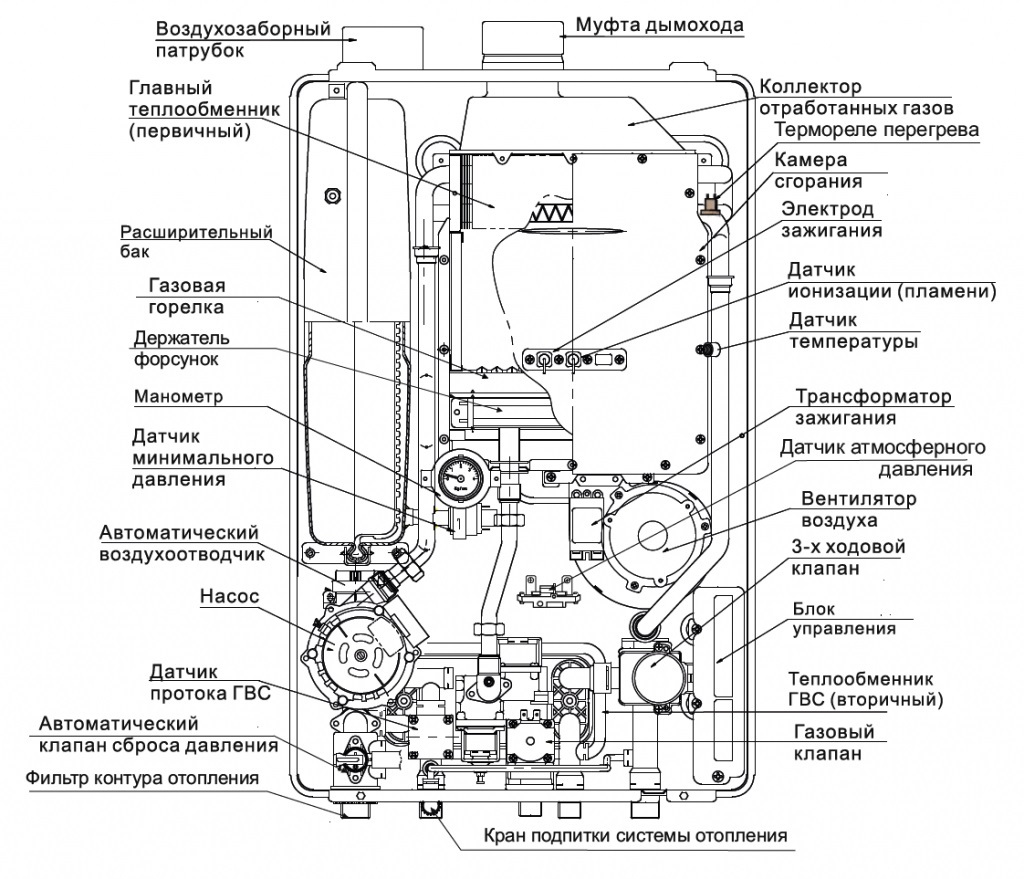

Failure of heating system units usually occurs at the most inopportune moment. At first glance, a gas boiler is a very complex device that can only be repaired by a trained gas service technician with experience, knowledge and manufacturer's accreditations.

