Gas boilers are manufactured by different companies, which is accompanied by the supply of equipment to the market that requires an individual approach to installation and operation. But I don't want to overpay for calling a specialist for installation work, right? But how to connect the Ariston gas boiler yourself, taking into account the individual characteristics of the purchased equipment?

We will try to help you deal with this task - our publication describes the procedure for installing, connecting and configuring a gas boiler. The sequence of work when performing the first start-up of the equipment is also given. The presented material is supplemented with visual photos and a video.

The content of the article:

-

The procedure for connecting the boiler Ariston

- Stage # 1 - studying the manufacturer's installation requirements

- Stage # 2 - preparation and installation of the boiler on the wall

- Stage # 3 - execution of hydraulic connections

- Stage # 4 - organization of air injection and chimney

- Stage # 5 - connecting the chimney / duct

- Stage # 6 - connecting the equipment to the mains

-

First start-up and adjustment of the boiler

- Performing the first launch

- Adjustment manipulations with the control panel

- Maximum / minimum power testing

- Commissioning of equipment

- Conclusions and useful video on the topic

The procedure for connecting the boiler Ariston

Wall-mounted boilers are perhaps the most common among household gas equipment - they are most often choose for home installation potential buyers.

So, a modern gas wall-mounted boiler of the Ariston Net model allows you to: start, stop and control the temperature background of heating and hot water supply. Moreover, all these actions can be performed from anywhere at any time by using a familiar smartphone or personal computer.

Potential buyers of the XXI century prefer to install such intelligent gas equipment using the example of the Ariston Net household boiler.

The system provides constant control of energy consumption, which is accompanied by significant gas savings. Thanks to special software, the owner of the equipment receives real-time notifications about faults.

In addition, if you activate remote control, it becomes possible to solve most problems remotely. However, let's first look at how to properly install a gas boiler for domestic use. brand Ariston, as well as the features of its connection, settings and procedure for the first launch.

Stage # 1 - studying the manufacturer's installation requirements

Judging by the requirements of the manufacturer of boilers Ariston, the installation of equipment is the prerogative of exclusively specialists.

Hence the corresponding conclusion - independent installation and the first switching on of the Ariston household gas boiler is theoretically impossible (more precisely, unacceptable). Moreover, the first start-up of equipment is prohibited without a representative of the gas service.

The manufacturer also reminds the future user regarding the quality of the water with which the gas wall-mounted boiler will work. It is noted: if the water quality (chemical composition) does not meet the technical requirements, the performance of gas equipment is not guaranteed by the manufacturer during the established warranty period.

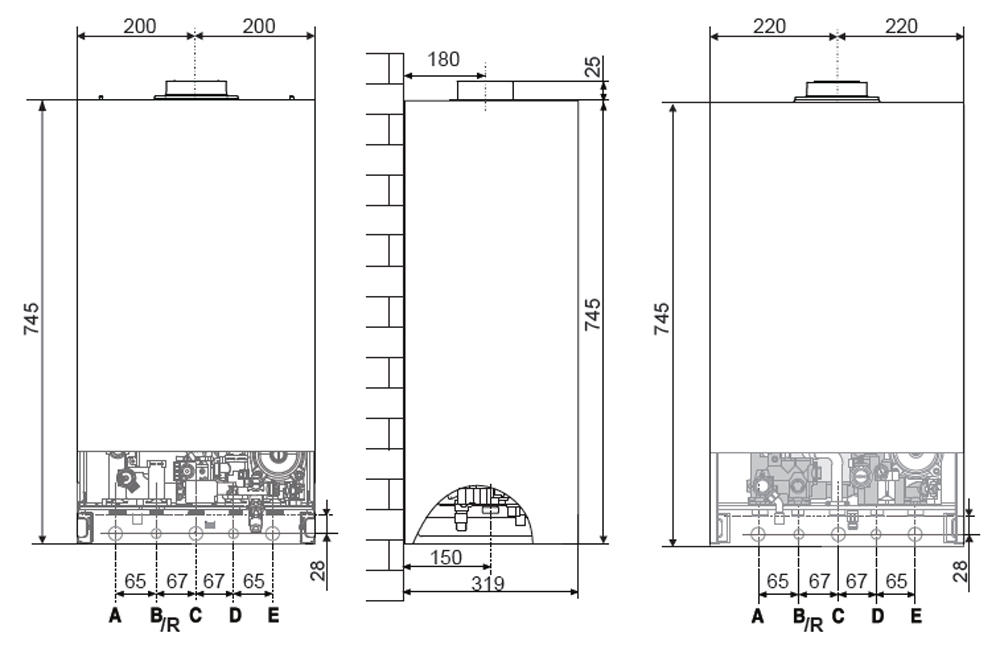

Mounting dimensions and connection points: A - water outlet to the heating system; B - water outlet to the hot water supply circuit; C - gas inlet pipe; D - cold water entry point; E - point of receiving the return flow of DHW

In addition to the technological connection points indicated in the diagram above, there are four more connection points as part of the structure of the Ariston gas boiler:

- Drainage from the safety valve.

