The reducer is a mandatory component of the connection diagram for tanks with liquefied and compressed gas mixtures. They are installed on gas tanks, single cylinders and cylinder installations for stabilization and reduction standard values of gas pressure entering household equipment, welding torches and heaters.

It happens that during operation, the device for ensuring stable pressure begins to make noise. We will tell you why the reducer on the gas cylinder hums, we will analyze why the sound appears. We will show you how to eliminate irregularities in the operation of the device, which can be determined "by ear".

The article presented by us describes in detail the types of gas pressure stabilizers and their design features. Methods for restoring full-fledged working capacity are presented. Our recommendations will help home craftsmen to cope with the repair on their own.

The content of the article:

-

Gas pressure reducing devices

- Types of gas reducers

- Design features and principle of operation

-

Disturbances and repairs

- How to change the membrane?

- How to fix the reducing spring?

- How to change a pressure reducing valve?

- Conclusions and useful video to the topic

Gas pressure reducing devices

The need to use reducers is due to the difference in gas pressure in tanks intended for storage and metered supply of gas to the devices, and the operating parameters of the pressure required by these devices to perform responsibilities. When taking fuel from a closed container, the pressure of the gas mixture must be reduced by a factor of ten or more.

Reducing the pressure of a liquefied or compressed gas mixture to operating characteristics is the main job of reducers. In addition, they automatically maintain the pressure of the gas flow within the limits required for normal operation. And they also protect the gas tank from a reverse shock, which is possible when the flame is activated.

Image gallery

Photo from

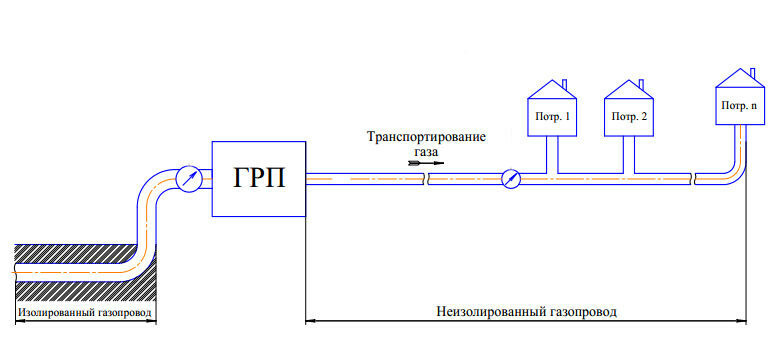

A reducer is an obligatory component of the scheme for connecting gas equipment to an autonomous gas source - a cylinder, an installation from a group of tanks, a gas holder

The task of the reducer is to lower the pressure with which vapors of the liquefied gas mixture are supplied from the tank.

In the simplest models of gearboxes for gas tanks, there are no complex technical components. There are either no adjustment devices at all, or they are primitive mechanical

Devices that regulate gas pressure are so simple that being outdoors and working in any weather have absolutely no effect on their work.

Pressure regulators for the standardized supply of gas from a cylinder are produced for steel and composite tanks. They differ in the amount of reduced pressure

Reducers are installed on all types of gas cylinder installations, including two or more cylinders, one or two arms, one of which is a backup

Structurally more complex gearboxes are installed at the outlet of the gas tank. They perform a two-stage vapor pressure reduction of liquefied gas mixtures

They install regulators not only for servicing stationary equipment, but also for supplying gas with standard pressure to gas burners, heaters, tiles

Gas cylinder with inlet reducer

Reducer with pressure gauge for pressure control

Simple frog model

Location of the reducer with a cylinder on the street

Composite cylinder pressure regulator

Gas cylinder installation with a reducer

Gas tank control devices

Gas supply to a mobile gas stove

With the help of reducers, the gas pressure is regulated. They can be configured to supply a gaseous environment with pressure settings that are acceptable for literally any type of domestic and industrial equipment. Despite the extensive list of functions, structurally all types of devices are simple, and even work on a similar principle.

Types of gas reducers

In order to understand why the gas cylinder began to make noise, you need to study its structure. Let's analyze which types of gearboxes to regulate and stabilize the pressure of gas mixtures are used in everyday life.

