Gas supply, which is usual for the majority, is by no means a universally available service, since there is not a central gas pipeline everywhere. Gas cylinders are not uncommon in such places. And if settlements are also remote from large residential areas, then even refueling household gas cylinders can become problematic.

In such cases, it makes sense to have several cylinders in stock so that you can continue to use gas without problems while a spare is filled. We will tell you about how the flasks are filled for storing and consuming blue fuel. Let's get acquainted with the rules that ensure the safety of refueling and operation.

The content of the article:

-

Cylinders suitable for gas filling

- Types of vessels for storage and consumption

- Technical features of the production of cylinders

- Gas storage for individual use

- Maintenance and repair of gas equipment

- Gas filling technology

- Check for defects

- Conclusions and useful video on the topic

Cylinders suitable for gas filling

It is no coincidence that gas is used in everyday life, since it is cheaper in terms of cost than electricity, and sometimes it is even easier technically.

In addition to applications for cooking, home heating, etc. blue fuel is consumed in various fields of activity.

Types of vessels for storage and consumption

The wide range of use made it necessary to develop for each of the areas its own container for the storage and operation of gaseous fuel. There are various modifications of cylinders of various sizes, which serve as gas suppliers in tourist trips, on vacation and in many other places.

Gas cylinders are almost a mandatory attribute of private houses that are not connected to a centralized gas supply. As blue fuel is consumed, its supply is replenished. Under normal technical condition, refueling is performed in the same process vessels

For tourism and recreation, it makes no sense to take a large-volume cylinder with you (well, if you do not plan a long vacation), and a small volume may not be enough or it will quickly end. Cylinders are not matches, you can't take them with a margin, it is pointless to carry excess weight, and the danger of moving vessels with blue fuel has not been canceled.

There are two main threats. The consequences for both hazards are the same. Since the cylinder is a high-pressure vessel, and the pressure itself is caused by a large amount of gas that can expand inside the cylinder when heated, it is accordingly explosive.

If you have to carry several gas cylinders with you on a camping trip as needed, then at home (whether individual house, summer cottage, etc.), the presence of spare gas tanks for servicing the kitchen, bath, boiler room is quite understandable and understandable.

Liquefied bottled gas is used by tourists and travel enthusiasts with stops at campsites. It is needed for refueling gas soldering equipment

Note that the gas transported through the pipeline directly to the consumer is a mixture with a predominance of methane. But gas cylinders are filled with a mixture of propane and butane, taken in various proportions.

Both main and LPG bottled gas are colorless and odorless. In order to be able to accurately determine the leakage, both mixtures are odorized, i.e. enriched with swamp gas, methane, which has a characteristic unpleasant aroma.

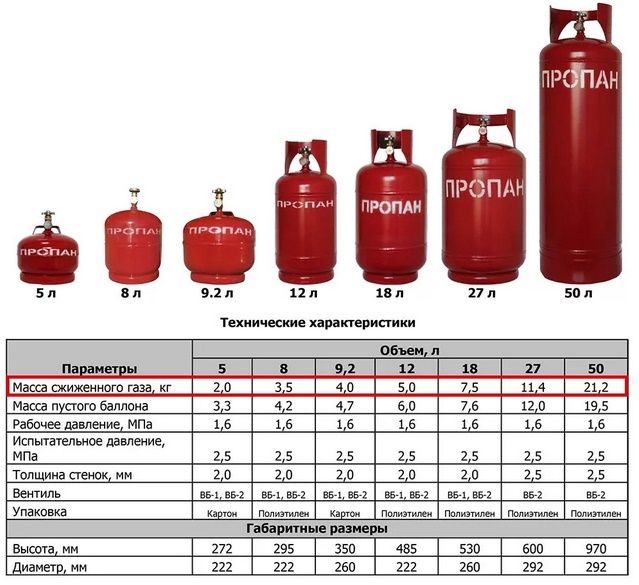

Taking into account the difference in consumption and operational specifics of gas equipment, the industry offers a wide selection of cylinders, differing in capacity and size.

If you turn to Internet search engines, you can find out that there are a lot of cylinders for transportation, use in everyday life, for work and storage of gas. Not only the volumes of the cylinders differ significantly, but also the technical design during production, the service life and even the design working pressure of the cylinders.

Technical features of the production of cylinders

How can a common man not make a mistake when choosing the required type of cylinder and related operational equipment? Let's look at these issues in more detail and turn to the main sources of information that can help with this - GOSTs.

Exactly at GOSTs all the technical nuances that apply to the manufacturers of cylinders, depending on the scope and characteristics of the fuel, have been discussed. Most of the regulatory documents relate to the production of industrial high-pressure vessels, since far from one or two types of gas are used in production.

