Despite the massive dominance of "warm floors", economical electrical panels and climate systems, sectional heating radiators are still in stable demand among everyone who is determined to make heating comfortable and cost-effective.

The reason for the popularity is that nothing more reliable, easier to repair and more efficient than water radiators has yet been invented. What are their advantages and disadvantages?

The content of the article:

- What are sectional radiators

-

Cast iron sectional radiators

- Cast iron battery options

- Advantages and disadvantages of cast iron registers

- Aluminum sectional radiators

-

Bimetal sectional radiators

- If it makes sense to buy bimetal

- Steel sectional radiators

- Sectional radiator dimensions

-

Calculation of heating radiators by area

- Calculation of the required power of the heating system for the house

- What to consider when calculating the power of sectional heaters

- How to properly connect sectional radiators

What are sectional radiators

Consumer choice is strongly influenced by advertising. There is an opinion that sectional heating radiators are not so effective, outdated morally and technologically, unreliable in operation. In addition, the appearance of the batteries is inferior to the design of panels, halogen or

infrared heaters. The buyer is also deterred by the fact that the assembly and connection of a sectional radiator requires the knowledge and skills of a specialist.For other points, the radiator heating system looks much more attractive:

- The battery case is heated by the heat of hot water or a steam-water mixture. Therefore, the sectional model is safer than competitors. Heating is provided by simple heat transfer. The design does not have electrical wiring, hot radiating spirals.

- A properly assembled sectional radiator will last longer than underfloor heating and electric heaters. Metal ages an order of magnitude longer than plastic, and if necessary, repairing or building up a heating system is cheaper than changing damaged channels underfloor heating.

But the main advantage of batteries is the sectional structure. This solution makes it possible to accurately calculate and supply the required number of sections that provide the desired level of comfort and at the same time save money spent on heating bills.

A sectional radiator is a set of separate sections or registers, cast from metal, interconnected into one panel using threaded inserts and gaskets. The number of register sections in one battery is limited only by common sense and the capabilities of the heating system.

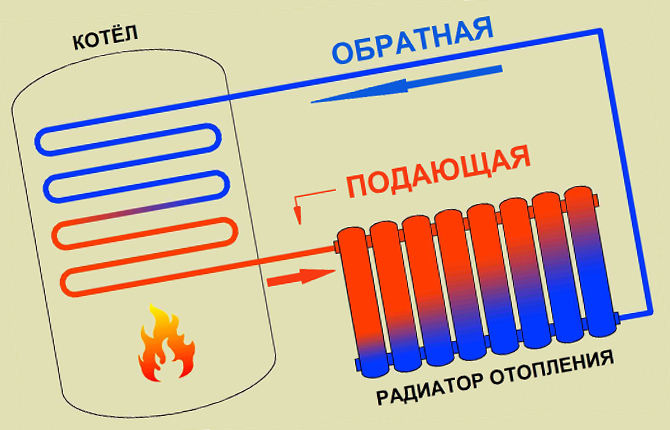

Inside each such section there is a system of vertical thin channels that circulate hot water from top to bottom along the metal case. In addition, each register has two pairs of large diameter holes at the top and bottom. After docking with other sections, two horizontal channels are formed inside the heating radiator, ensuring the flow of hot water with minimal hydraulic losses.

The entrance and exit to the battery can be located at opposite ends or on the same side. The input to the sectional radiator is usually performed in the upper part, the output can be located on the same level or in the lower part.

Each such section is a self-sufficient unit of the heating radiator - threaded bushings, seals and tightening nuts are sold as a set. To assemble the battery, apart from tools, no other parts are required.

Sections differ in body height and heat output. The thermal characteristics of the registers depend on the material from which the case is cast. They make heating radiators from gray cast iron, aluminum, steel.

Cast iron sectional radiators

Another 20-25 years ago cast iron batteries were the most massive, served in the heating systems of apartment buildings for 40-50 years. But at the first opportunity they changed owners for more modern aluminum sections. Old Soviet cast iron batteries looked unpresentable, especially after many years of enamel painting.

Cast iron battery options

On the heating equipment market, you can find three options for cast-iron sections for heating:

- The old design, cast according to Soviet technology in earthen molds. Because of this, the surface of the cast iron is rough, rough to the touch.

