Are you familiar with the situation when you see an error code and do not even roughly know what it means? Perhaps you always lose instructions for household appliances, and searching for information on the network does not give anything. In this article, we have indicated the errors of Bosch gas boilers, their decoding and the necessary steps to eliminate them. It will not hurt you to remember about it if you also have a Bosch boiler and an error suddenly flashes on its display. It will be good if the article helps you at the right time.

There is usually little space on the displays of boilers, so the problem has to be transmitted with a short code. Thanks to our material, you will be guided in all the main types of errors. You will not be afraid of the simple letters and numbers that appear on the boiler.

The types of errors and how to eliminate them depend on the principle of operation of the gas boiler, its internal structure. In the case of Bosch devices, there are not so many error codes in general, and most of them have been unified for all modern models of this brand.

The content of the article:

-

Error categories for Bosch boilers

- Category # 1 - error codes on A

- Category # 2 - breakdowns in C

- Category # 3 - faults on d

- Category # 4 - device problems on E

- Category # 5 - boiler errors on F

- Other errors of Bosch gas boilers

- Conclusions and useful video on the topic

Error categories for Bosch boilers

Bosch manufactures boilers of various capacities for heating running water, residential heating and underfloor heating systems. Devices series Eurostar produced under a common brand Junkers bosch.

Bosch and Bosch Eurostar boilers give out errors that indicate a particular problem or its cause. It is necessary to distinguish between error codes for devices from different model series under these brands, they sometimes differ. The crashes themselves do not yet indicate a hardware problem.

Boiler control panel Bosch Gaz 6000 W WBN 6000-24C RN: this device was adapted to Russian conditions and this is the first domestic boiler under an international brand, manufactured in Russia

Popular series and models:

- Bosch Gaz 7000 W ZSC: 24-3 MFA, 35-3 MFA, 24-3 MFK;

- Bosch Gaz 7000 W ZWC: 24-3 MFA, 28-3 MFA, 35-3 MFA, 24-3 MFK, 28-3 MFK;

- Bosch Gaz 6000 W WBN 6000-24C RN;

- Bosch Eurostar ZWE: 24-4 MFA, 28-4 MFA, 24-4 MFK;

- Bosch Eurostar ZSE: 24-4 MFA, 24-4 MFK.

In case of an error, you need to find out the reason from its decryption, inspect a separate part of the device and, by its state, determine that the notification did not appear by chance. In the worst case, the owners are waiting for repairs, replacement of parts or the entire device. It should be remembered that ordinary consumers should not touch the parts through which the gas enters the boiler. Most errors pop up not after breakdowns, but because of the working conditions.

Problems in the operation of boilers do not always appear as errors. Difficulties also arise with the temperature of the supplied water. The liquid sometimes gets too cold or hot. Only a gas boiler master will help in this case. If the device is new, then the problem may lie in the wrong type of gas.

Due to unregulated circulation pump sometimes there are inconveniences such as a long heating time and the noise of the water flow. Constant problems with starting the boiler indicate low gas pressure, clogged discharge paths or disruption of the links in the electrical circuit.

Circulation pump for a Bosch gas boiler: this part of the device accelerates the heated liquid through the heating system, due to which the coolant cools down more slowly, the second heating cycle becomes shorter, and the subsequent ones approximately correspond to the second

These are general problems only. Errors by main categories:

- A: A2, A3, A4, A6, A7, A8, A9, AC, Ad;

- C: C1, C3, C4, C6, C7, CC, CE;

- d: d1, d3, d4, d5, d7;

- E: E0, E2, E9, EA, ER;

- F: F0, F7, FA, Fd.

Errors also pop up due to the fact that the wizard did not install individual nodes or did it incorrectly. There is often a problem with the fan stage.

Category # 1 - error codes on A

A2 - there is an emission of flue (waste, waste) gases on the combustion chamber. All you need to do is to see if dirt has accumulated on the heat exchanger, to remove it. This is usually enough.

A3 - the system does not see the NTC flue gas temperature sensor. On the Bosch Eurostar ZWE 24-4 MFK and Bosch Eurostar ZSE 24-4 MFK boilers, the error warns of a short circuit or damage to the traction control fuse. In both cases, check the condition of the connecting (contact) cable and the NTC sensor.

A4 - discharge of waste gases at the flow protector. Inspect the flue gas line.

A6 - no combustion chamber temperature sensor detected. In this case, the contact wire and the temperature sensor of the combustion chamber are checked for damage.

