Have you decided to insulate the chimney and can't choose an insulating material? We will tell you what kind of insulation for a gas chimney will work as efficiently as possible in various conditions. Let's consider the types of thermal insulation and dwell on their technical characteristics in detail.

To choose the most optimal option, we will first get acquainted with the designs of chimneys and the materials that are used for their construction. This will help us in choosing thermal insulation protection, which will increase the efficiency of the gas boiler and ensure the maximum service life of the chimney.

The article proposed by us contains the rules for carrying out work on insulation. Our recommendations will help you decide on the most rational, simple and convenient option for implementation. The information provided will be extremely useful for independent craftsmen.

The content of the article:

- Why insulate the chimney of a gas boiler

- Chimney installation rules

-

Types of flue gas ducts

- Chimney pipes made of stainless steel

- Brick chimney device

- Chimney from asbestos-cement pipes

- Flue duct made of ceramic pipes

-

Types of heaters for the chimney

- Mineral wool group

- Insulation form

-

Methods for insulating a gas chimney

- Insulation of an asbestos-cement gas chimney

- Insulation of a steel chimney

- Insulation of a brick chimney

- Conclusions and useful video on the topic

Why insulate the chimney of a gas boiler

When passing through the boiler pipe, heated gases lose their temperature, giving off part of their own heat to the walls of the structure. But at the same time, the gas must be discharged outside.

The quality of draft largely depends on the temperature of the walls of the chimney. With insufficient draft, there is a possibility of smoke in the room and even poisoning with waste combustion products.

The efficiency of the removal of combustion products, in other words, the quality of traction, depends on the speed of overcoming the moment of condensation formation. This indicator is largely determined by the material from which it is made chimney.

In the insulated chimney, the moment of condensation formation is reduced and the quality of draft improves

If a stainless or galvanized steel pipe is used as a chimney, then the period of condensation takes 2-3 minutes, but a standard brick chimney needs much more time - about half an hour.

At the moment of the appearance of condensate and until it disappears, water is actively mixed with the products of combustion, as a result of the reaction that occurs, an acid solution appears. It is this acid that has a negative effect on the pipe, causing its destruction.

If an asbestos pipe or brickwork is used as a chimney, then the residual condensate can be absorbed into their walls. In the absence of high-quality insulation, the accumulated moisture will freeze and destroy the chimney. The advantages of chimney insulation

If you qualitatively insulate the chimney from a gas boiler, then you can identify a considerable number of advantages. The main ones are:

- Reducing the impact of atmospheric precipitation;

- Reducing heat loss during the heating season;

- Improving traction quality;

- Presentable appearance of the chimney;

- Reducing the volume of condensate that forms on the outside of the chimney.

Taking into account the above advantages, it is obvious that insulating the pipe of a gas boiler is simply necessary. For work, various heaters can be used, each of which differs not only in physical characteristics, but also in the features of the work.

Chimney installation rules

Before proceeding to an overview of heaters and the rules for working with them, you need to understand the requirements that must be met when installing a chimney. This point is very important, since violation of the norms can lead to the inability to operate the equipment.

