It's hard for a zealous owner to part with things that have served for a long time and have become familiar, isn't it? If you have purchased a new gas stove, and the old one is still operational, then, you must agree, it is more rational to take it to the country house, where it will serve for many more years.

To convert to bottled gas, you just need to replace the nozzles in the gas stove. Having the skills of repair work, this is not at all difficult to do on your own, so you can save both on the purchase and on calling the master. Why a replacement is needed and how it is done, we will consider in detail in our article. Here are step-by-step instructions, providing them with visual photos and useful videos.

The content of the article:

-

Purpose and design of jets

- The principle of operation and the device of the nozzle

- Diameter and thread of nozzles

- Popular injector malfunctions

- Cleaning tips

-

Instructions for replacing the hob and oven jets

- Instruction # 1 - replacing the hob nozzles

- Instructions # 2 - replacing the oven jets

- Helpful tips for replacing injectors

- Safety precautions when replacing an injector

- Conclusions and useful video on the topic

Purpose and design of jets

Of the three systems existing in a gas stove, the gas system, consisting of shut-off valves, pipelines, burners and burners, is the basic one. We wrote in detail about the device of the stove in this material.

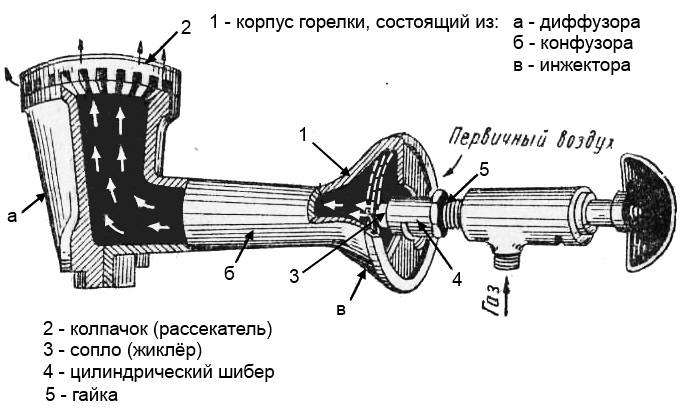

Regardless of the plate model, the composition of its components is the same, and together they serve for transportation gas supplied to the stove, mixing it with air (to saturate with oxygen), dosed supply to the holes divider. On the gas path, a shut-off valve and a burner nozzle, otherwise called a nozzle or nozzle, are responsible for the dosage and pressure of the gas.

The principle of operation and the device of the nozzle

The gas supplied to the gas stove burner (the device where the gas-air mixture is formed) can be of different types - natural (methane) or liquefied (balloon - propane).

For efficient, stable operation of the gas stove, gas mixing and supply to the burner divider must be carried out evenly, at a certain speed. For this, there is an important part in the design of the gas burner - the jet.

So that during operation of the burner no combustion products harmful to humans are emitted, dishes are not smoked, nozzles corresponding to the type of gas are installed in the burners of gas stoves. On the left - the flame when the nozzle matches the type of gas used, on the left - the nozzle does not match the type of gas used

Let's take a closer look at what jets are in a household gas stove. This is a part of the burner, designed to ensure that the gas enters the burner with the appropriate pressure in the required volume. For this, a calibrated through hole is made in the nozzle, which determines the parameters of the gas jet that meet the conditions specified by the manufacturer.

These conditions relate to the optimal power of the gas stove, determined by the maximum complete combustion of the consumed gas, indicated by the manufacturer among the technical characteristics of the equipment.

Diameter and thread of nozzles

The nozzles are bolt-shaped, equipped with an external thread and a hex head. The through hole (nozzle), located in the center of the part, has a diameter calculated according to the type of gas, its pressure, as well as the method of supplying the gas-air mixture and the power of the burner.

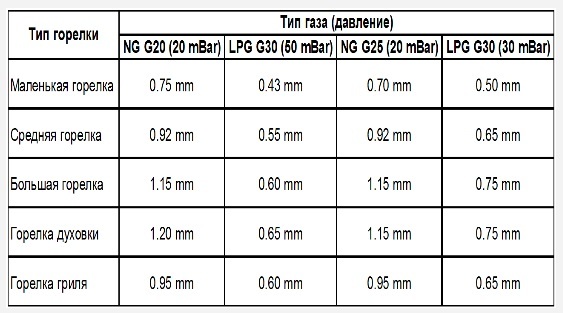

For bottled gas, the nozzle diameter (with the same design and burner power) is needed a little less, for natural gas, a little more.

