People have been using gas water heaters for over 100 years. They appeared in our country in 1956. The most popular are instantaneous water heaters, the popular name of which is gas water heaters.

Agree that this device is much more reliable than a boiler. However, it is not uncommon for a gas water heater to heat up the water very much. The temperature of the heated water should not be too high, as this causes a lot of inconvenience and negatively affects the water heater.

We will consider in detail the possible causes of this problem and the most effective ways to solve it. Do not rush to call the master. Try to repair the gas water heater yourself, and we will help you with this.

The content of the article:

- Instantaneous water heater device

-

Reasons for overheating the water column

- Low water pressure

- Untimely filter replacement

- Regulators incorrectly installed

- Low throughput of the mixer

- How do I troubleshoot?

-

Descaling the heat exchanger

- Hydrochloric acid cleaning

- Cleaning by means of a tank with a pump

- Uses of citric acid

- Care and maintenance of the gas water heater

- Conclusions and useful video on the topic

Instantaneous water heater device

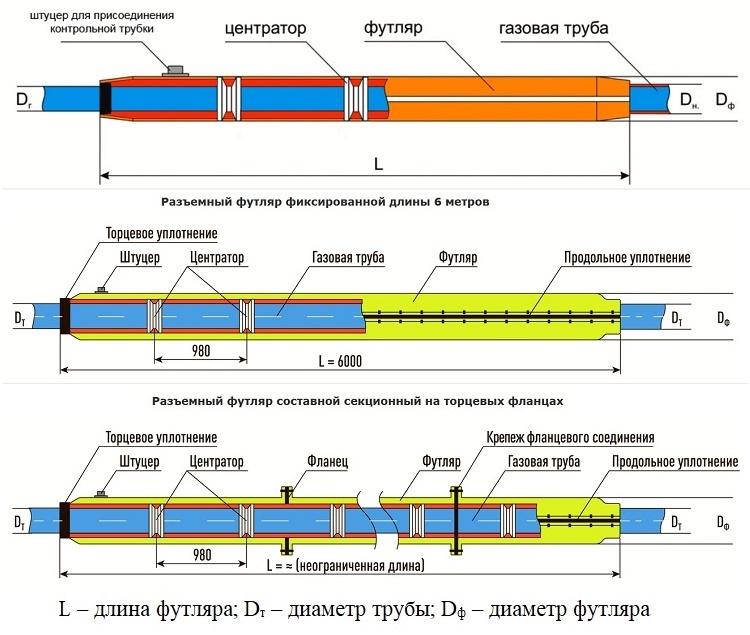

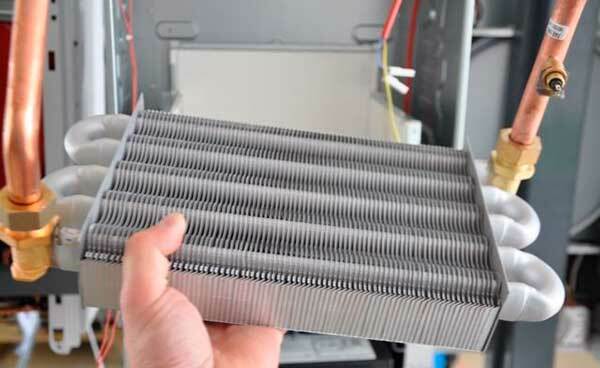

The geyser is able to instantly change the temperature of the water, which is heated in a once-through circuit. There is no tank in this equipment. The device has a plate heat exchanger, most often made of copper.

A water tube passes through it. Gas burners are located below. The heat exchanger plates are heated by the combustion gas and, in turn, heat the water tube.

For safety reasons, new models of gas water heaters are equipped with automation that controls the draft in the chimney and the flame. In the event of a malfunction, the gas supply is interrupted automatically

An exhaust gas collector is located at the top of the device. In it, the products of combustion of blue fuel are accumulated and redirected to the chimney. There are regulators on the body of gas boilers, with the help of which the water pressure and gas supply are adjusted. Thanks to them, the water heating temperature is set individually.

Recommended temperature values are not higher than 42-50 ° C. Higher temperatures lead to active salt deposits on the heater parts. As a result, excessive heating of the gas column housing occurs, and very hot water flows from the tap.

Reasons for overheating the water column

There are several reasons due to which the gas water heater overheats the water:

- the heat exchanger is clogged;

- minor water pressure;

- untimely filter replacement;

- regulators are incorrectly installed;

- low throughput of the mixer.

The most common cause of strong heating of the water or the body of the boiler itself is a clogged heat exchanger. Also, overheating may be the result of turning on the equipment with blocked water pipes and heating pipes.

Mineral salts that settle on the walls impede the movement of the coolant. As a result, water flows more slowly through the heat exchanger, and heating is performed with a normal intensity.

To identify the true cause, first of all, it is recommended to check the operation of the pump and the circulation of water through the heating system.

Low water pressure

If the water in the tap is extremely hot, then cold, the reason for such a "swing" is poor pressure in the main line or a discrepancy between the water pressure and the power of the column. The throughput capacity of such brands as Bosch, Ariston, Baltgaz, Nevalux, Electrolux, etc. 11 l / min. With a slight pressure, overheating occurs.

You can solve this problem yourself. To do this, it is necessary to install a pump capable of artificially increasing the water pressure in the system. As a result, the temperature of the liquid will be reduced.

To solve the problem with the pressure, contact the city water utility.

Untimely filter replacement

The water quality in the water supply system is poor. To minimize its destructive effect on the equipment, a mesh filter is installed. It retains small debris, cleans the water from impurities and softens it.

If the filter has not been changed for a long time, then water with magnesium and potassium salts enters the column. As a result, scale deposits on the parts. This calcium sludge often contributes to equipment failure.

