair dryer, after which you need to leave the device for a couple of days so that all residual moisture has completely evaporated.

A blown fuse is also a prerequisite for a sudden stop of the boiler. This part wears out quickly. As a rule, it is subject to a problem-free replacement.

If pops are found in the burner, pay attention to the condition of the gas burner. Usually it starts clapping if serious cleaning is required. This, however, may also happen due to improper adjustment of the gas valve - the minimum pressure will need to be adjusted.

If it is not possible to achieve comfortable conditions at the correct temperature of the coolant, it is most likely dirty or defective temperature sensor. Cleaning is required, if it does not help, replacement.

If there is insufficient output of heated sanitary water from a double-circuit gas boiler, it is worth checking the pressure. It is possible that weak pressure in a centralized system from which water is supplied to the boiler. However, the mud filter on the water supply branch may clog or the secondary heat exchanger - the one called the plate heat exchanger - may clog.

The service representative must regularly clean the gas burner with manifold. Remove dust with a rag, clean off carbon deposits with fine sandpaper, free internal channels from burning

If, entering the house / apartment, you smell an unpleasant gas smell, it means that a leak has occurred. The main thing here is not to lose your head and time. Immediately you need to open the window and open the door to form an air flow, then call the emergency gang. In no case should you turn on the light, strike with matches or a lighter! Any spark will cause an explosion.

Baksi will acquaint you with the decoding of the codes of violations in the operation of the boiler next article, which we advise not only potential buyers to read, but also all equipment owners.

Conclusions and useful video on the topic

Seoul will introduce the following video clip with the rules for servicing South Korean boilers of the Master Gas brand:

The rules and specifics of decoding errors are extremely useful information that allows you to quickly respond to all possible violations in the operation of the boiler. Nevertheless, the owner will have to face all kinds of failures first. It is up to him to decide on further actions.

Do you want to share your own experience in decoding errors of the Master Gas boiler and promptly fixing the problem? Do you have useful information not listed in the article? Please leave comments in the form below, ask questions and post thematic photos.