Today, the trend is to switch to blue fuel. Gas is used in internal combustion engines of cars instead of gasoline and diesel. He replaced wood and coal in heating boilers. It is worth trying to convert to propane-butane and hand tools, right?

Let the first in the arsenal be a gas torch from an injection-type blowtorch. It will retain all the functionality of the "donor". Along the way, with the provision of standard capabilities, the homemade product will acquire new useful qualities.

We will tell you how to make this equipment useful in everyday life with your own hands. Let's get acquainted with the design features and differences of the torch from a conventional blowtorch. Compliance with our recommendations for safe operation will eliminate risks and hazardous situations.

The content of the article:

- Blowtorch design

- What is the difference between a gas torch and a blowtorch?

- Assembly and testing in stages

- Safety measures during use

- Scope of application after rework

- Conclusions and useful video on the topic

Blowtorch design

If you already have a blowtorch, you most likely know how it works and how it works. But it will be useful to briefly recall some points so that the disassembly does not cause unexpected difficulties.

At the same time, we will define the terminology, because home craftsmen often name the details in a folk way, and instructions are given in a more technical language.

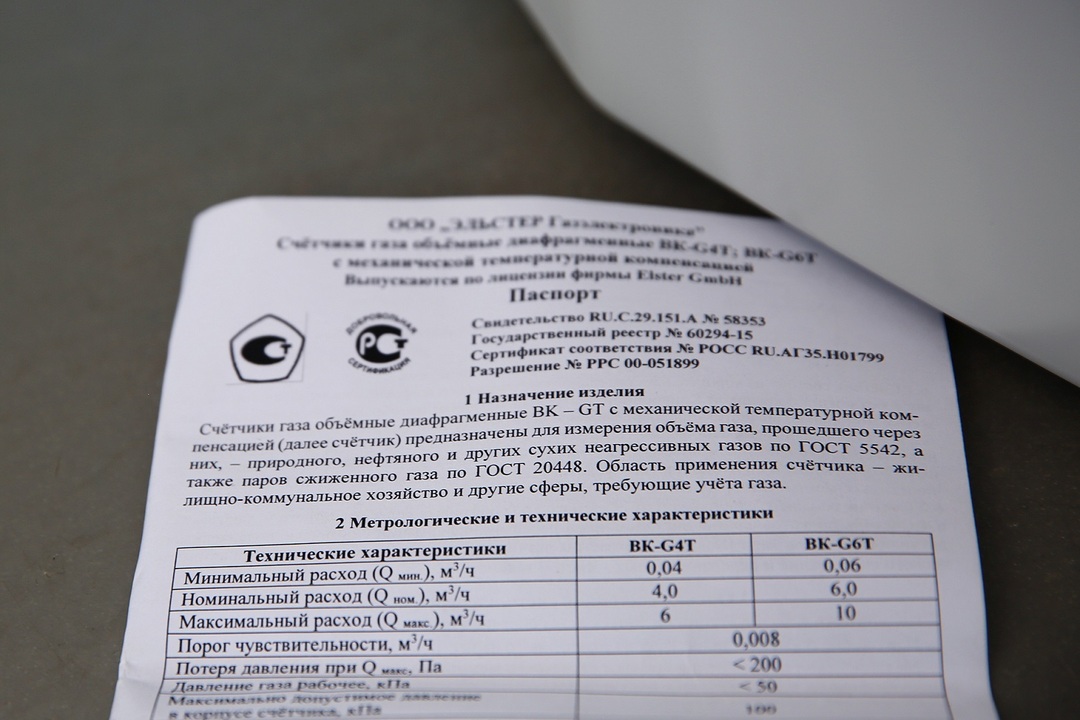

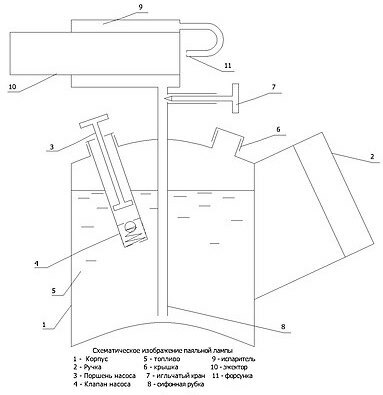

Blowtorch with injection torch, pump, handle for adjusting the flame strength, handle for holding and preheating bath

