The principle of operation of an injection burner for small forges is based on the suction of a gas stream into the burner body. You can buy it in the store. However, if you made an injection gas burner for the furnace with your own hands, it will serve no worse.

We will tell you how to build a tool according to all the rules. The main thing is to take into account all the requirements in the manufacture. After all, you still have to deal with an explosive mixture of gas and air.

The content of the article:

-

Characteristics and types of injection burners

- Burner operating principle

- Burner classification according to the main features

- Homemade injection burner

- Pros and cons of an injection burner

- Conclusions and useful video on the topic

Characteristics and types of injection burners

The degree of metal waste when heated for forging, the intensity of scale formation on the surface, and the total gas consumption depend on the design of the hearth burner. In closed forges, short flame burners are used.

Their design guarantees fast mixing of the combustible mixture, which ensures high efficiency. Combustion products from the working space of the hearth are removed evenly and as efficiently as possible.

Burner operating principle

In burners of this type, propane is burned coming from a gas pipeline or cylinder. Here, a mixture of gas and air is formed by ejection, i.e. suction of the latter inside the burner under the influence of the energy of a gas jet under pressure.

In the area where air is taken in, a vacuum appears, due to which the air itself moves in a given direction. Mixing in the burner body, the working mixture is pulled out of it under pressure, creating the required temperature.

Quality of work gas burner depends on the constancy of the ratio of the volume of gas and air. The change in gas density affects the ability of the burner to suck in air.

The fuel combustion device, or burner, is the main component of the gas furnace. Its operation depends entirely on the correct manufacture of this key element.

All changes in combustion temperature must be accompanied by similar changes in the air supply required for combustion.

In case of imbalance of indicators, it is necessary to correct the injection coefficient to achieve its stability. This is achieved by changing the gas pressure or by adjusting the air damper.

Burner classification according to the main features

They are classified according to various criteria. Based on the volume of sucked in primary air, a distinction is made between partial-mixing and full-mixing burners. The main characteristics of the former are the injection coefficient and multiplicity.

The injection ratio is determined by the ratio of the air volumes injected and the gas required for 100% combustion. The expression "injection rate" means the ratio between the primary air volume and the gas consumption of the burner.

Gas combustion in a mixture with air in an injection burner takes place in a special nozzle - a tunnel made of refractory material

Injection burners used in home smithies are low (up to 5 kPa) gas pressure and medium pressure - from 5 kPa to 0.3 MPa. When the gas in the burner is at a pressure of 20-90 kPa, the air suction power remains practically unchanged, even when the gas pressure and vacuum in the hearth undergo changes.

When the pressure drops below this bar, the injection coefficient increases, the pressure drops, and the rarefaction in the hearth increases. Depending on the presence of the distribution manifold, there are single and multi-flame burners.

There is a division by the number of nozzles: with one nozzle - single-nozzle, with several - multi-nozzle. Place these elements in the center or randomly. On this basis, there are burners with a central nozzle and a peripheral one.

Homemade injection burner

To a home-made burner of a standard design, gas is supplied from a cylinder through a special hose, as a rule, it is propane. There is no need for a reduction reducer, since the gas supply is regulated by a working valve located on the cylinder.

Opening and shutting off the gas supply is carried out using a shut-off valve, the rest of the burner adjustments are performed using a working valve. Gas hose, through which the gas flows, is connected to a special nozzle with a nipple.

This allows you to set the magnitude and speed of the flame. The nipple and tube are placed in a metal glass. Here propane is saturated with oxygen from the incoming air.

