BaltGaz is an exemplary brand producing comfort and premium gas appliances with a high class of reliability. All of them are equipped with high-tech features and protection, and have a large number of accessories and spare parts. But just like any other devices of this type, boilers from the Baltgaz company can show malfunctions over time. Fortunately, for the convenience of diagnosing problems that arise, they have an automatic recognition of system weaknesses and errors of Baltgaz gas boilers are displayed on the display in the form alphanumeric codes.

Programmed diagnostics using sensors helps to quickly identify weak areas of devices and eliminate malfunctions as soon as they occur.

Do you want to know how to deal with these codes, which will seem completely incomprehensible to many? We will help you and tell you what these letters with numbers are and how to correctly decode the codes of BaltGaz gas boilers.

The content of the article:

-

Errors of BaltGaz boilers

- Problem number 1 - difficulties with ignition

- Problem # 2 - heat exchanger malfunctions

- Problem # 3 - incorrect traction

- Problem # 4 - electronics failure

- Problem number 5 - irregularities in the temperature sensor

- Other boiler malfunctions

- Error codes archive

- Videos and useful conclusions on the topic

Errors of BaltGaz boilers

The decoding of error codes for gas boilers "Baltgaz Turbo" is in any instruction manual. However, if your manual is lost, damaged, or there is some other reason why you cannot look into it, use our recommendations.

It is not worthwhile to eliminate errors that require intrusion into the boiler zones subject to warranty repair before the boiler warranty expires, otherwise you will be denied a free service.

Immediately, we note that only those errors are subject to self-elimination that you can cope with without disassembling the boiler and without changing spare parts for it.

Repair of gas-using equipment has the right to be carried out only by an employee of the gas service or the company with which it is concluded maintenance contract gas equipment.

Problem number 1 - difficulties with ignition

If you see on the display error E01 - this means that you have problems with firing up the boiler. The ionization sensor, which monitors the ignition control, signals this to you. You have already guessed that there is a malfunction, when an attempt to ignite the device did not bring results. But with the help of the error, you can identify possible causes.

No fuel is supplied to the burner at all. Look to see if the shut-off valve on the pipe is blocked and, if so, turn it to the "open" position. Do not forget to bleed the air from the system when starting up the device for the first time.

Pay attention to the recommended pressure - 18-20 mbar. If everything is in order on the line, test the pressure adjustment on the nozzles according to the instructions for use of the device.

Another common reason is a breakdown of the gas valve and in the event of such an incident, the element should be replaced.