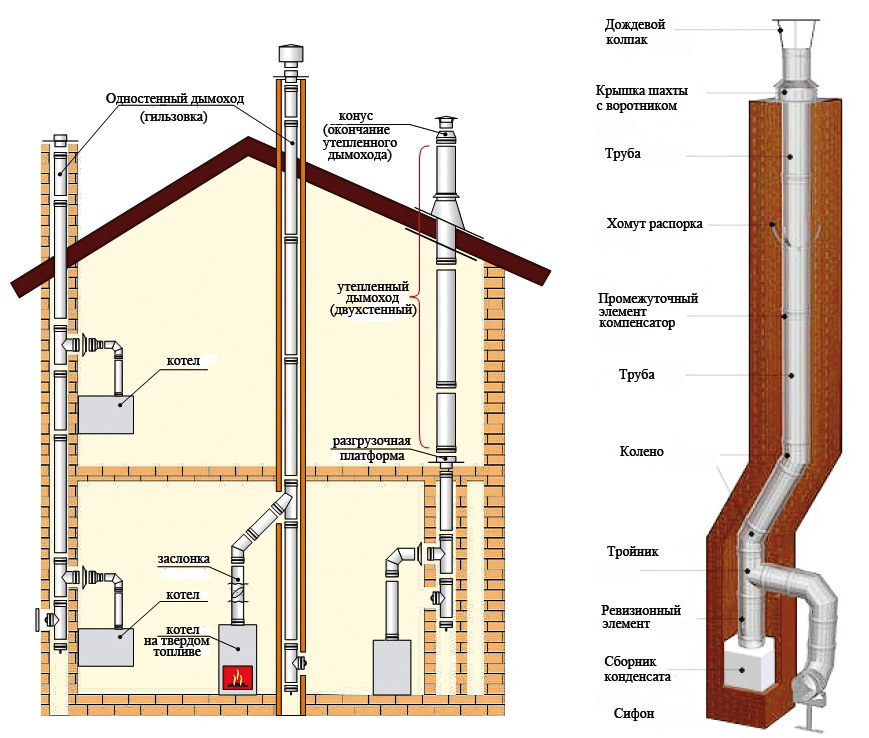

Compliance with standards and requirements for the construction of gas chimneys ensures their reliable and safe operation

Chimney ducts must comply with the requirements of DBN V.2.5-20-2001 and SNiP 2.04.05-91. The main requirements are as follows:

- The inner diameter of the chimney must be larger than the diameter of the outlet of the gas boiler;

- The main pipe cannot have curved or tapering sections, it must be located vertically, a slope of no more than 30 degrees is allowed;

- The branch line can have no more than three turns;

- The distance from the outer surface of the pipe to walls made of combustible materials is 25 cm, to walls made of non-combustible materials - 5 cm;

- The insulation of the joints of the chimney elements must ensure complete tightness of the joint;

- No connections are allowed within the passage of the roof (this part of the chimney must be solid);

- In places of turns, it is necessary to arrange inspection hatches;

- Bottom part chimney must be equipped with a structure for collecting condensate;

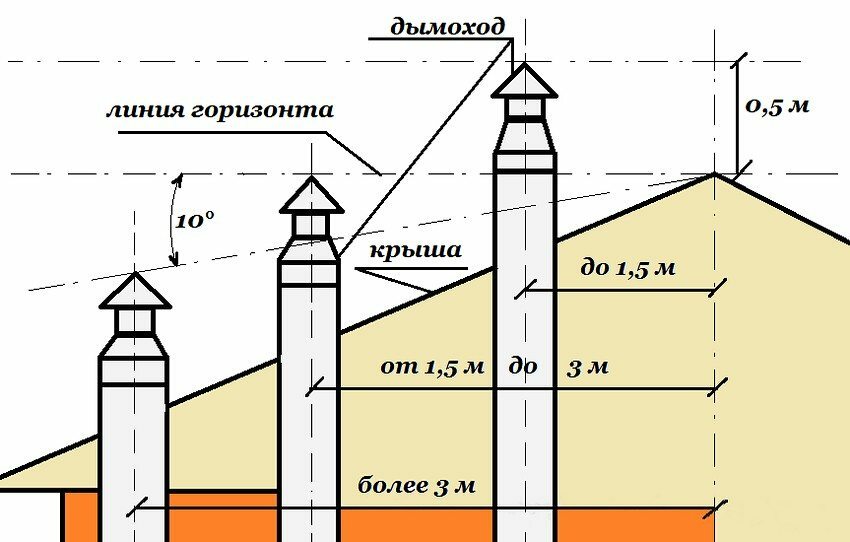

- The upper part should rise above the ridge of the roof by at least 50 cm, the length of the chimney itself should provide high-quality draft.

Compliance with the norms and requirements for the installation of gas chimneys, not only provides an increase in operational efficiency equipment, prolongs the life of the chimney, but also guarantees fire safety and eliminates the threat of smoke premises.

Types of flue gas ducts

Depending on the material used, gas chimneys are divided into several types, while brickwork is practically not used for exhausting gases.

However, brick is often used to tie the exhaust pipe. This is not a simple facing brick - it has a square shape, and its inner part has a circular cross-section.

Chimney pipes made of stainless steel

Metal chimneys are the most popular. Most often, stainless steel is used, which is characterized by high corrosion resistance.

Chimney pipes made of stainless steel are characterized by ease of installation and high corrosion resistance to any aggressive environment

The main advantages of stainless steel structures:

- Condensed moisture resistance;

- Resistance to atmospheric precipitation;

- Chemical resistance to soot resulting from gas combustion;

- Resistant to high temperatures;

- The inner smooth surface reduces the coefficient of friction, ensuring the smooth passage of gases with minimal soot deposition;

- Low weight allows the use of standard fasteners;

- Simple installation eliminates the complexity of work with significant destruction of walls;

- Quite a democratic cost.