If natural gas jets are installed on the stove connected to cylinder gas, the pressure of the gas entering the burner will be more, less air (and oxygen) will be captured, the flames will be noisy and long, have an orange color and smoke. In this case, the situation can only be changed by replacing the nozzles with parts with a smaller nozzle diameter.

Depending on the power of the burners, nozzles with different nozzle diameters are used for the gas stove. Maximum diameter for oven jets and large burners

In most models, the hex spline of different nozzles has the same typical size, so a 7 mm wrench is needed to unscrew the replacement part of different plates.

Different in jets are the diameters of the holes, the thread pitch and the length of the part (for natural fuel - the length is shorter, for liquefied fuel - longer). The dimensions of the channel diameter are knocked out on the part head (in hundredths of a mm, much less often the marking is in mm).

Table with the recommended average diameters of nozzles used in most modifications of gas stoves for different types of gas used

Jets are replaceable parts. When the stoves are sold, they are usually equipped with nozzles designed for natural gas. The components of many modern models of gas stoves also include nozzles designed to switch them to bottled gas. If this is not the case, then a set of jets can be purchased separately there, in specialized stores, or via the Internet.

The nozzles are made of brass. It is thermally stable, durable and corrosion resistant. During operation, they heat up slightly. In older plates, the vertical nozzles were made of brass, and the base into which they were screwed was made of aluminum alloy. Therefore, when replacing or cleaning the nozzle, be careful not to damage the threads.

If the documents for the unit are lost, determining the thread of the gas stove nozzle when purchasing replacement parts may cause some difficulty. However, it is not difficult to determine the thread pitch of the nozzles of most stoves, since there are only two values - 0.75 and 1.0 mm.

Until 2009, slab jets were manufactured with a thread pitch of 1 mm. Most new cookers manufactured since 2009 have 0.75 mm threaded nozzles. To determine the size, it is enough to attach a ruler with clearly visible millimeter divisions to the thread.

Applying a ruler to the thread, we look whether its pitch coincides with the millimeter risks of the ruler, or the distance between the turns is less

When converting the stove to gas from the cylinder, not only the nozzles are replaced. Replace and gas reducer.

Popular injector malfunctions

The jets usually last a long time. Their replacement is required when switching to a different type of gas or in case factory marriage. More often it becomes necessary to clean them from soot and clogging.

The following manifestations are associated with clogged nozzles:

- the stove smokes, instead of an even blue flame, red-yellow tongues appear above the divider;

- one of the burners does not light up;

- the burner does not burn well, sometimes it goes out;

- when you release the button (handle) that turns on the ignition device, the oven flame goes out, or does not ignite at all - this happens when due to insufficient gas supply, the generated heat is not enough to heat the temperature sensor, and the fuel supply is shut off by the gas control system automatically.

Replacing a separate nozzle is required if the gas burns so intensely on the burner that the flames break away from the diffuser. This happens in the case of a factory defect. If a similar picture is observed on all burners, it is worth checking the reducer.

You will need few tools for work related to nozzles: a set of open-end and ring wrenches, a Phillips screwdriver, a thin needle (it is better to fix it on the end of a pencil), a wire or fishing line. For cleaning, soapy water or other liquid dishwashing detergent is also useful. Do not use abrasives!

Keys are most often needed:

- for old jets - 8 mm (for liquefied gas - 7 mm);

- for burner nuts - 14 mm;

- for the tip of the oven line - 17 mm.

However, since the slab designs are different, different keys may be needed. Therefore, it is more rational to stock up on them with a complete set.

Cleaning tips

Most often, the nozzles do not need to be removed for cleaning. It is enough to remove the burners. In some models, you will also have to dismantle the hob cover and other parts.

First, try cleaning the jet hole without removing it.

In many models of gas units, it is quite easy to get to the nozzle of the brewhouse. To do this, simply remove the hotplate.

The nozzle opening is narrow, use fishing line, copper wire or a needle to clean it. You just need to scroll the needle around its axis with your fingers. After the needle has gone deep, before its recess, turn on the gas supply and remove the needle. A jet of gas blows dust out of the hole. A few seconds are sufficient to purge.