Regulators incorrectly installed

Do you change the position of the regulator in a timely manner depending on the season? Often the cause of strong water heating gas water heater is the change of seasons of the year. In the spring, the water in the utilities becomes warmer, and the gas supply regulator is set to the maximum value.

At the same time, the water supply regulator remains at a minimum level (as in winter). As a result, the water gets too hot in summer.

Low throughput of the mixer

Another common problem is when the water temperature in the kitchen is comfortable, and boiling water is pouring out of the shower.

It is not recommended to dilute a hot stream with a cold one. This leads to more rapid scale formation. As a result, equipment breaks down quickly.

In this case, the problem is caused by the low flow rate of the mixer in the shower. The only solution is to purchase a mixer with the maximum throughput.

How do I troubleshoot?

If the casing of the gas water heater heats up due to contamination in the communications, then they should be cleaned. To do this, you need to check the inlet and outlet hoses of the water supply, the valve box and the cartridges for the mixer. The hoses are cleaned under running water.

To clean the pipes, you can use reverse current or ask for help from a technician.

If the regulator is incorrectly installed, it is necessary to switch the operation of the water heater to summer mode. The initial outlet water temperature is influenced by the temperature index of the inlet liquid. For example, the device heats water up to + 35 ° C.

In summer, the inlet water temperature is + 15 ° C. Therefore, at the outlet, the liquid will warm up to + 50 ° C. In winter, when the inlet water temperature is lower, this indicator also decreases.

Descaling the heat exchanger

If you have a heating of the gas column housing, it is worth checking the condition of the heat exchanger. Since water is heated by means of gas, over time, parts of the equipment become covered with carbon deposits and scale.

The channels of the heat exchanger tubes are clogged with salts due to hard water, which disrupts the circulation of the liquid. To restore the operation of the gas boiler, it is necessary to clean the heat exchanger.

First of all, shut off the gas supply and disconnect the equipment from the power supply. After the device has cooled down, you need to disassemble the boiler according to the operating instructions. After removing the filter, it is cleaned mechanically. If the condition of the part is extremely neglected, it is recommended to replace it.

Hydrochloric acid cleaning

The first reagent for self-cleaning of a heat exchanger is hydrochloric acid.

This will clean the copper heat exchanger. If the part is made of a different alloy, it is better to take simple culinary citric acid for cleaning and prepare a 155-solution from it

Procedure for cleaning with hydrochloric acid:

- turn off the water and drain all the hot liquid by opening the mixer;

- remove the cover;

- unscrew the screws holding it;

- disconnect the thread of the heat exchanger (water may flow, therefore it is recommended to substitute the container);

- prepare a hydrochloric acid solution (no more than 3-5%);

- using a pipe or hose with a ½ inch thread, connect the inlet and outlet of the radiator;

- install a funnel on the pipe and pour the solution into it.

All work must be carried out with gloves. Foam can form as a result of the reaction between hydrochloric acid and scale. After completion of cleaning, rinse the heat exchanger from acid residues.

Cleaning by means of a tank with a pump

For work, prepare a 7-10% acid solution. You will also need a tank and a centrifugal pump.

Sequencing:

- shut off the gas and water supply;

- drain the remaining water by opening the mixer;

- unscrew the bolts to disassemble the casing and gain access to the radiator;

- pour the acid solution into the tank;

- connect the cleaning system to the heat exchanger;

- start the pump.

The liquid should be run through the heat exchanger for an hour until all contamination is removed. If necessary, after cleaning, the poured reagents should be neutralized with a special solution or rinsed well with water.

Uses of citric acid

Take a deep container in which the heat exchanger can fit freely. For 700 ml of water, 80 g of citric acid is required.

Fill a container with about 30% water, immerse the radiator in it and fill with the acid solution. Heat the contents for 30 minutes.

After cleaning the heat exchanger with citric acid, allow the liquid to cool down before removing it.

Before assembling the device, rinse the parts under running water to remove any residues of scale. Preventive cleaning is recommended once a year.

After cleaning the heat exchanger, all parts of the gas column are connected in reverse order. Before use, check the functionality of the entire device. With timely cleaning, the gas column will last as long as possible, and the heat exchanger will not consume more gas.

Care and maintenance of the gas water heater

Regular maintenance is essential for the reliable and long-term operation of the device. Every year of operation, the boiler must be inspected, its parts preventively cleaned, the control and safety elements checked, as well as the tightness of the gas and water distribution.

In order for the gas boiler to work correctly, it is necessary to control the pressure coolant at the exit from the equipment. If the pressure is below 0.8 bar, the heating system must be refilled.

Annual prophylaxis includes:

- checking the traction and performance of gas equipment;

- inspection of the condition of the heat exchanger;

- checking traction and ignition;

- inspection of the structure and determination of the need for cleaning the case.

In most cases, it is sufficient to clean the heat exchanger, housing and burner once a year.

Timely detection of malfunctions, as well as their prevention, will prevent serious damage

When the seasons change, it is necessary to prepare the equipment for further operation. Most often, the check is carried out before the onset of cold weather, when the load on the device increases.

Conclusions and useful video on the topic

Troubleshooting the gas boiler:

Do-it-yourself heat exchanger cleaning:

A gas water heater is an equipment that provides uninterrupted preparation of hot water and serves individual heating. In order for the device to work correctly, it should be regularly inspected. Without this, the equipment will quickly break down and will require major repairs or the purchase of a new boiler.

Share in the comments your history of operating a gas boiler, as well as what malfunctions you encountered and how you got out of the situation. If you know other ways to self-clean the heat exchanger, tell us about it by filling out the form below.