Modern gas equipment attracts by the fact that it does not require frequent repairs and any serious maintenance. All maintenance work is performed by representatives of the gas service, with which the owners of the house conclude an agreement. But when there is no need for heating or heating water, it is not difficult to turn off the boiler with your own hands, right?

Why not follow the shutdown procedure yourself instead of paying for a specialist call? In this article, we will analyze all the subtleties of this process - we will consider information on how to turn off the gas boiler, while observing the safety rules.

Especially for those who are used to doing household chores with their own hands, we offer 4 ways to preserve the boiler, which will reliably protect the heating system during downtime. After all, it is not enough just to dial a combination of buttons to turn off the unit - it is necessary to properly preserve all connected equipment. Let's take a closer look at how best to do this.

The content of the article:

- Reasons for turning off the gas boiler

- Step-by-step instructions for disabling

-

Methods for preserving gas boilers

- Method # 1 - dry stop

- Method # 2 - wet preservation

- Method # 3 - gas preservation

- Method # 4 - applying excessive pressure

- What rules need to be followed?

- Conclusions and useful video on the topic

Reasons for turning off the gas boiler

The gas boiler is the real "heart" of a private house. It provides the building with warmth, and double-circuit models - and hot water.

Thanks to the electronic filling, the main processes - turning on, turning off, switching to another mode, temperature control - are carried out automatically, without human intervention. The owner must set the program by pressing, depending on the manufacturer's instructions, on the appropriate buttons or keys.

Gas boilers are preferred because of the cheapest fuel - gas. Solid fuel units or wood-burning stoves are more often installed if there is no gas line nearby

Shutdown may be necessary for various reasons:

- moving to another place of residence;

- seasonal shutdown for a warm period;

- emergency stop due to boiler breakdown and the impossibility of quick repair or replacement;

- scheduled stop for maintenance - removing deposits, flushing the inner circuit or cleaning from soot;

- connection of other heating or hot water equipment;

- disabling one of the functions - for example, heating, etc.

Most often, you need to turn off the heating. To do this, the operation of 1-circuit units is completely stopped, and in 2-circuit units, only one line is blocked - the heating one.

Double-circuit models perform 2 functions: heating and hot water. Since hot water is also required in summer, the hot water circuit is left active, and the DHW line continues to operate as usual.

Many modern models have the option to switch to summer mode. At the same time, the boilers do not break down - they also continue to work, maintaining the optimal temperature and keeping the system “ready” for active start-up at any time.

In summer, especially in the northern regions, there are also cold snaps and even frosts, so the operating equipment is useful.

Step-by-step instructions for disabling

If the gas burner does not light up or goes out immediately after switching on, auto shutdown often occurs for inexplicable reasons, pops occur, the water temperature in the circuit does not correspond to the indicators, noise is uncharacteristic for the operation of the unit, there is a water leak in the case, the pressure has dropped - the equipment should be immediately switch off.

If, entering the house, you smell gas, do not turn on the lights, electrical appliances and do not light a fire. Call your service provider immediately, turn off the equipment and turn off the gas

The shutdown procedure for boilers is done in different ways, but the main steps are similar.

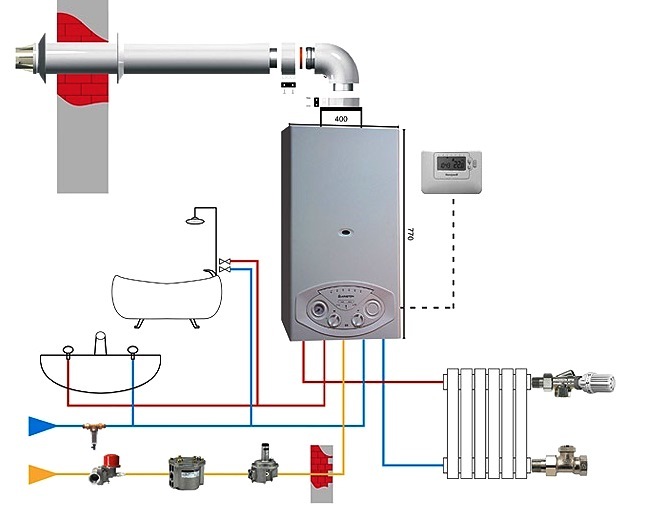

Consider, using the Baxi model as an example, how to properly and quickly turn off a gas boiler:

- Shut off the fuel supply by turning on the gas shut-off valve.