- Modern shape with smooth contours. Sections, as a rule, are made using modern casting technologies in ceramic or steel molds. Painted with beautiful heat-resistant enamel.

- Import models made in China, Turkey, EU countries. They differ from domestic ones in the configuration of the radiator housing, the cross section of the channels inside the section, a smaller wall thickness and a more elegant appearance.

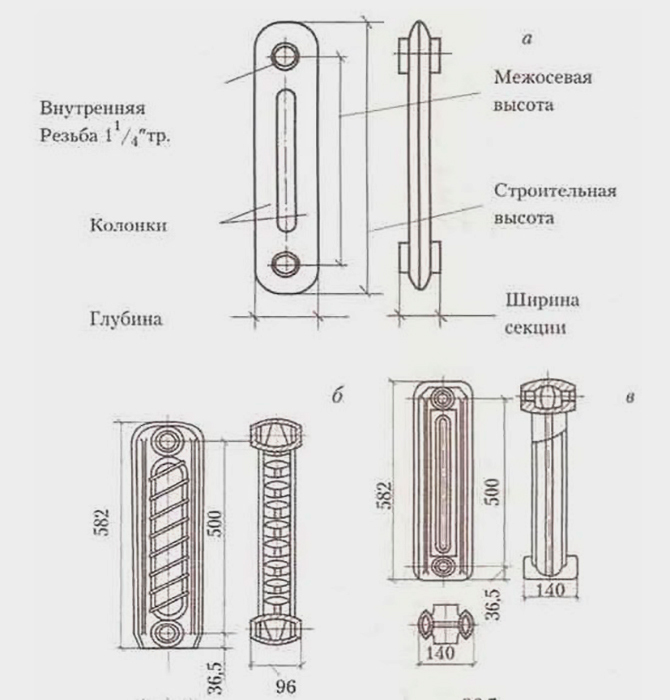

Heating radiators cast according to Soviet technology, as a rule, have markings beginning with the letters "MS", "M", "RD". Next come one or two numerical values indicating the depth or maximum size of the battery in the transverse direction.

For example, M-140 means that at least 140 mm of free space in depth is required to install a cast-iron radiator under the windowsill. In the marking of sectional batteries “MS”, the center distance or the size between the axes of the upper and lower pipes can be additionally given.

They are sold partially assembled. Radiators are not painted, only covered with a red or brown primer. It is more convenient to store this way - sectional sets can be stacked on top of each other without the risk of scratching the decorative coating.

Chinese sectional radiators are offered assembled for 5 or 7 registers. Some models are already painted with stoving enamel, but you can find just sets of registers with a primed surface.

Sectional radiators manufactured in Turkey or the European Union are supplied as separate registers, painted and prepared for assembly, or already assembled and fully functioning batteries that simply need to be connected to pipes.

It is better to choose already painted sectional batteries. Usually, for heating radiators, powder paints are used with additives that slow down the aging of the decorative layer under conditions of constant heating.

The quality and density of the powder coating is an order of magnitude better than the most expensive pentaphthalic or polyurethane enamel. The layer of powder on a cast iron radiator is much smaller than that of enamel. This means that the heat transfer will be higher than that of a sectional battery painted with a brush, and in addition, the buyer will be relieved of the need to periodically update the paint layer.

Advantages and disadvantages of cast iron registers

The reputation of cast iron sectional batteries was spoiled by the poor quality of Soviet cast iron radiators. This is due to the primitive, outdated casting technology.

In general, a sectional cast iron radiator turned out to be cheap. Due to the large number of defects and cavities, in order to achieve tightness, the walls of the sections had to be made thick (at least 8 mm). As a result, the battery turned out to be inexpensive, but heavy, and not very reliable. Therefore, when buying, you need to carefully inspect each section, otherwise there is a risk of getting a leaking heating system.

Chinese sectional radiators also "suffer" from casting defects. Cast iron batteries made in Turkey or the European Union are noticeably lighter, the geometry of the sections is highly accurate, but in general they turn out to be much more expensive.

Sectional radiators made using modern technologies are considered one of the best solutions for an apartment or private household. In conditions of contact with hot water, cast iron has a higher corrosion resistance, is not afraid of overheating or washing the sectional space with chemical reagents.

