Agree, gas supply to an apartment is much easier than to a private house. In the cottage, the boiler and gas stove, and in particular the boiler, consume methane in cubic meters, carefully calculated by a compulsory flow meter since 2019.

But the thermal calorific value and pressure of blue fuel are unstable, so the meter can wind up too much. The situation will be corrected by a gas corrector capable of reducing the "reeled" cubic meters to the norm of the standard aggregate state of methane. The particular convenience of the device requires almost no attention.

Let's talk about it, explain the effect of temperature on the cost of main gas and how the corrector helps to reduce utility costs.

The content of the article:

- What does this device do?

-

Features of installing the corrector

- Methods for integrating a flow meter with a corrector

- How to set up the device?

- Verification frequency

- Objectives of correcting readings of a natural gas meter

-

What is the use of correcting gas consumption?

- Convenience for regional gas services

- Benefits for household owners

- Conclusions and useful video on the topic

What does this device do?

The purpose of the gas volumetric flow rate corrector is to measure the pressure, temperature and working volumes of methane fuel recorded by the flow meter. The device is equipped with signal converters according to measured criteria obtained from a gas meter and analyzed by a microprocessor.

The compressibility factor is calculated either by the corrector itself (GOST 30319.2-2015), or is substituted according to a preset value.

Equipping a natural gas meter with a correcting device is possible both for "street" and "home" placement. In winter, methane will be equally cold

Measurement results allow converting consumed cubic meters of natural gas into volume under standard conditions methane in accordance with GOST 2939-63, taking into account the conditionally constant parameters of gas fuel - density under standard conditions, CO content2 and N2.

The relative error tolerances over the full operating temperature range are:

- by measuring pressure +/- 0.4%;

- by measuring the temperature +/- 0.3%;

- by bringing the volume to standard conditions +/- 0.5%;

- by measuring the volume of methane under operating conditions +/- 0.05%.

As the corrector accumulates data on the parameters of the incoming gas, they are archived at 60 minute intervals. Depending on the model of the device, it stores data for the last 270-365 days at the time of access to the archive. The archived data is stored on a smart card.

The device contains at least two batteries. They must be changed simultaneously with the verification of the device, i.e. every 5 years

The autonomous power supply unit of the device will provide it with energy for at least 7 full days, provided that the interface screen is active for no more than 15 minutes during this period. It should be noted that the main power supply source for the methane data correction device is the household electrical network through an AC-to-DC converter with a voltage of 9 V (current 100 A).

If necessary, the working functions of the corrector can be used to control blue fuel consumptionby setting a daily and monthly limit for tracking the balance.

Features of installing the corrector

The device for correcting accounting characteristics for methane is connected to a flow meter equipped with a pulse output signal (frequency range up to 2-8 Hz, pulse weight 0.01-100 m3). It is also permissible to connect to gas meter with a position-coding mechanism (encoder) installed in the counting head.

The physical fixing of the device for correcting (standardizing) the data on the consumed volume of gas fuel is carried out on the meter body (if there is a mounting space), on the bracket, or on the wall. The correction device usually weighs up to 3 kg.

It is obligatory to ground the corrector using a rectangular bus with a cross section of 4 mm or more2. External devices are connected to the device with a shielded cable with a conductor cross-section of 0.25 mm or more2, no more than 10 m long.

Methods for integrating a flow meter with a corrector

In the first version, gas consumption control elements are supplied separately: a gas meter with an electrical output (for example, a reed-magnet pair); pressure sensor with a unified current output; temperature sensor (electronic resistance thermometer); a correcting device for standardizing the characteristics of the consumed gas volume.

If the European models of such devices are mainly single-channel, then domestic devices are more often designed for two channels or more (i.e., for two flow meters or more)

Combined into a complex, these devices form a single system of measuring instruments. However, it can be used in this capacity only after agreement with the local department of the State Standard. The advantage of this complex is the admissibility of standardization of readings from several gas meters (i.e. from several gas pipeline inlets).

The disadvantage of such a system is the different terms of verification of its elements, among which temperature and pressure sensors will most often need to be verified. It will be easier not to verify the latter, but simply replace it with new ones. The general advantage of such a measuring complex is that its final cost is lower than that of a factory multichannel system.

In the second variant, the measuring complex is created entirely at the manufacturer. Here it is important to select a system with a close intertesting period of elements. For example, a rotary gas meter LGK-Ex has a verification period of two years, and a corrector and a pressure sensor - 5 years. This means the need to check the entire complex 2.5 times over a five-year interval of use, which is inconvenient and unprofitable.

