The gas pipeline is an engineering structure, each element and unit of which solves an important a certain functional task and is responsible for safety, quality and continuity functioning of the network. Various gas fittings and equipment differ in the complexity of execution, in the material of manufacture, in purpose and in type.

Fittings for gas pipelines are a wide class of fixtures and fittings that are mounted on gas pipelines, as well as on devices. With their help, switching off / on, changing the direction, quantity, pressure of the gas flow or complete removal of gases are carried out. A wide range of these parts is classified, making it easy to understand the issue of classifying gas fittings.

Let's take a closer look at all the variety of fittings for gas pipelines and the features of its choice.

The content of the article:

- Purpose of gas fittings and equipment

- Classification of fittings for gas pipelines

- Gas valve symbols

-

Features of valves

- The principle of operation of the valve

- What are taps for?

- Condensate traps and expansion joints

- Connecting fittings for gas pipelines

- Instrumentation and control devices in gas pipeline systems

- Features of the choice of fittings and equipment

- Conclusions useful video on the topic

Purpose of gas fittings and equipment

Gas fittings and gas equipment are intended for installation on pipelines used for transportation, supply and distribution of blue fuel. With the help of these mechanisms, the supply, pressure, quantity, direction of the gas flow is switched on and off. The valve has such basic characteristics as nominal pressure (nominal) and nominal diameter.

The nominal pressure is taken max pressure at a temperature of 20 degrees, at which long-term service of various connections of elements and assemblies with the pipeline is guaranteed. Nominal size (DN) is a characteristic that is used in pipeline networks as a general parameter of the connected parts.

The gas pipeline includes not only pipes, but also a large number of gas fittings, which ensure its reliable operation

Most of the types of fittings consist of a shut-off or throttle device. These are constructions in the form of a body closed from the outside with a lid.

The shutter moves inside the body. As a result of the movement of the valve relative to its seats, the area of the section through which the gas passes changes. This process causes a change in hydraulic resistance.

Simple design, affordable cost and the ability to use gas dampers in a wide temperature range - these are the main advantages of gas dampers.

The surfaces of the gate and the seat that are in contact during the shutdown of parts of the gas pipeline are called sealing surfaces. In devices of the throttle type, the surfaces of the valve and the seat, which, in turn, form an adjustable passage for transporting the working medium, are called throttle.

Classification of fittings for gas pipelines

All existing types of gas fittings, depending on their purpose, can be divided into:

- shut-off. Armature used for periodic shutdowns of individual sections gaswires, devices, equipment. This type includes gas taps, gate valves;

- safety. Serving to prevent the risk of gas pressure rise above the established norms. This type of fittings includes a relief safety valve;

- regulating. Designed to change and maintain pressure within specified limits. These are dampers, gate valves, etc.;

- reverse action. To prevent a change in the direction of gas movement;

- emergency and cut-off. For a quick auto-termination gas movement towards the emergency section in case of violation of the preset mode. This type includes a safety shut-off valve;

- condensate drain. The one that removes in automatic mode, condensate accumulating in condensate- collectors and in the lower sections of pipeline networks;

- control. Determines the pressure of the passing mass, temperature, etc.

According to the control method, valves can be of two types: managed and automatic. The first is driven by manual manipulation or by means of a drive: pneumatic, hydraulic, electromagnetic, electric.

The manual process is marked by a lot of effort and wasted time. The drive is more often installed and the possibility of emergency control remains in case of emergencies. And the second acts with the help of devices automatic actuation.

Flanged connection of gas pipelines is used at transitions from an underwater or underground site to an onshore one. This type of connection helps in the fight against electrochemical corrosion.