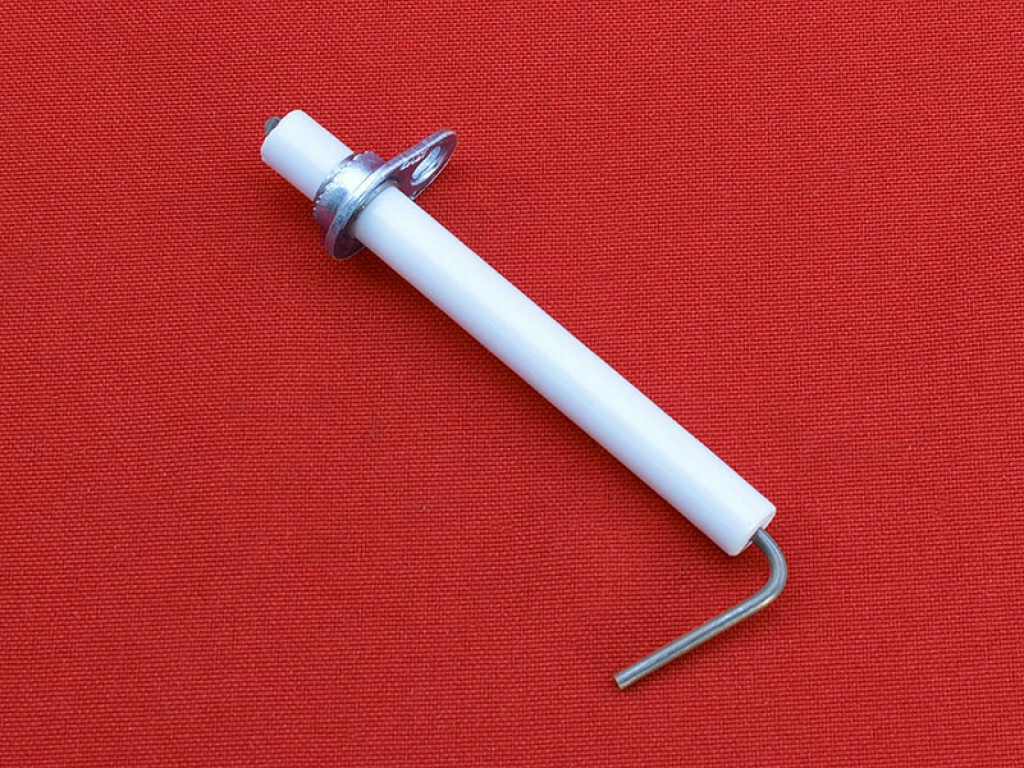

E01 is often observed when the ionization electrode malfunctions during ignition. It may be dirty (wipe and degrease) or it may be defective.

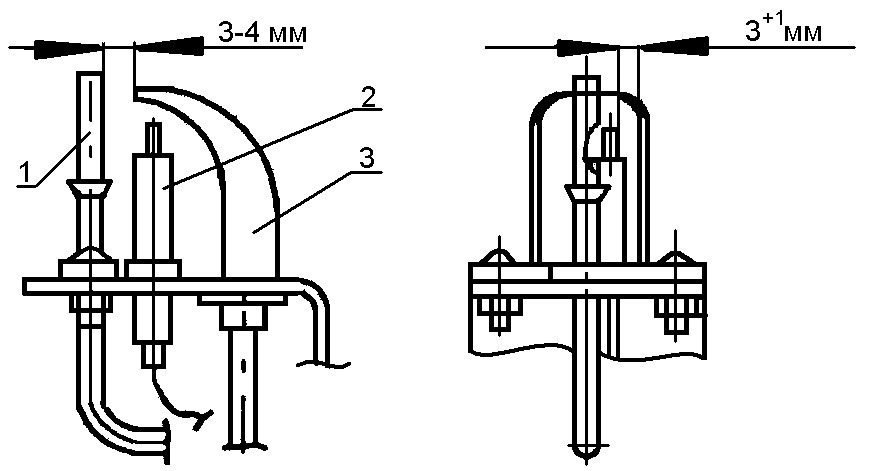

The cause of problems with ignition may be the wrong distance between the ionization electrode and the burner, which makes it easy to set and correct the distance (3 + 1 mm)

When there are problems in the gas valve coils, this indicates a possible short or open circuit requiring valve replacement. But it can also start to stick.

If the ignition power is not satisfactory, use the settings to correct it.

Burner block clogging requires cleaning, instructions for the implementation of which are usually found in the manual.

If the ignition transformer is faulty, you should consider replacing the electronic board. The same is true in the event of a breakdown. But if the board sees combustion, but it actually does not exist, you need to inspect the ionization electrode, or rather, its wiring, for damage or possible breakage.

The boiler also contains an element such as a thermostat. This is an overheating sensor. If its operation is disrupted, ignition will be impossible, therefore, it is necessary to carefully check the electrical circuit and all contacts.

Error E01 is accompanied by K1. That is, after correcting the malfunction, it must be pressed. It has 2 functions - selection of the information mode and the function of manual reset (RESET) blocking.

E02 signals that a false indication of combustion has been carried out due to blocking. At the same time, the boiler does not work.

First of all, check the electrical circuit of the electrode and the contacts from its connection. If the element itself is defective, it is recommended to replace it.

As with the E01, an incorrect gap between the torch and the electrode can also cause an error on the display. To eliminate, the actions are similar - it is necessary to set the gap (3 + 1 mm).

