Agree, blue fuel is very convenient to use and inexpensive. Its popularity enhances environmental friendliness and near-ubiquity. But have you ever seriously thought about why compressed gases are kept in special cylinders and how this affects your safety?

In this article, you will find detailed, technically sound answers to these questions. We will tell you what is the difference between a liquefied gaseous medium and a compressed analogue. We will acquaint you with the technical features of gas tanks, with the rules for their refueling and transportation.

The content of the article:

- Why are gases compressed and how does this affect cylinders?

- Design features of gas cylinders

- Application of liquefied propane-butane

- Cylinders for propane-butane mixture

- PBT properties and safety measures

- Rules for refueling household gas cylinders

- Safety of heating and hot water supply on a gas cylinder

- LPG for water heating

- Conclusions and useful video on the topic

Why are gases compressed and how does this affect cylinders?

In a gaseous state, substances do not have a definite shape, unlike solids. They can only be stored and transported in sealed containers.

But due to the low density, even a small amount of gas by mass occupies a large volume. For example, to transport only 26.9 kg of propane in its normal gaseous state would require a huge container with a volume of about 14,000 liters.

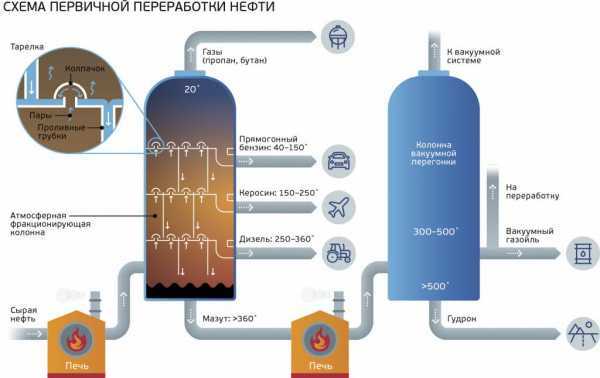

Propane and butane are the most demanded gases in the household sector. They are obtained during oil refining or separated from oil during its production, for example, using fracking technology

The problem is solved by compressing the gas by applying external pressure. As a result, its density increases and its volume decreases. After compression, the same 26.9 kg of propane fit into a 50 liter vessel.

When compressed, gases such as propane, butane, ammonia, chlorine, carbon dioxide pass into a liquid state of aggregation, therefore they are called liquefied. Oxygen, argon, methane remain in a gaseous state and are called compressed gases.

Here you need to make a clarification that any convert gases to liquid by compression, but the pressure force must be higher, and the temperature must be much lower than the normal air temperature.

Ordinary containers are not suitable for compressed and liquefied gases. Striving for expansion, gas will quickly destroy it and break free, and this is already fraught with explosions, fires, poisoning and financial losses. Therefore, special vessels with excess internal pressure, better known as gas cylinders, are used.

Design features of gas cylinders

Requirements for the design of gas cylinders, including dimensions, wall thickness, are determined by state technical standards. The more pressure is applied to compress the gas, the stronger the container must be.

The bodies of the vessels for compressed methane used as fuel for internal combustion engines are free from seams and consist of metal and composite shells. Designed for pressures up to 245 kg / cm2.

Oxygen and argon are used for welding. The cylinders for them are made according to GOST 949-73. The material is carbon or alloy steel. With a volume of 20-50 liters, alloy steel vessels with 6 mm thick walls are able to withstand an internal pressure of up to 19.6 MPa.

According to the accepted standard, they are painted blue with enamel on the outside and have a black inscription "oxygen" on the body. Argon vessels are gray with a green inscription "argon clean".

Steel welded cylinders for liquefied petroleum gas are manufactured in accordance with GOST and meet the established safety requirements

Propane, butane and their mixtures are contained under a pressure of 1.6 MPa in red welded steel cylinders. Since this gas is widely demanded for domestic and industrial applications, it costs more than consider in detail the features of its storage and transportation, as well as safety rules when refueling cylinders.

Application of liquefied propane-butane

Technical propane-butane (PBT), as it classifies GOST R 52087-2018, belongs to the category of liquefied petroleum gases (LPG). It is obtained during oil refining. A relatively small increase in pressure is sufficient for the transition of PBT to a liquid state. No drop in temperature is required.

At normal air temperature, a decrease in pressure leads to the evaporation of PBT and its transition to the vapor phase. When filling the cylinders, a two-phase system is formed in them, consisting simultaneously of liquefied gas and its vapor.

This property is an advantage over other types of fuel gases: the propane-butane mixture is stored and transported as a liquid in compact containers; they are used immediately as gas, without additional transformations, which gives additional convenience to the consumer.

Liquefied fuel gas in cylinders is delivered to consumers by specialized vehicles with mandatory observance of the rules for handling dangerous goods

Cylinders of the same volume of liquefied propane-butane hold almost 2 times more than compressed methane. In terms of heat release, liquefied PBT also surpasses compressed methane at the same volumetric amount.