The use of conventional stainless steel pipes is not recommended. This is due to the fact that exactly chimneys are made of special grades of stainless steel, which, due to the introduction of alloying elements are highly resistant to acids resulting from the formation condensate.

Brick chimney device

Currently, a brick chimney is used much less often, because it is built mainly for brick ovens, and they are actively being replaced by gas models. In addition, it takes a lot of time to set it up.

Along with this, a brick chimney has the following disadvantages:

- Rough inner surface for soot build-up and reduced traction;

- Not resistant to acid corrosion. Due to the hygroscopicity of the material, condensation is absorbed and rapidly destroyed;

- The complexity of the construction. Masonry from piece building materials takes much longer than assembling metal or ceramic modules.

You can eliminate the negative qualities of a brick chimney by inserting a sleeve in the form of a pipe made of asbestos or stainless steel.

Chimney from asbestos-cement pipes

Previously, asbestos-cement pipes were very widely used in the construction of chimneys for gas boilers. Despite the porosity of the material, the roughness of the inner walls and the far from ideal cross-section, the popularity of asbestos-cement pipes is due to their low cost.

The chimney made of asbestos-cement pipes is characterized by a low price, but for reliable operation it requires a strictly vertical arrangement

To avoid these disadvantages, the chimney from asbestos-cement pipes should be as straight as possible with sealed joints. A simple cement mortar is not enough here; dried joints must be treated with a sealant or special sealed clamps must be used.

In general, the work is not difficult. With proper sealing of the joints, the chimney made of asbestos-cement pipes will be in no way inferior to its analogue made of stainless steel. However, during active operation, it will not serve more than 3-5 years, after which it requires mandatory replacement.

Flue duct made of ceramic pipes

Chimneys made of ceramic pipes are distinguished by their reliability, durability, high corrosion resistance to aggressive substances and temperature extremes.

When installing a high chimney from a ceramic pipe, a reliable foundation is required, since they are erected according to the "root chimney" scheme

However, along with this, they have their disadvantages - large weight, the obligatory construction of a separate foundation and high cost. But all these shortcomings ceramic chimneys overlapped by tens of years of reliable and stable operation.

Types of heaters for the chimney

The choice of heaters for gas chimneys is quite limited due to the high requirements for heat resistance and fire safety.

Obviously, popular foam sheets, expanded polystyrene and similar polymers will not work. When exposed to high temperatures, they can not only easily deform, but also ignite if a spark hits them.

Insulation for a gas chimney must meet the following requirements:

- The minimum indicator of thermal conductivity, ensuring fire safety standards;

- Light weight to reduce the load on the roof;

- Plasticity and flexibility for simple thermal insulation of geometrically complex areas;

- Neutrality to the effects of chemical environments, precipitation and condensation;

- Long service life.

The ideal option is considered to be the device for thermal insulation of the chimney of a gas boiler using mineral heat insulators. Due to their low cost, bulk materials were previously most often used, which have lost their positions due to low efficiency and large mass.

They yielded the palm to cotton wool insulation made from minerals of basalt wool and fiberglass. These materials are characterized by high fire resistance, they are able to withstand temperatures over 400 degrees.

Mineral wool group

The class of mineral wool includes materials: slag fiber, fiberglass, stone wool. Each of the three groups is distinguished by its structure - fiber thickness and length, load resistance, moisture resistance and fire safety.

To understand the technical characteristics of mineral wool, we will consider each of the groups separately.

Glass wool specifications

The thickness of the glass wool fibers is in the range of 5-15 microns with a length of 15-50 mm. It differs in elasticity and strength, you need to work with the material as carefully as possible, since glass threads can not only dig into the skin, but also get into the respiratory tract.

Glass wool is an effective insulation, but work with it is associated with an increased danger due to the possibility of damage to the skin by fibers

Glass wool has an average hygroscopicity, the maximum heating temperature is 450 ° C. The thermal conductivity coefficient is 0.03 - 0.052 watts per meter per Kelvin.

Technical characteristics of slag

The thickness of the slag wool fibers is in the range of 4 - 12 microns with a fiber length of 16 mm, the basis of the insulation is blast-furnace slag. The material is highly fragile and hygroscopic.

