Gas boilers are simple and convenient to operate, do not cause problems during maintenance, and effectively cope with their functional task. They are bought much more often than electric and solid-fuel counterparts, but not everyone knows that before how to turn on the gas boiler in an apartment or a private house, you need to carry out preparatory activity.

In the article presented by us, you will find useful information about starting a gas unit and the rules for preparing it for the upcoming work. We will tell you about the features of filling the heating circuit with water. We will show you how to enable and select the settings you need.

The content of the article:

-

Launch preparation process

- Features of filling the system with water

- Removing air pockets

- Checking and flushing the system

- Turning on the gas boiler

- Important operating rules

- Conclusions and useful video on the topic

Launch preparation process

The sequence of actions for preparing for start-up depends on the type of gas boiler to be installed. It can be single-circuit or double-circuit, with a closed combustion chamber or open, floor or wall. The first launch is always associated with an increased level of responsibility and risk, so it must be carried out in compliance with all the nuances and subtleties.

The instructions for the gas boiler contain simple explanations, according to which you need to start a specific model. The gas boiler must at this point be connected to the communications in accordance with the agreed project. The first start-up is carried out after connecting the heating system into a single whole and installing equipment, radiators, pipes.

Gas boilers with a closed combustion chamber do not require a large chimney. Also, their positive characteristic is the ability to be located close to the wall with a gap of 2 cm, which saves space in the apartment.

According to fire safety regulations, the gas boiler should be located in places protected from the possibility of ignition, away from flammable objects and materials. In this case, the heating unit should be located at a certain distance from the wall and floor. The exact value of the distance is individual for each boiler and is indicated in the instructions.

Wall models are hung on the anchor so that there is a small gap between them and the wall plane. The installation of the boiler must be carried out strictly exactly at the water level. Equipment distortions and inclinations are unacceptable.

After installing the gas boiler to the wall, it is necessary to connect the device to the cold water supply pipe. To do this, you need to remove the plugs from the receiving pipes.

In addition, a coarse water filter, a mud collector is installed at the inlet of the communications to the boiler, which will protect the internal pipeline of the unit from clogging and sediment deposition. Ball valves are installed on all branch pipes during piping.

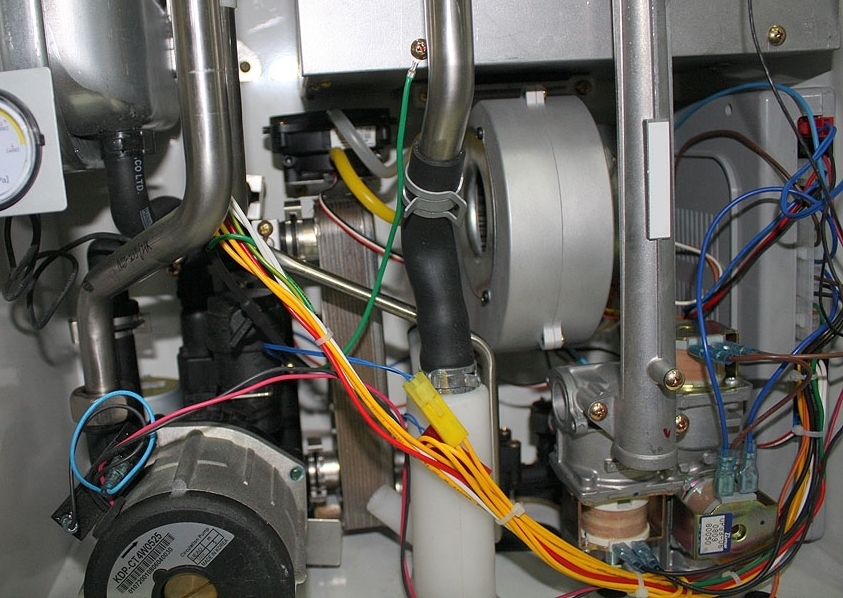

Installing and routing pipes to the boiler is an important task. As a result, the work should be done not only beautifully and aesthetically, but also assume easy access to the key links of the system.

Before starting the boiler, an important step is to lay a gas pipe to it. This work is not carried out independently. We'll have to invite masters from the GorGaz department with which you have a service contract.

Gas workers will calculate the required pipe length, lay it, install a gas meter and seal it. In order for the device to work for a long time and not smoke, you need to take care of the supply of good gas.