Due to the reduction in metal consumption, PBT cylinders are lighter in weight. All this makes transportation cheaper, reduces the number of deliveries and makes the use of propane-butane mixture for household and industrial purposes economically justified.

PBT is in demand in settlements that do not have access to main gas pipelines. For cooking, heating water and heat carriers in heating systems, it is used by private households, catering and trade enterprises, farms, recreation centers.

Cylinders for propane-butane mixture

PBT is in cylinders at a pressure that is ten times less than that required for storing compressed gases. Thanks to this, the production technology is simplified, the metal consumption of the cylinders is reduced. However, they are also subject to stringent requirements.

For the propane-butane mixture, welded steel cylinders with a volume of 5, 12, 27, 50 liters, designed for an internal pressure of up to 1.6 MPa, are intended.

It is also possible to keep them in composite cylinders designed for 2.0 MPa. The design, shape and dimensions of each cylinder part are determined by state technical standards.

Newer composite cylinders with a 20-year service life and a 5-year test period have become an alternative to traditional steel cylinders.

According to GOST 15860-84, the cylindrical element of the cylinder (shell), its bottom and backing rings are made of high-strength steel grades. The surface must be free of cracks, cavities and other defects that reduce the wall thickness.

The bottom is manufactured by hot or cold stamping. The elements are connected to each other by welding. The locking devices are installed in the neck of the cylinder. To completely seal the connection, lead litharge or red lead is used.

Safety caps can be steel and cast iron with threaded or unthreaded connections. The main requirement for them is the ability to provide reliable protection for the locking device.

The complete cylinder must be:

- durable;

- sealed;

- without deformation.

Outside, the balloon is painted with red enamel, resistant to weathering. The name of the contents "Propane" is written in white enamel in the center of the cylindrical part of the body. Inconsistency of the inscription and color with the established standard is the reason for the rejection of the cylinder.

Each cylinder on the collar or neck must have a nameplate indicating the manufacturer, date of manufacture and testing, technical characteristics

By GOST R 55559-2013 a composite cylinder consists of an inner sealing shell (liner) on which a composite material is wound. Other technical solutions are also allowed. The color of the composite balloon is also red.

The cylinder is equipped with shut-off and safety valves, including safety devices against pressure increase and temperature rise, which increases its safety.

When using composite cylinders, it is necessary to take into account the principle of operation of the safety devices. If the cylinder overflows or the gas expands due to a rise in temperature, its excess is discharged to the outside. This can lead to an increase in the concentration of gas in the room where the cylinder is located.

A leak detector with an audible alarm, which is mounted on the wall in a kitchen or other gasified room, will help to prevent excess gas concentration.

Before sending cylinders for sale, manufacturers carry out acceptance tests. In the future, both steel and composite cylinders must undergo technical inspection every 5 years.

Each cylinder is supplied with a passport, which indicates its technical characteristics and the timing of the technical examination.

PBT properties and safety measures

The physical and chemical properties of gases determine not only the requirements for the design of cylinders, but also safety measures during their filling, transportation and operation.

An increase in the outside temperature leads to the expansion of the liquid fraction of propane-butane, therefore, cylinders are allowed to fill up to a maximum of 85% of their volume. For example, 50 liter bottle, theoretically containing 26.9 kg of liquefied propane-butane, after refueling actually contains about 21 kg. The free space is filled with a vapor phase.

The lower explosive limits of propane and butane are respectively 2.3% and 1.9% of the volume of the room, which makes their gas-air mixtures extremely explosive. Consumers and personnel of gas filling stations must exclude the formation of explosive concentrations and sources of ignition of PBT.

Filling an LPG cylinder by more than 85% is fraught with explosion and fire, the risk is especially high in the autumn-winter period

Propane-butane mixtures are heavier than air and, even with small leaks, can accumulate in basements and basements in dangerous concentrations. Hence the ban on the installation of gas equipment in such premises.

Rub the laundry soap on a grater, add water, lather with a brush and apply soap solution to the problem area - the appearance of bubbles indicates a gas leak.

Propane-butane, like carbon dioxide, has a suffocating effect on humans and animals when the oxygen concentration in the air decreases to 19%. This can lead to deterioration of human health and death. PBT is odorless, so odorants are introduced to help determine its presence in the air.

Non-compliance security measures leads to emergencies due to gas leakage and its ignition. A gas release and explosion with the destruction of the cylinder is also possible.

Rules for refueling household gas cylinders

Refueling is carried out at specially equipped stations with mandatory automatic weighing and cutting off the gas by the dispenser. This allows you to control the degree of fullness with high precision.

Cylinders are not allowed for refueling in the following cases:

- faulty valve or valve;

- there is no residual pressure;

- the period of the survey is overdue;

- there are defects on the surface;

- marking and coloring do not comply with GOST.