Despite the permissible heating temperature of 300 ° C, slag wool is unsuitable for insulating a gas chimney due to high moisture absorption. In addition, the material is characterized by residual acidity, which has a negative effect on the metal.

Technical characteristics of stone wool

Heat-insulating material is made from gabbro-basalt rock waste. In fact, it is a product made of mineral fibers, which has another name - stone wool. The thickness of the fibers does not exceed 7 microns with a length of up to 50 mm.

In the production of insulation, the rock is crushed, followed by melting and stretching of the finest "threads". After preheating to 300 degrees, the threads are passed through the press twice. As a result, the resulting material is characterized by high fire resistance and strength.

Basalt or stone wool is highly fire-resistant and is an ideal solution for insulating a gas chimney

Stone or basalt wool has the following characteristics:

- Low thermal conductivity - 0.032 - 0.048 watts per meter per Kelvin;

- Hydrophobicity - moisture cannot get inside, as it settles on the surface. Resistance to atmospheric precipitation.

- Resistance and strength to deformation - achieved due to the mixed arrangement (vertical and horizontal) of the fibers, withstands a load of up to 80 kPa;

- High fire resistance - the material can withstand temperatures over 1100 ° C without losing strength. Taking into account that the ignition temperature of soot does not exceed 1000 ° C, the material is suitable for insulating almost any smoke extraction system.

Basalt or stone wool is an ideal solution for insulating a gas chimney, but due to the lower cost, glass wool can also be used.

Insulation form

The form of release of mineral wool - mats or rolls, along with this, they can be supplemented with special functional layers and elements. For example, a foil layer is capable of not only reflecting heat, but also preventing the fibers from weathering.

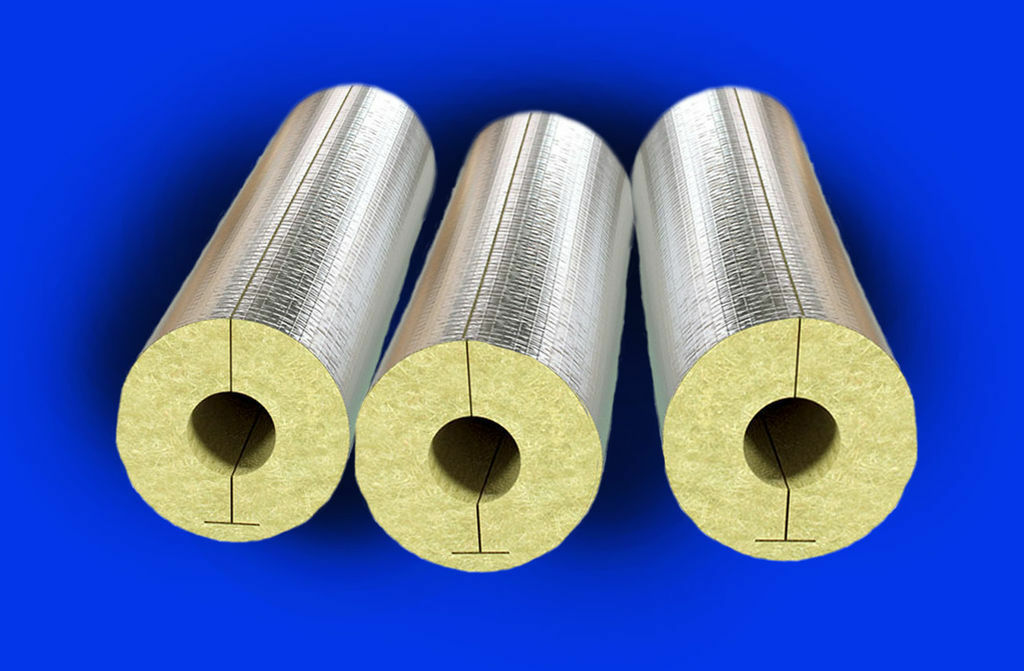

Sometimes it will be justified to use lamella mats, cut in the form of strips - they easily repeat the shape of the chimney. Roll materials and stitched mineral plates are highly practical. For chimneys with a circular cross-section, the ideal solution would be a heater in the form of cylinders made of basalt fiber.

Basalt wool cylinders are easy to use and provide reliable thermal insulation of the chimney

The cylinders have a slit and are a kind of drop-down sleeve. It is enough to unfold the cylinder with your hands and simply put it on the pipe. Such heaters have different thicknesses, they can have a foil coating on the outside.