Also for a gas boiler, for safety reasons, it is advisable to conduct a separate power line with its own installed machine at the entrance. An outlet should be placed close to the device, at a distance of 30-50 cm from the case. It is imperative to make grounding, it will protect users from receiving electric shocks in case of a breakdown on the case.

Reliable and high-quality pipes are the key to the durability of the heating system. Buy pipes and radiators only from trusted manufacturers. A cheap product in this case will only bring problems.

A boiler installed in a private house is equipped with its own chimney. She should go outside through the wall or through the attic space to the street. The chimneys of boilers in urban buildings up to five floors are connected to a public smoke shaft.

Depending on the specific device, the amount of work required for the chimney changes. Some devices with a closed chamber are also equipped with a pipe for supplying air to the combustion zone.

Upon completion of all preparatory work, the heating system and the boiler itself must be filled with cold tap water. After filling, the system is checked for leaks. Then a remote control panel and a thermostat are mounted on the wall, to which the temperature sensors are connected.

Features of filling the system with water

Before lighting the gas boiler and activating the system, you need to properly fill the heating system and all its elements with water. To start filling the heating equipment and the circuit connected to it with water, the boiler is first disconnected from the power supply. We must also shut off the gas supply.

Next, you need to start up the water by opening a valve or a tap supplying cold water, as well as a make-up tap located at the bottom of the boiler. The exact location of the make-up tap is indicated in the instructions for the device.

The master checking the system must necessarily go around all the rooms along the pipes and radiators and check them for the presence of water leaks. If a leak is found, then you need to shut off the water supply and start fixing this problem.

Before filling the system with water, you need to make an additional bypass of all heating devices and make sure that all connections are tight and tight.

You can drain the water from the system completely or shut off the corresponding link. Then it is necessary to unscrew the leaking pipe connection, drain the water or screw in the plug. After the necessary material and tool are prepared, the plugs are unscrewed, and the pipe is reconnected tightly to the radiator using sealant. Next, you need to check the tightness of the system again.

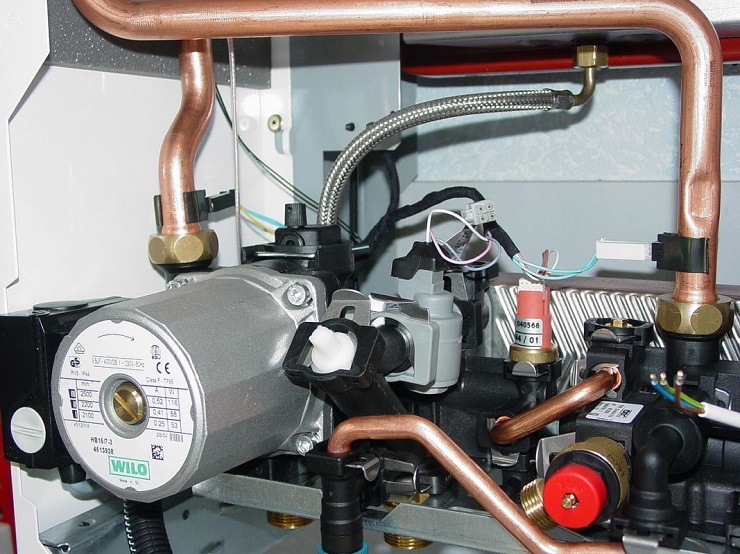

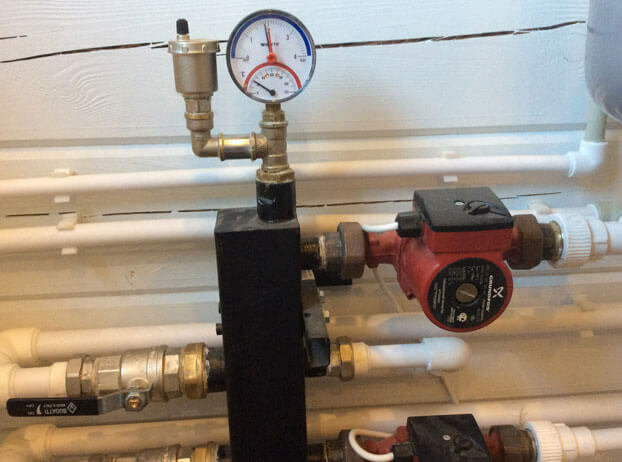

Water intake is accompanied by a characteristic sound. It is important to slowly and gradually unscrew the valve, avoiding sudden movements. If you open the tap sharply, then there is a high probability of air congestion. Simultaneously with filling the system with water, the pressure gauge of the gas boiler shows the current pressure in the system.