If cleaning fails in place, the nozzle should be removed, cleaned and rinsed. Replace after drying.

Instructions for replacing the hob and oven jets

Next, we will consider a detailed instruction on replacing the nozzles on the stove, as well as the oven.

Instruction # 1 - replacing the hob nozzles

Next, what to do and how to replace the nozzles on the gas stove. Since the designs of gas stoves differ, we will consider a few of the most typical options. In the designs of new modifications, access to the nozzles is easier (just remove the burners). Other common models are of interest.

Some models of Hephaestus and Darina stoves are similar in terms of burner design. To replace the nozzles of the Hephaestus hob, perform a series of steps in sequence.

Step 1. Remove the grate from the stove, dismantle all the burners.

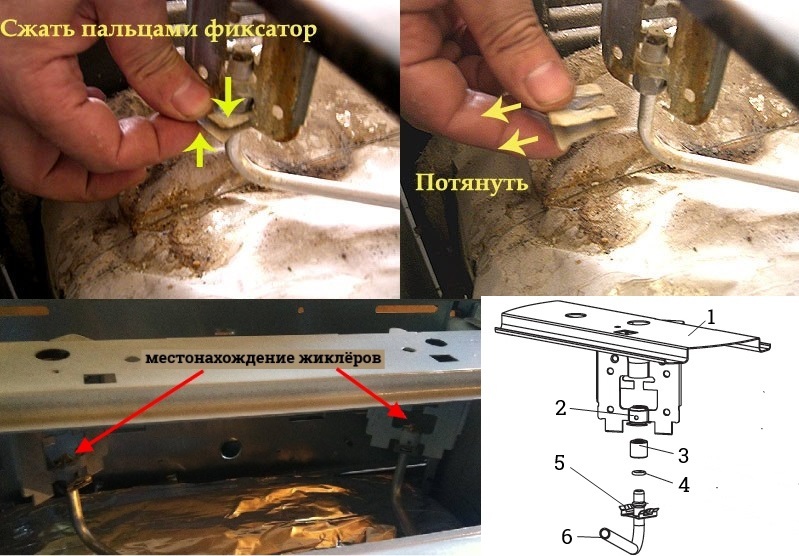

To get to the gas distribution system of Darin's stove, insert stops between the top panel and the body on both sides, press them with your fingers

Step 2. After unscrewing the fastening screws, remove (raise) the top panel. "Darina" has latches that are released by special stops from the plate kit.

Step 3. To release the burner, use a Phillips screwdriver to unscrew the two screws securing its structure.

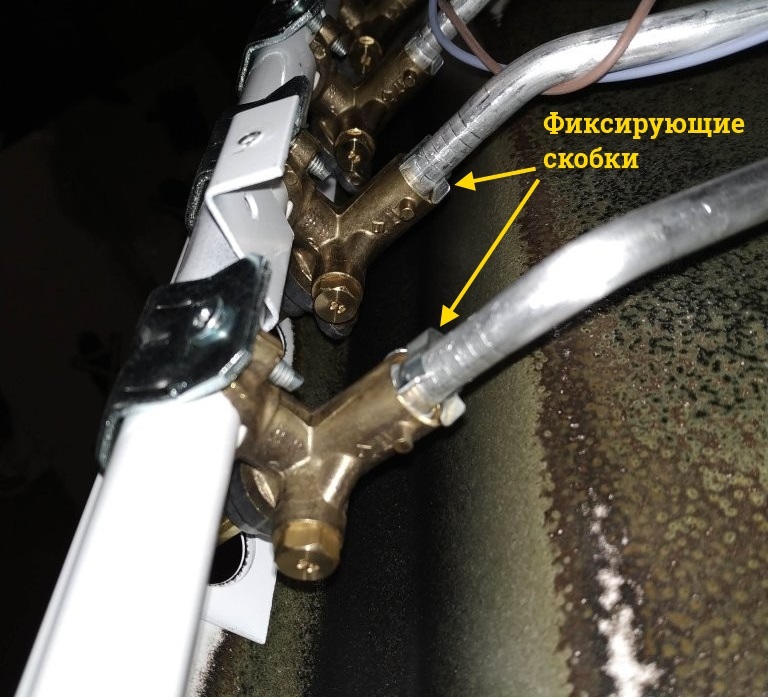

The clamp of the gas pipe to the gas tap is a plate bracket that is removed to disconnect the pipe when replacing the nozzle

Step 4. Using a flat-head screwdriver, remove the retainer (curved plate) from the side of the valve handle, freeing the pipe supplying gas to the burner. Take the tube to the side.