How to set up the device?

Setting constant information is not required, they are entered at the device manufacturer. Those. after installing and connecting the wires to the data source (gas meter), the corrector is completely ready for operation.

Access to changing the data of the corrector is divided between three parties - the metrological service, the gas supply organization, with which contract signed for service, and the consumer. Each side has its own code (an eight-digit combination of numbers) that gives access to the device's soft menu.

The consumer is given the lowest access priority, and the highest - the metrological organization. In fact, the user can only control the data output to the device interface - full or short display mode.

Making changes to the parameters required for calculating the volume of consumed gas fuel ("metrological" part PO) is allowed only with official calibration performed exclusively when checking volume correctors of natural gas. The button of the calibration lock is protected by a hinged seal (easily breakable!).

Verification frequency

Verification of the validity of measurements carried out by the device for correcting the consumed volume natural gas, it is required every 5 years (subject to the technical serviceability of the corrector during this period).

The calibration interval requirements for the correcting device and the gas meter are not necessarily the same. The frequency of verification of the entire complex depends on the device in its composition, which needs to be verified more often.

Verification methods are developed by manufacturers of correcting devices with obligatory approval by FSUE VNIIMS or regional FBU TsSM. The right to perform verification tests is granted to the state metrological service (FBU "TsSM") or to private metrological services that have a corresponding certificate of the Federal Accreditation Agency.

Objectives of correcting readings of a natural gas meter

Note that although the passport operating temperature range of the flow meter can be +/- 40OC, to the temperature coefficient that increases the price of gas fuel, this does not matter.

The rules for civil gas supply for household purposes No. 549 state the need to multiply the calculated counter of the volume of consumed methane by the coefficient of reduction to standard conditions (designation - Vp), normalized by GOST 2939-63:

- gas temperature - 20OC (also 293.15OTO);

- gas pressure - 760 mm Hg (also 101.325 kN / m2);

- gas humidity is zero.