Of the shortcomings, two can be noted:

- Cast iron does not tolerate thermal and mechanical shocks, therefore, if during the repair of the heating system it will be necessary to disassemble the sectional radiator, it is better to contact a specialist.

- During operation, cast iron parts - threaded bushings and nuts - tightly stick to each other. Therefore, if in the process of assembling a sectional radiator one of them “does not hold out”, then it will be difficult to eliminate the weak spot later.

The heat dissipation of cast iron sectional radiators is lower than that of aluminum, the massive cast iron construction heats up longer, although it dissipates heat into the air more efficiently. Cast iron batteries are recommended for use in central heating systems.

Aluminum sectional radiators

Structurally, sections made of aluminum are no different from cast iron. The same system of vertical channels inside the body and two pairs of holes for sectional nipples. The only thing is the shape of the case is different. Instead of the rounded contours characteristic of cast iron batteries, aluminum sectional radiators flat radiating surfaces.

As a result, the design is more compact, with a smaller body depth. But thanks to the developed system of thin ribs and jumpers, the total surface area of an aluminum radiator will be greater than that of a cast iron one.

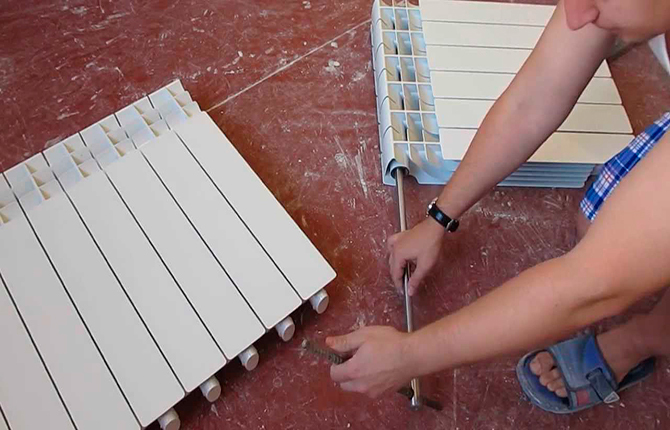

Assemble batteries using threaded bushings. Inside each section there is a threaded nipple insert. A feature of the part is that the direction of the thread on opposite holes is different. As a result, if you take two sections and try to wrap the connecting sleeve inside the insert, then due to the opposite direction of the thread, the sections will be pulled together. The only thing you need is not to forget to lay the gasket and seal.

Details of a sectional radiator are made by hot pressing in a steel stamp. Therefore, the stamping quality and section geometry are high. What is important, since the wall thickness on the internal channels is only a few millimeters.

One of the advantages of aluminum sectional radiators, which few people pay attention to, is the smooth surface of the fins and heat-releasing planes of the case. As a result, the airflow flows around the radiator fins at a higher speed, so the heat dissipation of the battery is improved. But if you paint an aluminum radiator at home, then the efficiency of the sectional heating battery will decrease several times.

Aluminum radiators are recommended for use in individual systems, regardless of the type of boiler. It is not recommended to connect aluminum sections to centralized heating because of the large amount of pollution in the water. In addition, most boiler houses regularly flush pipes with acidic reagents, which destroys the walls of the channels.

Aluminum oxidizes to oxide, flakes fall out inside the channels of the sectional radiator, which completely block the flow of water. It is difficult to clean the battery, you have to turn off the heating, disassemble it into sections and remove the plugs mechanically.

The durability and resistance of a sectional radiator largely depends on the quality of aluminum. The best material from Polish and German manufacturers.

Bimetal sectional radiators

An attempt was made to solve the problem of strong corrosion of aluminum in hot water by protecting the internal surfaces of the flow channels with steel 0.8–4 mm thick. Bimetal sectional radiator differs from the composite one in that steel thin-walled tubes are laid in the aluminum body, forming the flow part. Water or any other coolant does not come into direct contact with aluminum. The cost and complexity of manufacturing bimetallic radiators has increased markedly.

Bimetal can be complete and incomplete:

- In the first case, aluminum does not come into contact with water even along the thread, in the places where the nipples are screwed in. Thus, it was possible to solve the problem of leakage at the joints of sections, especially if the radiator was operated for a long time on strongly alkaline water.

- In the second - the ends and places for gaskets, the surface of the thread remains unprotected. Aluminum is covered with steel only in flow channels.