Most household blowtorches are of the nozzle, or otherwise, injection type. Such a lamp has a housing, which also serves as a reservoir for liquid fuel. This is the largest part of the apparatus.

A heating bath is fixed to the body and the upper part - the burner - is screwed through the fitting. The burner is the second largest after the body.

Its main elements:

- an evaporator in which, as a result of heating, liquid fuel is converted into gaseous fuel;

- a nozzle directing a gas stream to an ejector, at the exit from which it ignites, forming an open flame;

- adjusting screw to increase or decrease the flame.

Fuel from the reservoir enters the burner through a siphon tube. The reservoir also includes a pump. There are other parts, but they will not be included in the updated burner, so there is no need to consider them.

An outwardly simple apparatus consists of many elements, but for the manufacture of a gas burner only the upper part and a siphon tube are required

We showed a photo and a diagram of a blowtorch of a typical design, but your particular model may have minor differences.

What is the difference between a gas torch and a blowtorch?

Blow lamps run on liquid fuel: gasoline, kerosene, alcohol. As the name implies, the fuel for the gas burner will be liquefied petroleum gas, namely propane-butane mixture, which is contained in red cylinders.

Changing the design and switching to gas provides the following advantages:

- usability increases;

- increased safety;

- the scope of application is expanding;

- the cost of operation is reduced.

When working with a blowtorch, you are holding in your hands not only the torch, but also the tank with a flammable substance. The weight of a 2 liter blowtorch with a full tank is about 4 kg. Height and width, respectively, more than 30 cm and 20 cm. With such characteristics, the maneuverability of the hand tool is extremely low.

Unlike a blowtorch, a gas burner has compact dimensions, low weight, good lies in the hand and therefore is convenient for a variety of jobs that require an open, adjustable flame

For a gas burner, a reservoir is not required. Removing the most voluminous part of the blowtorch, you get a compact and lightweight apparatus that will help you perform various types of work, including in hard-to-reach places.

However, you do not have to hold a container with gasoline or kerosene in your hand directly near an open flame, as thanks to the long hose, the gas cylinder can be positioned at a sufficient distance from the worker places.

At ambient temperatures above -20 ° C, the gas burner does not require preparation before use. It is enough to open gas cylinder valve, adjust the strength of the flame and you can cook, solder, warm up... Even in a 5-liter cylinder, the gas supply will be enough for many hours of continuous operation.

Unlike a gas torch, a blowtorch needs preliminary preparation regardless of external conditions. It is necessary to pour gasoline or kerosene into the tray and set it on fire to warm up the evaporator. Only with sufficient heating will the first portion of the liquid fuel entering the evaporator go into a gaseous state.

Liquid fuel consumption is 0.6-0.8 liters per hour. Considering that a 2-liter blowtorch can be refueled only by ¾ of the tank's volume, the fuel supply will last at most for 2 hours. Then you will have to take the canister again and add fuel to the tank, but before that you still need to wait until the lamp has completely cooled down.

Recall that it is impossible to open the reservoir near a hot lamp, otherwise there will be contact between a hot burner and gasoline vapors, which is fraught with ignition and explosion. Only after waiting for the lamp to cool down can you pour fuel into the tank and the tray and repeat the entire preparatory procedure, including heating and pumping air, which will take about 10 minutes.

The blowtorch, during normal operation, gives off the smell of gasoline, which is not only unpleasant but also harmful. When operating on liquid fuels, soot and soot will more quickly clog the burner holes and settle on the outer surfaces, staining hands and clothing.