A7 - malfunction of the NTC hot water temperature meter. A short circuit or open circuit could have occurred. Find out what's wrong with the NTC sensor and its wire, replace if necessary.

A8 - no connection to the e-BUS bus. It is necessary to inspect the control knobs and the connecting cable.

A9 - incorrect installation of the hot water temperature sensor. Check the mounting location. Remove the sensor if necessary, reinstall it and add thermal paste.

The hot water temperature sensor is installed using a 15 wrench, in the photo - a device for Bosch and Junkers

AC - module connection error - for boilers Bosch Gaz 7000 W ZWC 24-3 MFK, ZWC 28-3 MFK, ZSC 24-3 MFK. Make sure that the Bosch module or remote control connected to the gas boiler is in good working order, as well as the connection itself and the outside temperature sensor. Troubleshoot problems.

In Bosch Eurostar devices, an AC error indicates a problem with the communication between the connected module and the Heatronic. Check the wire between them.

Ad - the boiler temperature sensor cannot be recognized - in Bosch Gaz 7000 W ZSC 24-3 MFA, ZSC 35-3 MFA, ZWC 24-3 MFA devices, ZWC 28-3 MFA, ZWC 35-3 MFA, Bosch Gaz 6000 W WBN 6000-24C RN, Bosch Gaz 7000 W ZSC 24-3 MFK, ZWC 24-3 MFK, ZWC 28-3 MFK.

In Bosch Eurostar ZWE 24-4 MFA, ZWE 28-4 MFA, ZSE 24-4 MFA, ZWE 24-4 MFK, ZSE 24-4 MFK devices, the Ad error indicates a damaged NTC temperature sensor in the tank. In both situations, check the contact wire and the temperature meter itself.

Category # 2 - breakdowns in C

C1 - opening of the differential pressure switch during operation. Inspect relays, connecting pipes and exhaust hood. In Bosch Gaz 6000 W WBN 6000-24C RN boilers, a C1 malfunction means a low fan speed. In this case, check the mains voltage and flue gas ducts. The latter sometimes have to be cleaned and repaired.

C3 - corresponds to the above error A2.

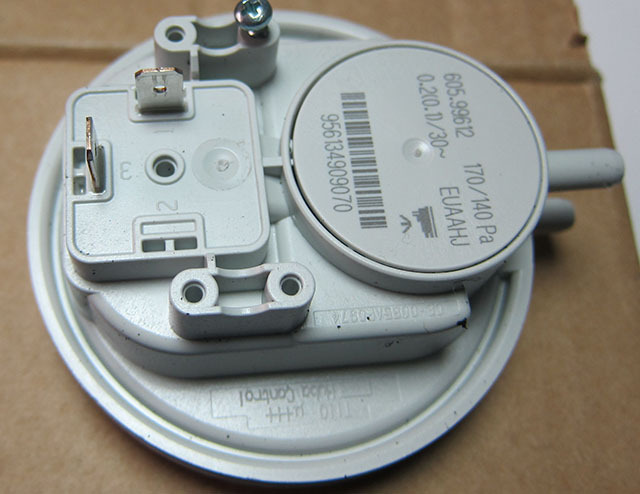

The differential relay operates in 2 modes: at normal pressure, the diaphragm does not change position, but if the system malfunctions, the membrane bends and all heating equipment stops work

C4 - the differential relay does not open when the fan is off. We need to see what happened to the relay.

There are two ways out of the situation:

- Remove the relay and blow through the tubes that come from it.

- Determine with a multimeter if there is a short circuit, an open circuit, or a mismatch with the resistance rating. Replace relay if required.

C6 - the pressure switch does not close. Look at the device itself and the flue gas elimination system. Remove the relay and remove the condensation from the pipes with a hair dryer. Do open and short test. Remove excess from the chimney. It can be frost, ice, etc.

C7 - the fan does not work. Check this device, its wire and plug.

CC - no external temperature sensor found. In the Bosch Eurostar series boilers, the CC code indicates an open circuit of this temperature sensor. Look for damage and possible breakage of the meter and contact cable.

CE - the pressure in the heating system is too low. If the pressure gauge indicates a red area, add water through the make-up valve. If the gauge needle is in the green area, there is a problem with it. Sometimes the problem occurs in the diaphragm or microswitch.