By the method of connection, equipment and any fittings for gas supply systems are:

- flanged - used for fittings with a medium passage of more than 50 mm. The connection to the pipes is carried out by screwing the flanges. The main advantage of such a connection is the possibility of multiple reinstallations, great strength and reliability. You can also note the universal applicability. As a disadvantage, only the large mass and large dimensions of such parts are distinguished;

- clutch - used to connect equipment with a passage of 65 mm or less. The connection is made by means of couplings with a thread located from the inside. The disadvantage of coupling joints is that the thread gradually wears out;

- tsapovyewith threaded external thread. One device is screwed into another device by means of a thread;

- welding - these are rarely used today non-separable connections. The advantages of this method are reliable tightness and minimizing maintenance activities. The disadvantages include the difficulty of dismantling the connection, which arises when repair is necessary, when the section of the gas pipeline is simply cut off;

- nipple - fittings are connected using a nipple;

- tie-down - the branch pipes are connected to the pipe flanges with studs and nuts, which are located along the reinforcement;

- choke - the fittings are connected using a union, union nut and O-rings. It is a reliable and dismountable connection method.

In addition to those listed above, there are other ways to connect gas fittings, but they are not used so often.

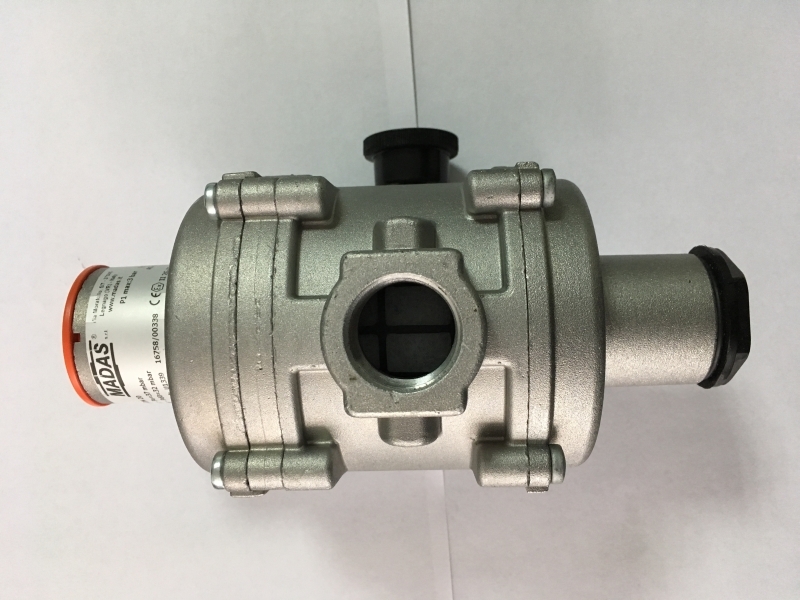

A flanged gas filter is necessary for cleaning the gas environment from dust and impurities, thereby increasing the service life and reliability of the functioning of gas appliances

Also, do not forget that the functionality of the pipeline and the reliability of the entire gas distribution system will depend on the quality of the connection made.

Gas valve symbols

The fittings used in the gas industry are standardized. Each detail must have a code consisting of 4 parts.

The first 2 digits of the code are the type of fittings:

- 11 - valves for pipelines;

- 14,15 - shut-off valves;

- 16 - lift check valves;

- 17 - safety valves;

- 19 - rotary check valves;

- 25 - control valves;

- 30, 31 - shut-off valves;

- 32 - gates.

In second place in the code is the conventional designation of the material for the manufacture of the case: carbon steel - c, acidresistant stainless steel - nzh, gray cast iron - ch, malleable cast iron - kch, bronze, brass - br, vinylplast - vp, alloy steel - hp, aluminum - a.

A gas valve made of cast iron is much less susceptible to corrosion, but it is more fragile than a similar device made of steel

The third place in the cipher is the serial number of the part. On the fourth is the designation of the material from which the O-rings are made: bronze or brass - b, stainless steel - nzh, rubber - r, ebonite - e, babbit - bt, there are no sealing rings - bk.

Features of valves

Shut-off valves are most commonly found in gas systems. It is used to adjust pipeline pressure and operates on the same principle as in water conduits. However, there are more safety requirements for parts in the gas industry.

If the concentration of gas in the air reaches a critical value, then the slightest spark is enough and a real catastrophe can occur.