You should not rely only on instructions from the Internet if a boiler breakdown requires special knowledge. It is best to invite a specialist to diagnose and repair emerging faults

If the grounding is broken or a potential arises between the ground and zero, E02 will "tell you" about it. The correction is logical, correct the grounding and remove the potential.

After completing the repair, also press K1.

Error with code F02 reported directly with error E02 and also indicates parasitic flame.

This starts:

- violation in the chain communication of the electrodes;

- malfunction of the electrodes;

- incorrect setting of the gap between the torch and the electrode;

- poor grounding and potential between ground and zero.

It is a prerequisite for the appearance of the E02 error.

At E08By the way, you don't need to press K1. But the error is no less important in its significance. Consider what it signals and how to fix it. When this code occurs, a failure of the flame circuit occurs, that is, its level is outside the normal range.

We look at the electronic board. The reason may lie in its malfunction.

As always, first of all, we check all the contacts and the electrical circuit of the electrode, as well as the element itself and, if necessary, change or clean it.

Then, you should check the gap between the burner and the electrode and, if necessary, set its optimal values according to the passport (3 + 1 mm).

Designations: 1 - thermocouple, 2 - piezo electrode, 3 - igniter. The ignition block is a device in which the igniter, thermocouple and spark / ignition plugs are fixed. To ignite a flame in the boiler, it is necessary to maintain a gap between the ignition electrode and the burner of 3 + 1 mm.

Error with code E09 means that the feedback of the gas regulator does not match the commands coming from the electronic board of the device.

There may be 3 reasons:

- Violations in the contacts and the electrical circuit of the regulator.

- Problems with the electronic board.

- Damage to the regulator itself.

If you yourself cannot diagnose and fix the breakdown, call a service specialist.

Error E82 denotes frequent flame extinguishment. This usually happens in a row with short breaks. The problem may be the failure of the electronic control board, as well as in many other cases.

What can be done:

- completely change the electronic board to a new one;

- try to contact a repair service;

- restart your heating unit, sometimes such problems are one-time and fix themselves.

There is one more possible reason, and it lies in the settings, when the minimum boiler power is set incorrectly.

Sometimes there is an accidental failure in the electronic module of gas boilers, which is recorded as a system error. With almost every error, except for violations of traction, leaks and power supply, you can simply try to restart the boiler. If the error repeats, then the boiler definitely needs repair.

Here it is even easier to correct the situation, just look at the manual and set up the boiler according to the manufacturer's recommendations. If you have not preserved your passport, you can download almost any instruction via the Internet.