The classification is made according to the following grouping characteristics:

- Principle of operation. Reducers are of direct and reverse action. The former reduce the pressure in the tank itself and in front of the branch pipe connected to the gas equipment. The second - first, the pressure in the cylinder is lowered, then at the outlet from it.

- Appointment. There are network (C), balloon (B) and ramp (R) devices. Network ones are installed on gas supply pipelines, ramp ones - on cylinder installations, which ensure the supply of gaseous fuel in large volumes. For domestic conditions and one-time welding works, balloon models are suitable.

- Reduced gas type. Pressure stabilizing devices are installed on all types of gas cylinders. In order to accurately select the required reducer, they are painted in the colors of the cylinder. Red is produced for propane tanks, blue for oxygen cylinders, and white for acetylene tanks.

- Regulation scheme. The setting of operating pressure parameters can be made and adjusted mechanically, such devices are single-stage (O) and two-stage (D). Reducers with pneumatic pressure selection are available in single stage only.

- Connection. Reducers are manufactured for installation on cylinders with flammable and non-flammable gases. The devices are connected to the oxygen tanks with union nuts with a right-hand thread, to cylinders with a propane-butane mixture - with nuts with a left-hand thread. The acetylene reducer is connected using a clamp and a stop screw.

Let's disassemble and study the design with the principle of operation of gas reducers, traditionally used in everyday life to adjust the flow gas mixture to devices.

Design features and principle of operation

Summer residents and owners of small private houses to supply gas to stoves, heaters and heating boilers use one of the most common models of a gas reducer in everyday life: NZGA RDSG-1-1.2, which received the popular name "frog", or her analogs.

Image gallery

Photo from

The pressure regulator of the liquefied mixture of propane and butane is intended for servicing gas equipment that consumes at least 1.2 m³ / h

The body of the regulator is made of materials resistant to external influences and pressure of the gaseous medium, dimensions are 158 × 111 × 50 mm. It can work at temperatures from -30 to + 45 ° С

The regulator is connected to the gas tank valve using a union nut with a left-hand thread. A textile-rubber hose Ø 9.0 mm is connected to the equipment

In order for the reducer to serve for a long time and without problems, it must be protected from direct UV exposure and precipitation.

LPG pressure regulator RDGS-1-1.2

Overall dimensions of the device

Connecting the cylinder gas reducer

Conditions for normal gear unit operation

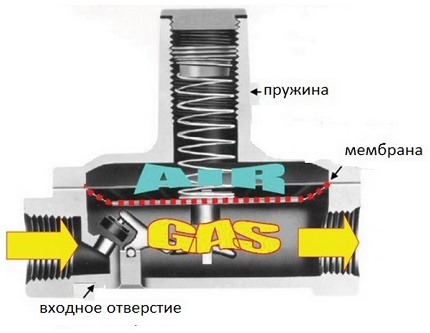

The one-stage model is arranged very simply. The reduction is carried out by a diaphragm pressed from the outside by a spring. The membrane limits the path for gas movement through the cavity of the device so that a flow with a given volume and standard pressure enters the gas hose or pipe from the outlet.

If the pressure in the reducer cavity rises, the valve and washer connected to the diaphragm rise and cover the inlet. This is how the pressure stability is ensured. And if it is necessary to change the operating characteristics of the pressure, these control elements are displaced, increasing or decreasing the cross-section of the inlet.