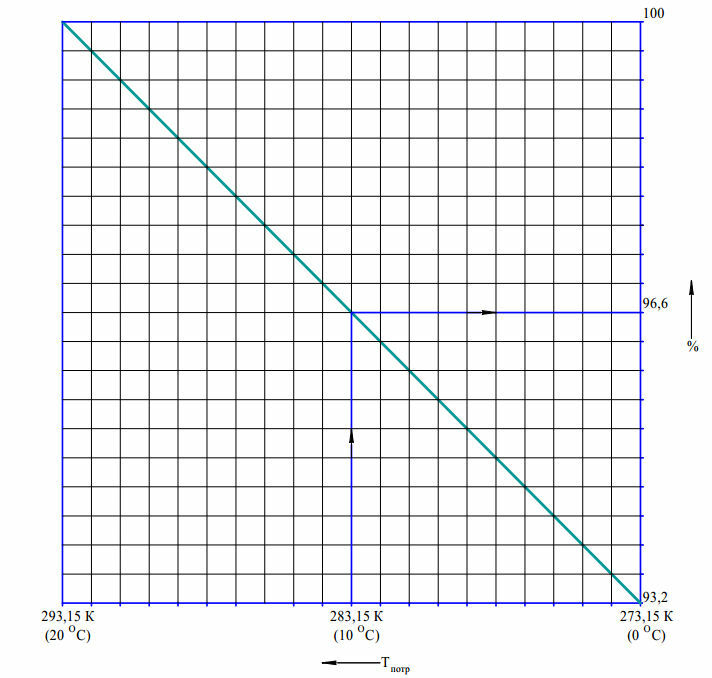

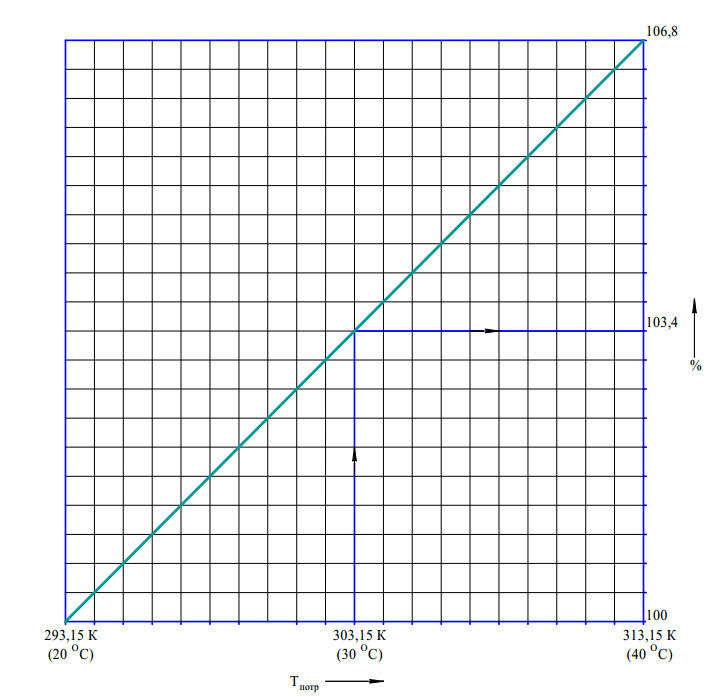

As the "outdoor" temperatures change over the calendar year, different conversion factors are applied to the consumed gas volume to the "gas standard" - in the winter months they are always higher.

The values of these coefficients are set by the Federal Agency for Metrology. In particular, since 2019 in the regions of Russia there are temperature coefficients determined by order No. 1053.

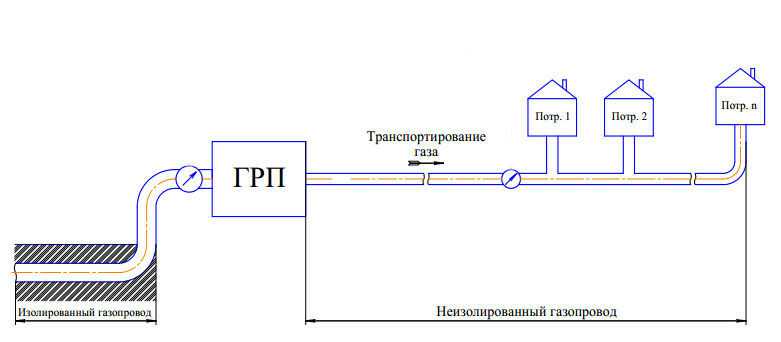

Since the gasification of the private sector often uses the simplest distribution scheme (air), then the cooling of methane, increased fuel extraction and pressure drop in the gas pipeline is a matter of usual. Therefore, it is useless to put the device in the hydraulic fracturing

To avoid multiplying the consumed volume by the regional coefficient established by the norms, the homeowner should choose a flow meter equipped with a temperature compensator to meter gas consumption.

The location of the gas meter - external (outside the house) or internal (in the technical room) - does not matter. Here either the payment for the consumed volume of methane, taking into account the temperature coefficient, or the installation of a gas flow meter with a built-in temperature compensator.

The device that compensates for temperature differences in gas fuel is a bimetallic plate built into the mechanism for measuring the volume when methane passes through the meter. Under the influence of the temperature of natural gas, the plate bends in a certain way and affects gas consumption metering process so that readings correspond to standard condition conditions fuel.

What is the use of correcting gas consumption?

Gas fuel is supplied to consumers in settlements from the main gas pipeline by a system of common high and medium pressure collectors stretched for tens of kilometers.

Before transferring gas volumes to a company that directly supplies fuel to end-users via branch gas pipelines, at the outlet of the gas distribution station, the main parameters of methane are measured - volume (or flow rate), temperature and pressure. These parameters directly affect the income of organizations involved in the transportation and distribution of methane to households.

Therefore, the reduction of the volume of burnt methane in the boilers, boilers and gas stoves to standard temperature conditions in accordance with GOST 2939-63 is initially carried out in the interests of natural gas suppliers.

Convenience for regional gas services

In frosty winter months, the pressure in the gas pipeline-"air" decreases, since its value is directly proportional to the gas temperature (Charles's law). In this case, the density of the gaseous fuel increases, and the volume decreases (Boyle-Mariotte law).

The graph shows the percentage change in the proportion of the initial (supplied to the hydraulic fracturing) volume of methane in the air-gas pipeline, depending on the decrease in the temperature of the blue fuel by one degree

As a result, there is a so-called imbalance between the delivered and consumed volume of blue fuel. Those. a home gas meter will record a smaller number of cubic meters of methane than actually consumed by the heating devices of the cottage.

Conversely, at summer temperatures above 20OA gas meter in a private house will show more methane consumption than actually received. However, in summer, natural gas is burned less by households, because its main consumption is associated with the heating season.

The graph reflects the dependence of the change in the volume of the volume fraction of gas with its warming up by one degree after leaving the hydraulic fracturing and following to consumers via "air"

Thus, the use by households of a full-fledged gas corrector or only a thermocorrector, or payment of the consumed volume of methane fuel with surcharge factors usually occurs to the benefit of the gas supply organizations.