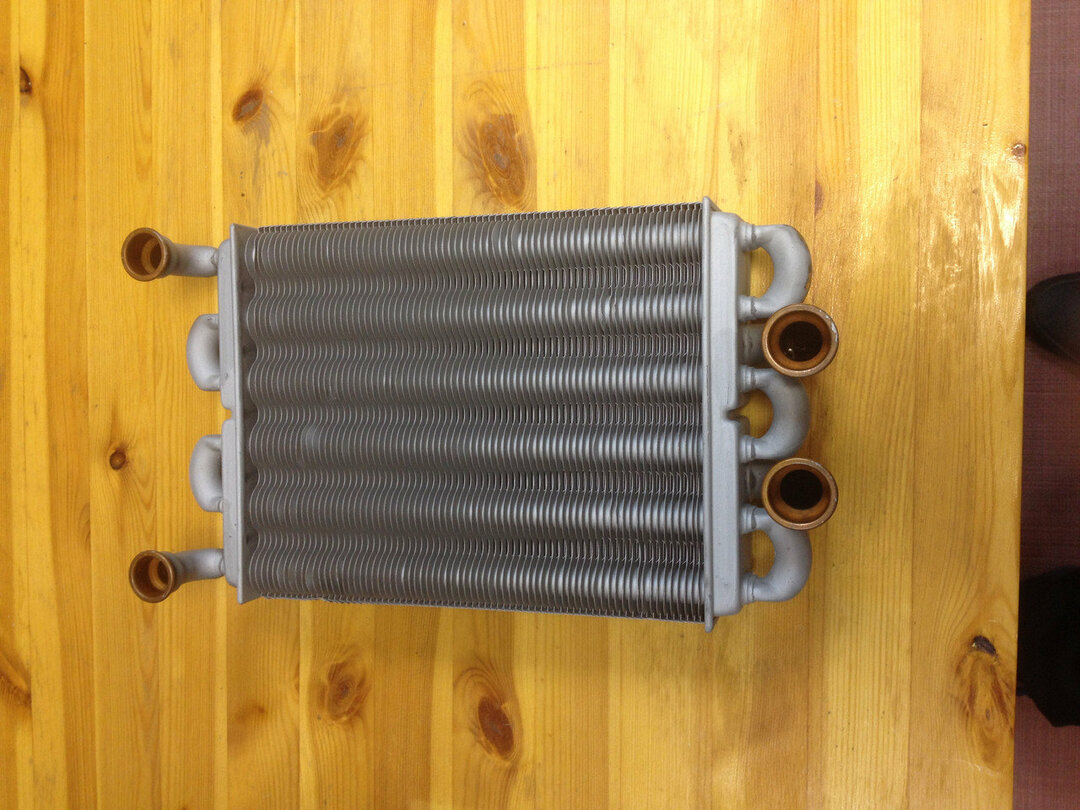

Problem # 2 - heat exchanger malfunctions

Error with code E03 will prevent the boiler from working. Such malfunctions of gas boilers of the Baltgaz company mean overheating of the coolant. This is due to a number of possible reasons. In general, it looks something like this.

The safety thermostat is usually 105 degrees. The nozzle goes out as a result of the increase in temperature, but the heat exchanger continues to heat up. If, after 10 seconds, the temperature rises beyond 105 degrees, the boiler will shut down for a short time.

The overheat thermostat, located at the outlet of the primary heat exchanger, will perform its function and send a signal to the control board. Therefore, if there is no efficiency and the temperature drops to 100 degrees, an error will appear.

For example, you will see such a code when blockages appear in the system or heating filter, which must be cleaned to eliminate the error.

Do not forget to check the thermal relay, and if necessary, replace it or ensure its high-quality contact with the control board.