The working pressure must be found in the instructions for use of the boiler. When the pressure reaches the working range, you need to stop the water supply by closing the valve. Typically, the operating range of the boiler is a pressure value of 1.5 - 2 atmospheres.

It is recommended to fill the system with water during the warm season. If the outside temperature is freezing, then you should first warm up the room with a portable radiator to about 20 degrees Celsius.

Removing air pockets

At the end of the filling phase, the system must be checked for air locks, bleed off excess air and, if necessary, add cold water. If you do not let off excess air, then the radiators will not heat up enough, since there will be a space in them that is not filled with a heated coolant.

The Mayevsky crane is a simple device that is a needle valve. With the help of it, air is released from the batteries.

For the first start to be successful, you should bypass each radiator with a screwdriver or other tool and bleed the air from the heating devices. Some batteries are equipped with an air vent for this procedure, Mayevsky cranethat can be operated by hand.

The air from the pipe system and the heating devices connected to it is released until water flows out. As the air flows, a characteristic hissing sound is emitted.

For convenience, it is worth preparing a bowl or ladle in advance, into which the water will be drained, as well as a rag, which then gently covers the trickle of water so as not to stain the wall or nearby devices. After the air is released, you need to tighten the radiators so that no water leaks from them.

Modern boilers are equipped with devices that allow air locks to be automatically removed from the heating system. However, such devices do not always effectively cope with the task assigned to them. Therefore, it is often necessary to deflate the air manually.

Having completed the bleeding of air from the closed heating circuit, they begin to fill the space freed from air plugs with water. Without this operation, there will be no working pressure in the system, because it is not sufficiently filled.

To replenish the circuit with water, the unit is connected to the power supply and the make-up valve is opened and the “Power” button is pressed. In this case, the pump should start and the boiler burner will try to ignite. However, after a couple of seconds, the electronics will block all attempts, and an error code will appear on the display, because gas is not supplied to the nozzles.

This procedure will need to be repeated several times. It will be necessary to recharge until all the air is released from the pipes and devices of the boiler, as well as the circuit connected to it. When the stage of filling the system and freeing it from air locks is completed, it is necessary to check the pressure and open the gas supply.

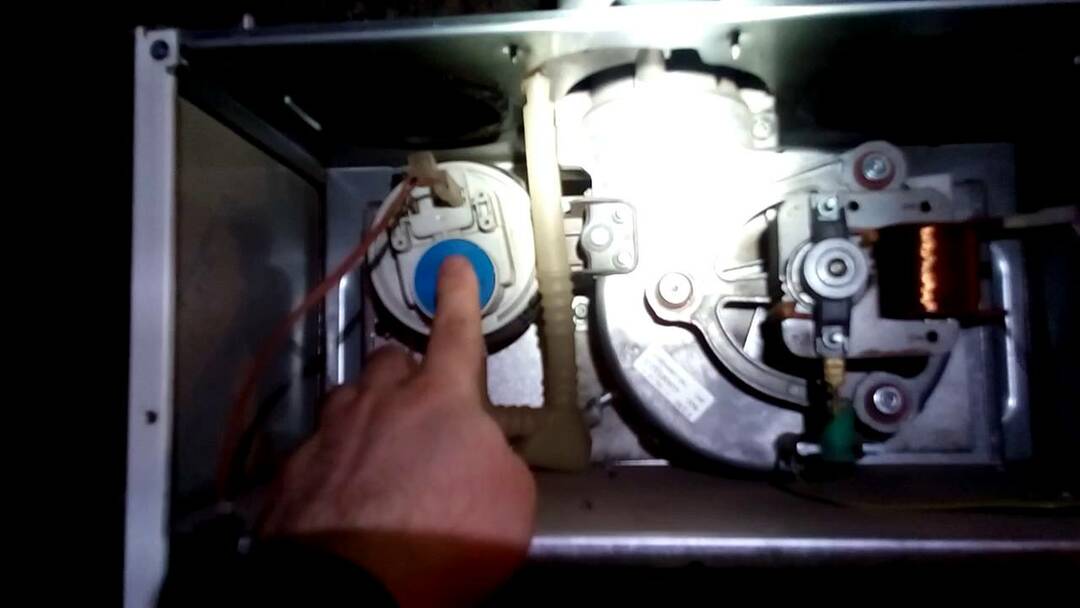

The circulation pump ensures the movement of the coolant. It is prohibited by the manufacturer to independently perform any manipulations with it, otherwise the warranty will automatically expire. In the event of a pump breakdown, they simply change it.