Category # 3 - faults on d

d1 - there is no response signal from the LSM sensor (safety position sensor). Look for the problem in the wires coming from the LSM. Inspect the floor heating limiter.

d3 - no jumper 161 on ST8. Find out if there is a jumper. If so, also inspect the external stop and insert the plug correctly.

The scheme of operation of the floor heating regulator-limiter: this is how the temperature in the circuit is controlled, and if the limiter breaks, then the boiler efficiency will decrease, and in winter time the risk of appearance condensate

d4 - excessive temperature difference. Check bypass valve and pump, deal with the pressure in the boiler. The return flow temperature can be much lower than the flow temperature, which can cause problems in the operation of the device. The boiler issues an error so that condensation does not form later, there are no breakdowns and failures.

d5 - defect in the external temperature sensor. Check the meter as well as the connection wire.

d7 - error in the control valve. Determine what is wrong with the regulator. Make sure the connecting cable is in order.

In the Bosch Gaz 6000 W WBN 6000-24C RN model, a malfunction code d7 indicates a faulty gas valve. Look into it and replace it if necessary through the gas industry. It could also be about the connecting wire.

Category # 4 - device problems on E

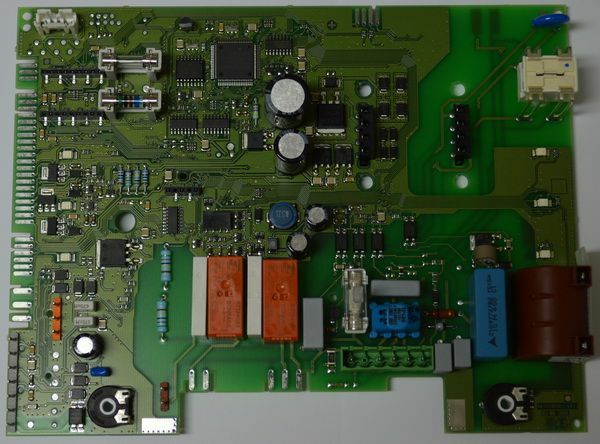

E0 - a problem inside the printed circuit board. Inspect electrical contacts, replace defective board.

E2 - the temperature sensor in the flow line does not work. The error is also referred to as a problem in the NTC feed line. Call the temperature sensor for open circuit, short circuit and other faults. Examine his cable. Clean the oxidized wires and connect them if the circuit is broken.

The printed circuit board may break after a thunderstorm, and in this case, replace individual microcircuits and a double diode in the harness, in the image - a board from a Bosch boiler

E9 - the temperature limiter has been triggered.

Do some of the following:

- Check the connections to the board for oxidation and mechanical damage. Clean and connect the wires if necessary.

- Inspect the heat exchanger temperature limiter. Make sure its wire is intact. Replace items if repair is not possible.

- Do the same for the flue gas temperature limiter. The problem may be bursting or melting.

- See if the system pressure has dropped. Fill with water until it returns to normal.

- Evaluate the pump performance by starting. He could just be jammed. If the problem is serious, replace pump.

- Inspect the fuses on the board and power supply cover.

- The boiler may have drawn too much air. Delete it.

- Inspect the heat exchanger water circuit. Descale and restore throughput, flush the heat exchanger.

EA - no flame detected when switched on.

EA is one of the most common mistakes, which is caused by many factors, but cleaning the ignition and control electrodes, for example, with fine-grained sandpaper, may be enough to eliminate it.

We'll have to work out a lot of options that cause this error:

- Take a look at the position of the gas valve. Open it all the way.

- Determine the fuel pressure if the error persists. In case of non-compliance with the standard parameters, contact your boiler technician or gas service.

- Check the mains voltage. If the indicator is below normal, it will help Voltage regulator or autotransformer.

- Inspect the mechanical contacts of the wires. Strip them and connect.

- Free the chimney from clogging and dirt. Find out the concentration of carbon dioxide. Check serviceability.

- Clean the soot from the ignition electrode. Straighten it if bent, and set it according to the requirements in the instructions.

- Ring the gas monitoring sensor with a multimeter for an open or short circuit. Repair or replace.

- Remove limescale from the heat exchanger.

- Check the condition of the gas valve. A complete inspection, repair and replacement must be carried out by a gas operator.

- Inspect the electronic board and replace if there are no other options.

In the devices of the Bosch Eurostar line, the EA designation indicates the absence of an ionization current. Examine the ionisation electrode and do other steps above.

ER - the boiler does not work correctly. Check all units of the device and repair them in case of malfunction.

