Owners of gas boilers will not have a desire to overpay for space heating. But no one will put up with the insufficient efficiency of the heating device, leading to a decrease in living conditions, right?

Moreover, the situation can often be corrected, and independently. But for this you should have knowledge of how to increase the efficiency of a gas boiler with your own hands. This is what we will talk about in our article, having considered the reasons for the decrease in efficiency and the best ways to eliminate them.

The content of the article:

-

The reasons for the decrease in efficiency and their elimination

- Method # 1 - elimination of chemical underburning

- Method # 2 - elimination of mechanical underburning

- Method # 3 - reducing heat loss

- Method # 4 - maintenance and flushing of the heat exchanger

- Method # 5 - cleaning the coolant

- Safety measures to improve efficiency

- Conclusions and useful video on the topic

The reasons for the decrease in efficiency and their elimination

There are many different reasons for the insufficient efficiency of gas boilers. Therefore, the procedure for increasing efficiency should begin with their identification.

The task is facilitated by the fact that all causes fall into only three categories.

Which are:

- Chemical underburning - arises due to a general lack of oxygen in the furnace, poor mixing of air with combustible substances released from the fuel, or a low temperature in the furnace itself. As a result, incomplete combustion of gas occurs, and, consequently, less heat is generated. The reasons for such underburning lead to the fact that the efficiency can decrease by a considerable 7%.

- Mechanical underburning - arises as a result of the fact that part of the fuel for various reasons, including due to poor mixing with air, falls out of the process of mixture formation with air and does not participate in combustion, but is carried away into the chimney. Which leads to a decrease in efficiency by 3-7%.

- General heat loss. They are caused not by the malfunctioning of the boiler itself, but by other elements of the system, which directly affect the efficiency of the heater. For example, radiators, ventilation. And quite often the total heat loss leads to the greatest decrease in the boiler efficiency.

Knowledge of the nuances will help to identify the cause and increase the effectiveness.

Manufacturers in technical data sheets traditionally indicate the efficiency of their gas boilers. But, by and large, such a figure is the reference and maximum possible. And then whether the heating equipment reaches the value specified at the factory depends largely on the owner, his knowledge and skills

Method # 1 - elimination of chemical underburning

Since incomplete combustion of fuel is a sign of chemical underburning, it is easy to determine how to increase efficiency in this case. To do this, it is sufficient to carry out a visual inspection of the boiler structural elements. As a result, significant deposits of combustion products will be revealed on the surfaces of the heat exchanger, gas burner, and heat protection housing.

Any gas boiler is part of the heating system. Therefore, in many respects, its efficiency depends not on its own settings, technical condition, performance, but on power, condition, correct choice and installation of other structural elements. For example, from heating radiators

There are several reasons for the lack of oxygen due to which chemical underburning occurs.

The main ones are:

- clogging of the chimney and / or ventilation ducts;

- poor quality commissioning work when connecting the boiler.

A significant amount of soot and other combustion products is deposited on the surfaces of the channels of smoke exhaust systems. Over time, this leads to the fact that the process of removing exhaust gases from the combustion chamber of the boiler slows down. As a result, less clean air enters there, which leads to underburning.

In this case, it will be possible to increase the efficiency by cleaning the chimney channels, ventilation system, burner surfaces and other contaminated structural elements. To avoid similar problems in the future, you should regularly carefully monitor the condition of the pipes and the boiler. This procedure must be carried out before the start of each heating season. More about servicing gas boilers we spoke here.

Poor-quality commissioning works, their non-fulfillment can lead to the fact that the electronics will not be able to choose the optimal operating modes, for example, to control the size of the flame. As a result, the gas will not completely burn out, especially at the stage of ignition.

It is possible to eliminate the indicated reason, and, consequently, to increase the efficiency, if the necessary commissioning works are performed.

Method # 2 - elimination of mechanical underburning

Most often, several reasons can lead to incomplete combustion of gas as a result of mechanical underburning and a subsequent loss of efficiency.

Although the combustion processes in gas boilers are more efficient than in their solid fuel counterparts, some of the fuel still does not burn. This phenomenon is called "underburning" and it is one of the main reasons for the decrease in the efficiency of a gas boiler.

The main ones are:

- high thrust;

- incorrect setting of the boiler output.

High draft is generated when the exhaust system is too efficient. As a result, the combustion products are removed at such a rate that the gas simply does not have time to burn.

In this case, it is quite simple to eliminate the cause of underburning. To do this, you just need to block off part of the smoke exhaust duct using a draft limiter. If such a device is not provided, has lost its functionality, then to increase the efficiency it should be installed or replaced. That is easy when using modern modular chimneys. Otherwise, you will not be able to achieve the desired result.