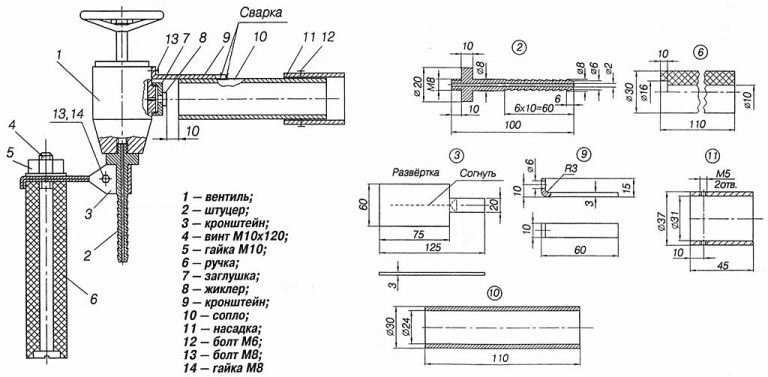

Standard gas burner diagram. On its basis, you can develop your own design. For the convenience of repair and operation, it is better to make it easily collapsible

From a metal cup, the combustible mixture enters the combustion zone through a nozzle under pressure. To keep the process continuous, there are special holes in the nozzle that act as additional ventilation.

For self-production, you will need a drawing of a gas burner for a furnace, as well as a set of tools and materials:

- pieces of pipes, hardware;

- Bulgarian;

- semicircular or round file;

- the drilling machine, if not, can be replaced with a drill;

- semi-automatic welding;

- tap, scribe, drill, metal brush, hammer, pliers;

- circles - stripping, cutting;

- sheet iron with a thickness of 1.2, 3 mm;

- protective equipment for welding.

All work on the manufacture of a fuel combustion device consists of five stages.

When creating a gas burner, the mandatory requirements for them must be taken into account: safety of gas ignition, stable combustion, safety in the event of a change in thrust (reverse impact) and the likelihood of an outbreak of a combustible mixture, insensitivity to moisture inside bugle

At the first stage, a diffuser is made. As a starting material for it, you can take a piece of pipe of a suitable diameter. For example, a stainless steel muffler or a water pipe.

Along the pipe with the help of a grinder, cuts are made to the desired length. A bearing cage with a suitable diameter is stuffed onto the tube. The same is repeated on the other side.

The cuts are welded, then a flap wheel is taken and the surface is processed until it is completely smooth. Brew and clean all existing pores and uncooked areas. With the help of a round or semicircular file, the burrs are removed inside the part.

To carry out work in an economical mode at relatively low temperatures, the pipe 3 has thin walls, which increases the speed of gases, promotes better mixing, prevents the mixture from igniting in pipe

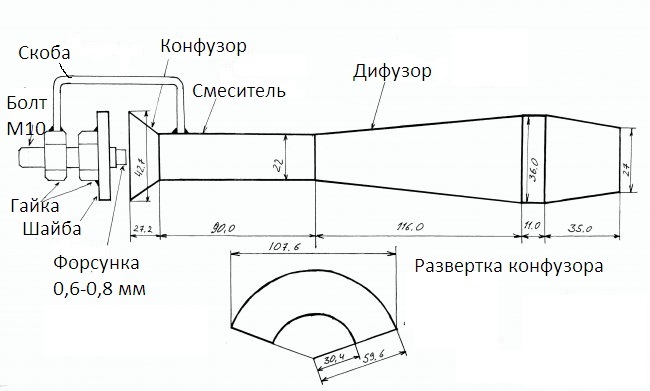

The next step is to manufacture a mixer and a confuser. The first looks like a tube. A water pipe with a diameter of about 2 cm and a length of 9 cm will do. The tube is welded to the diffuser, and to it the confuser is a cone for air intake.

A blank for it can be cut out of a sheet with a thickness of 1.2 mm. Then it is bent, the seam is welded and the finished part is welded to the mixer. A plane is made from the end for abutting the adjusting washer. By decreasing / increasing the gap between the confuser and the washer, the incoming air flow is adjusted.

Next, they begin to manufacture the mechanism for feeding the components of the gas-air mixture. This step requires an M10 long thread bolt. The hat is cut off, then a through hole of 5 mm in diameter is drilled from the end, the M6 thread is cut.

To create a nozzle, you can use a tip for feeding a welding wire from a semiautomatic device. Since it has a decent length, it needs to be cut. In this case, approximately 3-4 mm should remain after the thread. The rest is enough to make another jet.

