A gas boiler room in a country house means comfort, warmth, always hot water and saving the family budget on fuel costs. The main thing is that the "heart" of the heating system - the gas boiler - does not fail in the cold season.

Units of the Navien brand have established themselves as powerful, conscientious machines, easy to install and convenient in operation, capable of working for a long time without repair and replacement of spare parts. But even with such reliable assistants, sometimes troubles happen - breakdowns due to wear of parts, improper operation or poor quality of the coolant.

Thanks to self-diagnostics, errors of the Navien gas boiler are immediately displayed on the display, and it becomes clear to homeowners which part of the boiler needs attention. We present an overview of the problems that users of Navien boilers most often encounter, as well as tips on how to respond to certain error codes.

The content of the article:

- Classification of boilers Navien

-

Coaching on error codes

- 02 - violation of the circulation of the coolant

- 03-04 - ignition is not performed

- 05-08 - open temperature sensor

- 09 - fan malfunctions

- 10 - failure in the smoke exhaust system

- 13 - the flow sensor has broken

- Review of less common mistakes

- Conclusions and useful video on the topic

Classification of boilers Navien

Gas units of the South Korean brand differ in the place of installation and the principle of operation, respectively, codes errors stated by the manufacturer in the instructions also vary and may change with the advent of new models. Consider current offers.

Gas models are of two types - wall-mounted and floor-standing. Wall-mounted units, in turn, are divided into two categories: traditional and condensing.

Traditional series:

- DELUXE;

- DELUXE S;

- DELUXE Comfort;

- ACE (atmosphere);

- DELUXE PLUS;

- SMART TOK.

Condensing series:

- NCB 700;

- NFB-98H;

- NPE;

- NCB 52-H.

Now only 2 series of floor standing boilers are produced:

- GA;

- GST.

All models of this manufacturer have a whole list of advantages that have made the brand popular in Russia. According to surveys of users who have been using the technique for a long time, 4 main advantages can be distinguished:

Image gallery

Photo from

Traditional wall-mounted appliances heat up almost 14 liters of water per minute - enough to simultaneously use a hot shower and a sink in the kitchen

Low-power wall-mounted boilers can be mounted directly in the kitchen - they work quietly and do not cause any hassle. For more powerful models, it is better to equip a boiler room

The design of the units is thought out so that users can independently service them: read information from the display, clean, change some parts

Navien units are easily recognizable: compact, stylish, with a large logo and convenient control panels. A fragment of a floral ornament is applied to the cases of floor models

High productivity and efficiency

Possibility to install in a convenient location

Easy installation and operation

Beautiful brand design of models

The assortment is constantly changing: old models are replaced by updated, more perfect ones. Not so long ago, a wall-mounted SMART TOK boiler appeared, which can be controlled directly from a smartphone. In the "smart" series there are 6 options with power from 13 to 35 kW, and you can choose the comfort mode right on the way home from work.

Coaching on error codes

By introducing electronic circuits into the algorithm for controlling gas boilers, manufacturers have made it easier for ordinary users to use the units in everyday life.

Now you do not need to call the representatives of the service organization on every occasion, with which contract signed for the supply of fuel, inspection and repair of equipment. Errors are displayed on an electronic board in the form of digital symbols, and instructions for correcting them are given in the technical manual.

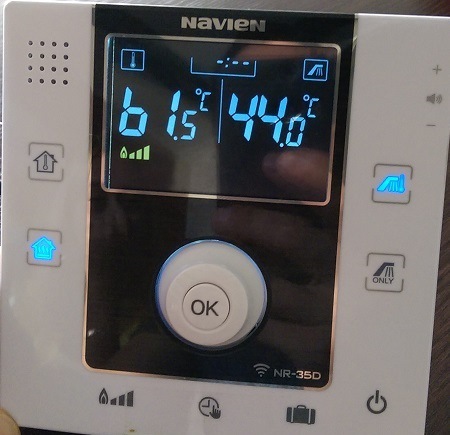

Sample control panel. In modern electronic models, the display is located on the control panel, and the symbols are clearly visible even in the dark thanks to the bright LED backlighting in red, orange or blue

Please note: for Navien boilers, information can be shown both in digital and alphanumeric characters. This means that there is no difference between the error "15" and "E15" - it carries the same information. So, let's move on to the symbols, their decoding and instructions for further actions.