- Leave the fan running for another 15 minutes.

- Turn off the fan, stop the smoke pumping system.

- Wait until the temperature in the circuit is below +30 ° С, turn off circulation pump.

- Disconnect the power by turning the switch to the Off, 0, or other position as specified by the manufacturer.

- Carry out work on the conservation of the boiler and related equipment.

Not all systems are completely drained of water. Some manufacturers recommend adding an anti-limescale liquid to the coolant. The most effective for household communications are recognized propylene glycol or antifreeze with special additives.

In the event of force majeure situations, you have to quickly figure out how to quickly turn off the gas boiler, while maintaining the system's performance and not harming yourself. Next, we will consider special cases.

Sometimes, when overheating or lack of traction, the boiler is automatically turned off. It stops working, therefore, the heating of the house is suspended. If the auto shutdown occurs very often, once 5 in 15 minutes, you should turn off the gas and contact the service department.

When the gas equipment is automatically turned off, an error code is displayed on the electronic board. In this case, you need to find this code in the instructions and act according to the manufacturer's recommendations.

Problems in the flue gas system also automatically stop the unit. It usually gives an error on the display and stops working for 12-15 minutes and then turns back on. If the problems are not eliminated during this time, auto-shutdown occurs again - and so on until the problem is completely eliminated. To clean the gas outlet, turn off the gas and turn off the boiler.

Many boilers are protected against freezing automation. The protection works if the boiler sensors are connected to the power supply, the system has normal pressure and the gas is not cut off.

In the event of any malfunction, if the temperature of the coolant in the circuit drops below + 8-10 ° C (depending on the model), the operation of the unit is suspended. As a last resort, if you cannot quickly cope with the circumstances - turn on the boiler and establish its functioning - you can try to drain the water so that the pipes and unit parts do not burst.

Methods for preserving gas boilers

Let's consider the main methods of preserving heating equipment, but with one caveat - not all are used in home maintenance. Some of the methods are more suitable for equipment installed in a production plant floor.

For home service, alkalis are used - caustic or soda ash. It is not recommended to use acidic reagents on your own, hydrochloric or sulfuric acid can only be used by qualified specialists.

The process of preserving the heating circuit is preceded by a preparatory stage, which includes several points:

- Disconnecting the boiler from the gas main and the central water supply, installing plugs. If water is supplied by a pumping station, the pump is stopped.

- Removing water or other heat carrier from the system.

- Cleaning the internal surfaces from scale.

- Flushing of parts of the boiler and the circuit.

Professional cleaning from calcium deposits can only be carried out by specialists - and the service organization has such a service. There are two most effective and simple ways of descaling - chemical, mechanical (manual cleaning), but the former is recognized as the most effective.

The internal parts of the boiler, on which large deposits have appeared, are sanded with a power tool, and scale in hard-to-reach places is removed manually, with brushes or scrapers.

Method # 1 - dry stop

Dry preservation is performed in production, usually for maintenance activities or during routine inspections, when it is necessary to shut down facilities for up to 30 days. It consists in completely freeing equipment and pipelines from liquid and in further drying.

The procedure is called dry shutdown. It is applicable to any boiler model, regardless of pressure, but is contraindicated for units in which the drums are connected to the pipeline by rolling joints.

Procedure:

- Cooling the coolant in a natural way.

- Stopping the boiler.

- Displacement of liquid under a pressure of 0.8-1.0 MPa.

- Drying the system naturally or by ventilation.

- Installation in collectors of pallets with desiccants - quicklime or calcium chloride in grains.

- Closing the furnace and gas duct, plugs - complete sealing of the system.

At home, water is drained through special taps installed at the bottom of the pipeline. Then they carry out repair or maintenance work, leave the equipment in a "dry" state until the next heating season.

The drain valve belongs to the shut-off valves that must be installed when arranging the heating system. More often used models of brass, matched to the diameter of the pipe

The reverse filling circuits with coolant produced using a pump. The heating function is only switched on after the pipeline has been completely filled with water, the circulation has been checked and diagnosed.

This method is the only correct one if it is necessary to suspend the operation of the boiler for the winter or for an even longer period.