- Make-up with water from the network.

- System drain channel.

- Boiler return line.

The Ariston gas boiler is provided for inclusion in hot water supply and heating circuits that are suitable for technical characteristics.

Operation of equipment is considered unacceptable if the operating mode does not correspond to the intended purpose of the system. It is also unacceptable, according to the manufacturer's requirements, to independently carry out repairs.

Stage # 2 - preparation and installation of the boiler on the wall

Installation of the main unit (gas boiler) is carried out on a wall with a high degree of strength. The presence of any vibrations transmitted along the structure of the wall where the Ariston gas boiler is installed is not allowed.

The pipelines connected to the equipment must be protected from possible mechanical damage, as well as the electrical wires supplying the gas boiler.

The room for the installation must be selected taking into account the provided technical and sanitary conditions:

- a sufficient level of lighting;

- effective ventilation;

- durable structures.

Finally, during the installation process, the established safety rules must be observed.

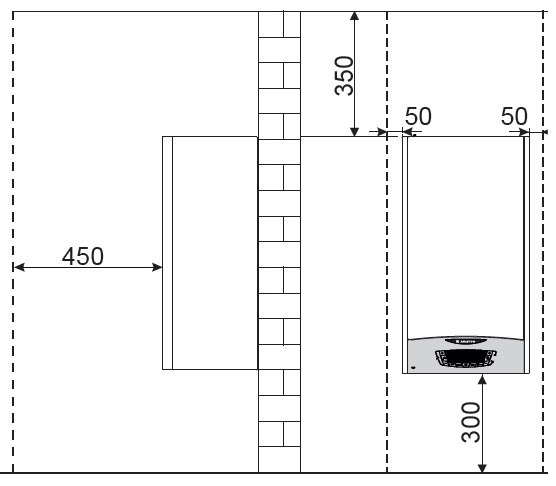

Permissible minimum installation dimensions - parameters that should be taken into account during the installation of the Ariston gas boiler in the area of the working room

Before starting the installation of the system, it is necessary to carry out the following operations:

- flushing of DHW and heating circuits;

- check the gas for compliance with the type of fuel;

- check the design of the gas duct for compliance with the required standard;

- check the quality (chemical composition) of the water.

Ariston boilers of typical design "C", endowed with a sealed combustion chamber, supporting the function of supplying external air, not limited by the requirements of ventilation and the dimensions of the worker premises.

The normal operation of the Ariston gas boiler continues at a minimum operating temperature of +5 ° C inside the working room. At the same time, it is recommended to protect the boiler from the possible impact of external factors and atmospheric precipitation.

The Ariston household gas boiler is mounted on a solid wall, built on a non-combustible material, which is capable of supporting the full weight of the equipment. The location of the gas boiler must be selected taking into account the minimum allowable distances (diagram above) to nearby objects. These requirements are designed to provide access for easy maintenance.

Stage # 3 - execution of hydraulic connections

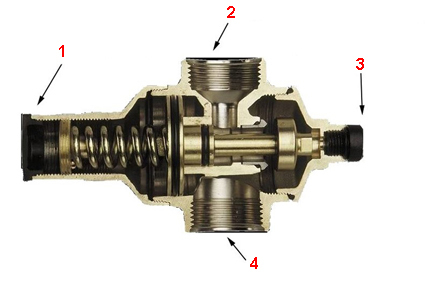

According to the manufacturer's technical parameters, the maximum allowable pressure inside the pipes of the system water supply is allowed at a level of no more than 6 atmospheres. If this limit of the centralized network water pressure is exceeded, it will be necessary to additionally install a pressure reducer in the system.

Water pressure reducer design: 1 - adjusting screw; 2 - inlet pipe for water; 3 - connection point of the pressure gauge; 4 - water outlet

The determination of the dimensions of the water pipelines and heating devices that make up the heating circuit is carried out according to the residual pressure. The level of this pressure is calculated as a function of the required water flow rate. In this case, the technical characteristics of the circulation pump are also taken into account.

The instruction manual requires a drain pipe (supplied) to be connected to the outlet to the safety valve. The drainage outlet of the safety valve is connected to the drain siphon according to a scheme that makes it possible to visually observe the operation of the safety valve.