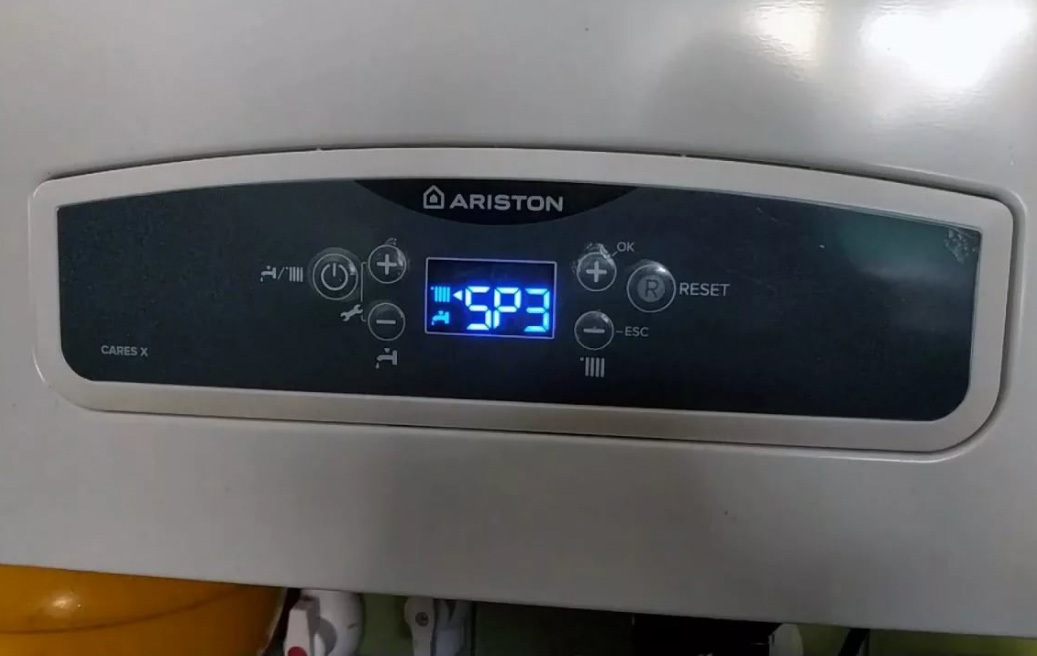

However, in order to quickly identify the cause, it is not necessary to study to be a gas worker. When an error occurs in the Ariston gas boiler, the system recognizes the problem and displays a fault code on the screen. In most cases, you can find a malfunction and adjust heating yourself.

We will tell you how to timely identify maturation or the appearance of a breakdown. In the article presented by us, you will find the decoding of the codes and tips for correcting the situation. Our recommendations will be useful to those who decide to repair equipment with their own hands.

The content of the article:

- Heating circuit problems (error 1 **)

- Hot water supply faults (error 2 **)

- Electronics failures (error 3 **)

- Communication with peripheral devices (errors 4 **)

- Flame and ignition control (errors 5 **)

- Air supply and flue gas removal (errors 6 **)

- Problems with multi-zone control (errors 7 **)

- Conclusions and useful video on the topic

Heating circuit problems (error 1 **)

For boilers with the Ariston logo, all error codes are grouped by nodes. For each case, you can determine the most likely causes of the problem and ways to solve it. It should be noted right away that not all malfunctions can be eliminated by hand.

The heating circuit is an integral part of the heating system. Gas boiler reacts to behavior coolant and provides the user with information about emerging problems. Their solution can be associated with both the boiler and the circuit elements.

In the event of a malfunction, an error code is displayed on the LCD screens of modern gas boilers. This is much more convenient than counting the number of flashes of LED bulbs as on older models.

Mistake number 101. It occurs when the heating medium overheats and boils in the primary heat exchanger, when the temperature at the NTC1 sensor exceeds 102 ° C.

This problem occurs in the following situations:

- Excessive maximum pressure within the gas valve, resulting in severe heating. It is necessary to adjust this parameter.

- Low speed of movement of the coolant. The problem may be caused by a clogged filter, build-up of scale deposits, or a breakdown of the built-in circulation pump. You need to check and fix these problems.

- Failure of the temperature sensor. In this case, its replacement is required.

Mistake number 102. The pressure sensor reading is out of range. This can be caused either by a problem with the pressure in the circuit or by a breakdown of the sensor itself.

The latter situation usually occurs as a result of wiring problems - short circuit or open circuit. It is necessary to ring the wire from the device to the central board.

You can call the sensor itself with an ordinary tester. Resistance should be minimal - 1-2 Ohms. If it is absent at all, then the sensor will definitely have to be changed.

Errors No. 103-107 occur at extreme values of the temperature of the coolant. The system reacts when analyzing the temperature in two places - at the water supply to the circuit and at the return point:

- № 103. 3 times within 4 minutes the rate of increase of the supply temperature exceeds the value of 7 ° C / sec.

- № 104. An increase in one of the indicators by a value exceeding 20 ° C per second was recorded.