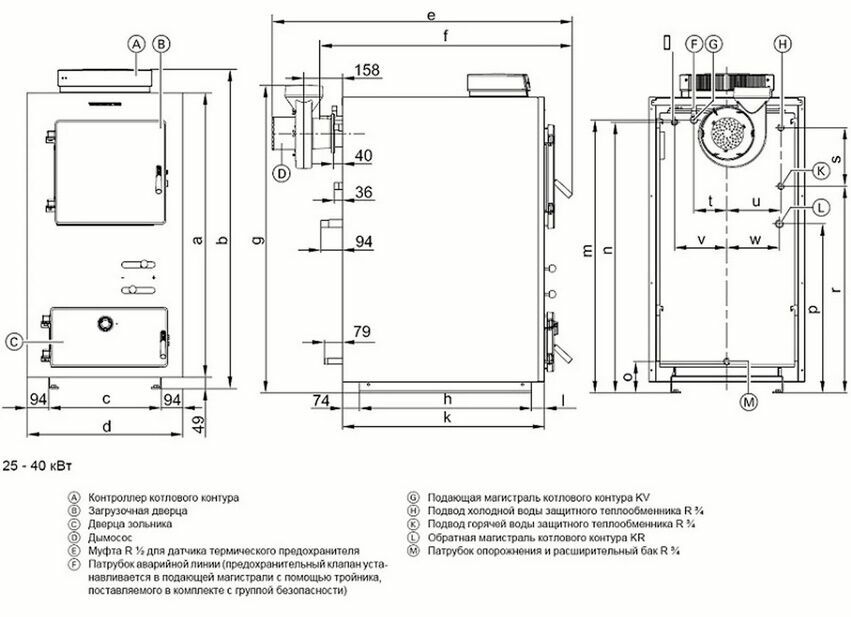

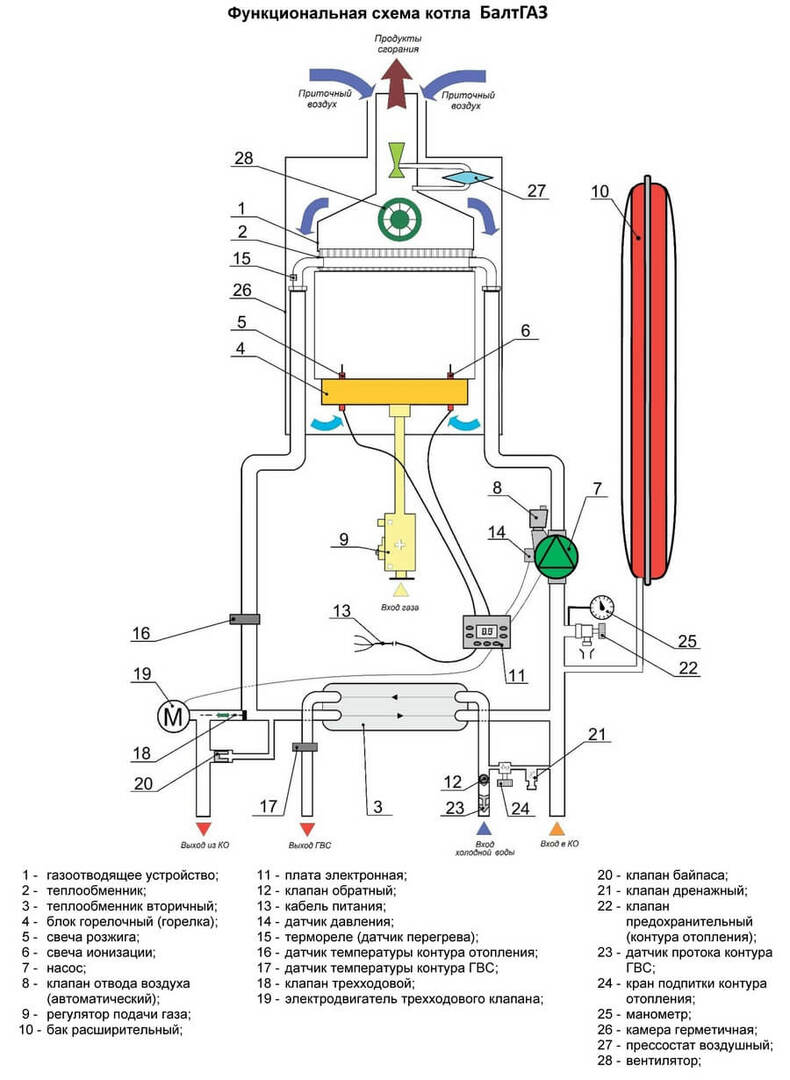

Before eliminating possible malfunctions, you should carefully study the gas boiler diagram, which is in every passport. But in general, it is recommended to entrust global repairs to specialists, especially since such work cannot be performed without a special permit according to the law.

Still haven't found the reason? Then pay attention to bypass valvewhich may be defective or incorrectly installed. It needs to be replaced, just like a pump or an air exhaust valve needs to be replaced if the reason is their breakdown.

Failure and malfunction of the electronic control board is suitable for many errors. Including this one. Accordingly, the board is usually changed, it is possible to repair it in rare cases.

As in error E01, there may be an open circuit in the overheating sensor electrical circuit. Pay attention to this probability and examine everything carefully. And, of course, don't forget the K1 button. In this case, it is also relevant.

Error E70 also leads to blocking of work, and requires a subsequent reset to K1.