For further work, you will need a washer with an outer diameter of 43 mm. You can purchase it or make it yourself from a sheet of metal. A hole with a diameter of 1.2 cm is drilled in the center of the washer. An M10 nut is welded to the finished washer.

In the assembly of the unit, screw the nut onto the bolt, install the adjusting washer, screw in the gas nozzle. The jet is inserted flush with the washer by rotating the latter. The first screwed nut is placed in the center of the thread.

Before proceeding with the installation, you need to make a bracket for the assembly to the body. It can be cut from sheet metal. Without changing the position of the assembly, they apply it to the confuser, attach the bracket and weld it to the nut and body. The place of welding is not very important, but it is necessary that the structure be rigid.

By twisting and unscrewing the bolt, the degree of ejection is adjusted. As practice shows, the optimal result is achieved when the nozzle enters the confuser to a depth of about two mm. The amount of incoming air is controlled by a washer.

The final step is testing. For this, a hose is put on the bolt. A pressure indicator of 0.2 kg / cm² is set on the reducer. You can experiment with this value, but you need to remember that with a high gas flow rate, a cylinder, especially with a capacity of 5 liters, can quickly freeze up. In this case, a 0.6 mm nozzle is more suitable.

Before ignition, the washer must be closed completely or a small gap must be left. After igniting the gas, the air supply is gradually increased. The flame will acquire an increasingly intense blue color and gradually move away from the burner nose. A feature of the burner operation in an open hearth is that with further intensification of the air stream, the flame is separated from the burner, and its attenuation occurs.

To avoid such a phenomenon, an obstacle (divider) is placed along the flame path or a burner is used in an enclosed space. In this case, the fire exiting from the nozzle will ignite the gas and the combustion will be maintained.

An injection burner is brought into the hearth through an equipped hole in the wall of a heat-insulated container. An important condition for safe work is the presence of a forced draft

If the burner is running on main gas, then in ideal conditions its flame should be bright blue. When the gas source is a cylinder filled with a propane-butane mixture, the combustible mixture looks like yellow tongues.

Such an injection type burner works well in an enclosed space. If you set it well, you can get temperatures up to 1200⁰. These conditions are suitable for forging workpieces from files, annealing blades, melting non-ferrous metals.

Gas is supplied to the burner from the network or cylinder, the process is controlled with a regulator. To check the regulation and pressure, a test run of the gas is carried out or gas mixturewhile monitoring the smell.

Pros and cons of an injection burner

The use of a quality gas burner for forge has a number of advantages:

- the use of gas energy for air injection;

- good mixing of air with gas;

- the ability to control the volumetric gas / air ratio when changing the temperature regime of the burner;

- ease of use;

- profitability;

- simplicity of design.

Backgammon with advantages, there are also some disadvantages. Single-nozzle burners, taking into account the heat output, are quite long. It is necessary to ensure strict alignment of the axis of the nozzle and the burner. They make a lot of noise during operation.

The power of an injection burner is determined by the volume of gas that it consumes per unit of time. This parameter is significantly different for different burners.

Significant disadvantages of low-pressure burners are the long flame length, as well as the dependence of the secondary air supply rate on the combustion dilution.

He will acquaint you with the types of gas burners for bath stoves and the methods of their installation next article, which is worth reading to all owners of suburban areas with their own baths.

Conclusions and useful video on the topic

The injection burner developed by Alexander Kuznetsov is especially popular. In this video, he tells what the structure consists of and how to assemble it:

An example of the operation of an injection burner:

Correctly designed and made with your own hands exactly to the requirements, the injection burner will become a reliable assistant for a long time. This device will replace expensive factory-made tools. With its help, you can solve many everyday problems without resorting to the help of professionals.

Do you want to talk about how you assembled an injection burner for forging with your own hands? Do you have any useful information on the topic of the article? Please leave comments in the block form below, ask questions, post photos.