A hood in the kitchen is needed to remove vapors, smoke, harmful combustion products and odors during cooking. An air duct connects the hood to the ventilation duct. To provide ventilation, it is not enough just to buy a good range hood. It is necessary to choose the right chimney. In order not to be mistaken, you should learn about the differences between different types, take into account the peculiarities of operation, installation and much more.

A hood in the kitchen is needed to remove vapors, smoke, harmful combustion products and odors during cooking. An air duct connects the hood to the ventilation duct. To provide ventilation, it is not enough just to buy a good range hood. It is necessary to choose the right chimney. In order not to be mistaken, you should learn about the differences between different types, take into account the peculiarities of operation, installation and much more.

Plastic pipes for kitchen hood

Material. PVC.

Attention! Earned on our website kitchen designer. You can get acquainted with it and design your dream kitchen for free! May also come in handy wardrobes designer.

Diameter. In cross-section, the pipe is round and rectangular. The latter is also called flat. The most popular diameters: 100, 125, 150, 200 mm. As for rectangular, the greatest demand is for the following dimensions: 55-60 mm by 110-204 mm.

Resistance. The plastic is smooth, so the duct made of this material has low resistance to air flow. If we compare the round with the rectangular, then the air will move a little faster along the first.

Exploitation. The working temperature of the plastic is up to +70. It does not corrode and does not require cleaning: grease and dirt do not adhere to a smooth surface.

Noise level. The plastic air duct is smooth inside, the flow has nothing to cling to, so ventilation is silent.

Assembly. Installation is simple, but connecting with adapters takes time. Too complex configuration of kitchen furniture and walls plastic duct «repeat» cannot: sharp and frequent bends impair ventilation.

Price. It is not high, but the cost is increased by adapters, which you cannot do without.

Appearance. PVC pipe in the kitchen looks aesthetically pleasing. This is especially true for the one that has a rectangular section. In addition, the plastic can be painted in a suitable color.

Metal pipe

Material. Speaking of a metal duct, they most often mean an aluminum corrugation. This flexible pipe can also be made of plastic, but due to its low cost, it is aluminum that is most widespread. It is made of multi-layered foil folded like an accordion. It has a frame inside - rings made of steel wire.

Material. Speaking of a metal duct, they most often mean an aluminum corrugation. This flexible pipe can also be made of plastic, but due to its low cost, it is aluminum that is most widespread. It is made of multi-layered foil folded like an accordion. It has a frame inside - rings made of steel wire.

Diameter. In cross-section, the corrugation is only round. The greatest demand is for such diameters: 100, 120, 125, 150 mm.

Resistance. Although the corrugation is stretched at the time of installation, the grooves still trap air a little. It moves faster on a smooth surface.

Exploitation. Working temperature - +300 and above. Corrugation is resistant to corrosion, but requires periodic cleaning. Fat and soot stick to the ribbed inner surface.

Noise level. Air «clings» for the rings inside the pipe. This makes it vibrate, making noise. Therefore, a metal duct works louder than a plastic one.

Assembly. Installation takes place very quickly: it is simply pulled over long distances. The flexible sleeve can be lengthened by 4.5 times. It is easy to turn the air duct in any direction, which means that L-shaped adapters are not needed. Corrugation «adjusts» for any configuration of furniture and protrusions on the walls.

Price. Cheaper than plastic, plus savings on adapters.

Appearance. A flexible metal duct is not as beautiful as a plastic duct.

Duct outlet options

With two entrances

Not a very common option. When there are two separate openings in the wall - the entrances to the exhaust duct - everything is simple. A pipe is brought out into one, and the other is left for natural ventilation. However, during the operation of the exhaust hood, a nuisance may arise - reverse draft. Proper ventilation suddenly starts working in the opposite direction, filling the kitchen with unpleasant odors. Let's consider why this happens and what to do.

Not a very common option. When there are two separate openings in the wall - the entrances to the exhaust duct - everything is simple. A pipe is brought out into one, and the other is left for natural ventilation. However, during the operation of the exhaust hood, a nuisance may arise - reverse draft. Proper ventilation suddenly starts working in the opposite direction, filling the kitchen with unpleasant odors. Let's consider why this happens and what to do.

If there is no hood in the house, but only a ventilation duct, the air must still change. This is how natural ventilation works. Warm indoor air is less dense than cold outdoor air. Less dense means light. It rises and goes out into the ventilation shaft.

Fresh air must flow into the kitchen from the cracks in the windows and doors. When designing the houses, it was assumed that this is how ventilation would be carried out. Today, almost everyone has sealed plastic windows and doors with seals that violate the principles of ventilation. Ideally, if the glass units do not provide air flow, the situation should be corrected with supply valves. They are installed in a plastic window or wall next to them.

If install a kitchen hood, the situation will become more complicated. Modern hoods are very powerful. During their operation, all the air from a small kitchen is taken very quickly. Suppose in an hour she «took away» 1000 cubic meters of air. Tightly closed windows keep air out of the street. Then the ventilation begins to supply waste, unpleasant-smelling air to the kitchen.

In order to prevent backdraft, when turning on the hood, open the windows or install a check valve in the second ventilation hole. When it is turned off, the valve will close, preventing dirty air from entering the kitchen.

With one entrance

Most often, the kitchen wall has only one ventilation window. Above, it was told about the features of different pipes for the hood to the kitchen. It was this most common option that was meant.