The error means that the heat exchanger is frozen, which occurs mainly in the event of a prolonged power failure. The error is easily prevented by the presence uninterruptible power supply, but if you do not have it, you will have to turn off the power supply to the device, turn off the gas supply on the pipe and then defrost the element.

When the temperature of the coolant in the heating system is less than +3 degrees, the pumping equipment will turn on for 3 minutes. When the boiler burner is running, it will turn off and ignition will not take place. In the case when, after this time, the coolant warms up by 1 degree, the operation of the boiler will be restored, if not, it will be blocked with an error

When propylene glycol is used as a heat carrier, it is necessary to set a zero value for this function in the parameters, according to the recommendations in the passport of the device.

Error with code F37 helps to determine that the coolant pressure in the system is too low. And the first thing you need to do is measure it and correct it to the recommended value.

The pressure switch monitors the minimum pressure of the coolant and the exclusion of airiness in the heating system. If it breaks or faulty connections, error F37 may appear on the display.

Other possible reasons:

- air locks;

- a problem with the pressure sensor;

- faulty electrical circuit leading from the pressure sensor to the board.

As always, we check all the specified parameters and troubleshoot.

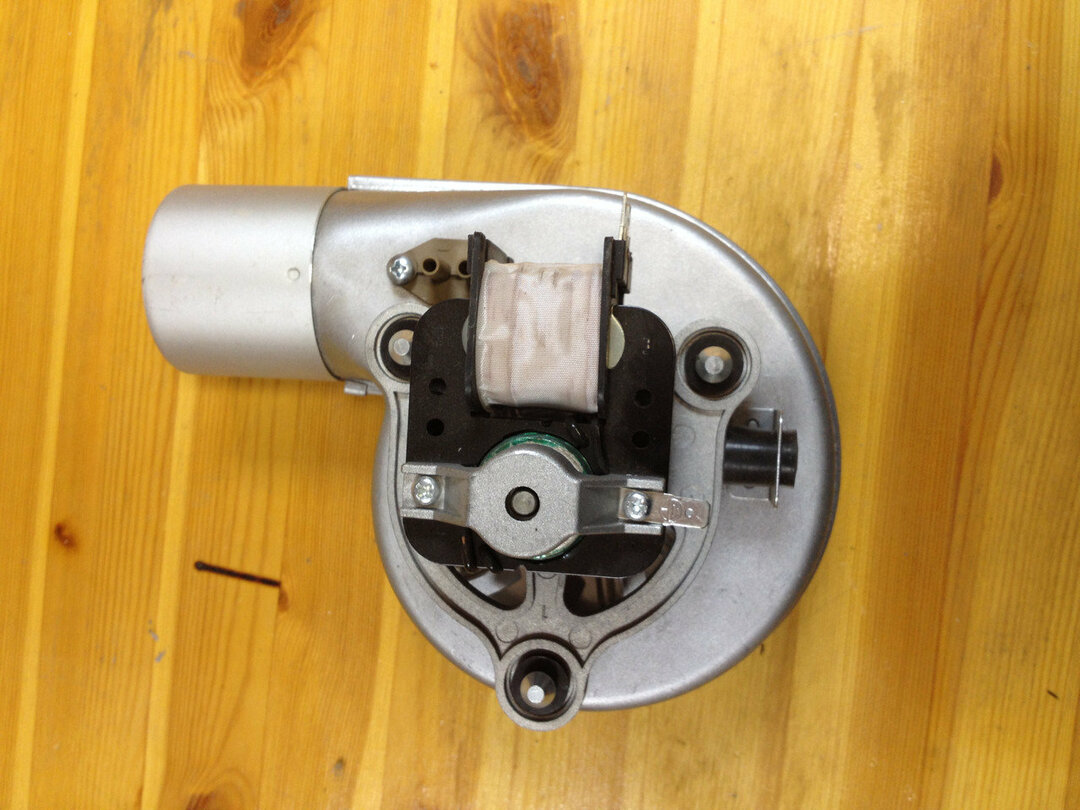

Problem # 3 - incorrect traction

Errors with codes E04 and E05, stem from blocking F23 and mean that you are bad with traction. In order for the boiler to work correctly, as you know, it needs to provide good draft, which facilitates the removal of flue gases.