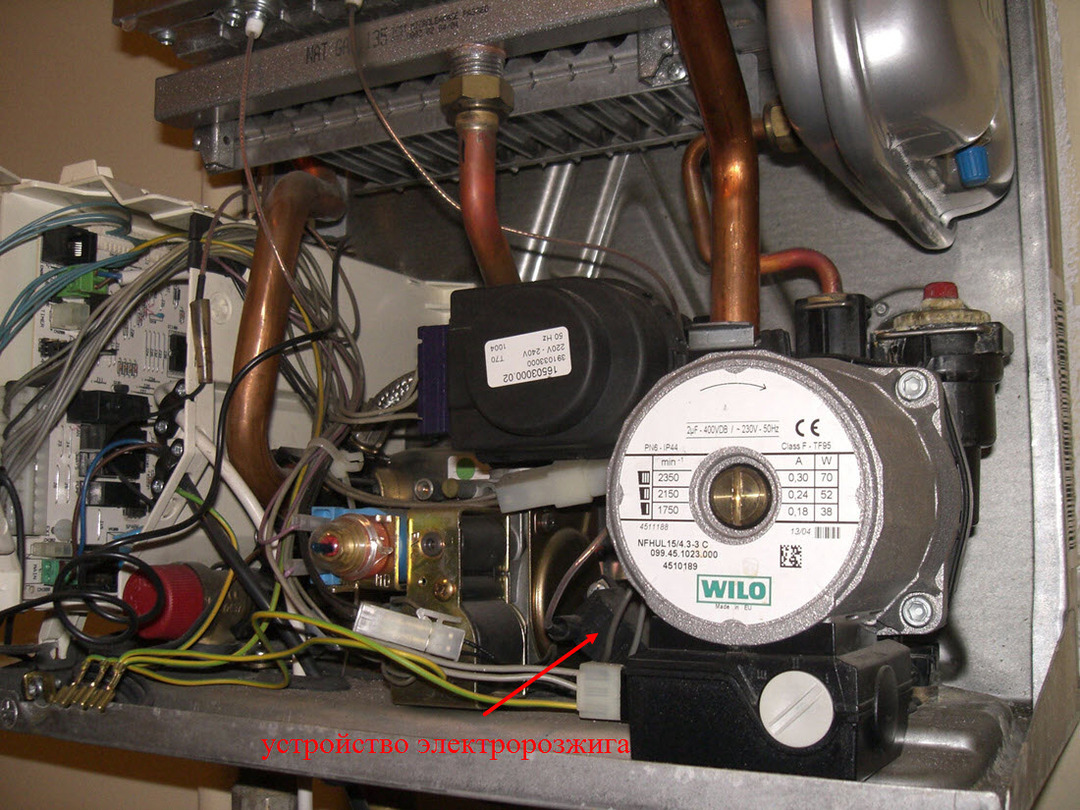

Incorrect setting of the boiler output most often manifests itself in the form of the phenomenon named clocking. It is a mode of operation in which start / stop cycles occur too frequently. And since the gas supply is greatest when the boiler is turned on, a significant part of it does not have time to burn out.

The situation is aggravated by the fact that the electronics are always programmed so that the command to the piezoelectric elements to start generating a spark is given with some delay. This is done to ensure high-quality ignition.

In the latter case, it will be possible to increase the efficiency quickly and at no cost. It is enough to enter the service menu of your gas boiler. And then using the "-" button to set a lower power value.

In some cases, it will be possible to increase the efficiency of your gas boiler using the settings in the service menu. But it should be remembered that for the most part they belong to the category of thin ones and therefore will increase the efficiency of the heater by only 3-8%. To enter the service menu, you must enter a special code set by the manufacturer

The efficiency will reach optimal values if the boiler power and the total heat output of the radiators are approximately equal. The necessary data on the performance of the equipment can be obtained from their technical data sheets or from the manufacturer, seller.

Sometimes it happens that the power of the boiler will be significantly lower than the similar total parameter of the radiators. In this case, the efficiency can be increased by increasing the power of the heating unit. You can also do this yourself by going to the service menu.

It is possible to change the operating characteristics of boilers, because they have a maximum and minimum power value. And they are supplied tuned for average performance.

Method # 3 - reducing heat loss

General heat losses are the reasons that most often lead to a low indicator of the boiler efficiency. And it is no coincidence that experts assure that the efficiency of the heating device itself by an impressive 80% depends on the correct choice, installation and performance of radiators.

Change in total heat output

At the same time, manipulations with these elements of heating systems are costly. But it should be remembered that without them the boiler will not reach the maximum efficiency values.