The design of the Ariston gas boiler provides for the connection of an external indirect boiler for the production of hot water. The default hot water temperature is controlled by an NTC sensor. If the temperature control is organized by means of a thermostat, it will be necessary to amend the settings for the gas boiler control.

Stage # 4 - organization of air injection and chimney

The design of the Ariston gas boiler allows the organization of installation according to the scheme "B" (room air is used) and according to the scheme "C" (outside air is used).

In order to prevent the penetration of combustion products into the air duct system, careful execution of mounting seals is required. The installation of the flue gas exhaust module is required taking into account the exclusion of damage to the seals and the prevention of the penetration of flue gases into the air duct.

Combustion products removal system developed for some models of gas equipment manufactured by Ariston. Different configurations are possible depending on the typical system design

According to the manufacturer's instructions, the horizontal sections of the gas ducts are mounted with a slope of about 3%, directed away from the boiler. So prevented accumulation of condensation.

Installation of gas equipment according to the "B" scheme requires the organization of efficient ventilation and air intake in the working rooms.

Premises where corrosive vapors may appear in the air, it is allowed to use only installation according to the "C" scheme (outside air inflow). Such requirements provide corrosion protection for Ariston gas boilers.

Mounting coaxial (dual) system (gas evacuation and air supply), the manufacturer requires original accessories and accessories.

The chimney must not be installed in close proximity to materials that are flammable. It is also prohibited to install a chimney through structures made on the basis of flammable materials. If the old boiler is replaced with a new one, all parts of the ventilation and combustion products removal modules must be replaced.

Stage # 5 - connecting the chimney / duct

There are several options for connecting the chimney, depending on the configuration of the gas equipment:

- coaxial system (pipe in pipe);

- separate system;

- single-channel chimney.

For the pipe-in-pipe connection of a gas boiler, materials and components are used that have a high degree of resistance to condensate. We talked in more detail about the installation of a coaxial chimney in this article.

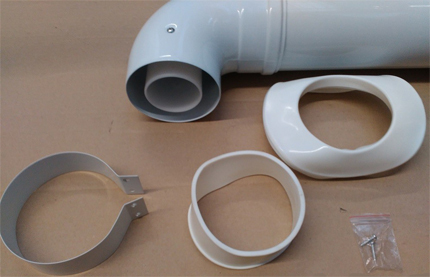

Chimney / air duct connection kits are usually not included in the Ariston gas boiler equipment list. Accordingly, additional kits are ordered for a specific connection.

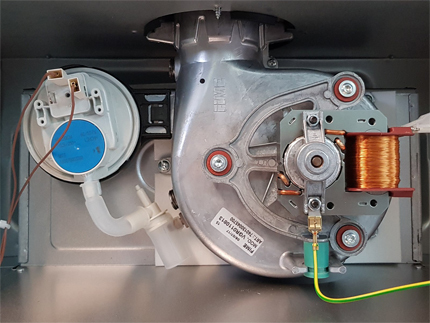

This is how the "pipe in pipe" system looks like, which is used as part of the construction of Ariston gas boilers of some models

Many gas boilers of the Ariston brand are made taking into account the supply of air and the removal of gases through a coaxial system, the pipe diameters of which are 60 and 100 mm. Alternatively, a separate version can be used with pipes for diameters of 80 to 80 mm. The selection of the configuration of the gas outlet and the air duct is accompanied by taking into account the additional aerodynamic resistance.

Stage # 6 - connecting the equipment to the mains

To ensure complete safety, the manufacturer requires the involvement of a qualified specialist to connect and check all electrical connections of the Ariston gas boiler. The manufacturer removes the warranty for the equipment if a poor-quality power supply is used and grounding system.

A grounding circuit for a gas boiler installed inside a private house is a must an event required not only for boilers of the Ariston brand, but also for any other similar equipment

The power supply system is designed for the maximum power consumption parameter of the gas boiler. To connect the equipment, electrical conductors with a cross section of at least 0.75 mm are used.2. The correct safe operation of the gas boiler is ensured by reliable grounding.

The power supply parameters must be brought in accordance with the norms of the 230V / 50 Hz network, observing the polarity and the presence of a grounding conductor. The grounding conductor must be used with a greater length in relation to the phase conductor and the neutral one. Wired connection - strictly permanent, without the use of sockets and plugs, made through bipolar circuit breaker.

First start-up and adjustment of the boiler

When you are done with the installation work and connection, you can proceed to setting up and testing the equipment.