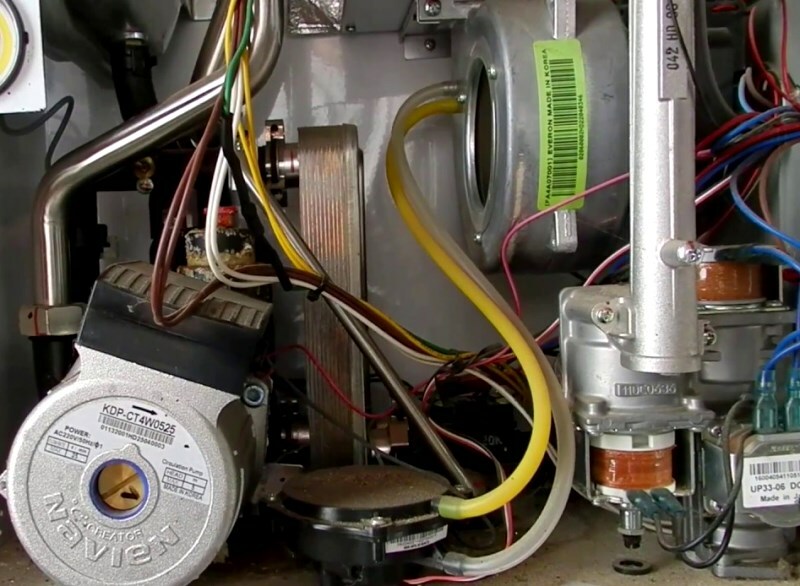

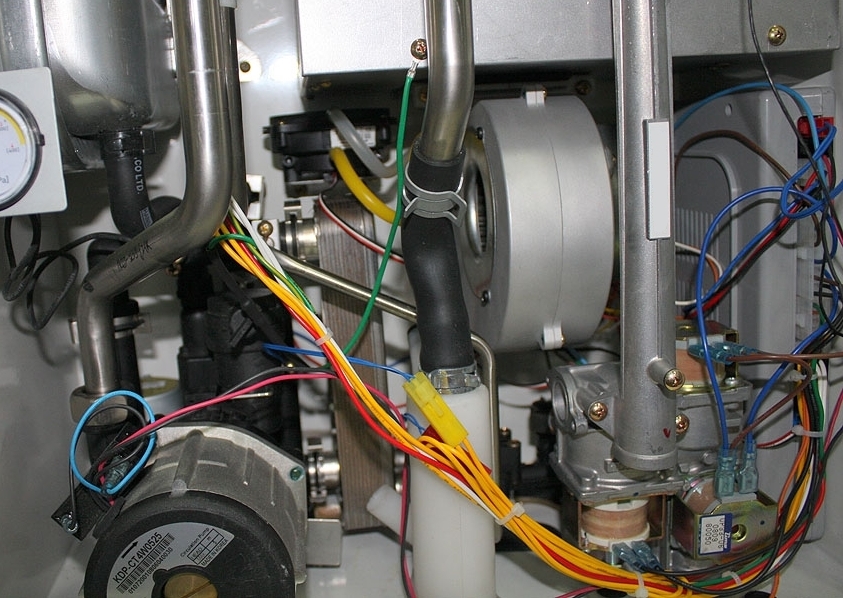

02 - violation of the circulation of the coolant

Outwardly, it looks like this: the heating circuit is operating normally, and cold water suddenly starts flowing from the hot water tap. The information screen, however, displays data on heating the water to the desired temperature.

Causes of error 02:

- breakdown of the circulation pump;

- airing one of the circuits;

- the pressure sensor is out of order;

- decrease in pressure below the working pressure;

- the tap in the coolant distribution area is closed;

- the automation board has broken.

The consequence of any of these troubles is the lack of circulation of hot coolant.

As you can see, there are many reasons, and each will have to be considered. We recommend starting with the simplest steps: check if the valve on the manifold is closed, try to bleed air from the system, equalize the pressure in the network. Check the filters too - circulation may stop due to a banal blockage. In winter, icing of the pipeline is quite possible in a non-insulated section.

If you have a boiler with a closed combustion chamber, code 02 may appear even if the liquid level in the system is insufficient. To eliminate the error, it is enough to add water to the circuit.

If the malfunction of the Navien gas boiler is more complex and concerns a breakdown of a sensor, pump or automation unit, it is better to contact a service center.

03-04 - ignition is not performed

If the flame does not ignite, a spark does not occur, or the combustion is uneven, "pulsates", code 03 may be displayed. Sometimes it looks different: the flame flares up and then goes out.

Possible causes of error 03:

- the connection between the control unit and the electrode is broken;

- breakage of the sensor or electronic board;

- grounding problems.

The safety system of Navien boilers works in such a way that it allows the torch to burn only with a stable air supply from the fan. If the air is supplied intermittently, the flame can be extinguished automatically.

What should be done:

- check if there is a spark;

- make sure that the electrode is connected to the control unit, that is, it reacts to ignition;

- diagnose the operation of the fan;

- see if everything is in order with grounding.

It also happens that the ignition button does not work due to a power outage - check the shield. Worst of all, if the electronic board is out of order, you will have to replace it.

05-08 - open temperature sensor

Often, the communication of the sensors with the control board is interrupted, and a false suspicion arises that some components in the system have broken down. For example, code 05 reports that the connection between the control unit and the temperature sensor has been lost.

This occurs for many reasons, including due to condensation moisture on the contacts of the board or the sensor itself, or in connection with a decrease in the temperature of the coolant to below + 14˚С.

To diagnose the performance of parts, we recommend checking the resistance of the wiring, and if a problem is found, replace the NTC sensor installed in the heating circuit

Error 06 appears if there is a short circuit in the temperature sensor circuit. For this reason, both the sensor itself and the control board may fail, therefore, diagnostics of all "participants" of the process should be performed.