- № 105. The heating medium on the supply to the circuit is 55 ° C hotter than the return flow. The problem was fixed 3 times in 4 minutes.

- № 106. The return temperature is 10 ° C higher than the flow temperature. Recorded 3 times within 4 minutes.

- № 107. The return temperature is 30 ° C higher than the supply temperature. Fixed once.

Considering that the temperature sensor has an elementary structure and there is, in fact, nothing to break, it remains to identify and eliminate the problem with insufficient movement of the coolant.

It can be caused by the following:

- Airiness of the heat exchanger or heating circuit. You may have to check all the way for traffic jams.

- Clogged filter. This part needs to be cleaned or replaced.

- Pump malfunction. Replacement or repair of the device.

Error number 108 displayed according to the readings of the minimum pressure switch. It can be caused by the same reasons that are typical for errors # 103-107. In addition to them, a breakdown of the sensor or wiring to it is possible, as well as depressurization of the circuit and partial leakage of water.

If a leak occurs, there will be a drop in pressure in the system. The gas boiler will stop by itself, which compares favorably with its solid-fuel counterpart or an ordinary stove

Error number 109 occurs when there is a problem of overpressure - more than 3 bar. This can happen if the make-up tap is not completely closed. For further work, it is necessary to drain some of the water to reduce the pressure in the circuit.

Mistake number 110. Failure or banal wear of the temperature sensor. First of all, you need to check the contacts and the integrity of the wire. If they are ok, then the sensor itself will have to be replaced.

Error number 111 occurs when the pressure in the circuit is below the allowable one. The factory setting of this parameter for Ariston boilers is 0.4 bar. Possible sensor breakage or water leakage from the circuit.

Mistake number 112. Return temperature sensor problem. You need to check its contacts or replace the sensor.

Mistake number 114. Outside temperature sensor problem. You need to check its contacts or replace the sensor.

Mistake number 116. Safety thermostat tripping (opening) warm floor. You need to close the TA2 jumper on the main board. If the operation occurs again, then there are problems in the underfloor heating system. This is usually the presence of an airlock.

Mistake number 117. On some older models, there is a control of the difference in temperature values at the inlet and outlet after 8 seconds after starting work. The boiler will stop if the heating does not start. Possible problems and solutions are the same as for errors No. 103-107.

A clogged water filter causes water circulation problems. This leads to stoppages of the boiler, and also has a bad effect on the pump.

Sometimes the indicator lights up codes 1P1 - 1P4. These are not errors, but warnings that signal one-time sudden temperature changes. Such effects sometimes arise due to hydrodynamic processes characteristic of a flowing hot liquid in a narrow flow. You shouldn't pay attention to them.

Hot water supply faults (error 2 **)

These types of faults occur in Ariston double-circuit gas boilers. For hot water supply, the security system is autonomous, which allows you to quickly identify the problem.

Many models of Ariston boilers support the ability to connect a solar system as an alternative source of energy for hot water supply. Therefore, some errors and warnings of the “2 **” series are associated with the operation of solar panels.

Error number 201. Temperature sensor power supply problem - open or short circuit. It is necessary to eliminate the breakdown of the wiring.

Errors No. 202-205 related to the operation of sensors. When a signal stops coming from them or it behaves unpredictably (sharp data jumps), then these errors are triggered:

- № 202. Sensor problem boiler or solar systems.

- № 203. NTC temperature sensor problem.

- № 204-205. There is a problem with the temperature sensor that records the operating values of the solar collector.

To solve problems No. 202-205, you need to check the tightness of the contacts. If this is not the case, then the faulty sensor will have to be replaced.

Error number 206. Cold water temperature sensor problem in heliosystem. The solution is the same as for errors 204-205.

The temperature sensor is easier to replace than clean. They are inexpensive, and it is easy to find them, since parts with standard parameters are installed in boilers.

Error number 207. Overheating of the solar thermostat. This may be due to the fact that solar energy is not being used to heat the water. Then the collector must be turned off. Also, this malfunction can occur if the thermostat breaks down. In this case, it will need to be replaced.