As a result, bimetallic sectional radiators can be operated on alkaline water with an increased pH of 10-12. Aluminum are allowed for operation at pH 6-8.

If it makes sense to buy bimetal

It would seem that sectional radiators with steel channels and an aluminum body are a more advanced design compared to conventional aluminum batteries. This is true, but bimetal costs 1.5-2 times more than aluminum. At the same time, its heat transfer is worse, since the thermal conductivity of steel is 45 W / m * K, and that of aluminum is 220 W / m * K. The presence of steel only worsens the efficiency of the sectional radiator.

Bimetal is recommended for use in centralized heating networks, in conditions where it is not possible to control water quality. In other cases, aluminum installation may be more efficient.

Many manufacturers of heating radiators for bimetal use lower quality metal, and most often silumin is a cheap alloy of aluminum and silicon. Whereas on pure aluminum sections metal goes after additional purification from impurities.

Steel sectional radiators

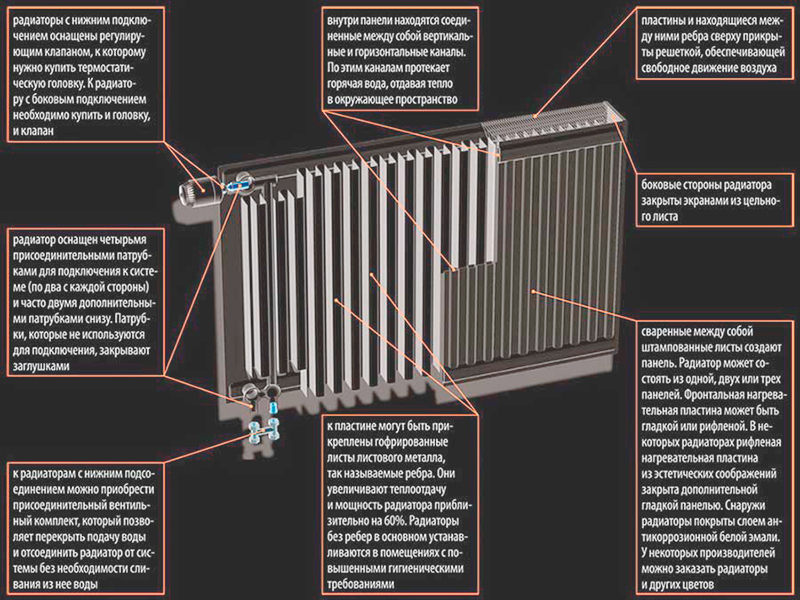

Heating sections made of steel are no less common in everyday life. Usually in the market, the consumer is faced with cheaper and more affordable steel heating panels. Such a radiator is a package of several flat sections welded from sheet steel. All panels are approximately the same size, differing only in the number of sections in the package. It can be from one to three pieces, welded into a non-separable structure.

In fact, this is one heating battery assembled in the factory. It is impossible to change the number of heating surfaces, which is very inconvenient.

Real sectional steel radiators are assembled from sections welded from steel pipes in such a way that the number of elements can be unlimited.

Structurally, such a section is a package of two or three vertical pipes interconnected by stamped manifolds made of sheet steel. The shape and size of the pipes in a sectional radiator is determined by the developer or designer.

The only drawback of the design is a lot of welds, which reduces the reliability of the battery.

The cost of a sectional radiator is higher than batteries based on standard steel panels. But the heat transfer efficiency is much higher due to the open design and good air flow around the heating surfaces.

Sectional radiator dimensions

Cast iron batteries of domestic production, as a rule, are produced in the center distance standard of 500 mm. Sectional radiators differ only in the width and depth of the body and the amount of heat transfer.