The frog-type pressure regulator most often starts to make noise due to damage to the membrane or loss of tightness in the event of its displacement

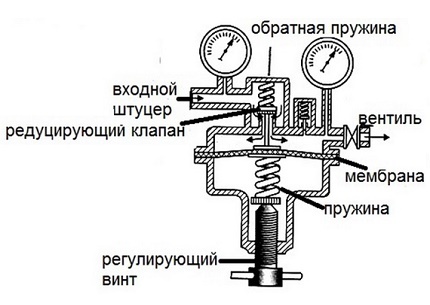

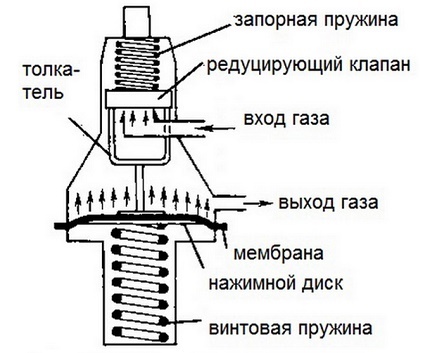

In slightly more complex devices, for example, in the model FL92-4 PS, the reduction is carried out by a valve that restricts the flow and thus forms the pressure required by the devices.

The membrane in such devices does not directly participate in the formation of pressure, but only reduces the initial parameters. On the one hand, the gas flow acts on it, on the other, a helical spring pressing from below.

In the connection diagrams of reducers with the possibility of adjusting the gas pressure, a pressure gauge is required. It is needed to control the set parameters and monitor the state of the gas mixture in the tank.

These devices are characterized by some pressure loss as the blue fuel is consumed in the tank with the gas mixture. Therefore, there is an adjusting screw on the body that allows you to adjust the performance. In order not to make a mistake with the adjustment, such models are equipped with pressure gauges.

In more complex models of reducers, the pressure characteristics of the gas mixture required for operation are set by both the bending diaphragm and the opening valve

In devices of the third type, for example, TECH CONTROL series OX OR-128 brand Svarog 95255, the reduction and stabilization of the pressure characteristics is carried out due to the simultaneous movement of both the valve and membranes.

The gas flow entering the cavity of the reducer is held and controlled by a valve on one side, and a membrane supported by a spring with a transfer disc on the other.

Two pressure gauges are used to monitor the pressure parameters in regulating devices with a working valve and a diaphragm. Mount them at the inlet and outlet of the gearbox

The operation of gearboxes of the third type should be controlled by two pressure gauges installed at the inlet and outlet of the device. They also tend to change the operating pressure at the outlet of the reducer as the gas source becomes empty.

Disturbances and repairs

We examined the structure of typical models of gas reducers and made sure that there are no technically complex assemblies in the design. Everything is so elementary that it is not at all necessary to contact gas workers to repair devices. Simple repair operations can be easily performed with your own hands.

You just need to figure out in advance what to do so that the reducer on the gas cylinder stops buzzing.

Image gallery

Photo from

In order to independently determine the cause of the malfunction of the liquefied gas pressure regulator, the device will need to be disassembled

Often, the cause of noise in the gearbox, which appears due to deformation or displacement of elements, can be eliminated in the process of a banal bulkhead and cleaning.

Regulator parts that have received serious damage, cracks, chips, breaks must be changed using repair kits of the same production as the gearbox

To replace the gearbox membrane, a similar element can be cut from a rubber-fabric material with exact observance of the size and shape

Dismantling the gas pressure regulator

Cleaning and replacing sealing elements

Broken thread on the reducer tube

Damaged gas reducer diaphragm

The reasons for the appearance of noise in the reducing device include:

- Deformation and damage to the elastic working element (membrane) of the device, which is often caused by the excess pressure of the gas mixture at the outlet of the cylinder or gas holder.

- Incorrect operation. Most often, due to inaccurate and illiterate actions in the process of self-adjustment, the spring or membrane is damaged.

- Preparation for supplying low-quality, poorly purified gas mixture to gas appliances.

Often, at the initial stages of the appearance of noise in the gearbox, it is enough to simply correct the factory settings. However, we note that the "frog" refers to unregulated devices, in any case it will have to be repaired. Repairs are made by simply replacing damaged parts: a membrane, the end of the bypass valve or a spring.

How to change the membrane?

To replace the membrane, it is better to use a repair kit commercially available from the manufacturer of the gas reducer. This elastic element belongs to the abraded and periodically worn category, therefore manufacturers of expensive gearboxes supply replacement parts for sale.