Error (warning) # 208. Insufficient heating in the solar circuit. There is a risk of the coolant freezing. It turns on when the anti-freeze function is activated. Part of the energy from the gas will go to heat the collector.

Error (warning) # 209. Overheating of water in the boiler connected to the boiler. There may be a problem with the thermostat or with its contacts.

Electronics failures (error 3 **)

Such sophisticated modern equipment as gas boilers is equipped with electronics for automatic operation and response to different situations. Control boards can fail due to aging, power surges, excessive humidity, or mechanical damage.

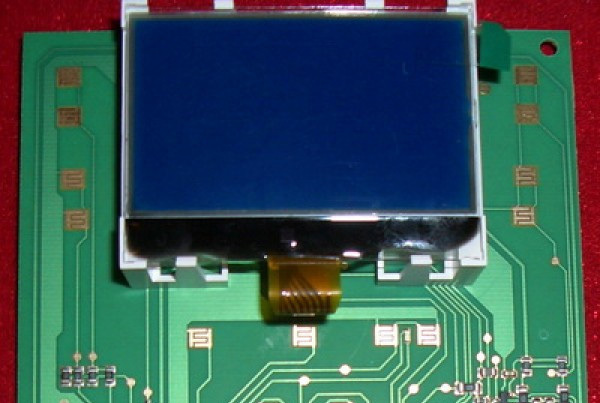

Error number 301. Problems with the EEPROM board (non-volatile memory) of the display. If such a message appears, you need to check the correct installation of the EEPROM key on the motherboard. This should be done as described in the user manual for the corresponding model.

If the key works correctly, then you need to check the contacts of the ribbon cable from the motherboard to the display board. There may also be a problem with the LCD itself. Then it will have to be replaced.

The display is connected to the board with a ribbon cable. If the boiler is working, and the screen has gone out, then first of all you need to check the quality of the connection. Naturally, when the power is completely off

Error number 302 - a special case of the previous problem. Both boards pass the test, but communication between them is unstable. Usually the problem lies in the fracture of the veins of the loop, which will have to be replaced. If it is OK, then there is a malfunction on one of the boards. They can be removed and taken to a service center.

Mistake number 303. Main board malfunction. Restarting usually does not help, but sometimes it is enough to turn off the boiler from the network, wait and turn it on again (this is the first sign of aging of capacitors). If this problem becomes regular, then the board will have to be changed.

Error number 304. More than 5 reboots in the last 15 minutes. Speaks about the frequency of emerging problems. You need to turn off the boiler, wait a while and turn it on again. It should be monitored for some time to identify the type of warnings if they show up again.

Error number 305. Failure in the program. Let the boiler stand off for some time. If the problem persists, you will have to reflash the board. This must be done at the service center.

Error number 306. EEPROM key problem. The boiler must be restarted. If the error persists, you will have to change the board.

Error number 307. Hall sensor problem. Either the sensor itself is faulty, or there is a problem on the motherboard.

Mistake number 308. Incorrectly set combustion chamber type. It is necessary to check the set combustion chamber type in the menu. If the problem is not resolved, then the wrong EEPROM key may be installed or the motherboard is faulty.