Method # 2 - wet preservation

I use wet preservation if it is necessary to stop the boiler for a short period. The main goal is to keep the equipment in working order, protect it from corrosion, and prevent oxygen from entering the circuit.

To fill pipes at home, use a special liquid that prevents the formation of rust. It is sold in specialized stores in concentrated or ready-to-use form.

For regions with severe frosts, liquids that do not freeze at low temperatures are used. For example, concentrated antifreeze is in a liquid state down to -60 ° C. To prevent the substance from thickening, it is diluted with water. But it must be remembered that the freezing point of an aqueous solution rises.

Antifreeze also has other disadvantages:

- "Eats" rubber;

- has a high degree of fluidity;

- does not tolerate overheating - turns into acid;

- expensive.

Instead of antifreeze, sodium sulfate solution is used at the rate of 10 g / liter of water. The liquid poured into the system is heated to expel air, and then all openings are hermetically sealed. A pressure test pump is used to pump water into the circuit.

Method # 3 - gas preservation

For private houses, the gas conservation method is not used, since this requires special equipment and professional skills.

The essence of the technology is that gas is injected into the pipes, which, in contact with metal, unlike oxygen, does not cause corrosion. These gases include argon, ammonia, helium, nitrogen.

Some types of gas are hazardous to health, and without observing safety rules, you can easily get poisoned or get burned. All procedures are carried out strictly according to the instructions and in protective clothing

The conservation process is complex and is carried out in several stages:

- the system is flushed with deaerated water;

- connect a gas cylinder and reducercontrolling pressure;

- fill the circuit with gas displacing water;

- close the drain valve;

- at an indicator of 0.013 MPa, the gas supply is stopped;

- block the branch pipe, turn off the cylinder.

The main condition for gas preservation is lack of air in the system, therefore, during the entire period of downtime, it is necessary to monitor its tightness.

Method # 4 - applying excessive pressure

The high pressure preservation technology is usually used in enterprises where all the conditions have been created for this. It is used for hot water and steam equipment.

The main task is to prevent oxygen from entering the system. To do this, a pressure above atmospheric pressure is created inside the circuit, while the usual coolant is replaced with deaerated water.

The overpressure method is suitable if it is necessary to suspend the operation of the gas boiler for a short period of time - up to 10 days. Usually, during this period, repair work is carried out that are not related to water heating equipment.

What rules need to be followed?

When carrying out measures for the preservation of boilers in production, they are guided by the requirements set forth in RD 34.20.591-97 "Guidelines for the conservation of thermal mechanical equipment."

The same standards should be observed by owners of equipment installed in private homes.

If you are unsure of your knowledge or skills, contact your service provider. Specialists will carry out work on stopping the boiler and preserving the equipment in compliance with all safety requirements

What you need to remember if you decide to preserve heating or hot water equipment yourself:

- Turn off the gas before any repair work. The main valve is installed at the entrance of the gas pipeline to the house.

- Even the slightest ingress of oxygen into the system will cause corrosion of the boiler parts and piping, so you need to choose one of the preservation methods and perform it strictly according to the instructions.

- When working with chemicals, it is necessary to protect body parts with tight clothing, wear comfortable shoes, gloves and a mask.

- To keep the pipes and units of the unit in working order, it is necessary to observe the dosage when diluting concentrated compounds and dry chemicals.

- Work with explosive or flammable substances may only be carried out by specialists.

- At the end of the work, it is necessary to turn off the power supply to additional equipment - for example, a pump.

The above rules must be followed in order to protect your own health and to preserve the equipment.

After a long standing time of the heating and hot water system, de-preservation will be required - a process that also requires compliance with certain rules.

Conclusions and useful video on the topic

Some boilers are very easy to shut down:

On the transfer of the modern model to summer mode and possible mistakes:

One of the ways to drain the heating system:

If you are leaving home for a long time, you cannot throw away gas equipment without first stopping. In the absence of the owners, an unforeseen situation may occur, which can deprive you not only of the heating system, but also of the house. It is better to first consult with experts on how to turn off the heating and stop the gas boiler, and act according to the recommendations.

Qualified cleaning and preservation can also only be carried out by professionals. Automatic shutdown or transfer to a more suitable mode can be done independently, according to the manufacturer's instructions, but only if you leave the house for a short time.

Do you have any questions in the process of self-preservation of gas equipment? Ask our experts and other site visitors for advice, participate in the discussion - the comment form is located below.