Today, instead of steaming with plaster solution, leveling walls and ceilings, gypsum board or gypsum fiber sheet is often used (hereinafter I will use the abbreviation - GVL). Fast, practical and sustainable - what more could you ask for? When carrying out work, the end result depends not only on the quality of the gypsum fiber board, but also on the fasteners used. In this article we will talk about self-tapping screws for drywall and consider what their types and sizes are. And at the same time, let's go over the quality criteria when choosing fasteners.

Types of fasteners depending on the material of the frame

The content of the article

- Types of fasteners depending on the material of the frame

- Most common fastener length

- A little about slots

- Quality criteria for the selection of fasteners

As such self-tapping screws for drywall not separately - the choice of fasteners for work occurs according to a number of criteria, which we will now talk about.

By itself, drywall as a material is very fragile and crumbles quite easily. And how to judge what is better to screw into it? In this case, it is more appropriate to talk about fasteners, with the help of which the frame and GVL will be connected to each other. Depending on the material from which the frame is recruited and its thickness, you can use:

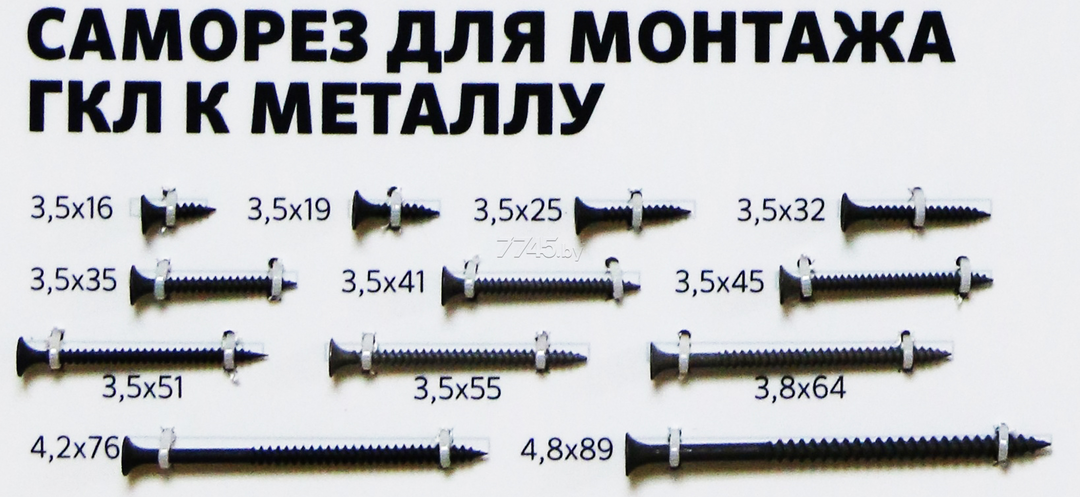

- Self-tapping screws for metal without a drill bit - they are made of carbon steel or stainless steel. Galvanizing, oxidation and phosphating of fasteners are used as protection against weathering. Brass products, although better protected from oxidation, are not strong enough to work with metal. A characteristic feature of self-tapping screws for metal is a frequent thread pitch.

- For metal with a drill bit - as well as without it, made of steel. A characteristic feature is the presence of an independent drill on the nozzle, which allows working with metal frames with a thickness of 2 mm and even more. If you do without such a tip, you will have to pre-drill holes in the frame.

- By wood - if a wooden frame is sheathed with plasterboard, then it is advisable to use this particular type of fastener. In this case, we can talk about both steel and brass self-tapping screws, since the wood is quite soft.

There are also so-called double-threaded self-tapping screws for bonding materials of different density together. They have a larger thread size than the other. When using them, the reliability of the connection is significantly increased.

On a note. If, when screwing in brass fasteners, problems arise such as licking the slot or breaking off the head - drill a hole with a diameter of 2 mm less than the thread thickness in the place of the proposed connection self-tapping screw. Craftsmen also suggest washing the threads - it also helps.

Most common fastener length

For the assembly of drywall structures, self-tapping screws up to 200 in length and up to 5 mm thick are mainly used. Depending on the specific purpose for which the self-tapping screw is used, I recommend stocking up on the following dimensions:

- for a set of metal frame - small, 9.5 mm, better with a drill bit for quick and easy work;

- joining the sheet with the profile - 25 mm, type of fasteners and the presence of a drill bit, depending on the material of the frame;

- when connecting the frame with two layers of drywall - 35-40 mm;

- for attaching hangers and guides to each other - 45 mm.

Of course, it will not be possible to foresee everything, you need to look at the place, what sizes are missing.

A little about slots

If different types of fasteners are in use - for wood, metal, with or without a drill - I strongly recommend that when buying, pay attention to their heads, if possible, if not the same, then at least similar configuration. As they say, ugly, but uniform.

Another thing is the slots on these heads. If you initially miss this moment, then in the process of work you will have to change the bit on the screwdriver and waste time. Why not take all the fasteners under the spline, say, Ph2 or Pz2? There is a very significant difference between them, and you will feel it, trying to twist them with a bat of the wrong size or standard.

Quality criteria for the selection of fasteners

When buying a batch of self-tapping screws, pay attention to the following details:

- Color spectrum. There is no need to think about the purely aesthetic side of the issue. The fact is that with poor-quality coating, the color of the fasteners can vary greatly. It happens that rust on steel fasteners, especially with a phosphated coating, appears even in the store.

- Slot should be located in the center of the screw head and be with a clear outline, without extraneous inclusions of metal in it. If you miss this moment, when tightening such a fastener, a lot of quiet, kind words will be said, and some of it will be thrown away.

- Evenness of fasteners, especially long enough. You can work with him, but the process itself will cause a storm of emotions, and again you will have to discard some of it.

- Make sure the package all self-tapping screws match in thread and length, unless, of course, you deliberately buy such a "hodgepodge".

The quality of the material from which the fasteners are made, unfortunately, is unlikely to be verified when buying. If it is low, it will float up already in the course of work - the splines will begin to break off and the heads will break off, and the products, when working with them, can bend in the manner of Turkish sabers.

Subscribe to our Social Networks