A similar trouble, but already in the DHW system, is indicated by the appearance of errors 07-08 on the display.

18-19 - errors of the return temperature sensor, 21-22 - at the inlet of the service water.

Advice: before replacing sensors or handing over the control board for repair, carefully check all connections - often a failure occurs due to a simple break in the contacts.

09 - fan malfunctions

If the fan speed drops sharply, namely, it drops to 400 rpm and remains in this state for 3 seconds, the protection system will work and ignition will be impossible. If the low speed lasts 10 seconds, the display will show code 09.

The program is set up so that in half a minute it will again start the blowing device. If the speed returns to normal, the boiler will turn on and work in the selected mode, if not, the self-test will be repeated

Indicator 2 thousand. rpm indicates a short circuit. Most likely, as a result, the board is out of order or the fan is broken.

What to do:

- Wait until the unit restarts and tries to fix the error itself.

- If the restart continues to be repeated, it is necessary to check the board, the wire contacts, to clarify the data of the alternating electric current - from 100 to 220 V.

- With normal current parameters and low performance of the blowing device, a fan breakdown is unambiguously diagnosed.

- Replace the fan yourself or invite a specialist.

The matter may also be in the clogging of the outlet filter. Check for blockages and clean if necessary. Often, after this simple action, the boiler starts to work like new.

10 - failure in the smoke exhaust system

Code 10 appears if there is an obstacle in the way of the flue gas outlet from the boiler to the outside. The smoke extraction process is regulated by a smoke exhauster, which creates draft.

Possible causes of error 10:

- blockage in the chimney, reducing the working diameter of the chimney;

- complete lack of traction;

- malfunction of sensors;

- chimney resistance caused by strong wind;

- icing of the pipe.

If the hoses are incorrectly connected to the APS sensor or kinked, code 10 may also be displayed.

To normalize the operation of the Navien boiler, you need to clean the chimney, adjust the draft within acceptable limits, replace the failed sensors

The effect of wind on the combustion process can be reduced by installing a hood on the chimney outlet. If any actions do not help, you should call the wizard for professional diagnostics, maintenance of the Navien boiler and possibly replacing the control board.

13 - the flow sensor has broken

Error 13 reports a malfunction of the control board, which can cause a short circuit. If after testing the breakage is confirmed, the board needs to be replaced. Sometimes everything is simpler - the contacts that need to be tightened are simply weakened.

One of the reasons is the "sticking" of the flow sensor inside the heating system. To determine it, you need to turn off the unit, ring the lines, and if they ring, check the position of the sensor

For repair or replacement, remove the outer panel and look at the position of the flag: when the boiler is on, it must be in a lowered state.

If you turn off the circulating pump, code 13 may also be displayed. As soon as the pump starts working again, the error can be cleared manually by pressing the "Stand-by" button.

Review of less common mistakes

We have listed the error codes that most often bother users. But there are other designations that indicate violations in the operation of Navien gas boilers and potential repairs.

11 - failure in the operating parameters of the water level or pressure. This error appears on the displays of boilers with automatic make-up. To fix it, you need to turn off the system, check the operation of the water filling valve, remove the remaining water in the pump drain, reconnect the pump and restart the system. If it does not help, call the technical service.

12 - lack of flame. There are many reasons, and we recommend that you act as in the case of errors 03-04. First, check if the gas taps are closed, if power is supplied and if everything is in order with grounding.

15 - problems with the control board. If it does not respond to the power supply, then it requires repair or replacement.

16 - overheating of the system, and any of the units can overheat: fan motor, heat exchanger, pump motor. What you can do yourself: clean the filters and heat exchanger, change the thermostat. After a half-hour "rest", the unit can be restarted - most likely, it will work.

17 - errors related to the DIP switch. It is necessary to correct the settings of the control board and restart the boiler.

27 - breakdown of the pressure sensor. If there is no blockage, you need to check the health of the sensor and the fan, and then replace the failed part.

30 - overheating of the smoke thermostat. It is necessary to turn off the boiler, let it cool down for 30 minutes, then restart. If it does not work, check the fan and air pressure sensor, clean the chimney.

93 - the on / off button has broken. It should be replaced on its own or by a specialist.

Many problems are solved on their own, so the manufacturer gives brief instructions on how to resolve emergency situations.

But when it comes to complex repair or replacement, it is better to repair the unit in a service center, with a subsequent guarantee for new parts.

If an unknown error code appears on the display for the gas water heater or the Navien floor-standing model, you should also contact the specialists.

Conclusions and useful video on the topic

Decoding error 02:

Error 03 and how to fix it:

How to disassemble the unit and clean the heat exchanger:

The self-diagnosis system of boilers Navien is a faithful assistant even to an inexperienced user who understands little about the technical intricacies. Thanks to the error codes, you can quickly cope with the stop of the unit, which means that you can keep the house warm.

Before starting operation, we recommend that you familiarize yourself not only with the design and technical characteristics of the gas boiler, but also with the code table carefully provided by the manufacturer.

Please write your comments in the block form below. Share your own experience in identifying boiler errors by decoding the code and eliminating malfunctions. it is possible that your advice will be extremely useful to site visitors.