Connoisseurs of classic barbecue are sure that for fun gatherings in nature it is worth building a gas grill with your own hands, without overpaying for the finished product. Such a simple design will allow you to cook your favorite dishes on the grill at any time of the year, while you can install it both in the gazebo and on the terrace or balcony.

Today, buying a gas barbecue grill is not a problem, but if you want to get a real reliable design, and save on buying a finished product, you can build a gas grill with his own hand. Let's see what is required for this.

The content of the article:

-

Varieties of gas grills

- Mandatory components of the design

- Required set of tools

- Preparatory work before installation

- Grill from an old gas stove

-

Making a gas grill from a receiver

- We build an automatic spit

- Burner connection to gas cylinder

- What difficulties can arise?

- Conclusions and useful video on the topic

Varieties of gas grills

Depending on the purpose of using the grill, its size may vary. So, for the preparation of dishes from small or large pieces of meat, different designs will be used, which have their own manufacturing characteristics.

Grill from an old gas stove. To prepare barbecue, sausages and small steaks in the kitchen, it is enough to build the simplest option. A home gas stove is used as a heater, on which an old saucepan with a cut-off bottom is installed. A grid or stainless steel mesh is attached to the top of the pan.

With your own construction of a gas barbecue, you can save on materials by using an old receiver or a metal barrel as a body

Mobile grill with separate burner. This option is ideal for preparing large portions of steaks or homemade sausages. Since the “royal” portion of barbecue is unlikely to be cooked in the kitchen, you will need to build a mobile structure with the ability to connect to a gas cylinder.

Large-sized grill on gas, handmade, often made from an old receiver, and implies the installation of a cover, a temperature regulator, and a massive grill.

It will not be difficult to build a grill from an old gas stove, but in this case, all "gatherings in nature" will be limited to barbecuing in the kitchen. The ideal option is to make a mobile grill with a separate gas burner that can be installed anywhere in the yard.

For convenient transportation of a homemade grill, it is recommended to install two metal wheels, and equip the other two legs with support platforms

In this article, we will consider both methods, which will allow you to familiarize yourself with the features of the construction of two different designs of a gas grill, and choose the right option for yourself.

Mandatory components of the design

Regardless of the structure of the structure, the classic gas version has unchanged components, which include.

Frame. Food stainless steel is used as a grill container. When constructing a structure with their own hands, they often install a frame from an old gas cylinder, a beer kegs or a large saucepan.

Heaters. Often, burners are mounted from a conventional gas stove or homemade nozzles. The main condition is that the heaters must be insulated from dripping grease.

Lattice. The structure should be made of small stainless steel rods and fixed to the sides of the grill.

Rotary skewer. Both on the sides of the container and on its lid, it is necessary to mark the triangular notches for the rotation of the skewers.

Collector of fat. To prevent the cooking zones from being completely filled with grease, the drip tray must be installed in advance.

In the absence of a factory burner, you can build homemade nozzles by installing several metal pipes with the same holes for gas outlet

Lid. The presence of such a simple element distinguishes the grill from the barbecue, since only the lid provides the highest possible temperature inside the container, and evenly distributes the heat.

Required set of tools

If for the construction of the simplest design you can limit yourself only to a locksmith's tool - a hammer, a file for metal and a drill, then in the manufacture of a high-quality autonomous device you will need to arm yourself as follows:

- measuring equipment. Specialized tools include a caliper, ruler, and level;

- welding machine and electrodes. To connect two stainless steel elements, it will be enough use welding. In the absence of such equipment, the body will have to be welded from ordinary iron;

- equipment for metal cutting. In this case, all metal trimming work is carried out with the help of a grinder or plasma cutter.

If you have previously had to work with professional equipment, then you can quickly figure out the principle of building a stand-alone grill. The main condition is compliance with the rules of proportionality, on which the correct functioning of the gas barbecue will depend.

Preparatory work before installation

The process of cooking meat on the grill involves interaction with an open flame, so it is important to secure the location of the structure in advance.

If the gas grill is installed outdoors, then a stable base with good fire-fighting characteristics will need to be prepared for it.

Paving slabs or sand can be used as a material to create a flat surface. Even if the structure topples over, such a non-combustible base will help prevent the spread of fire to the nearest areas of the territory.

If the barbecue design is based on an old gas stove, and its installation will be carried out indoors. The floor and walls will have to be finished with slabs of fire resistant materials for the role of which tin sheets or ceramic tiles are ideal.

For such a design, it is better to allocate a separate room with good ventilation, and try to install it away from objects with a high level of flammability.

Grill from an old gas stove

If your dacha has an old gas stove that still functions, then assembling a homemade barbecue will only take you a few hours.