For this reason gas cylinders should be painted in their own color, ie. in a color that matches the gas that is stored in this cylinder. In addition to color, the cylinder must have a corresponding inscription, this can be seen in the picture below

The color of gas cylinders depends on what type of gas it is allowed to fill. Only bright red tanks are suitable for replenishing LPG

According to the rules regulated by state standards, household cylinders must be painted red and have the inscription "PROPANE" or "PROPANE-BUTANE" in white. This is a mandatory requirement for tanks containing liquefied combustible gas.

The main regulatory document that stipulates the conditions for the production of cylinders for household (not excluding production) use is GOST 15860-84, which is called “Steel welded cylinders for liquefied hydrocarbon gases for pressure up to 1.6 MPa. Technical conditions ".

Gas storage for individual use

With what frequency is required filling for cylinders, depends primarily on the volume of consumption. Those. on the amount of gas equipment that consumes gas. In an individual residential building with connected gas stove and a heating boiler, gas consumption is much higher than when using a gas stove in a country house.

Cooking in the country (even with permanent residence) is temporary in nature, therefore, consumption is much lower. In this case, refueling a gas cylinder for the operation of a gas stove will be much less frequent than for a house in which a gas boiler is also installed.

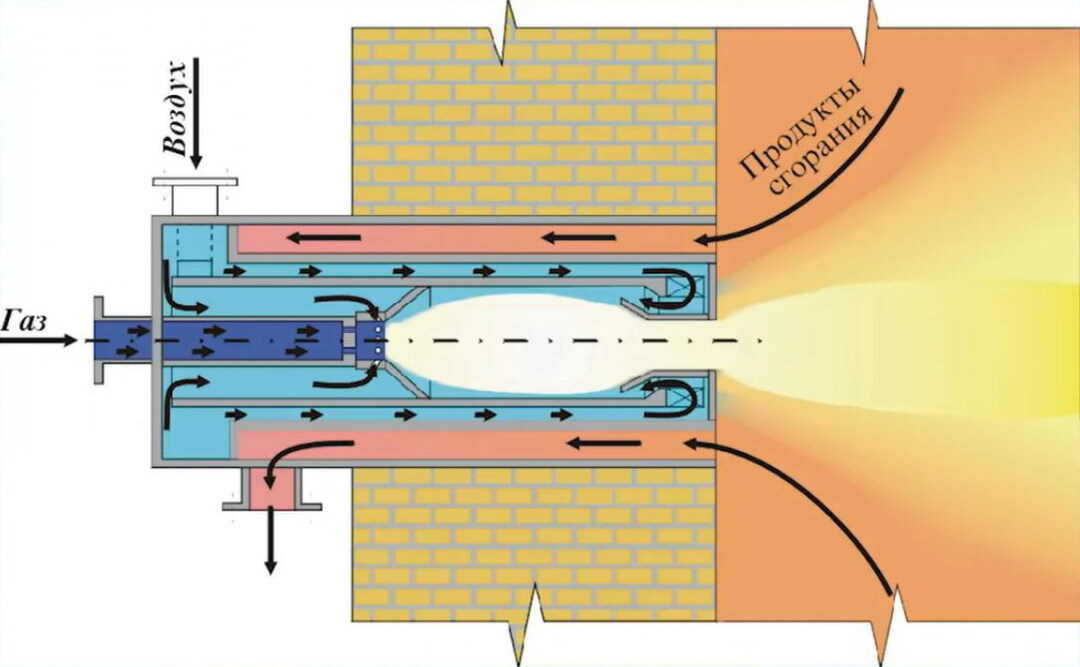

The main reason for such differences in gas consumption lies in the fact that the design of the gas burner of the boiler differs significantly from the design of the burner of the cooking equipment. In such cases, it is difficult to manage with one cylinder, even if the cylinder has a large volume (50 liters), it will have to be changed with enviable regularity.

If cylinders with a volume of 5 liters and 12 liters are allowed to be installed near the gas stove (at a distance of at least 1 m from the cylinder to plates), then cylinders with a volume of 27 liters and 50 liters should be installed outdoors in specially equipped places (+)

With high consumption, it makes sense to use an individual balloon installation consisting of several cylinders. This option allows you to have a much larger supply of gas in stock, and to replace empty cylinders less often.

However, one should not forget that an increase in the volume of stored gas entails an increase in responsibility for the technical condition of gas equipment.

A specially equipped place is, as a rule, non-combustible cabinets located on the street. They fix the balloon equipment and connect them to the gas pipeline supplying the gas equipment.

Cabinets of individual balloon installations must be located in such places that there are at least five meters from the paths of people (entrance to the house, etc.) and them. They need to be firmly fixed. The cylinders inside the cabinets must be in a stable position. It is recommended to fix them to protect them from accidental falls.