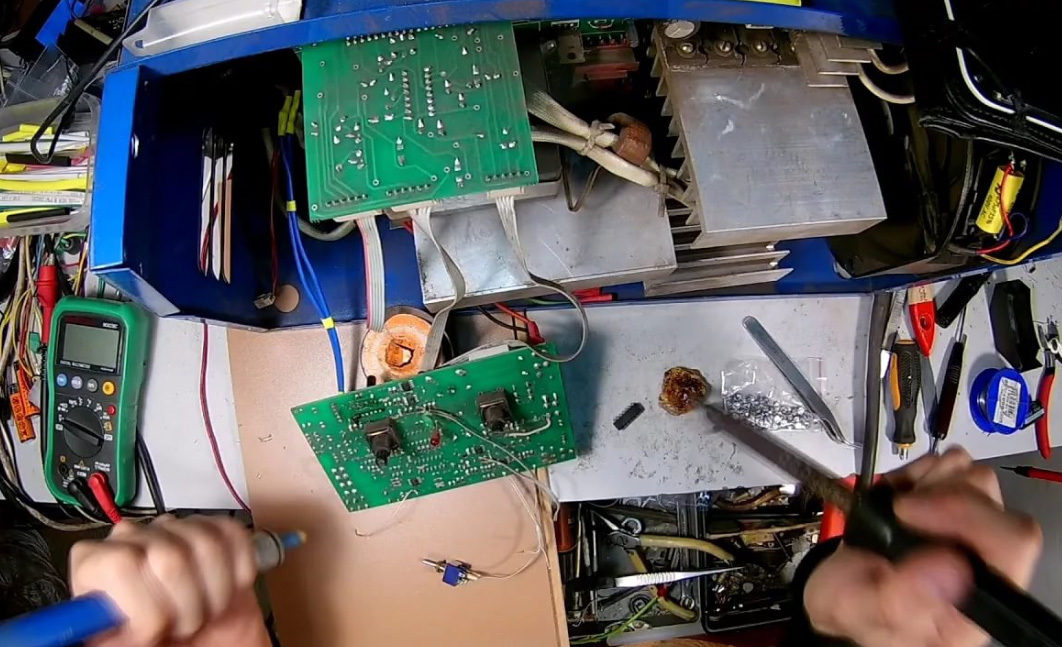

Any electronic boards can be tried to be repaired at computer repair shops. Especially if the problem is caused by loss of contact or aging of capacitors

Error number 309. Flame registration after blocking the gas valve. In addition to a malfunction of the motherboard (it will have to be replaced), there may be a problem in the ignition unit - a loose closing of the gas valve or a malfunction of the ionization electrode. If the problem is in the electrode, then you can simply try to dry it.

Communication with peripheral devices (errors 4 **)

The Ariston gas columns display error codes for standard peripheral devices. This is to explain the reaction. boiler automation for an emergency situation. In this case, the consumer will be able to try to eliminate the breakdown or conflict of the equipment on his own.

Error number 401. Communication problem between the bus and the data transmission device. It can be caused either by a malfunction of the device itself or by a damaged bus. Repairs are only possible at a service center.

Error number 402. Malfunction of the GRRS / GSM modem. You need to check its connection or replace the device.

Error number 403. SIM card problem. The contact is loose or the card itself is damaged.

Error number 404. Failed to transfer data between the modem and the motherboard. First of all, you need to check your contacts. If they are tightly connected, then the modem is faulty.

The GSM gas boiler control module allows you to remotely control the heating modes of the building. However, in addition to the obvious pluses, there is also a minus - this is another knot that can break

Error No. 405-406. Data bus (interface) problem. Usually the fault lies in loose contacts. Less often, the tire itself needs to be replaced.

Error number 407. Interruption in the signal from the room temperature sensor. You need to check the connection (wire and contacts). If they are in good condition, then the sensor itself must be replaced.

Flame and ignition control (errors 5 **)

Problems can arise with both open and closed combustion chambers. Although it must be admitted that there are few types of malfunctions here compared to other components of a gas boiler.

Error number 501. No flame on ignition.

This situation can happen for many reasons:

- There is no gas. You need to check the tap on the supply. It must be open.

- The system will not turn on if the voltage between the neutral and the earth conductor is more than 10 V. It is necessary to eliminate the leakage current.

- The ionization electrode is out of order. Before changing it, you need to check the quality of the connection to the motherboard.

- The power of the smooth ignition is lost. You need to adjust this parameter according to the instructions for a particular model.

- Malfunction of the main control board.

Error number 502. Flame registration before activating the gas valve. It often occurs in the absence of a ground loop. If it is made according to the standard, then you need to perform the same actions as for error No. 309.

If there was no grounding in the house, then it will have to be done for a gas boiler. Moreover, according to all the rules, otherwise the protective mechanisms will block the start of heating

Error number 504. Flame separation on the burner, if it occurs at least 10 times during one cycle. Check gas pressure, flue gas outlet and gas valve.

Air supply and flue gas removal (errors 6 **)

The system for supplying air and removing flue gases generated during the operation of a gas boiler can be natural and forced. Therefore, for different devices, some errors may not occur. But we'll look at all of them.