First, you need to carry out calculations of the stove and the components of the future grill, on the basis of which you can draw up a detailed drawing or diagram. After preparing the equipment and purchasing all the necessary materials, you should start manufacturing the structure.

For better stability of the structure, at a height of 10 cm from the floor, it is recommended to weld a metal shelf on which the gas cylinder will be placed

A small hole is drilled into the bottom of the hob to collect fat and liquid. When cooking meat, a huge amount of fat is released on the wire shelf, which can prevent the burners from burning. A branch pipe is connected to the hole, and a flexible tube is fixed. This setting will keep the inside of the brazier clean as well as underneath it.

Next, you need to assemble a frame that acts as a base for the frying chamber. The structure is welded from several steel corners. The upper frame must be sized to match the dimensions of the stove and the side of the stove. The suitable height of the legs is 70 cm, while at a height of 10 cm from the floor, fittings are welded to the legs, from which the frame for the gas cylinder is formed.

After assembling the frame, you should start making the sides and bottom of the barbecue. The height of the sides should be no more than 20 cm. First, the sides are welded to each other, after which the bottom is welded between them.

To ensure a sufficient supply of heat, holes with a diameter of 10 mm are drilled in the bottom, while the distance between them should be 7 cm. The holes must be so that there are no burners underneath. A stainless steel grate is installed above the bottom.

The rectangular grill lid is cut from a sheet of steel, while a handle with a wooden plate must be welded in the center. In the cover itself, there should be slots for the grill handle. If you plan to use the gas grill as a homemade brazier, then you will need to make triangular cuts for the skewers around the edges of the sides and lid.

The next stage is the assembly of the finished structure, and the connection of the grill to gas cylinder. On a flat surface, you will need to install and fix the frame in a static position. If necessary, permanent grooves can be welded for added stability.

If you wish, you can independently weld a strong mesh of stainless rods, or "digest" the grate from an old gas stove

Next, the gas stove is installed on the base, and fixed to the corners with self-tapping screws. A brazier is mounted above the stove, which can be fixed in the grooves or simply welded to the frame. It is important to check the stability of the fryer chamber immediately after installation. It is necessary to insert a gas cylinder into a special strip for the receiver, which will subsequently be connected to the stove.

If the gas grill is working properly, then you can start cosmetic procedures for cleaning and painting the finished structure. All steel parts should be cleaned of scale and rust, after which the product is covered with fire-resistant paint.

Making a gas grill from a receiver

A gas cylinder grill is ideal for classic barbecue lovers when you have to cook meat for a large company. This oversized design is ideal for outdoor barbecuing without having to worry about stocking up on firewood or charcoal. The construction of the grill from the receiver is carried out in several stages.

Any food stainless steel container with a diameter of at least 40-50 cm can be used as a grill body. It could be an enamel pot, an old beer garden keg or a body from an old receiver. In this case, a propane cylinder will be used.

When preparing the gas receiver, the valves and the valve of the axle box are removed, after which the cylinder should be filled two-thirds with water, and boil. Next, a sector is cut out in 1/3 of the side surface, which will later be closed with a special cover. To remove the paint from the cylinder, you will need to burn it, and, after heating, remove the remaining coating with sandpaper.

The size of the cut-out sector should be 1/3 of the side surface of the cylinder, since only such the dimensions of the cut allow you to install the grate to the full thickness of the container, which means you can place more meat

To collect fat, it is recommended to install a special tray in the form of a removable bottom, or drill several holes in the bottom of the container and fix the tray to the frame. On the lower part of the container, nozzles are installed - metal tubes, 1-3 cm thick, with drilled holes of 3-4 mm.

It is through these holes that the gas-air mixture will pass. It is better to make the nozzles removable so that they can be cleaned later.

Installation of nozzles is carried out as follows: into the wall of the cylinder welded 3-4 cm piece of pipe (connector) connecting the nozzles and the mixer. The diameter of the pipe should be chosen so that the nozzle fits tightly into it by 2-3 cm, and at the same time is securely fixed.

A gas and air mixer is connected to the outer part of the connector, which is a tube with the same diameter as the nozzle and 5-8 cm long. A hole is made in the wall of the mixer, into which the gas jet is inserted.

The grate is installed at a distance of 5-10 cm below the edge of the container. It is recommended to use a stainless steel grate with a rod diameter of 3-5 mm. If you do not want to waste time making a mesh, you can cut it out of the original grill from the barbecue. The structure must stand firmly on the supports and, if necessary, can be easily removed.

The cut out part of the cylinder body will be used as a cap, which will need to be attached with hinges. A thermometer can be installed in it, allowing monitor the temperature inside the frypot and regulate the gas flow. The final stage - welding handles on the lid for the most comfortable use of the grill.

When painting a product, it is better to give preference to aerosol packaging, which allows you to evenly distribute the paint over the entire surface of the structure.