Step 5. Detach the second end of the tube from the seat by removing the fixing plate with your fingers or using pliers (in Hephaestus) / screwdriver (in Darin).

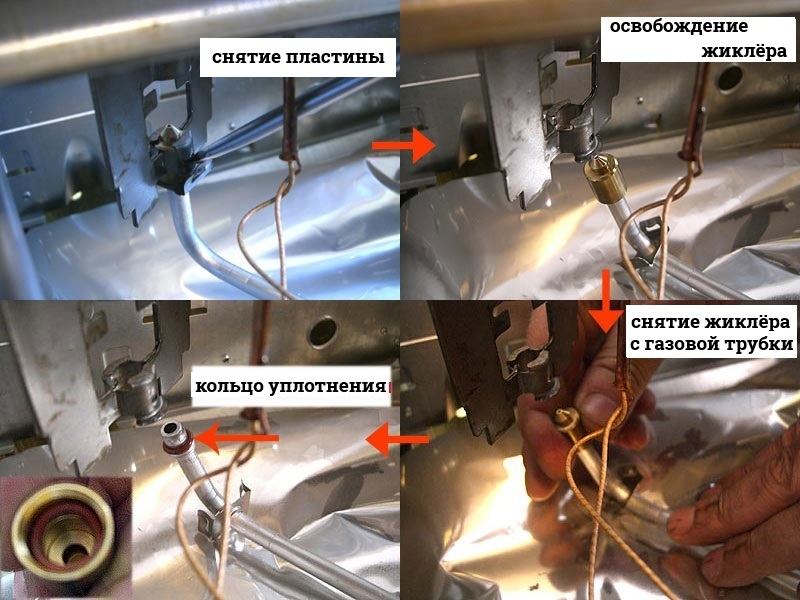

Removing the fixing plate in the Hephaestus gas stove (top row), the location of the distant nozzles (bottom left). The numbers indicate: 1 - traverse; 2 - seat; 3 - nozzle; 4 - a sealing ring; 5 - fixing plate; 6 - aluminum gas tube

Step 6. In the Hephaestus plate, the end of the gas tube is connected to the nozzle through a transition cone (a sealing ring is installed on the tube under the cone). Throw a key (14) on the hexagonal platform of the cone, in order to hold and not damage the tube when unscrewing, unscrew the nozzle with the second key (8).

Step 7. Having unscrewed the old nozzle, replace it with a new one, lubricating the threads with graphite grease. The sealing ring is also replaced, which is convenient to do with a match. Use a 7 key to tighten.

Jets are easily found at the end of gas pipes. Use a flat screwdriver to pick up the brackets from the square brackets. After snapping off the mounting plate, the tube with the nozzle is taken to the side and the jet is replaced

Nozzle seal ring. It is better to install a new ring from the repair kit into a new jet, covering it with an appropriate lubricant

Step 8. Collect the entire unit in reverse order.

A similar operation is performed for the remaining burners of the cooking table.

Taking advantage of the fact that the upper part of the unit is open, they clean it from debris and dirt. In addition to replacing nozzles, screws in the plates can also be replaced to regulate low gas flow (or low flame). They regulate a reduced gas supply, sufficient so that the flame on the burner does not die out with a minimum gas supply.

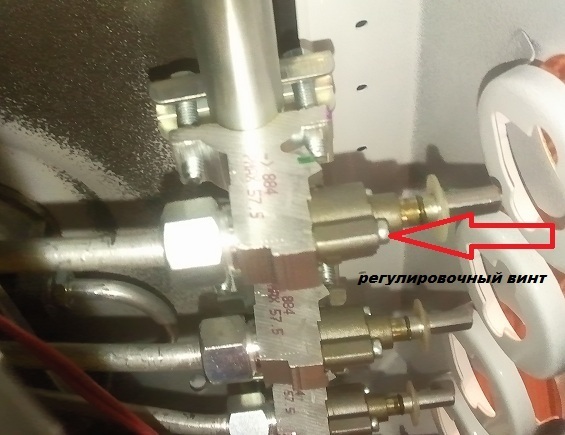

Low flame adjusting screws are located on the gas cock. You can get to them by removing the front panel (in the photo, the place of the panel on the right). Use a screwdriver with a suitable slot for adjustment.