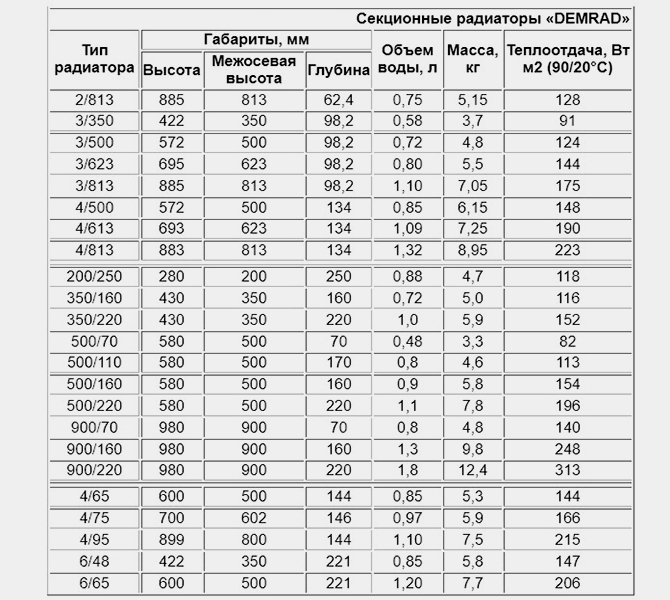

For imported batteries, for example, the popular Turkish company DEMRAD, the center distance ranges from 200 mm to 813 mm.

The choice of depth for Turkish sections is greater, the quality of cast iron is better, although the price is higher.

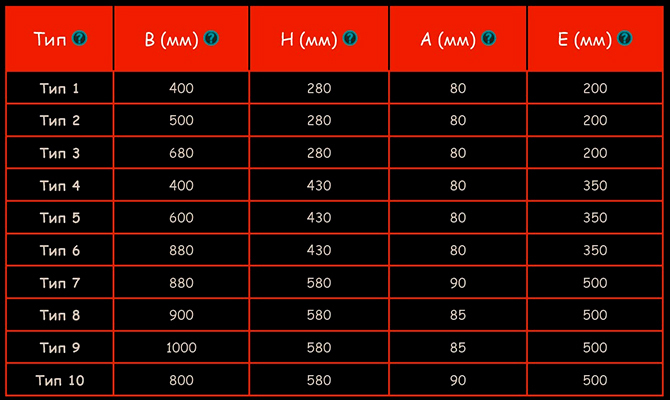

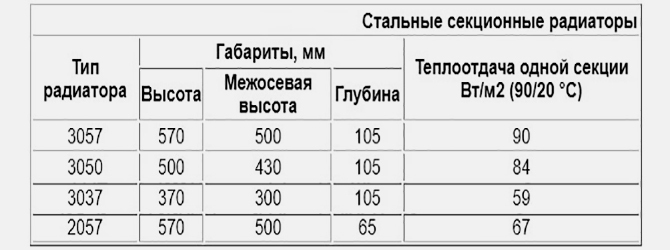

Recommended dimensions for bimetal radiators.

In this case:

- B - the optimal length of the sectional battery;

- E - inter-nipple distance;

- A - depth;

- H is the height of the hull.

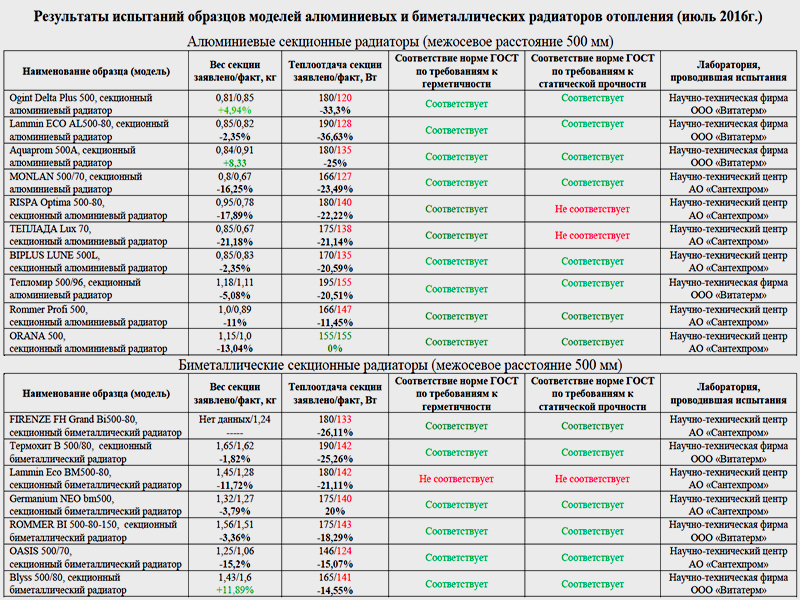

When choosing a particular model, pay attention to parameters such as wall thickness, maximum pressure, heat dissipation and warranty period. Different manufacturers have different parameters.