Before firing up the boiler, the gas operator carefully checks the compliance of the connection diagram with the design solution, on the basis of which it was assembled. The technician once again makes sure that the pressure in the system corresponds to the parameters recommended by the manufacturer. Tests the tightness of all communication lines and their connection nodes.

Checking and flushing the system

In order to make sure of the high quality of the work performed and to prevent possible water leaks, plumbers recommend that before starting the boiler, system pressure testing. This procedure will require expensive equipment - a pressure pump. However, there is no need to buy it, so it will only be needed for half an hour to check the system.

Such a device can be borrowed from friends or rented. You can also use the service of an on-call wizard who will independently check the system and correct any problems if necessary.

The purpose of pressure testing is to identify leaks in the system and eliminate them. The system that has gone through this process is guaranteed to serve for a long time and will not fail at the most inopportune moment.

There are two methods of crimping: with a water column or with compressed air. The essence of the procedure is the injection of air or water into the system to establish a pressure level in it above the operating pressure by about one and a half times. After pumping it is necessary to fix the pressure value on the pressure gauge and wait 10 - 15 minutes.

Before pressure testing, it is important to take into account the characteristics of all elements that make up the heating system. In addition to checking the performance of the system, it is also important not to damage its structural elements by excessively high pressure.

If at the end of this period of time the pressure remains at the same level, then the system is considered pressurized and free of leaks. If the pressure has dropped, then you need to identify the place where water seeps out and eliminate this problem. Then carry out the procedure again.

Note that before installing a new unit, flushing of the circuit, which has been in operation for several years, must be done without fail. All manufacturers gas equipment warn that the installation of a gas boiler in an old circuit uncleaned from mineral deposits is prohibited. If the rule is not followed, the owner of the boiler loses the warranty.

This process is carried out in two stages. Initially, a rough flush is carried out. This removes the largest contaminants. The pressure in the system during flushing should be about 3.5 atmospheres. After stirring up the water under pressure, it is released from the system through the drain cock.

This often clogs the coarse filter. It may need to be rinsed once or twice. Fine flushing is carried out using injection pumps.

After finishing flushing, check the coarse filter. It must be uncontaminated. The supply of contaminated water to the boiler is highly undesirable.

After carrying out the preparatory work, you can proceed to launch the device.

Turning on the gas boiler

A prerequisite for warranty service of a gas boiler is the first start-up exclusively by a master from the gas service. If the user follows all instructions and safety precautions during self-start, you can also count on the reliability and durability of the heating system.

The initial start-up of the wall-mounted boiler is carried out strictly after checking the following points.

The first step is to make sure that the gas pipes are tight when the gas valve is closed and open. If within 10 minutes after connecting all pipes the gas flow rate is not recorded, then it can be argued that the system is hermetically sealed.

The gas supplied from the main pipeline must comply with the requirements specified in the instructions for the boiler. When converting the unit for processing a liquefied mixture, the nozzles must be changed in advance.

You also need to check the pressure level in the system. It should correspond to the recommended one. Check the air intake and carbon dioxide exhaust pipes for blockages.

Sometimes users are faced with the problem of poor pump circulation. Low mains voltage is often the cause. This problem is solved by installing a stabilizer

Make sure that the boiler room has a working ventilation system. Additionally, the smoke safety pressure switch is checked.

After carrying out the preliminary work, the boiler start-up procedure follows:

- The gas boiler is connected to the network, the gas supply to the device is opened;

- Check that all valves at the inlet and outlet of the coolant to the unit are open;

- Press the button or turn the switch on the dashboard of the boiler, depending on the method of switching on, specified in the instructions.

You can adjust the temperature using the corresponding buttons. Working in automatic mode, the boiler independently turns on the burner if it is necessary to heat the water in the system. If the boiler is double-circuit, then in the event of hot water turning on, the burner automatically turns on for heating.