Replacing the jets, check their action; if necessary, adjust the low flame combustion process with screws.

After replacing the nozzles, adjusting the low flame and air supply, as well as cleaning the interior of the stove, the cooking part is assembled in the reverse order.

Instructions # 2 - replacing the oven jets

The number of burners and their arrangement is different in the designs of different stove models. So ovens can have one (bottom) or two (top for grilling and bottom) burners. In modern ovens, the burners are more often oriented along the stove (longitudinally), and the jets are fixed on the back wall. On older cookers, the gas supply is from the left (side orientation) and the jets are also located on the left side of the oven.

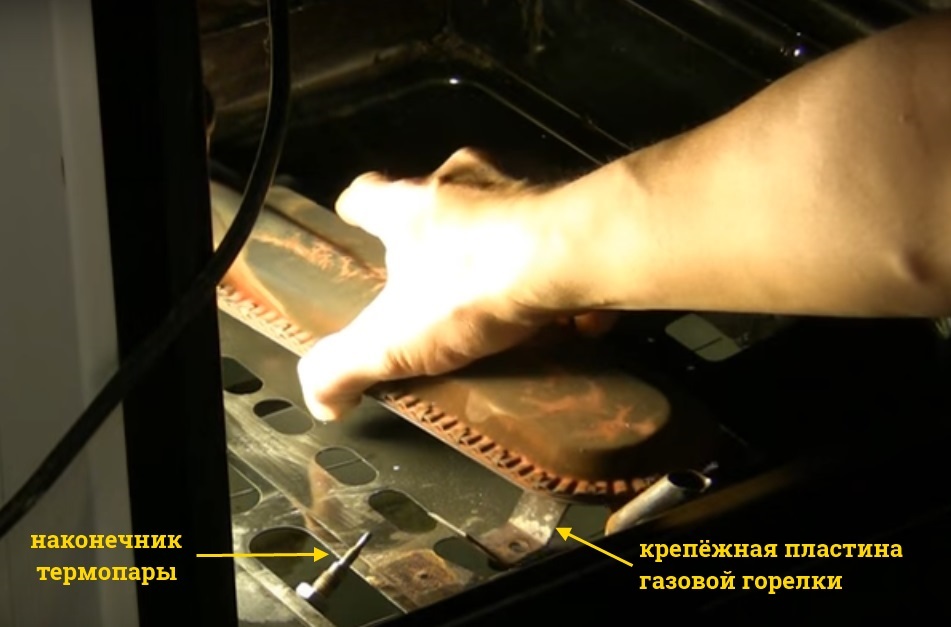

In order to get to the nozzle of the upper burners, remove the door, unscrew and remove the grate covering the burner, unscrew the screw that secures the burner to the frame. Pulling the burner towards you, carefully remove it from the oven, after which the nozzle becomes visible. On some models, the tip must be disconnected to remove the torch. thermocouple.

In the Indesit gas stove, gas is supplied to the oven burner from the back panel. The jet is also installed there.

The location of the burner nozzle opens when it is removed. The jet often "sticks", so you need to turn it out very carefully so as not to break the structure of the gas system

The nozzle is unscrewed using a socket wrench. Having installed a new part, the oven accessories are assembled in the reverse order. If the nozzle cannot be unscrewed from this position without applying great effort, then it is reached from the back side of the plate.

In some models, access to the lower burners is opened from the space of the lower technical box. In others - from the oven, as, for example, in the MORA stove, the replacement of the nozzle of which we will give as an illustration.

The longitudinally positioned lower burner of the MORA hob is accessible from the oven. For dismantling, remove the bottom grate of the bottom

The unscrewed torch does not allow removing the thermocouple tip fixed on the same bracket. To disconnect it, unscrew the nut

The burner is installed in a longitudinal position. Attached to the slab with a curved iron strip with two screws. A thermocouple is attached to the same strip.

The burner can only be removed after disconnecting the thermocouple tip. It is taken out together with an iron strip.

By unscrewing the nut, the thermocouple is pushed back. The disconnected burner is removed from the oven chamber by pulling it towards you and you get direct access to the nozzle

The sequence for replacing the nozzle with the side burner position can be tricky.