Performing the first launch

The initial action accompanying the first start-up of an Ariston brand gas boiler is filling the heating circuit water. In this case, it is necessary to install the radiator air valves in the working (open) state.

The same actions aimed at bleeding air from the system apply to the boiler circulation pump. As the circuit is filled with water, air is removed from the system, the water pressure on the manometer reaches 1 - 1.5 atmospheres, the tap on the make-up line is closed.

The first start-up of a gas boiler is usually accompanied by preparatory operations related to filling the system with water, bleeding air, checking the tightness of gas lines

At the next stage of commissioning of a gas boiler, actions related to the gas supply are performed.

The procedure is approximately as follows:

- open the doors and windows of the working room;

- exclude the presence of sources of open fire;

- check the burner circuit and control system for leaks.

Testing the regulator unit and burner for tightness is carried out by short-term opening (no more than 10 minutes) of the main shut-off valve of the gas line. In this case, the solenoid valve and the manual boiler shutter are set to the closed position. In this position of the system, the gas flow meter should show a zero result (no leakage).

Adjustment manipulations with the control panel

Modern gas heating equipment is equipped with a control panel where the user can set the desired parameters of the unit. Next, let's take a closer look at how to set up a household gas boiler of the Ariston brand.

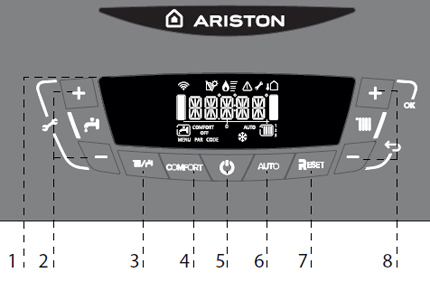

Control during the operation of the boiler, as well as control in the mode of the first start-up with the necessary settings, is carried out through the user control panel Ariston

Actually, the user's actions on the control panel are obvious here:

- Switch on the device by activating the ON / OFF button.

- Mark the operating mode parameters on the display.

- Mark the service mode functions on the display.

Next, the gas parameters are checked, for which the front panel of the boiler is dismantled, the panel plate is lowered control and test manipulations are performed with the connection of the measuring pressure gauge to the selection pipes pressure.

These operations are the prerogative of gas service specialists.. Self-execution is not recommended, since it is necessary to clearly know the functionality of the equipment.

Ariston control panel keyboard layout: 1 - information screen; 2 - regulation of the DHW temperature; 3 - mode selection key (Mode); 4 - "Comfort" function; 5 - ON / OFF key; 6 - "Auto" mode; 7 - reset key "Reset"; 8 - regulation of the temperature of the heating circuit

Then the boiler starts up in test mode through the system function "Chimney sweep". To enter the test mode, activate the reset button and hold it down for at least 5 seconds. Exit the test mode by re-activating the reset key.

Maximum / minimum power testing

This type of test also provides for a control selection of pressure at specialized points of the equipment, followed by measurement of parameters on a pressure gauge. It is necessary to disconnect the compensation pipe of the combustion chamber. Again, the "Chimney sweep" mode is applied, activated through the control panel.

The boiler is tested for the minimum power level in the same way. True, the modulator adjusting screw is additionally used if it is necessary to correct the value of the minimum operating pressure of the boiler. On this occasion, a video is posted below, where the modulator is for some reason called a motor.

Commissioning of equipment

The device startup process involves the following user actions:

- Activate the ON / OFF button.

- Select standby mode.

- Hold down the Mode button for 3-10 seconds.

- Wait for the evacuation cycle to complete (about 7 minutes).

- Open the gas line valve.

- Switch on the DHW operation mode by pressing the "Mode" button.

If all actions were performed by a specialist of a specialized company, then he checks the conformity of the gas pressure during the operation of the unit and draws up the corresponding act.

And also conducts briefings on safe operation gas equipment and puts the boiler under warranty.

Conclusions and useful video on the topic

A video about the features of the first start-up of the Ariston boiler, in particular, the service setting of the circulation pump is demonstrated. In fact, this is the work of specialists, but as the video shows, you can do it yourself:

Wall-mounted gas boilers from a series of modern equipment of the Ariston brand are quite complex equipment, even for domestic purposes. Hence the logical conclusion on the installation and start-up of the Ariston gas boiler - the initial start-up of the system should be entrusted to specialists. The costs are, of course, inevitable, but on the other hand, the correct operation of the gas system is guaranteed.

Were you installing and configuring a gas boiler of the Ariston brand on your own or entrusted this work to specialists? Share your experience with other visitors to our site in the comments block - add a photo of your boiler, tell us about the difficult moments that you encountered in the process of your own installation equipment.