At gas filling stations that do not have a separate license and appropriate equipment, filling household cylinders prohibited at the legislative level.

The filling station equipment is intended only for automobile cylinders equipped with cut-off valves (multivalves), which do not allow filling over the norm.

To refuel household gas cylinders, special equipment is required, which differs from the equipment of a conventional gas station

It should be remembered: if at low temperatures fill the cylinder with propane-butane to more than 85%, and then bring it into a warm room, an explosion is possible.

When moving, the cylinders are protected from falls and impacts, they are not turned upside down with their caps. Loading and unloading from the vehicle is performed with the engine off.

Safety of heating and hot water supply on a gas cylinder

In the absence of access to centralized gas supply, liquefied gas can be used as fuel for autonomous heating systems and water heaters. It is cheaper than electricity. Unlike firewood, coal or diesel, it does not pollute the air with solid combustion products, that is, it is more environmentally friendly.

Instead of cylinders in private households, gas tanks with a volume of up to 20,000 liters can be used, if there are no problems with filling them.

When organizing a heating and hot water supply system for LPG, it is necessary to take into account the requirements of SNiP 42-01-2002.

In addition to cylinders (50 l), the following equipment is used:

- gas boiler;

- reducers;

- shut-off valves;

- gas pipeline components;

- radiators.

The boiler can be single or double-circuit, but always with a burner for liquefied gas. If bottled gas is a temporary solution and the house is planned to be connected to a centralized gas supply, it is rational to buy a boiler for main gas and additional equipment for LPG. The double-circuit boiler will provide both DHW and space heating at the same time.

It is possible to install a highly efficient condensing boiler equipped with two heat exchangers for heating the heating medium and hot water supply. In such a boiler, the water vapor formed during the combustion of gas is converted into a liquid, which makes it possible to obtain additional heat energy.

Boiler power is selected based on the area of the heated room and models with higher efficiency are preferred.

Several gas cylinders are connected to gas boilers, which increases the total gas volume and extends the interval between refueling

Several of the most capacious 50-liter cylinders combined into a single battery are used at the same time. The cylinders are placed in metal, ventilated cabinets on the street on the north side of the house, in order to avoid heating by solar radiation. Another option is a free-standing non-residential building.

To prevent the pressure in the system from dropping during severe frosts, the cabinets must be insulated with non-combustible materials, and the room must be provided with minimal heating.

It is important to ensure that the distance from the boiler is at least 2 meters and that the equipment has free access for inspection. There should be no drain pits, cellars, basements, ditches near the gas equipment. Gasification of basements and basements is prohibited.

The cylinders are connected to the gas pipeline through gas reducer, which allows you to regulate the gas pressure when it is taken off. It can be separate for each cylinder or common for all.

The color of the reducer must match the color of the cylinder, that is, be red (for propane-butane). Do not allow it to clog, otherwise pressure may rise and equipment failure. Once a week, the gearbox is checked for gravity and safety valve performance.

When combining cylinders into a single battery, it is rational to use a pressure stabilization ramp, consisting of a connection module, a reducer, a filter, a valve, a stabilizer

To create a gas pipeline, steel pipes with walls at least 2 mm thick are used. The section of pipe that goes through the wall is placed in a protective case. A flexible hose can be used to connect to the boiler gas pipeline. The reducer is connected to the gas pipeline using a durit hose (rubber hose).

It is written in detail about which gas mixture is better to use for storage in a gas tank. in the next article, which we recommend that you familiarize yourself with.

LPG for water heating

Flow columns and storage gas water heaters (boilers), like heating boilers, are capable of running on propane-butane. Conversion from main gas to liquefied gas is also carried out by replacing the burner nozzles. On sale there are models equipped with sets for LPG by the manufacturer. Connection to gas cylinders is carried out through a reducer.

The column is installed in a non-residential area with ventilation and an exhaust hood. The minimum distance from the gas water heater to the surrounding objects is determined by standards and must be observed for safety reasons. Installation in the bathroom is prohibited.

Equipping water boilers and boilers with automatic control and regulation devices increases their efficiency and safety. Modern models have overheating protection systems and protection against switching on without water, flame control. LED display, displays important information, for example, the temperature of the water entering the taps.

Conclusions and useful video on the topic

Gas cylinder inspection for safety, service life and rejection:

The reasons for the drop in gas pressure in the system at -42 ° C and how to combat freezing of gas cylinders:

After compression, the hydrocarbon gas is in the cylinder at an elevated pressure and is capable of rapid expansion with increasing temperature.

Compliance with safety rules and the use of gas cylinders that meet established standards helps to avoid accidents. situations and effectively use blue fuel for cooking, heating premises and hot water supply of private houses.

Tell us about how you use bottled gas in the country or in a country house. Please leave comments, ask questions, post photos in the block form below. Share valuable information on the topic of the article that is worth sharing with your site visitors.