Gas is the cleanest fuel, so the gas burner needs to be cleaned less frequently. In principle, there should be no smell of gas during use of the burner, and its appearance indicates a malfunction of the device, which requires immediate termination of operation and elimination of the causes of the leak.

Assembly and testing in stages

Consider several options for assembling a gas burner and each of them will require its own materials and tools. The minimum set includes a grinder, a wrench, FUM tape, a brush, a handle, 2 fittings with nuts and clamps.

You will definitely need gas hose length 10-20 meters, liquefied gas cylinder (propane-butane), reducer to it and the actual blowtorch with a working burner.

When working, use personal protective equipment: glasses and gloves. Do not smoke under any circumstances: firstly, there may be flammable fuel residues in the tank, and secondly, if handling gas equipment, which includes LPG cylinders, it is also necessary to observe the measures security.

The burner is connected to a gas cylinder only through a pressure reducer that lowers and stabilizes the pressure. The most convenient will be a 5 liter cylinder with carrying handles.

Having prepared the tools and materials, you can proceed directly to the alteration of one apparatus into another.

The main stages of the process:

- disassembly of the blowtorch;

- preparation of parts for assembling a gas burner;

- assembly of a gas burner;

- tests.

Unscrew and remove the pump immediately. In the future, it will no longer be needed. Unscrew the entire top of the blowtorch, i.e. the torch assembly. It will become the basis of a new, already gas burner.

It is advisable to clean the burner parts of an already used lamp from carbon deposits and soot. The nozzle is cleaned with a special needle, which usually comes with a blowtorch.

If such a needle is not available, use a wire that fits easily into the nozzle hole in diameter. The same needle or wire is used to clean the fuel pipe. The soot is cleaned from the outer surfaces with a brush.

Having made four cuts with a grinder, remove the fitting with a siphon tube. The part of the body, which will remain on the fitting when it is cut out, is removed with the help of a grinder, the area under it is cleaned of notches. After processing, the union is screwed into the burner branch pipe, sealing the connection with aluminum gaskets.

As a tube for connecting the burner to the hose, you can use a siphon tube, having previously cut it out with a grinder from the reservoir of the blowtorch

You can do without cutting the fitting out of the body by replacing the "native" siphon tube with a new metal tube. The end of this tube is welded to a nut, which is pre-screwed onto the burner pipe. The formed weld is cleaned with a grinder equipped with a flap disc.

Having connected one end of the tube to the gas burner, the other end is connected to the hose. But before that, you need to put a handle on the handset so that you can use the device as conveniently as possible.

The handle is made from a block of wood that is turned on a lathe to give it a rounded shape. You can also use a hacksaw and chisel for this purpose. In the center of the bar, a through longitudinal channel is drilled to fit the diameter of the tube. To avoid chipping, the surface of the handle is protected with sandpaper or a grinder.

If you don't want to waste time sharpening a block, make a handle from a wooden handle from a shovel, hoe, or other garden tool. In a cut of a suitable length, a longitudinal hole is also drilled, the sections are cleaned. You can use other materials at hand, the main thing is that they are not flammable and, in order to avoid burns, have low thermal conductivity.

The next step is to connect the hose to the tube. If the diameter allows, the hose is pulled directly onto the tube and secured with a clamp. But it is better to connect the hose through the fitting. To do this, you will need to cut a thread at its other end in advance, even before you attached the tube to the burner.

This can be done on a lathe or using a die (scraper) - a hand-held threading tool. It is recommended to chamfer the end of the pipe and then apply a small amount of machine oil to it to make it easier to screw on the die.

If you have the time, the lathe and the skills to work on it, you can make a gas torch without using parts from a blowtorch

An FUM tape (fluoroplastic sealing material) is wound onto the threaded end of the tube to seal the connection, and the fitting is screwed on. A hose is put on the fitting. The second end of the hose is also connected through the fitting to the reducer of the household propane-butane cylinder.