Category # 5 - boiler errors on F

F0 - in Bosch gas boilers, it means a malfunction inside the device. Check the condition and tightness of the plug contacts and wires to the electronic board. If the connections are broken or oxidized, repair the board. If not, it should be replaced.

If you took out the board and identified the problem in it, then take it to the service center - the tracks will be restored there and the parts will be soldered

F7 - when the boiler is off, a flame is detected.

Take steps like this:

- Clean or replace electrodes.

- Check the connecting wire.

- Make sure that the gas exhaust ducts are in good condition. Remove dirt. Repair the system if necessary.

- Check the moisture content of the board. Dry her.

In boilers of the Bosch Eurostar ZWE and Bosch Eurostar ZSE lines, this error warns of an incorrect ionization signal. Tears and cracks can occur between the cable and the ionisation electrode - check this. Look for moisture in the Heatronic junction box.

FA - after shutting off the gas supply, a flame was detected. Inspect and, if necessary, replace the gas fittings and their wiring. But not on your own. Check electrodes and connecting cables. Also inspect the gas exhaust channel, clean, repair, if necessary.

In Bosch Eurostar series boilers, the FA code indicates that when the regulator is turned off, the ionization current is maintained. It is worth looking at the gas fittings and their wiring, the ionization electrode.

Fd - pressing the button for too long. The error pops up after half a minute of continuous holding of the button. Press it again and do not hold it for more than 30 seconds.

Other errors of Bosch gas boilers

These are not core codes and do not fall into the main categories. Occur in all or only in specific models.

11 - corresponds to the above error E9. Occurs on the Bosch BWC 42 boiler.

Professional flushing of the heat exchanger: prevention of the E9 error includes flushing every 2 years to maintain the boiler efficiency, and you will need a 20-liter container and flushing solution for this

50 - there is no flame. Appears on boilers Bosch Gaz 4000 W ZWA 24-2 A and 24-2 K.

Follow these steps:

- Inspect and repair the security cable.

- Open the gas cock to the maximum.

- Determine the gas pressure in the line. If there is a discrepancy with the nominal indicator according to the passport of the device, call the gas service.

- Check if there is voltage, if it is within the normal value.

- Look in the chimney and clean it if necessary.

- Test the throttle setting at the minimum and maximum levels. Adjust according to instruction tables.

- Check the gas control relay and replace if necessary.

- Inspect the gas fittings for external damage. Do not test, repair or replace it. Let it be done by a gasman or a gas boiler master.

- Clean and flush the heat exchanger.

70 - breakdown of the differential relay at startup. The most common cause of this error can be problems in the relay itself. Inspect its condition, determine the resistance. Change to a new one if the resistance does not match the nominal.

There may also be mechanical damage to the wires and contacts going to the relay. If so, then you need to restore the connections. Another reason may be incorrect setting of the fan or its failure. Reconfigure the device. Doesn't help - repair or buy a new one.

b1 - no coding plug found. Insert it correctly. If the error persists, ring the plug and replace if broken.

P - it is impossible to determine the type of boiler. Set its type.

A coaxial chimney can have a complex pattern due to an electric blower, but according to general requirements for high-quality operation, its total length should not exceed 4 meters

se - the heating system is not full enough. Add water and check the result. The error also appears due to depressurization of heating pipes and leaks. Reduce the heating temperature and find the problem area. Seal the joints and seal the leak points.

This will not work with hot pipes - a small amount of water will evaporate quickly. If the heating pipes are ok, remove and clean the heat exchanger.

There is also code 23. This is not an error, but an indication of the type of gas used.

Conclusions and useful video on the topic

Eliminating similar errors C4 and C6 and installing a filter to collect condensate:

Quick video tutorial to fix EA error:

What to do if the pressure in the heating system drops, setting the expansion tank:

Identifying the fan problem and solving it:

We examined the errors of different Bosch boilers sorted by the first letter, as well as other codes that sometimes pop up on displays. Before correcting the problem by the code, try to reconnect the device, look at the position of the taps and control levers. It didn't help - disassemble the device and proceed step by step as required by the instructions.

An old Bosch gas boiler may need professional repairs, despite the reliability of this technique in general. Only certified technicians and gas workers have the right to touch gas pipes.

Ask questions and leave comments on the topic of the article. Write which gas boiler you use and whether you are satisfied with the operation of the device. Tell us about the breakdowns, if any, indicate your steps in solving the problem. The contact form is located below.