If they come out poorly, carbon monoxide will get into the room, which is very dangerous. In modern boilers, this is monitored by special traction sensors and if it is not enough, they will give a signal to the board and the unit will automatically shut down.

First of all, the reason for this error is in the chimney. If its diameter is unacceptable, or the device is not mounted correctly, is clogged or ice has formed in it, of course, the thrust will not be good. This is also influenced by the length of the chimney.

Elimination of errors E04 and E05 associated with the chimney system should be carried out according to the manufacturer's recommendations. How to correctly install the chimney on a specific appliance you will find in the instructions for the gas boiler

Of course, the solution here is obvious - replacing the chimney if necessary, or cleaning it, as well as deflector installation. But these are not all possible reasons.

Also, this error indicates problems with the pressure switch, most often, the closure of its contacts, which must be checked and, if necessary, replace the pressure switch or connect it correctly. If the tightness of the pressure switch tubes is broken, change them. Do not forget to inspect the electrical circuit as well.

If elements such as the fan and the electronic board are faulty, it is likely that they will also need to be replaced.

Errors E04 and E05 differ in that in the first case there is usually a closure of the pressure switch, and in the second it is jammed. And with E05, do not forget about the lock, which must be removed by pressing К1 RESET.

E06 value very similar due to blocking with E04 and E05. That is, there is also no traction.

The steps to check and troubleshoot are the same:

- check the electrical circuit and contacts (replace if necessary);

- inspect the fan;

- diagnose the pressure switch;

- ring the control board.

E07 - still no traction. But this time the problem with the ventilator takes the main place in the symptomatology.

When an E07 error appears, it is recommended to carefully inspect the fan, all its connections, impeller, shaft and other elements. Unfortunately, most often a malfunction requires the replacement of this part.

What malfunctions with this element can be:

- the control board is junk (if necessary, it will have to be replaced);

- the fan has broken down - damage, lack of lubricant for the shaft, clogging in the impeller;

- the electrical circuit is broken.

Well, do not forget about unblocking K1.

Error with code F23 accompanied by a complete violation of traction, its absence. First of all, the pressure switch is checked and, if it malfunctions, they must be replaced. Then they look through all the electrical circuits and contacts, and then the main elements - the fan, the electronic board.

Problem # 4 - electronics failure

E09 and F25 - it is always the replacement of the electronic board due to an error in its internal memory.

Be careful! On the Internet and in many ordinary stores, supposedly universal electronic boards are offered for purchase. You should buy special ones designed for specific devices and only in the absence of the necessary spare parts, you can consider other options and then, under the supervision of a specialist

By the way, please note that blocking does not occur, that is, you do not need to press K1 after troubleshooting. But the boiler still does not function in the period after the detection of this malfunction. F25 indicates a failure of the internal ROM and EEPROM memory.

E21 again, it is associated with the electronic board and indicates an error in checking its components. Unfortunately, in the event of a malfunction, you will have to change it, you can only hope that the problem is in the electrical circuit or contacts.

The good thing is that Baltgaz produces spare parts for its gas boilers and they are easy to purchase in ordinary or online stores.

F13 also referred to as remote reset interlock. It is necessary to disconnect the power supply to the device and restart it after turning it on.

F22 indicates a voltage surge of 170 - 250 V. To restore the boiler operation, it is necessary to adjust the voltage.

In general, such work is difficult to carry out without having any experience in handling gas-using equipment. It is best to call a foreman from the service department or a specialist from the supplier's GDO.

Problem number 5 - irregularities in the temperature sensor

F31 and F32 - failure of the heating circuit temperature sensor.

The error can be temporary and after 5 seconds your boiler can resume operation again, but just in case, check if there is any condensation on the sensor connector with the controller. If there is no moisture and the boiler does not start by itself, it is recommended to replace the sensor.