That is, if using the methods described in the previous sections of the article failed to bring the effectiveness of the device heating to optimal values, then you will have to get out of the situation by performing a number of procedures with radiators.

The gas boiler will become more efficient by several percent after cleaning the external surfaces of the gas burner, heat exchanger from combustion products, caked dust and other types of contaminants

Which include:

- change in the total heat capacity;

- correct installation.

This method of increasing the efficiency of a gas boiler, such as changing the total thermal power of the available radiators, is quite complicated. But it will have to be used if the desired result could not be achieved with the help of adjustments of the heater, defeated by clock.

The method is the addition of one or more radiators to the heating system. Or replacement of existing batteries to more powerful ones.

This is done in order to equalize the boiler output with a similar total indicator of the radiators. In order to eliminate frequent starts / stops of the boiler. This leads to an increase in efficiency, a decrease in equipment wear and the consumption of expensive gas.

The described method has to be resorted to in cases where the low total power does not allow increasing the boiler productivity in order to increase the efficiency. Such a need arises when the temperature of the coolant reaches 70-75 ° C. The fact is that with such a heating of the water, dust particles begin to burn on the surface of the radiators, which does not create comfortable living conditions.

And the worst thing is that at the specified temperature, high wear and tear of the structural elements of the heating system from polymer plastics, which have been actively used in recent years, begins. As a result, instead of the expected increase in efficiency, you can get a coolant leak, and not even in one place.

The photo shows a chimney clogged with soot and other combustion products. And even at first glance, it is clear that in this form, this equipment will not be able to provide the expected efficiency. Therefore, the condition of the ventilation system and the chimney must be monitored regularly. And the approach to the procedure is not formal, but quite responsible. Since the efficiency of the entire heating system depends on this

Checking the correct location of the radiators

If the regulation of the boiler does not help to increase the efficiency, and the power of the equipment is similar and sufficient for heating the premises, then attention should be paid to the location of the radiators. Since their effectiveness will be optimal if a number of requirements are met.

Namely, the radiators should be located:

- in places of premises where heat losses are most significant, for example, near windows;

- 12 cm from the floor;

- 10 cm from the windowsill, in addition, it should overlap the radiator by 2/3;

- 2 cm from the wall.

If the listed requirements are met, natural convection will occur. At the same time, a small part of the heat is spent on heating the walls, blocking heat losses, and all the rest of the energy is used to solve the main task - heating the premises. In this situation, the load on the boiler will be the smallest, which significantly increases the efficiency.

It should be remembered that a radiator skewed when installed by more than 1 ° will affect the efficiency of any gas boiler. And, if there are several incorrectly installed devices, then no boiler adjustments will be able to compensate for this. And the only correct solution would be to eliminate the shortcomings, although it is expensive

But with high heat losses due to the low energy efficiency of the building, it will not be possible to achieve high efficiency of the heating equipment. So, most of the heat goes through old windows with cracks, not insulated walls, doors and roofs.

That is, in such cases, due to cracks, drafts and other shortcomings, the efficiency of even modern boilers drops by tens of percent. That cannot be compensated for by settings or by any other means. In such a situation, you have to think about replacing windows, wall insulation, gender or ceiling, or better - about everything at once.

Method # 4 - maintenance and flushing of the heat exchanger

It is possible to achieve and maintain the high efficiency of any gas boiler not by spontaneous actions (after identifying it low efficiency), and with the systematic implementation of certain procedures - maintenance of the heating unit. We recommend that you familiarize yourself with the specifics of choosing a gas company and concluding a maintenance contract gas boiler.

This complex of operations consists of inspection and verification work. They will allow you to identify and eliminate all sorts of shortcomings that reduce efficiency, even in the early stages. That will exclude not only a decrease in efficiency, but also wear of the boiler and other elements of the heating system.

Particular attention should be paid to flushing the heat exchanger. The reason is that plaque begins to form on its internal surfaces rather quickly. It resembles the lime settled on the surface of an ordinary teapot. As a result, after some time, the gas boiler needs more time to warm up the coolant to the desired temperature. That is, there is a decrease in efficiency, in addition, during clogging, the heat exchanger overheats, which is fraught with its early failure.

The photo shows that the channels of the heat exchanger are clogged with carbonates (salt deposits). Which leads to a significant decrease in efficiency and early failure of the boiler. You can avoid these negative consequences if you regularly clean the channels.

Gas boiler flushing can be done in three ways.

Namely:

- manual cleaning (mechanical method);

- using a special solution for flushing the boiler heat exchanger (chemical method);

- hydrodynamically.