Since the receiver itself is quite heavy, it is better to install the finished grill on a metal base welded from a steel square pipe, with a separate place for a gas cylinder. To make the structure easy to move around the territory, two of the four legs can be equipped with wheels from a wheelbarrow, for example.

After completion of all work on the construction of the gas grill, the outer surface of the body is painted with heat-resistant black paint.

We build an automatic spit

Installing an automated skewer will enhance the functionality of this simple design, allowing you to expand your classic BBQ menu. To do this, the design will have to be changed a little: instead of the grate, install a holder for the skewer. On one side there is a simple tube, in which the sharp end of the skewer is turned, and on the other, there is a triangular cutout for fixing it.

Outside the case, a motor from a conventional tape recorder is attached along with a power supply. After installation, a strap from the motor is thrown onto the skewer, and the spit rotates at the speed that you specify. In this case, the pulley diameter acts as a speed regulator.

Burner connection to gas cylinder

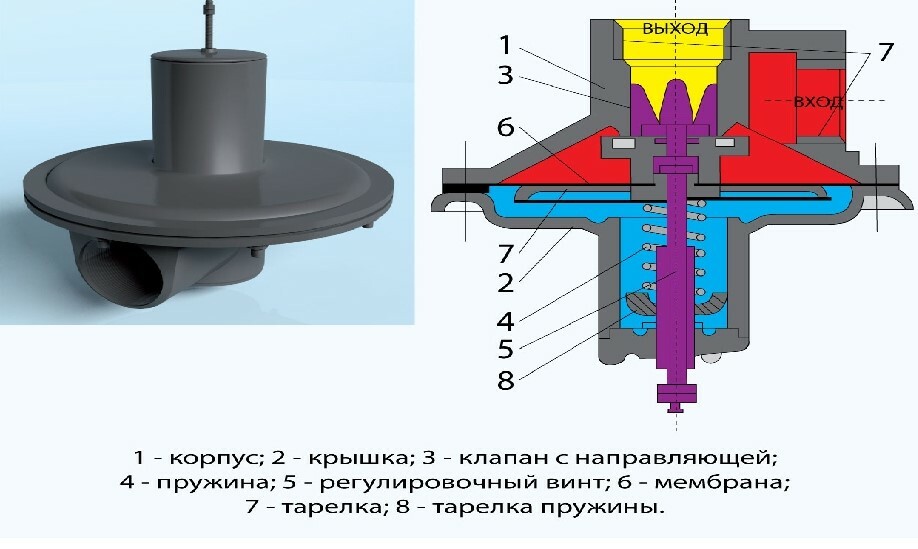

When connecting a home-made grill to the receiver, you will need to purchase and install an adjustable gas regulator, which allows, if necessary, to regulate the gas pressure in the nozzle.

When constructing an autonomous gas barbecue, the safest option would be to connect it to a gas receiver

For safe use of the system with a cylinder, you must perform the following algorithm:

- close the taps on the grill, open the cylinder valve and adjust the gas pressure using the reducer;

- light a match, turn the grill tap and ignite the gas above the nozzles through a special hole;

- after the completion of the cooking process, it is necessary to turn the gas on the cylinder, and after complete attenuation, turn the grill valve in the opposite direction.

Often, a grill from an old gas stove is connected to the main gas, while it is enough to screw the tap onto the pipe and connect it to the grill using a special gas hose. For maximum safety while using your grill, it is important to seal all joints and threads.

What difficulties can arise?

The main task when creating a gas grill is to guess the proportionality of all the details. The cut of a sector that is too small in the body will not allow full-size grill, which means that it will be impossible to cook the required portion. If you install a nozzle that is too powerful, the meat will simply burn during the frying process.

The inner part of the case must be made of food-grade stainless steel, or coated with a special heat-resistant Teflon-based compound.

You can spy on the correct location and number of holes on the burner of an old gas stove, and build homemade nozzles with an identical structure

Unless absolutely necessary, do not paint the inner surface of the case, since choosing the wrong or low-quality coating can lead to poisoning. All heated parts of a home-made grill should not emit smoke or smell - during the frying process, the meat absorbs all toxic fumes.

Therefore, before proceeding with the preparation of the first batch of barbecue, it is necessary to make a test run of the barbecue. During this time, all paint and dirt will be burned off and your gas grill will be ready for further use.

Conclusions and useful video on the topic

Making a gas grill with your own hands does not require special knowledge, because for this you just need to understand how the structure works. If you have all the necessary tools and materials, you can build a gas barbecue grill with connection to a gas cylinder, saving round money on buying a factory grill the amount.

With such a multifunctional gas grill, you can arrange barbecues with friends in your summer cottage:

If you can supplement our material or share your own experience in creating a gas grill, please write your comments, ask questions in the block below.