If there is only one ventilation hole, in no case should it be completely covered with an air duct. Many people think: since there is a kitchen hood, it means that the ventilation is of high quality. In fact, the hood is not mentioned in the regulations. Ventilation ducts, on the other hand, are mandatory in the design of buildings. If the hood with its air duct blocks the entrance to the ventilation shaft, then ventilation in the kitchen is impossible.

No matter how powerful an exhaust hood is, it is not able to suck in air that is far away, for example, under the ceiling or against the opposite wall. The hood cannot remove the air mass at a distance greater than its inlet opening. So she «works» only with air above the stove. The rest should exit through the exhaust duct.

The optimal solution is to install a special grill on the ventilation hole. It differs from the usual one in that it consists of two parts: a hole for an air duct and a grate for natural ventilation. In addition, a non-return valve is needed.

Outside

Unfortunately, the dimensions of the ventilation shaft entrance are often modest: 130 x 130 mm. If most of the opening is given for the duct, there will be very little space for natural ventilation. Therefore, the ideal option is to bring the exhaust pipe to the street, and leave the window to the ventilation duct with the usual grate.

You cannot cope with this work on your own - you need to invite specialists. They will make a hole in the wall with a diamond drill, install a pipe and a protective deflector. This is a device that increases traction and protects the air duct from precipitation and ice crust formation. The deflector also has a valve that closes and does not let in cold air.

The rule for all types of pipes

It sounds like this: the longer the air duct, the more bends in it, the lower the extraction performance. With each additional meter, it works 5 - 10% worse. Each turn slows down the air flow.

It sounds like this: the longer the air duct, the more bends in it, the lower the extraction performance. With each additional meter, it works 5 - 10% worse. Each turn slows down the air flow.

If the gas stove is rigidly fixed and the window to the ventilation duct is located nearby - great. If at a great distance, there is nothing to be done. It is advisable to move a gas stove on a flexible hose or an electric one closer to the ventilation duct. It is good when the arrangement of kitchen furniture allows you to do this. The worst case scenario is when the ventilation duct and the hood are located on opposite walls. It is desirable that the ventilation pipe does not exceed 3 m.

Purchase of a ventilation pipe. What is the length, diameter and shape?

The pipe is bought after purchasing the hood and after deciding where to take it out.

The pipe is bought after purchasing the hood and after deciding where to take it out.

- Length. Both plastic air ducts and corrugation come in different lengths, so it's easy to find the right one. If the pipe is too long, it is shortened: the plastic one - with a hacksaw, and the corrugation - with scissors. To build up metal, use aluminum reinforced tape.

- Diameter. The instructions for the hood indicate what diameter the duct should have. If plastic pipes of the required diameter are not on sale, then adapters are used for the connection. But it is worth remembering: when its diameter is greater than the diameter of the exhaust pipe, the load on the motor increases. If the corrugation is a little wider, it is simply pulled together with a clamp.

- The form. The pipe may not be in line with the hood opening or ventilation grill opening in shape. Then use adapters from round to square.

Installation of a plastic duct

Speaking about installation, we will bear in mind exactly the most common way of removing the air duct - into an exhaust duct with one inlet.

Speaking about installation, we will bear in mind exactly the most common way of removing the air duct - into an exhaust duct with one inlet.

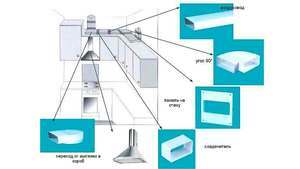

To assemble a plastic pipe, adapters are needed. In a general sense, adapters are called elements for connecting in a straight line (without turning), at a right angle, for connecting an air duct with an exhaust hood and with a ventilation grill. When connecting, the joints must be insulated so that the exhaust air does not pass into the kitchen.

A grill is installed on the ventilation duct for natural and forced ventilation. It is a two-piece plate. At the top there is a round opening for the ventilation shaft with a flange, and at the bottom there is a grill. If the diameter of the duct does not match the diameter of the flange, or if the pipe is rectangular and the flange has a circular cross-section, in such situations, adapters are used.

Installation of a round corrugation

To assemble flexible ventilation, adapters are not needed, because the corrugation bends and turns at any angle. The corrugation is put on the hood branch pipe and tightened with a clamp. Then they stretch it as much as possible so that over time it does not sag. The other end is inserted into the flange of the ventilation grill, fixed with a clamp. The ends of the corrugation are not sealed for two reasons. First, because the flexible pipe has to be cleaned from time to time inside. Secondly, because during operation, it vibrates, which may cause cracks. Throughout the corrugation, every 1-1.5 m, it is fixed on clamps so that it does not swing.

How to hide the duct

Ventilation can be overwhelming and ruin the kitchen environment. To make the pipe less conspicuous, it is usually laid above kitchen cabinets or under the very ceiling. If the duct is plastic, the simplest thing to do is paint it to match the walls or furniture. All these are half measures. It will take time and materials to hide it from outsiders.

- If ventilation does not go through the entire wall, it can be hidden in a wall cabinet by drilling holes. It's good when the entrance to the ventilation duct is directly above the hood. It is convenient to hide such a straight duct in a decorative metal box to match the color of the hood or plastic.

- When the pipe is very long, you can make a moisture-resistant drywall box under the ceiling. And to justify its presence, decorate with decorative lamps.

- If ventilation is installed during the repair, then you can hide the air duct in the structures of a multi-level ceiling - suspended or tension.

Now, understanding the features of ventilation pipes for the kitchen, you can choose an air duct to suit your requirements. Knowing the nuances of installation, you can assemble it yourself. By understanding how to properly remove it, you can ensure good ventilation in the kitchen.