In the marking, as a rule, the size is given not of the heating radiator, but of a single section, indicating the dimensions in the format HEIGHT x DEPTH x WIDTH.

Steel sections are inferior in terms of thermal power to bimetallic models of similar sizes.

Calculation of heating radiators by area

The traditional way to calculate the heating power for an enclosed space is to multiply the area of the room by the factor K=100W/m2. This scheme is recommended for calculating the size and power of sectional radiators for apartments inside multi-storey buildings or for the interior rooms of a private house. Under one condition - the room should be located inside the building, respectively, not have external main walls.

In other cases, especially for corner apartments or private houses, such a method for calculating the heating power is not entirely correct.

Calculation of the required power of the heating system for the house

Private housing constructions differ in the quality of thermal insulation and the amount of heat loss through windows. In order not to make a heat engineering calculation of heating, taking into account the thermal conductivity of the walls, leakage through window openings and ventilation, you can calculate the power of the system according to the required heat influx into the room of a given volume.

A simple technique is used:

- For non-insulated cinder block buildings, buildings with walls in one brick, the heat influx per hour should be at least 70 kcal / m3.

- For insulated rooms - at least 50 kcal / m3.

To determine the power in watts, it is enough to use the conversion factor KP=1.163 W/m3*kcal. To calculate the heat dissipation of the heating system, multiply the volume of the room by the conversion factor and the amount of inflow. For example, for a bedroom with an area of 3x3 m, with a ceiling of 2.5 m, the volume of internal space will be 23 m3.

We multiply 70x23x1.163 \u003d 1872 W / h. The power of the heating battery must be at least 1900 W / h.

What to consider when calculating the power of sectional heaters

The resulting value will provide the required level of comfort only with electric heating. Sectional batteries connected to hot water pipes are somewhat different from an electric heater.

In the standard version, the water sectional heater-battery consists of 5-10 sections connected to each other by nipples through sealing gaskets. Each manufacturing company indicates in the passport for the section the thermal power at a certain temperature (usually 70 ℃ or 95 ℃). If all sections were heated to the same temperature, then the power of the heating battery could be calculated by multiplying the passport data of one by their number.

But the heat transfer in different sections may vary. Hot water with a temperature of 70-90 ℃ is supplied to the inlet to the sectional body of the battery-heater, and the flow at the outlet is already from 50-60 ℃.

In order to determine the real thermal power, it is necessary to calculate the average case temperature. For example, (70+50)/2=60℃. Next, take the power of the radiator section from the passport, for example, 180 W at 90 ℃. We recalculate the power reduction factor in the proportion 60/90=0.67. It remains only to multiply by the nameplate power 180 * 0.67 = 120.6 watts.

Knowing the heat dissipation of one section (120.6 W), you can calculate the power of the entire sectional radiator by multiplying by their number. Only after that, the required number of heater batteries for heating a particular room is calculated.