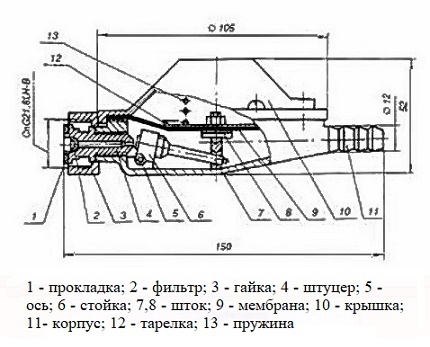

In order to competently perform repairs and change damaged parts, you need to thoroughly study the device using the technical documentation attached to the product

If you do not have a diaphragm for your gearbox brand, then you need to find out the following characteristics:

- Dimensions of the rubber-fabric diaphragm (membrane).

- The thickness of the oiled elastic fabric from which the membrane is made.

- The location of the fixation points around the circumference of the membrane.

The data can be found in the technical documentation for the device or obtained as a result of banal measurements.

One of the typical reasons for a malfunction of the gas pressure regulator from a cylinder is a loss of tightness in the area of contact of the membrane or damage to it itself

It happens that the sound in the gearbox appears not because of a broken or deformed membrane, but because of the loss of tightness between it and the body.

In this case, it is enough to simply sort out the reducer. Before reassembling, the parts of the body in contact with the membrane must be lubricated with a sealant, then the components must be connected, having achieved a flawless fit of the diaphragm to the rigid base.

How to fix the reducing spring?

Replacing the spring that presses the valve or diaphragm is as easy as installing a new diaphragm. In the design of reducers used in circuits with gas cylinders, reducing springs of the 1st degree, Ø 15.5 with the number of turns of 12-14 pieces, are used.

Springs are used in the construction of all types of gas reducers. They are found in elementary unregulated “frogs” and in more complex devices with adjusting devices.

The spring during operation can simply crack, lose its elasticity and elasticity, and stretch. Due to any of the listed faults, the diaphragm and the inlet valve will not be able to balance their force, i.e. control over the gas supply to the reducer will be lost.

In the event of a breakage of the spring, it is replaced with an absolutely similar part. If it is just a little stretched out, the problem is solved by installing a gasket. The thickness of this seal is selected based on the situation, measuring the distance necessary for reduction in fact.

How to change a pressure reducing valve?

This work is more serious than the previous steps. An important functional part of the reducer is associated with the adjusting screw, the position of which determines the gas pressure. It is pressed by a spring, which can be easily damaged with excessive force.

In addition, the valve may not cope with the duties due to damage or deformation of the end of the tube abutting against it. The movement of the rocker arm may be impaired by a displaced or damaged part. More failures in the operation of the valve are observed due to wear of the gasket.

In the device of pressure regulators for compressed gases, used in everyday life mainly for gas welding and cutting metals, similar structural elements are used

Naturally, to restore the valve's performance, you will have to disassemble the gearbox housing. The rocker arm mobility is ensured by installing the offset parts in place. If necessary, sand the edge that prevents free movement.

It often happens that all irregularities in the operation of the valve are associated with just a leaky gasket. Because of it, the elements of the device slightly change their position, but even fractions of millimeters are reflected in the functionality of such a sensitive device. "Cured" by installing a new gasket.

If the end of the tube is damaged, you just need to grind it. If the tube or rocker is seriously damaged, it is best to replace it. Replacement is carried out using repair kits produced for the maintenance and repair of gas fittings.

Conclusions and useful video to the topic

The following video will illustrate the device and principle of operation of a reducer for a liquefied gas mixture:

The video will introduce you to the recommendations for choosing a “frog” type gearbox:

Video presentation of propane reducer with pressure gauge:

It should be remembered that the inspection of the technical condition and repair of the fittings of gas appliances must produced by gas workers involved in the supply of blue fuel and maintenance equipment. However, you can handle the simplest operations yourself. This happens, for example, if it is difficult or impossible to call a gasman to the dacha.

Do you want to talk about how you repaired the gas pressure regulator with your own hands? Do you know the intricacies of the process that can help your site visitors? Share them, useful information and photos on the topic of the article in the block below.