But in one, by the way, rather frequent situation with the supply of gas, the device correcting the parameters of the blue fuel can bring real benefits to the homeowner.

Benefits for household owners

During the frosty months, residents of suburban real estate are worried about another problem - the excessively low pressure in the gas transmission network, which complicates the process of heating the house. The flame above the burner barely glows and the boiler equipment either turns off on its own or warms up coolant in the house heating circuit no more than 60OWITH.

The application of the coefficient markup to the volume of natural gas consumed by the household is associated with a change in the volume of fuel during hypothermia or overheating during delivery on an uninsulated (air) pipe

The reason for the weak gas supply in winter is clear - heating floor and wall-mounted boilers houses burn more methane, otherwise households simply won't be heated. And most owners of year-round country cottages are resigning themselves to the weakened pressure in gas pipeline, supplementing gas heating units with boiler equipment using alternative fuels (wood, coal).

However, they do not realize that they not only have to endure the cold atmosphere of the house every winter, but also pay extra for cubic meters of gas!

According to the "gas" Boyle-Mariotte law, with a drop in pressure in a gaseous medium, its volume increases. Those. when the pressure in the "air" decreases, the volume of methane supplied to the flow meter increases and the meter will start to wind up non-existent cubic meters. The overpayment on "winding" gas bills can reach 5-7% for the heating season.

And only a flow meter with an electronic natural gas corrector, adjusted according to the "local" parameters of methane standardization by the official metrological service, will allow consumers to pay for the cubic meters of blue fuel burned by thermal equipment according to the actual consumption.

Conclusions and useful video on the topic

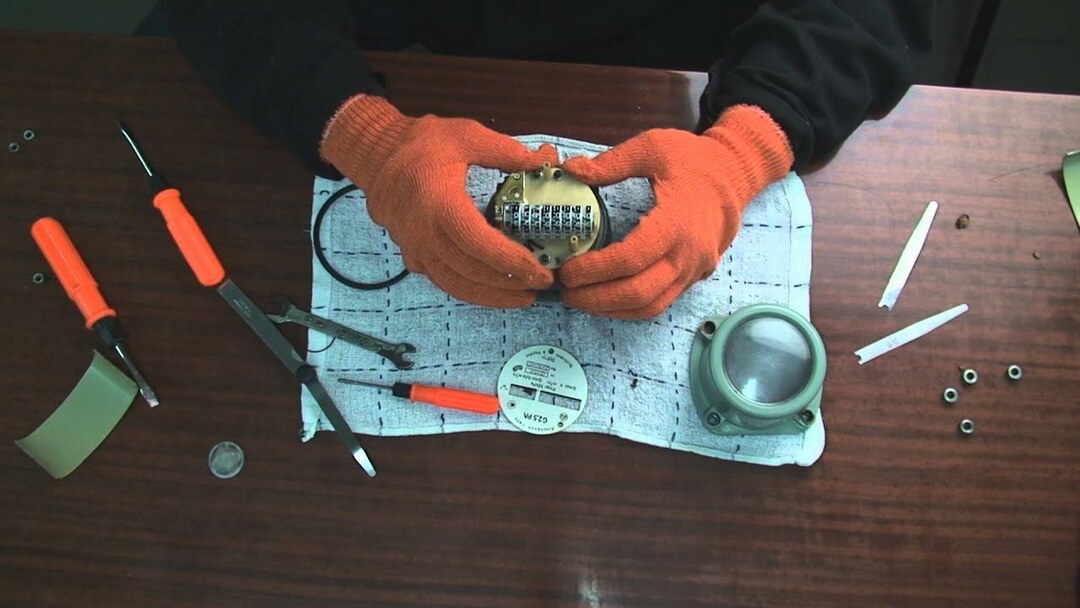

How to use the menu of the device for correcting the volume of consumed gas (for example, EK270):

How the device for standardizing the volume of methane inside is arranged (for example, LNG 741):

How to read and adjust the parameters in the corrector menu (for example, LNG 761):

With the retrofitting of a gas flow meter with a corrector, savings in consumed gas costs will be noticeable if the consumption of blue fuel is more than 4 cubic meters per hour. After all, if you have to put up with weak pressure in the gas pipeline supplying the household, then there is absolutely no need to endure overpayment for non-existent volumes of gas consumption.

Would you like to share your own experience in using a gaseous fuel consumption corrector? Please write your comments in the block below, ask questions, post photos on the topic of the article. It is possible that your recommendations will be useful to site visitors.