According to the type of movement of the functional mechanism, shut-off valves for gas pipelines are divided into the following types:

- tap - in the crane, the locking element with the body of rotation moves, while rotating around its axis. It can be positioned arbitrarily with respect to the direction of flow;

- gate - in this part, the disc-shaped element rotates around its axis at an angle or perpendicular to the flow;

- valve - in the detail, the locking body on the spindle moves reciprocally parallel to the flow;

- gate valve - in it, the adjustment element moves perpendicular to the flow.

It can be summarized that shut-off valves include devices that are designed to tightly shut off sections of a gas pipeline. These devices must guarantee tight shutdown, quick action, low hydraulic resistance and ease of maintenance.

The principle of operation of the valve

Most often, valves can be found on pipelines from different types of valves for gas equipment. They are used when it is necessary to shut off the gas flow in gas pipelines with nominal diameters from 50 mm to 2000 mm, when the working pressure is in the range of 0.1–20 MPa.

In valves, the gas flow is regulated by changing the position of the valve relative to the sealing surfaces. Spindle non-retractable does not slide out of the lid when opened. When it rotates to open the hole, the running nut is screwed onto it, raising or lowering the shutter. In this type of gate valve, the travel assembly is located inside the working environment, so it is more susceptible to the negative effects of corrosion.

The equipment with a rising spindle moves the spindle and the shutter by rotating the threaded sleeve, while the upper part of the spindle is extended upwards. The advantage of this design is the absence of the influence of the external environment on the running unit.

The valves differ in the design of the constipation for 2 types. Wedge valves have a valve with sealing surfaces located at a certain angle to each other. They are also produced with a hinged valve consisting of 2 discs and a solid wedge. Parallel gate valves have a gate consisting of 2 discs, between which there is a spacer wedge.

Throttle valves are often used due to their simplicity and reliability. The throttle smoothly regulates the flow of gas flowing through it

For gas pipelines designed for pressures up to 0.6 MPa, valves made of gray cast iron are used, for gas pipelines in which a pressure of more than 0.6 MPa is used - from steel.

But what are the advantages of gate valves in comparison with the rest of the valves? In the open position, there is little resistance to flow, besides there are no turns of the gaseous medium. The gate valves have a small face-to-face length. They are easy to maintain and allow gas movement in any direction.

Dampers can be distinguished separately in this category. They relate to shut-off and control equipment, thanks to which the gas flow is regulated, it is also possible to stop its supply in the gas pipeline. The dampers consist of a body, a shut-off disc member, and a drive shaft.

The dampers can be used over a wide range of temperatures or pressures of the medium. They have a simple design, low weight and low metal consumption. The dampers have a small face-to-face length and a minimum number of elements. Their big plus is an affordable price.

The pressure on modern gas pipelines is monitored by many sensitive sensors that detect the slightest deviations and transmit information about them to the dispatcher's console.

What are taps for?

In addition to the above devices, stop valves include taps and valves necessary for the fastest connection / disconnection of the device or regulation of the flow rate of the working medium. According to the shape of the shutter, these parts can be divided into ball, cylindrical, conical.

To achieve a higher seal in the valve, a special grease is injected under pressure between the sealing surfaces. It is fed into the hollow channel in the upper part and, by screwing a bolt, is pressed through the channels into the existing gap between the plug and the body.

In the valve body, a ball acts as a gate element, and a through hole is made in the gate, the diameter of which coincides with the diameter of the gas pipeline

The plug is lifted slightly upward, the gap is increased and an ease of rotation is provided. Brass gasket and ball valve prevent grease squeezing out and subsequent gas seepage.

In addition to taps that need lubrication, simple rotary taps are used in gas pipelines. They can be divided into tension, stuffing box, self-sealing. They can be installed on overhead gas pipelines, on-site gas pipelines, on auxiliary lines (on blowdown gas pipelines, etc.).

Condensate traps and expansion joints

To collect and remove water and condensate at the lower levels of gas pipelines, install condensate traps.

They can be of different capacities: a large capacity is necessary if the transported gas has a high humidity, a smaller one is suitable for transporting dry gas. In addition, depending on the pressure of the passing working medium condensate traps differ in low, medium, high pressure devices.

Low pressure devices - this is a container with an inch tube led out under the gas carpet. The tube ends with a sleeve and plug. Condensate is removed through it, measured pressure, the gas pipeline is blown.

