One of the most common problems with gas equipment that runs on mixed propane and butane is the formation of frost on the surface of the gas cylinder. This indicates that the gas inside the metal container is freezing. This problem contributes to the incorrect operation of the gas equipment or the complete cessation of the gas supply from the cylinder.

So why is the gas cylinder covered with frost and how can this problem be avoided? This article contains comprehensive information on the causes of frost formation and how to prevent it, on the basis of which you can ensure the correct operation of your equipment.

The content of the article:

-

The reasons for the formation of frost on the cylinder

- Reason # 1 - low air temperature

- Reason # 2 - high butane content

- Reason # 3 - increased gas consumption

- Actions in case of freezing of the container

- How to properly reheat a gas cylinder?

- Compliance with safety precautions

- Conclusions and useful video on the topic

The reasons for the formation of frost on the cylinder

We will try to figure out why it happens that the gas in the cylinder located outside freezes when the air temperature drops.

So, first you need to understand that the cooling of the particles occurs with the intensive release of gas from the cylinder. Since the gas inside the tank is pumped under pressure, it is concentrated in a liquid state. As a result, the liquid gas partially freezes during its release.

As is known, gas cylinders fill by about 80%. This is done for reasons of safe operation of gas equipment. Since the gas tends to expand, this can lead to the fact that the cylinder will burst from the excess pressure. The expansion of the gas inside the cylinder occurs due to its heating, regardless of the heat source. The expansion process begins even when exposed to direct sunlight or other heating element.

Reason # 1 - low air temperature

Based on the practice of using cylinders, the optimal temperature at which the equipment will be normal work is about 10 degrees, and when this mark drops, problems begin with the gas supply to system.

If your equipment is located in a room with heating, then you should not pay attention to these indicators. Also, don't worry that your gas cylinder will freeze and break down if you leave it indoors without heating during the winter season. The winter temperature is too low to completely freeze the fuel.

To prevent the gas cylinder from freezing, the air temperature should not be lower than 10-15 degrees, for this it is necessary to move the equipment to a warmer place or install an electric heater

Reason # 2 - high butane content

Now let's figure out if the gas inside the cylinder can freeze, and how to prevent it. So, in order to ensure the correct operation of gas appliances, it is necessary to observe the correct ratio of propane and butane. Correct proportions will help to achieve maximum fuel consumption and correct operation of devices at negative ambient temperatures.

Fuel proportions in summer

As mentioned earlier, the freezing point of butane differs from the limiting freezing point of propane. Through practical research, the optimal proportions for the operation of the equipment in winter and summer have been derived.

For the warm season, the fuel is mixed in the following proportions:

- Propane - 40%;

- Butane 60%.

This ratio is considered to be the most efficient for consumption. It should be noted that this option has a lower cost than fuel with a "winter" proportion.

Winter fuel proportions

For the use of gas cylinders in winter, the proportions will be different, namely:

- Propane - 60%;

- Bhutan - 40%

In some cases, the amount of propane can be as high as 80 percent. But, assuming that propane is more expensive than butane, the final fuel price will also be higher.

Propane and butane are filled into gas cylinders at special filling stations, which are equipped with tanks filled with gas of the right proportion for optimal use at a certain time of the year.

We talked in more detail about the types of gas mixtures in cylinders in this material.

Freezing point of gas

Now let's talk about at what temperature the gas in the cylinder usually freezes.

And the temperature of complete freezing of these components is different:

- Propane freezes at a temperature of -188 degrees;

- Butane freezes at a temperature of - 138 degrees.

Therefore, in the summer season, propane is filled into the cylinder in a smaller amount than butane. Very often, unscrupulous companies fill tanks with the "summer" concentration option, since the price of propane is cheaper than the cost of butane.

The main reason for the formation of frost on a gas cylinder is the physical properties of the gas molecules inside containers, which, upon intensive release, are cooled and lead to freezing of the metal surface

As a result, a container with gas quickly freezes if the equipment is installed in an unheated room and the gas supply is cut off.

Reason # 3 - increased gas consumption

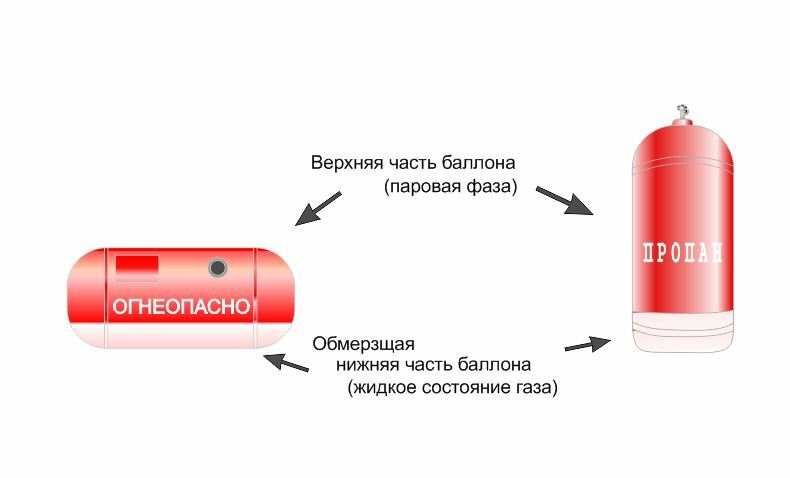

But still, why is the container covered with frost only in the place where the gas is in a liquid state? Low ambient temperatures are not the only cause of freezing. As you know, a gas stove, fireplace or other equipment that is powered by a gas cylinder functions by converting a gas from a liquid state to a vaporous state.