Error number 601. The actuation of the draft thermostat occurs when the contact is broken or the smoke exhaust thermostat breaks down internally. Clogging of the air exhaust system is also possible.

Error # 602. The same, only for VMC type combustion chambers.

Error number 604. Hall sensor defective (it needs to be replaced) or low speed of the fan blades (it needs to be cleaned or also replaced).

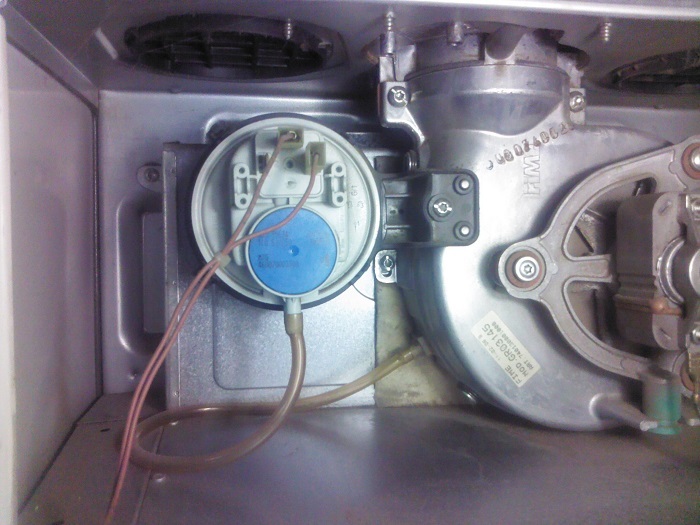

Error number 607. The contacts of the controlling pneumatic relay were closed before the fan was turned on. This detail confirms that there is sufficient draft before firing up. To eliminate the early short circuit, you need to carefully remove the pneumatic relay and blow through its tubes, removing dirt or condensation. If this does not help, then the part will have to be replaced.

The pneumorel is connected to the extraction chamber with a silicone tube. Sometimes there is a condensate trap. If the problem is with the pressure switch, then first you need to check the integrity of the tube

Error number 610. Thermal fuse contacts open. It is necessary to replace this part.

Error number 612. Same as bug # 604, but on early Ariston models.

Problems with multi-zone control (errors 7 **)

Ariston boilers allow you to divide the house into zones, for each of which its own heating mode will be set. If a problem occurs with one of the sections, the system accurately determines the malfunction, so repair a specific circuit can be carried out without interfering with the rest of the normally working fragments heating network.

Error # 70X. Problem with the flow temperature sensor in zone X. It is necessary to check the sensor contacts or replace this part.

Error # 71X. The same thing, only with a sensor on the return line.

Error # 72X. Overheating detected in zone X. First of all, you need to check the operation of the thermostat responsible for this area. The matter may be simply a loose contact or a breakdown of the unit. If it works correctly, then you need to change the settings.

Mistake number 750. Hydraulic circuit error. The correct type of connected hydraulic module must be set (menu parameter 720). If there is no error here, then the problem is in the settings of the circuit itself.

Conclusions and useful video on the topic

Periodic maintenance of the gas boiler can prevent many problems. How to do this using the example of the BS II series:

Change of a number of parts on the Ariston boiler - pump, make-up valve, three-way valve. How to clean filters and passages:

The presence of a signal about the errors of a modern gas boiler provides the user with the opportunity to deal with the problem of the malfunction. Further, it is imperative to analyze the troubleshooting methods yourself.

Sometimes, to restore the operation of the Ariston gas boiler, it is enough to clean the contacts yourself, adjust the gas supply power or restart the device. However, all breakdowns associated with malfunctions of the electronics and the gas supply system to the combustion chamber should be entrusted to representatives of the gas organization.

The boiler also reacts to breakdowns in peripheral equipment or problems with the heating circuit. In this case, it makes no sense to call a boiler repairman.

Do you want to share your own experience in troubleshooting and repairing a gas boiler from Ariston? Do you have any useful information on the topic? Please leave comments in the block below, ask questions, post photos.