Medium and high pressure devices additionally equipped with one more protective tube and a valve on the internal riser. There is a hole at the top of the riser for equalizing the pressure of the working medium in the case and in the riser. Without a hole, condensate would fill the riser under gas pressure, which could lead to its rupture at low temperatures.

The gas condensate trap will remove water and condensate from the gas transported through the gas pipeline system. This device is especially important in winter.

Under the influence of gas pressure, auto-pumping condensate. When the valve is closed, the gas opposes the condensate and it slides down. When the tap opens, the condensate rises to the surface.

During the operation of gas pipelines, the temperature difference can reach several degrees. Such a large amount of change can cause a stress of several tens of MPa. Therefore, to ensure the normal operation of the gas pipeline, expansion joints must be used. They can be lenticular, U-shaped, lyre-shaped, etc.

The gas pressure compensator will greatly extend the life of the gas pipeline. But when installing such a device, it is necessary to take into account the nominal and maximum gas pressure in the system.

Lens and bellows expansion joints are more common. U-shaped and lyre-shaped expansion joints are made of bent, often seamless pipes. Their main disadvantage is their large size. On pipelines in mining and seismic-hazardous areas are established rubber-fabric devices that are capable of accepting deformations in both the longitudinal and transverse directions.

Connecting fittings for gas pipelines

During the installation of a gas pipeline, it may be necessary to connect pipes made of different materials or different diameters. In this case, a connecting flange element - auxiliary parts of the docking - is built into the network.

This category of fittings includes flange adapters, clamps, plugs, couplings, bends, crosses, tees, in a word, parts whose design does not provide for the presence of a shut-off and regulating mechanism.

Connecting fittings will be required if it becomes necessary to connect pipes from different materials, sections of pipelines of different diameters, as well as when turning and branching

Tees and bends are used for branching the gas pipeline. They are installed in cases where the pipe reaches the distribution section for a settlement, but this point is not the final one.

With the help of control valves, the pipeline is divided and part of the transported gas goes to the settlement, and part is transported further.

Steel tees are made from various grades of steel. They can be used in almost any work environment. They provide a high-quality pipe connection and have a good tightness.

Devices Instrumentation in gas pipeline systems

In addition to all of the above, numerous devices are used in gas pipeline systems. Instrumentation (instrumentation and automation).

In addition to gas fittings, instrumentation and automation are installed on gas pipelines. This allows you to constantly monitor the condition of the equipment and the progress of the technological process. And also promptly identify pre-emergency and emergency situations

The most popular devices used in gas systems are:

- gas signaling devices;

- equipment for emergency shutdown of incoming gas;

- equipment for measuring the volume of passed gas;

- electronic regulators of the passed gas volume;

- autonomous power supplies;

- gas valves for automating various processes and optimizing the operation of pipelines;

- gas regulators for regulating the volume of the medium passing through a section of the pipeline.

Such devices are high-tech equipment operating in a wide variety of conditions.

Features of the choice of fittings and equipment

Choosing fittings for gas pipelines you should be especially careful about the chemical and physical properties of the material from which it is made.

The most demanded materials for the manufacture of gas fittings are cast iron and steel. This is due to the requirements for an increased level of strength and reliability. Polymer elements that are great for water pipes are not applicable here, in addition, they can be easily damaged.

Steel is the most popular material for the manufacture of gas fittings. Such equipment has an affordable cost and high durability.

Experts do not recommend using equipment with bronze sealing inserts on gas pipelines. This is due to the fact that the composition of LPG contains hydrogen sulfide, which can have a negative effect on bronze and copper alloys.

Conclusions useful video on the topic

You can learn how the maintenance of shut-off valves on the gas pipeline is carried out in the following video:

The design features of the wedge and pinch valves will be discussed in this video:

All gas pipelines are classified as high-risk facilities, therefore, the choice of gas fittings and equipment should be taken seriously, and, if necessary, consult with specialists. Only high-quality gas valves will be able to ensure ease of maintenance, quick repairs, high tightness of pipeline units.

If you have questions on the topic of the article, or you can supplement our material with interesting information, please leave your comments in the block below.