F31 arises due to open circuits in the element connection circuit, when the sensor no longer contacts the electronic board or the temperature readings differ from the recommended parameters.

But there is one more reason - a short circuit on the sensor if the temperature rises above the recommended one. To check, you need to measure the resistance of the element, and all the specified parameters are in the manual. Usually, in this case, a new sensor is installed, if it did not work out, pay attention to a failure in the control board.

The F32 code is also associated with a thermal sensor, only external, remote, if it is installed in the system. Regardless of everything, the boiler works actively for heating. The reasons are a malfunction in the electrical circuit, a breakdown on the board or the sensor itself. It should be noted that the error will be removed automatically and the unlocking will not need to be performed after the problem has been eliminated.

Other boiler malfunctions

In addition to the code settings, there may be problems that are not fixed on the display.

If you smell gas, it is necessary to shut off the burners not only on the Baltgaz boiler, but also on the gas stove and close the shut-off valves on the gas pipelines. Then call 04

The boiler does not turn on at all.

Possible reasons:

- There is no power supply. Check if the line is de-energized and energized. No - contact your electricity supplier to find out the reasons and timing of the outage.

- Also, a fuse in the board could have blown, and in this case they simply install a new one.

- If the reason lies in the fact that water got on the board, try putting it on natural drying for 48 hours until the moisture completely evaporates.

- The boiler does not start even if the control board fails. Try restarting or replacing this item

If the actions have not brought any positive result, there is only one way out - contact the service center.

If you cannot light up the boiler, first of all, pay attention to whether you forgot to open the gas supply valve located on the pipeline leading to the boiler.

The burner makes strange sounds like popping:

- Insufficient air supply occurs when the duct is clogged, improperly installed, or for other reasons.

- A spark flies past the burner.

- The burner is clogged.

There is no hot water or insufficient pressure. Check filter, heat exchanger and flow restrictor for blockages.

The device does not heat the room, but at the same time it functions in the DHW mode. The problem may be associated with jumpers, a malfunction of the thermostat and temperature sensor, or simply with incorrectly set temperature parameters.

The heating medium at the inlet is too low. Check the set temperature and temperature sensor.

The pressure in the heating system is too low. Inspect the system for possible leaks, inspect the gauge for correct operation, clean / replace safety valve.

Error codes archive

You can see the archive of errors and blockages on the boiler.

Error codes appear on the display of the Baltgaz gas boiler. Pay special attention to the K1 button through which the blocking that occurs after some errors and to other buttons with the letter "K", which will be used not only to control DHW and heating, but also to navigate through the settings, for example, access to the archive mistakes

Unfortunately, the error archive is not provided for all models of gas boilers.

To access the archive, proceed as follows:

- Plug in the gas boiler.

- Press the "reset" button (K1). Hold it for 10 seconds to activate some functions of the boiler.

- Using the K5 and K6 buttons, you need to get into the H1 archive.

- When In appears on the display, press K1.

- To select the item you need in the archive, navigate the menu using K5.

- After selecting the desired parameter, you must press K3 (or K4).

To exit the archive, you need to either press K2 or wait 2 minutes for automatic exit in idle.

The error archive is needed to diagnose the "illness" of the boiler by the specialists of the service department or in the event that you are not at home at the time of the appearance of the code, when no one else has fixed it.

Videos and useful conclusions on the topic

Brief overview of the BaltGaz-Neva gas boiler, inspection, possible malfunctions and maintenance:

Thus, repair or diagnostics of the Baltgaz gas boiler will not bring much trouble to the owners. Most of the most common faults will be almost instantly captured by the appearance of an alphanumeric code on the display. At the same time, many of them are easily eliminated with the help of automatic functions, which can be started using the manual for the device.

Have you installed a Baltgaz boiler at your home? Did you get error codes and how did you deal with them? Share your experience in the comments and ask questions of interest on the topic of the article.