It is recommended to adjust all boiler parameters on the boiler display after initial start-up. The instructions usually indicate the sequence of necessary actions.

An interlock system shuts off the gas supply if the burner does not ignite within about ten seconds. At the first start, it may be necessary to remove the ignition lock due to the presence of air in the gas line. It is necessary to wait until the air is displaced by the gas. The lock is released when the device is restarted.

To start a floor-standing gas boiler, you need to carry out the same preparatory procedures as for a wall-mounted one. Before starting directly, you need to ventilate the boiler room, make sure that all the taps on the heating pipes are open and that there is a draft in the chimney. You can check traction with a piece of paper.

There are two options for turning off the floor gas boiler. It is possible to turn off only the main burner or the main burner together with the pilot

Switching on the floor boiler:

- The door of the device is opened, the position of the boiler control knob in the off position is checked.

- The gas supply valve opens.

- The control knob is set to the piezo ignition position.

- Next, you should press the handle for 5 - 10 seconds so that the gas passes through the pipes and displaces the air. The piezo ignition button is pressed.

- Then the presence of a flame in the burner is checked. If the burner fails to ignite, the procedure is repeated.

After the main burner has been ignited, the heating temperature can be adjusted using the control knob.

Important operating rules

In terms of operation, gas boilers with a closed combustion chamber are considered safer. Their firebox does not communicate with room air. However, the power of such boilers is significantly inferior to the power of boilers with an open combustion chamber. Therefore, in private households, the second type of boilers is often installed.

The choice of the future coolant depends on the goals and operating conditions of the system. If frequent shutdown of the boiler is expected, then it makes sense to think about using antifreeze

The operation of such boilers requires compliance with safety precautions. So, for the arrangement of a powerful floor-standing boiler, it is customary to use a separate room with certain dimensions. The boiler is mounted at some distance from the walls. Nearby walls must be protected with fireproof material to prevent fire.

A ventilation system must be installed in the boiler room. There should also be a source of natural light. The width of the front door must be at least 80 centimeters. The chimney is laid in accordance with the instructions for the boiler and is made of heat-resistant material. The chimney should rise above the roof ridge by at least half a meter.

One of the security measures is to establish carbon monoxide sensors. A gas alarm will promptly detect a volatile toxin leak and warn users about it. It can also be configured to automatically turn on ventilation and turn off the gas supply. Modern automation allows you to implement a variety of smart systems.

If the temperature, pressure or gas content sensor is out of order, then you need to immediately turn off the boiler and call the service technician. Using the boiler without these devices is fraught with serious negative consequences.

The requirements of SNiP state that the gas boiler must be connected to the mains by means of a copper pipe or a bellows hose. In this case, a crane must be installed.

If you find signs of a gas leak, you must immediately turn off the gas valve and open the windows to ventilate the room. Do not turn on the light and try to illuminate the room by lighting matches or a lighter.

The gas boiler must be serviced at the intervals specified by the manufacturer. Information on the necessary procedures is indicated in the instructions for the device. For example, you need to clean the chimney, remove scale from the heat exchanger or clean the burner from the burner. Then the boiler will serve for a long time, and the risk of serious malfunctions will be significantly reduced.

When using a gas device, do not turn it on at maximum power for a long time. This can lead to the generation of steam, which is unacceptable.

Sometimes the boiler starts to emit unusual noises and vibrations. This may be due to fan operation. We warn you that all actions for which you have to disassemble the boiler casing automatically deprive the owner of the right to warranty repair or replacement.

However, the owner of the unit needs to control the operation of mechanisms and systems that protect the boiler from fire. It is necessary to maintain the temperature in the circuits at around 50 degrees, which significantly reduces the likelihood of the formation of mineral deposits on the inner surfaces of pipes and devices.

Conclusions and useful video on the topic

How to pressurize the expansion tank:

How to start a gas boiler:

Putting a gas boiler into operation is a responsible and difficult job. In order for the device and the heating system to work for a long time, a number of important requirements must be met. After combining the system into a single whole, you need to check its tightness. If water seeps through the pipe connections, the pressure will constantly drop.

The gas pipe connection also requires a leak check. When turning on the boiler, it is necessary to strictly observe safety precautions, since working with gas equipment involves an increased risk.

Do you want to share your own experience in the field of connecting a gas boiler and preparing it for the first start? Do you have any useful information on the topic of the article? Please leave comments, ask questions, post photos in the block form below.