There are two options for converting gas, namely:

- heating fuel;

- natural evaporation.

In this case, all particles with powerful kinetic energy are rapidly directed to the top of the container and are separated from particles in a liquid state with a lower kinetic potential.

The gas, which is in a liquid state inside the cylinder, is always at the bottom, and the vapor part tends upward. Thus, the fuel is released and supplied to the gas stove or other equipment.

Due to these conditions, the liquid fuel begins to lose temperature. It follows from this that with an increase in gas consumption, the temperature of its liquid state decreases. Simply put, the more fuel the equipment consumes, the faster the gas cylinder will freeze.

As the particles cool down, the ability to self-vaporize the liquefied gas decreases. It follows from this that the colder the particles are, the slower the gas will evaporate. In this case, the equipment starts to work intermittently or stops functioning altogether.

Actions in case of freezing of the container

If you notice that your equipment began to work intermittently, then you should pay attention to the surface of the gas cylinder. Most likely it was covered with frost. To resume the correct functioning of the equipment, it is necessary to create optimal conditions for this. If this is not done in time, then the gas appliance may completely stop working.

The first step is to determine for what reason freezing occurs. If this is due to weather conditions, then you need to create the optimal temperature regime for the container, how to do this will be written further.

If the cooling takes place due to the intensive consumption of gas, then it is necessary to reduce the consumption. This can be done by installing an additional cylinder, several can. Depending on the amount of fuel consumption. The connection of several cylinders is carried out using a special uniting ramps.

To connect several cylinders to the gas system, use a special metal ramp, to which a certain number of gas cylinders are connected, a valve is installed on the ramp and pressure gauge

A pressure compensation valve and a pressure gauge should be installed in the rail to monitor the fuel level in the combined system.

How to properly reheat a gas cylinder?

Now we will consider how to ensure the correct operation of gas equipment at low air temperatures, and what can be done so that the gas does not freeze. To address this issue, there are several options.

First of all, try to move the gas cylinder to a warm room, after a while, frost from the surface will gradually evaporate, and the conditions necessary for converting the liquefied gas into a vaporous gas are formed inside the cylinder condition. After that, the gas supply will be restored, and the gas appliance can be used for its intended purpose.

But, if it is not possible to transfer the equipment, then it is necessary to heat the container on site so that the gas inside does not cool down. Very often, owners of gas appliances resort to heating the cylinder by direct exposure to fire. It is strictly forbidden to perform such actions, since this contributes to the rapid transformation of the gas into a vaporous state, respectively, the pressure in the container rises rapidly and can cause an explosion.

To reduce the likelihood of fuel cooling, you can insulate the cylinder with special materials that prevent cold penetration. But this method is suitable for small temperature changes in the environment.

In order to prevent freezing of the gas cylinder, you can insulate the container with a special material with a thermo-regulating base, but you cannot create the effect of a thermos

If the temperature outside is colder, then you can use special heating equipment. An electric heater is able not only to warm up the gas cylinder, but also to provide a constant temperature at which the device will perform its functions with the greatest efficiency.

Thus, fuel consumption is reduced by up to 30 percent.

Compliance with safety precautions

It is very important to observe the basic safety rulesto prevent tragic consequences. Working with gas equipment is extremely dangerous, therefore it is not recommended to independently connect or change the structural elements of the equipment.

If gas equipment is used improperly, the cylinder may explode, which in most cases leads to a severe fire with tragic consequences.

Before connect the cylinder to the stove or take some action to repair it, it is best to contact a gas equipment specialist. In case of improper handling of gas installations, or if the operating conditions are violated, the gas cylinder may explode and cause a fire.

To date, a lot of tragic cases have been recorded, including fatal ones. Therefore, we strongly recommend that you take responsibility for the performance of work related to gas, as well as during the use of the equipment.

Conclusions and useful video on the topic

Watch the video to clearly see why the gas appliance freezes up. Here you will also see which heater to use to maintain the optimum gas temperature inside the cylinder.

Now we know the main reasons why a gas cylinder can freeze up. If you notice that your gas cylinder is covered with frost, then you need to take measures to eliminate this problem. Otherwise, the equipment will not be able to function properly, or will stop working altogether, since the cooled gas stops evaporating.

To ensure the normal operation of the release of gas molecules, it is necessary to create normal operating conditions (increase the air temperature). If this is not possible, then you can use a special heater for the cylinder, or install a heating device.

Do you use bottled gas at home? Tell us how you cope with the problem of its freezing, add useful recommendations on methods of cylinder insulation, take part in the discussion - the comment form is located below.