How to properly connect sectional radiators

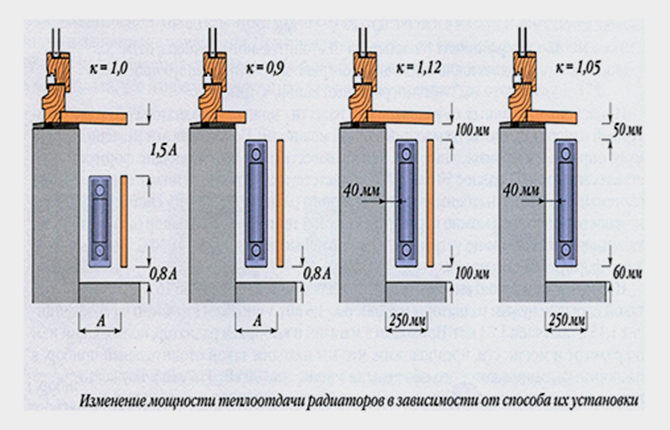

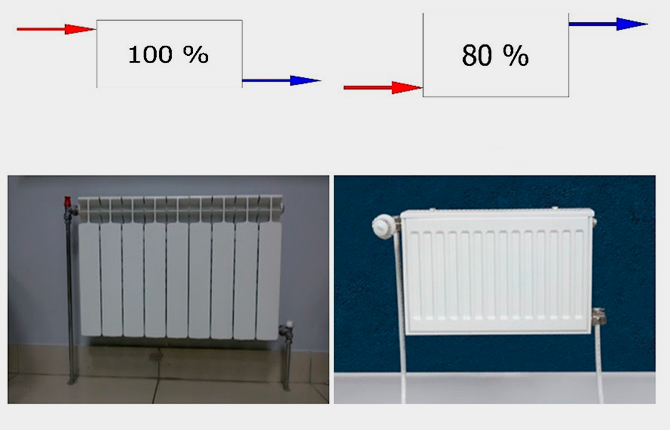

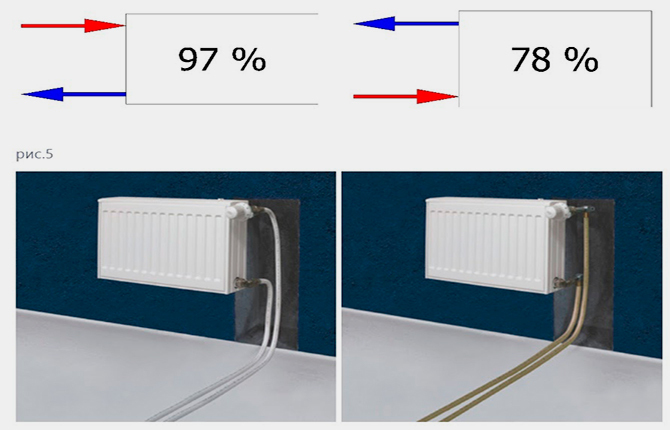

The first thing that must be observed when connecting to the heating system is the distance from the battery to the walls, floor, window sill. Depending on the location of the case, the heat transfer capacity may increase or decrease.

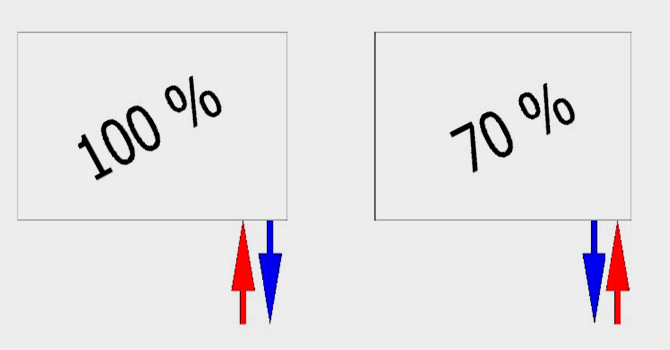

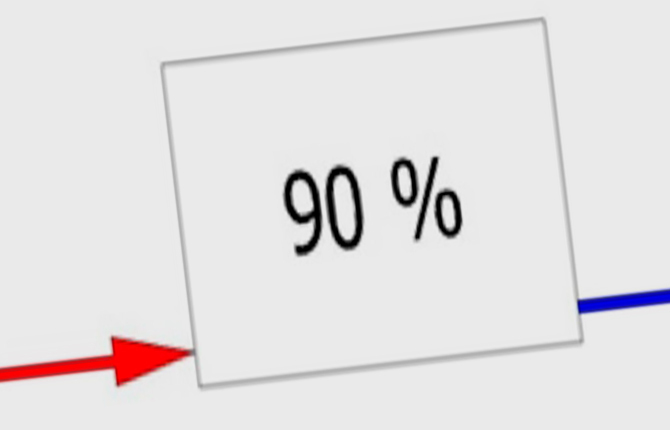

Next, select the connection point for the pipes on the radiator housing. Incorrect variant of the supply of hot and cooled water usually leads to a decrease in heating efficiency.

If the connection is made to the bottom, then the "hot" fitting must be located on the side of the body.

When connecting pipes to the lower side fitting on the same line, the efficiency is reduced by 10% or more.

If a hot pipe is connected diagonally to the outlet pipe, then the heat dissipation may drop or remain at the same level.

A one-way connection almost always results in losses in the heating system.

Sectional heating radiators for today are the best that was invented for water heating of a room. The possibility of more or less accurate selection of power, simple repair - the replacement of the section more than compensates for the increased price of the battery.

Share your experience of installing and operating sectional heaters. What do you remember the most, positive or negative? Write in the comments. Bookmark this article so you don't lose the information you need.