Before connection, the fittings are purged to remove debris particles. Perform all manipulations with the gas cylinder with the valve closed. The hose must be one piece. Never use interconnected hose sections.

Having assembled the gas burner, you need to test it. Apply soapy water to threaded and welded joints. After slightly unscrewing the cylinder valve, apply gas. If bubbles do not form, there is no smell of gas, which means that the connections and gas lines are tight.

Do not check for gas leaks by holding an open flame near the problem area.

Now it remains to test how the burner functions, and you can use it as intended. When testing, do not immediately set the adjustment knob to the maximum value. Check how the device functions under moderate conditions and add power only if the result is positive.

Safety measures during use

Remember the explosion hazard of liquefied petroleum gas, including propane-butane mixture and others gas mixturesused in gas equipment. Observe the safety rules both during testing and during further use of the gas burner.

Do not use a gas burner closer than 10 meters from a gas cylinder, this violates safety rules and may cause an explosion and fire

It does not matter whether the burner was made at the factory or made by hand, if it is used improperly and if the gas cylinder is mishandled, the following negative consequences are possible:

- the outbreak of a fire;

- explosion of a gas cylinder;

- getting burned.

A burn can be obtained not only from an open flame, but also by touching heated surfaces. To minimize risks, install the gas cylinder strictly in an upright position on a level surface, in a well-lit area, but not in direct sunlight or in an aisle or doorway opening.

The distance from the cylinder to the open fire should be at least 10 meters, and from heat sources - at least 1 meter. Protect the cylinder from knocks and falls. Do not connect more than one burner to it.

Check the reducer quarterly, the burner monthly, and the hose daily. The need for daily inspection of the hose is due to its vulnerability - even a slight mechanical exposure can lead to ruptures, cracks, which will become the place of gas leakage, which should be excluded.

The risk of gas leakage increases, and if the nozzles and tubes are dirty, it is therefore necessary to clean them regularly. For inspection and maintenance of the burner, first disconnect it from the gas cylinder.

With timely maintenance of the torch, its flame will be powerful and stable, which will allow welding of many materials at temperatures around 1000 ° C.

Do not use open flames to heat a frozen gearbox. Operate the burner outdoors or in a well-ventilated area. Unplug the power supply when working near electrical appliances, do not pinch or bend the hose, do not wrap it around your waist, etc.

After finishing work, be sure to tighten the cylinder valve and put on the protective cap on the cylinder.

Scope of application after rework

Gas burners are used in household and agriculture, in construction and repair work, in the repair of vehicles and equipment,

In addition to the listed areas, gas appliances are used for the following purposes:

- installation of heat shrink tubes;

- melting the solder before soldering;

- heating metal water pipes;

- heating bitumen for roof repair.

In addition to the above, the device serves to remove paint and varnish by firing the surface, for welding materials with a melting point of about 1000 C. With its help, right on the construction site, you can cook or warm up food, boil water for tea.

Conclusions and useful video on the topic

A detailed story and a visual demonstration will help you better understand all the features of the process and then repeat it yourself:

Guidelines for unscrewing the top of the blowtorch, cutting the siphon tube out of the body, and assembling the gas torch:

As the catch phrase says, how many people, so many opinions. By analogy, we can say: how many home craftsmen, so many methods of making homemade burners. The following video confirms this;

Making a gas torch from a blowtorch is easy. You can get by with the simplest tools that a home craftsman will probably find. With minimal skills, all work will take no more than 30-40 minutes. As a result, you will receive practically free of charge the apparatus necessary for the household, and at the same time the satisfaction from the successfully done work.

If you have experience in assembling a gas burner or upgrading equipment already in use, please share it with your site visitors. You can leave stories about your own making, useful tips, a photo of the process in the block below. In it, ask questions on unclear and controversial points.