The cabinet must have ventilation openings or ventilation grilles, which must not allow gas to accumulate (in the event of a possible leakage) by natural ventilation. Ideally, such a cabinet should be equipped with an alarm sensor against a dangerous gas concentration.

However, given the fact that the volume of stored gas is not so large, and there is also the possibility of its natural dissipation due to natural ventilation, in individual balloon installations this may not required.

Maintenance and repair of gas equipment

An important issue, which is often overlooked by the owners of a non-gasified private house or summer house, is the maintenance of gas cylinders and individual cylinder installations. At large enterprises, maintenance is carried out by personnel who have been trained and tested on technology knowledge, while in individual farms, no one undergoes such training.

When supplying and replacing cylinders by an organization that offers filled cylinders, an instruction is conducted with a record in the logbook of the gas supplying structure about its conduct. Such instruction concerns the issues of correct operation of already installed balloon equipment and safety measures during use.

Maintenance of balloon equipment and individual balloon installations should be carried out by representatives of organizations that have profile permits for these types of work. During the work, not only the condition of the cylinders themselves, but also of the cabinet of the individual cylinder installation should be checked.

Inspection of the gas pipeline from the installation to the gas equipment is carried out, the gas equipment itself is examined. It is imperative to check the connections for leaks. All connections are "washed" in order to detect leaks

If during the maintenance process any violations were identified, then they must be eliminated without fail.

A number of rules that are mandatory for those who use gas cylinders:

- the cylinders in the places of installation should not be exposed to direct heating;

- the installation of gas equipment in the basement or basement floors is unacceptable, since gases can accumulate there in the event of a leak;

- to install cylinders near heating devices (radiators, etc.) and a gas oven should be no closer than 1m;

- the room in which the cylinders (and gas equipment) are installed should not have basements in which gas can accumulate.

Questions about whether and how it is possible to refuel a gas cylinder directly at home are often asked by the owners of individual cylinder installations. This is understandable, because for refueling they need to carry several cylinders, and sometimes over considerable distances.

The answer to this question is unambiguous - you cannot refuel a gas cylinder at home. There are several reasons for this and they relate to the technology of filling cylinders.

Gas filling technology

First of all, when taking a balloon for refueling the organization that will carry out the work must check the technical condition of the cylinder. What is meant and what is hidden behind this technological definition?

If the cylinder is in an unsatisfactory technical condition, then it may be refused to be accepted for refueling. What specific defects can cause a failure, it is worth considering in full detail.

Replenishment of the stock of liquefied gas in the cylinder is allowed only at gas filling stations that have equipment for filling and weighing vessels

The main defects, in the identification of which they may refuse to refueling gas cylinder:

- if a malfunction of the shut-off valves was detected (defective cylinder valve);

- in the presence of obvious damage to the integrity of the body - these can be obvious cracks in the weld, or traces of deep corrosion, dents or bulges on the body;

- the absence of a nameplate or an unreadable plate is also the reason why they may refuse to accept the cylinder.

It is unambiguously not subject to refueling with blue fuel a cylinder of a color that does not comply with state norms and requirements, as well as a tank without a standard inscription.

In the presence of defects in the body and fittings, filling the cylinder with gas is prohibited. It will need to be replaced or repaired

The requirements for the color of the cylinder and the inscriptions made by the refueling tanker have already been considered above, technical malfunctions of the fittings and the body are quite understandable claims.

Consider the requirements for the plate. This is actually a passport of the cylinder, which reflects all its data, starting from the moment of production and ending with the date of the last verification (survey).

What exactly should be indicated on the plate:

- first of all, it is the brand of the cylinder and the stamp of the OTK of the manufacturer;

- then the specific type of cylinder and the batch number in which it was issued are indicated;

- the weight of the cylinder must be indicated with an error of no more than 200 grams;

- respectively, the date of manufacture (release) of the cylinder;

- the date when the cylinder was last surveyed and the date of the next verification;

- the working pressure of the cylinder and its test pressure are indicated;

- the volume of the container must be indicated, i.e. its capacity is accurate to 0.2 liters.

In the absence of a plate, identifying the cylinder will be problematic. Therefore, her condition must be monitored regularly. If the operating information is stamped directly on the body of the cylinder, then the inscription should be covered with a colorless varnish and outlined in white.

The plates, which are not embossed on the body, but attached separately, should also be kept intact, and the data on the “balloon passport” should be well distinguishable and easy to read.

The plate of the liquefied gas cylinder contains all information about the technical characteristics, checks and other data of the container for gas

What is this data for? It is these characteristics that will be checked by the organization that refills the cylinder for compliance. Information about the weight of a cylinder and its volume tells how much gas can be filled into that cylinder.