Further, we will consider in more detail the features of insulation of each type of chimney and the rules for the use of heaters.

Methods for insulating a gas chimney

Insulation is required only for the part of the chimney that is located outside or in an unheated attic. In this case, the pipes attached to the facade of the building must be completely insulated, including the horizontal section passing through the wall.

The choice of the method of insulation is determined by the material from which the gas chimney is made. Insulation of the chimney from a gas boiler depends not only on its design, but also on the material chosen.

Insulation of an asbestos-cement gas chimney

It is possible to insulate an asbestos-cement pipe in three fundamentally different ways. Mineral wool, brickwork or plaster are suitable for their implementation.

Insulation by brickwork

Insulation with brickwork with filling voids with bulk insulation is allowed, but the process is quite laborious and takes a lot of time.

This method is most often resorted to if there is already a brick chimney, and an asbestos-cement or galvanized steel pipe is used as a sleeve.

Chimney insulation by plastering

Asbestos-cement pipe has high adhesion, so plastering can be used as insulation. Before working on the pipe, it is necessary to fix the reinforcing mesh.

The solution is prepared in the following proportion:

- 3 parts of sieved slag;

- 1 part cement;

- 2 parts lime with water.

The solution should have a thick plastic consistency. The first layer is applied 20-30 mm thick. All subsequent layers are applied only after the previous one has dried. Before painting or whitewashing, the surface of the plaster must be sanded, and the cracks that have appeared must be putty.

Mineral wool insulation

Carrying out work is reduced to fixing a layer of mineral wool on the outside of the pipe. Before starting work, the pipe must be cleaned of dust and the layer of rolled insulation must be fixed with clamps. Considering that mineral wool is capable of absorbing moisture, it is recommended to hide it under a galvanized steel casing.

In order to save money within the attic, you can do without a steel casing, but under the influence of atmospheric precipitation, the service life of mineral wool is unlikely to exceed 2-3 years.

Insulation of a steel chimney

Chimneys made of stainless steel are essentially two pipes of different diameters, the space between which is filled with insulation. You can purchase a ready-made structure in the form of a sandwich pipe. In this case, it is enough to carry out installation work without insulation, since the insulation is already installed initially.

But the cost of sandwich pipes is high enough to save money. a similar design yourself. To do this, it is enough to wrap the inner pipe with a roll of mineral wool insulation or use a ready-made shell or cylinders of the same material. Instead of stainless steel, the outer tube can be made of galvanized steel.

It is best to use special clamps to secure the mineral wool to the inner steel pipe.

Another way that allows you to carry out insulation within the attic is the device of a wooden box using backfill. Slag, sand, expanded clay can be used as bulk materials.

It is easy to insulate a steel pipe with a wooden box with expanded clay backfill. It is important to avoid contact of flammable materials with heating surfaces.

In places where the box contacts the roof or crate, it is necessary to install protection from steel sheets to prevent fire.

Insulation of a brick chimney

A brick chimney is traditionally insulated by plastering with the preliminary fixing of a reinforcing mesh. The advantages of this method are low cost, the disadvantages are low efficiency. Heat losses are reduced by no more than a quarter.

Facing a plastered chimney with natural slate tiles will not only protect the chimney from destruction, but also give it an original aesthetic appearance

It is possible to increase the efficiency of insulation of a brick chimney using mineral wool mats.

The insulation should fit snugly to the plastered chimney, so the appearance of cold bridges is excluded. Taking into account the fact that mineral wool easily absorbs moisture, it must be covered with a layer of vapor barrier film, followed by fixing with construction tape.

Conclusions and useful video on the topic

Insulation of a steel gas chimney:

To ensure high-quality removal of gases resulting from combustion, insulation of the chimney is a vital necessity. Mineral wool is considered an ideal insulation, it is this material that meets all the requirements of a high-quality and reliable insulation.

Acquisition of ready-made insulated modules will help speed up the installation work. But you can independently carry out insulation with basalt wool, and get an analogue of a sandwich pipe at a lower cost. The use of cylinders and shells made of mineral wool can significantly speed up the process of chimney insulation.

Do you want to share your own experience in thermal insulation of a gas boiler pipe? Do you have useful information that will be useful to site visitors? Please write your comments in the block form below, ask questions, post photos on the topic of the article.