For mechanical cleaning, after shutting off the gas supply and draining the coolant, the boiler is disassembled. Which ends with the dismantling of the heat exchanger.

Further, using a scraper, brushes, a conventional vacuum cleaner, deposits are removed from its internal channels. In doing so, care must be taken as the heat exchanger can be easily damaged.

After cleaning is completed, the boiler is assembled and the tightness of the heat exchanger and its connections is checked.

Cleaning chemically (using a flushing solution) - the procedure is simpler and more effective. But the heat exchanger will still have to be dismantled. And then a special agent is poured into it, which copes even with the most persistent deposits (ferric iron, salt carbonate). After the acid has been drained, its residues from the heat exchanger should be removed with water by running it through the heat exchanger with a booster.

The only significant drawback of the chemical method for cleaning the heat exchanger is the need to use special equipment (booster)

Hydrodynamic flushing is the simplest way to clean a gas boiler in order to increase efficiency. Since the dismantling of the equipment is not required and all that is needed is to pump ordinary water (with abrasive filling) into the heating system and pump it over. Moreover, with a gradual increase in pressure. To complete the procedure, you need a pump and special nozzles.

It is necessary to clean the heat exchanger at least once every 2 years, which will help keep the efficiency of the gas boiler at a consistently high level.

The most affordable way to clean the coolant is the mechanical method - manually cleaning the brushes

The most affordable way to remove plaque from a heat exchanger is to clean it with brushes and other materials at hand. But the most effective and not laborious method is the use of special solutions.

Method # 5 - cleaning the coolant

Another affordable way to improve the efficiency of heating equipment is installation of filters into the heating system.

It is recommended to start this procedure with an analysis of the quality of the coolant, moreover, laboratory. You will have to spend money on this, but it will become known which filters should be used.

Today, the following varieties are actively used:

- rough cleaning;

- fine cleaning;

- magnetic.

The first type (filters rough cleaning) are effective if the coolant contains large particles of dirt (from half a micron). Filters fine cleaning serve to purify water if suspended matter with the smallest particles is found in it. Often, products of both types are used together.

Magnetic filters successfully cope with cleaning the coolant from metal particles. They do not protect gas boilers from other types of pollution.

Cleaning the coolant, together with flushing the heating equipment, allows you to get a significant increase in efficiency. And most importantly, such a result will be stable throughout the entire service life of the boiler.

Safety measures to improve efficiency

Even 20-30 years ago, the price of energy resources in the post-Soviet space was low, so no one paid attention to such a parameter as efficiency. After all, productivity could decide everything. But when gas began to rise in price, and modern technologies were not yet available, craftsmen began to modernize gas boilers, in order to increase efficiency, in affordable ways.

When performing any work with gas equipment, you must observe safety measures and possess special skills and tools. And also do not use methods of increasing efficiency prohibited by law.

For example, attaching copper, aluminum plates to heat exchangers to improve heat transfer. Reduced heat loss of structural elements of heating devices by welding third-party elements. Automation and heat exchangers were changed. Other similar methods were also used. The efficiency increased, and the state and the gas service did not react to the "creativity" of the craftsmen.

Now everything is different and specialized laws prohibit changing the design of gas boilers, which must be certified, like all their individual elements. As a result, it is impossible to increase efficiency by replacing mechanical, electrical and other components of heating devices with third-party ones.

Violation of these requirements may result in:

- Administrative responsibility. If the Gorgaz employees detect interference with the boiler design, and there were no incidents, then a fine of 10-15 thousand rubles will have to be paid. rubles. This is indicated by the article 7.19 Administrative Code. In severe cases, the gas service has the right to even terminate the service contract and stop fuel supplies.

- Criminal liability. As evidenced by the Federal Law of No. 229-FZ dated July 29, 2018 "About making changes to the article 215.3 UKRF and articles 150 and 151 of the Criminal Code of the Russian Federation». These regulations will come into effect if the design changes lead to serious consequences.

That is, risking people's lives in order to raise the boiler efficiency by a few percent is not worth it.

Conclusions and useful video on the topic

The first video will help you understand how the boiler heat exchanger is cleaned, which will help to significantly increase its efficiency.

The following video will give an opportunity to understand how the gas burner is cleaned in order to increase the efficiency of the boiler.

Experience shows that the maximum efficiency from the boiler can be achieved with its systemic maintenance with timely cleaning of burners, heat exchanger from combustion products, dirt. And also with proper placement, use of radiators. In addition, only modern high-tech equipment can be distinguished by high efficiency.

Did you see a discrepancy or want to supplement our material with useful recommendations for increasing the boiler efficiency? Leave your comments, participate in the discussion and ask your questions to our experts - the feedback form is located below.