To make this clear, we will consider the main nuances of the technology of the rules for refueling household gas cylinders, which are spelled out in standard instructions for refueling cylinders with propane or propane butane mixture.

Refueling of cylinders should be carried out in accordance with the recommendations of the manufacturer, the norms for filling the cylinder are:

- for technical propane, this is a volume of about 0.425 kg for each liter of the cylinder;

- for technical butane - this is a volume of about 0.4338 kg for each liter of the cylinder,

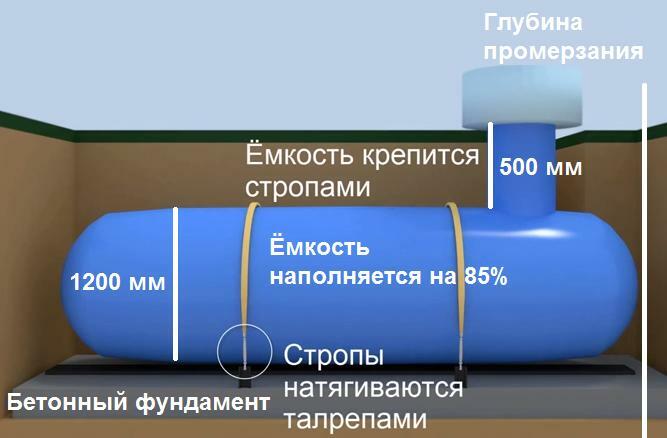

In this case, the liquid phase of the gas should not exceed 85% of the geometric volume of the filled cylinder.

The vessel with gas is filled so that 15% of the total volume remains free. This is necessary in case of thermal expansion of the gas during heating.

The cylinder must be weighed before filling. It must necessarily have residual pressure if it has already been in operation. After filling, the cylinder must be weighed, and the plug of the valve on the gas storage and use tank must be checked for leaks using soaping all places where leaks are possible.

Check for defects

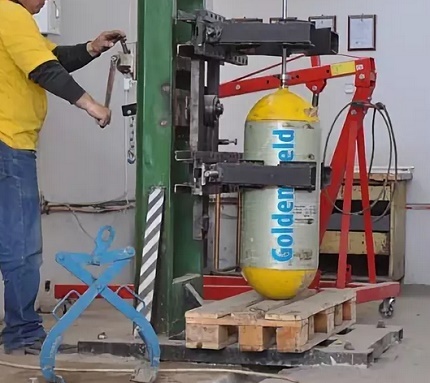

Refueling of cylinders is carried out if, upon acceptance of the cylinder, refueling no defects were found, and the verification period has not yet expired. If the verification period is missed, then the cylinder requires not only maintenance, but testing, which can only be performed by a specialized organization that owns the necessary equipment.

The survey allows you to identify defects that may not be visible to the naked eye, or even be inside the cylinder body. What kind of manipulations with the balloon will be performed should be considered in more detail.

The hydraulic cylinder testing method is used to detect microcracks. According to this technique, a pressure of 2.5 MPa is injected in a cylinder filled with water. Duration of testing is not less than 1 minute.

Then the pressure is reduced to the normal operating level, after which the cylinder is inspected by tapping all welds (knocks hammer weighing 0.5 kg).

If no leaks were detected during hydraulic tests, the cylinder body did not receive any significant deformations or ruptures, then such a cylinder is considered to have passed hydraulic trials

The final stage in the study of the technical condition of the cylinder is a pneumatic study. This is the placement of the cylinder in a volumetric container with water. From the upper parts of the cylinder to the surface of the liquid in which the vessel is immersed, there should be 3-4 cm.

The cylinder is pressurized to 1.6 MPa for at least 2 minutes. If there is a leak in the cylinder, it can be easily identified visually by traces of bubbles. If the pneumatic test did not reveal any defects in the case, then the cylinder can be dried and sent for recharging.

According to the current regulations, the service life of household gas cylinders should not exceed 20 years. During the use of the cylinder, it can be repaired, but not more than 2 times and with subsequent inspection after the restoration of technical characteristics.

The survey of cylinders must be carried out at least once every five years, with the obligatory indication on the plate of the date of the survey and the date of the next check.

Conclusions and useful video on the topic

Explosion of a gas cylinder under the influence of high temperature on the case:

We examined the main aspects that relate to the operation of gas cylinders in everyday life, examined the issues of operation and maintenance of gas equipment. In addition, they listed the main technical requirements for recharging cylinders and their certification by specialized organizations.

Possession of useful information will allow you to avoid a lot of dangerous situations. The attentive reader will be able to determine whether his cylinder needs refueling. Will be able to supervise the work of employees of an organization engaged in replenishing individual tanks for blue fuel.