Consider the step-by-step instructions for replacing further:

Step 1. We open the lower door of the stove drawer all the way, getting the opportunity to fully open the oven door.

Step 2. We open the oven door to the limit. To remove the burner, remove the floor of the oven chamber by pulling it towards you through the slot.

Step 3. Unscrew the two screws securing the burner. Remove the burner.

Step 4. Now we can see the nozzle on the left in the wall. It is good if it is not stuck and you do not need to make a lot of effort to unscrew it. If so, the jet is removed and replaced at this stage.

Having freed the burner from "binding" to the bottom of the chamber, it is removed from the stove. The bottom left provides access to the jet socket

Step 5. If the jet is stuck, then we leave it. Dismantle the left wall of the slab. To do this, you need to unscrew the fixing screws.

Step 6. Having removed the wall, we expose the gas line leading to the burner. At the very bottom of the gas pipe there is a 17 nut, which can be unscrewed with a wrench without much difficulty.

Step 7. We move aside the gas pipe with the nut and disconnect the nozzle holder from the stove.

Step 8. Lubricate the sticky WD-40 nozzle or another suitable agent, wait until it works, and unscrew the jet.

Having removed the side wall of the stove, they get access to the oven burner nozzle body, which is fixed to the frame with two screws

The jet body is fixed to the gas stove frame with two screws. At the other end, the body is connected with a union nut to a gas pipe

Step 9. We install a new jet in the body and assemble all previously removed parts, not forgetting to install a new sealing ring.

Helpful tips for replacing injectors

To check that the stove is working properly and that there are no gas leaks, it is recommended to call once a year gas service technicians. General cleaning of the stove is best done weekly. Table cleaning - after every cooking.

Excessive force can damage the gas tube or jet, which can result in more serious stove repairs or jet breakage. Therefore, where there are special turnkey platforms, when unscrewing and twisting the nozzle, use two keys - one to hold the tube, the other to rotate the nozzle.

The shape and color of the flame on the burner of an oven equipped with a thermostat must be checked correctly when the oven is cold. Otherwise, a thermostat intervenes in the process, reducing the gas supply when the temperature reaches a certain threshold. This is its purpose.

In the equipment of the old model, the speed of air supply to the burner is additionally adjusted.

In new units, the nozzles are screwed in without thread winding. In older gas structures, the last 3-4 thread pitches are sealed with fibrous materials.

The nozzles in gas stoves of different models can be located in different ways. Therefore, before starting work, you need to read the instructions for your device.

If seals are installed in the joints, it is better to replace the old rubber rings with new ones.

On the forums, there are tips for changing the cross-section of the orifice of the nozzle by coining or placing a wire in the hole. These are rather crude methods that are not recommended to be used. None of these methods can accurately adjust the gas flow. You will also not be able to drill a narrow hole with a thin drill. The best solution would be to buy a new jet with the correct orifice diameter.

Safety precautions when replacing an injector

Ensuring safe replacement is critical when performing gas related activities.

Therefore, do not neglect a number of rules:

- Disconnect the stove from gas and electricity before replacing the jets.

- Make sure the burners are cool.

- Before starting work, open windows, turn off devices that operate on electricity that can generate a spark.

- You cannot engage in self-modification of plate parts or replace them with non-native ones, inappropriate in size or made on your own.

- After installing parts, be sure to check all gas connections for possible leaks. For this, the connections are washed from all sides (using a brush or sponge) and, turning on the gas supply, observe whether bubbles are formed. If a leak is found, the connection is either tightened or disassembled and reassembled.

Do not use nozzles intended for a gas burner of completely different designs or other gas appliances.

You should not replace the nozzles in the gas stove yourself if you are unsure of your capabilities.

Conclusions and useful video on the topic

Home craftsmen have always preferred to do everything on their own. In the video, you can see how the fixing elements were empirically found and the nozzle was replaced in the oven of the MORA stove:

The nuances of cleaning the nozzle in the following video:

Converting the Lada plate to bottled fuel:

Replacing such a seemingly small, but necessary for the correct operation of the stove, the details are not difficult for those who are used to working with their hands. Knowledge of how to properly change the jets on an old gas stove, a minimum set of tools and spare parts, careful adherence to the replacement rules - this will be enough for a successful business.

Are you familiar with the process of replacing jets by hearsay? Tell us about your experience, share useful tips with other users, take part in discussions - the feedback form is located below.