Wood is considered an environmentally friendly material for the construction of residential buildings, so it is not surprising that the demand for beautiful and comfortable houses from timber or round logs does not decrease. First of all, a residential house should be safe from the point of wiring.

It is important to understand how to conduct an electrician in a wooden house, so as not to harm the health of the residents and ensure the safety of property. In the article we have in detail displayed all aspects of this issue.

In the presented materials the general requirements for the wiring, the technique of introducing the electrical network into the house, the rules for the arrangement of the electrical panel and the methods of cable installation are presented. All electrical work must be carried out in strict accordance with fire regulations that we have indicated in the article.

The content of the article:

- General wiring requirements

- Entering the power line to the house

- Features of the device electrical panel

- Open wiring rules

- Wiring methods for closed wiring

- What is the ground loop for?

- Fire Protection Measures

- Conclusions and useful video on the topic

General wiring requirements

The main difference between wooden houses from reinforced concrete and brick structures is a high degree of fire hazard. This means that increased requirements are applied to the choice of electrical equipment, cables and the conditions of their installation.

According to statistics, about 1/2 of the cases of fires or fires in wooden houses or in houses with wooden decoration are due to gross errors of electricians.

It is wrong to install the socket, not enough to carefully connect the wires in the terminal box, ignore the grounding rules, as a fire may occur, and after it - a fire.

Undemanding owners of the wooden house entrust the work on wiring to neighbors, acquaintances or do it on their own, without knowing thoroughly the rules of EIR. The sad result of gullibility and lack of professionalism - in the photo

Know the basic rules of electrical installation is necessary for two reasons: to be able to independently perform part of the installation or repair work and to control the actions of unscrupulous "Specialists".

Keep in mind the following requirements:

- Technical characteristics of cables and electrical equipment should correspond to the maximum power consumption of the instruments of each separate group.

- Operation of sockets, switches, emergency shutdown devices must be carried out taking into account the load placed on them.

- The use of cables, wires, terminal connections with their regular heating is prohibited.

- It is necessary to completely eliminate the transition of fire from cable to structures made of wood or other flammable materials using fireproof protection.

Wiring should be completely safe for home owners, their families (especially young children) and pets.

Strict requirements come to the fore, while sometimes you have to sacrifice aesthetics. For example, owners of a wooden cottage need to come to terms with external sockets and enhanced protection of both hidden and open wiring (airbags 246-97)

The material from video reviews and instructions posted on the Internet is very controversial, so you shouldn’t fully rely on the opinion of people in work overalls. It is necessary to focus on excerpts from the regulatory documentation - sections of the OLC, SNiP, GOST.

Entering the power line to the house

In Russia and some other countries (unlike, for example, from Europe, where the wires are hidden in the ground), electricity reaches consumers through elevated power lines - to the final support.

Further, it is transmitted to users in three ways:

- self-supporting insulated wire (CIP);

- underground;

- on the rope (extremely rarely used).

The first option - the most popular.

In the local area it is recommended to install a wooden or concrete pillar with a metal shield for the electrical switch on the input. This is the best option to turn off the power supply at the time of repair or replacement of networks.

Electricity metering devices are also assembled with the machine gun. Special shields (SCHE) are designed specifically for this. By the rules, SCHUE can be mounted box on the front of the house, and inside the building, then the wiring will change a little.

From the central line of power supply to the support in a private area or directly to the house, a CIP is drawn (with a cross section of at least 16 mm), which is fixed with anchors or clips. Height from ground to tensioned wire 2.75 m and more

For insulation of wire running along a wooden surface, use a fireproof box or corrugated wiring. The passage through the walls and floors is carried out in metal protective sleeves, plastic analogs are unacceptable.

But it is recommended to use a polymeric gasket on kinks to protect the cable from wear. Plastic materials are treated with fire retardant solutions with flame retardants (for example, special paint).

Inside the house CIP do not turn on. According to the norms, only copper wires can be laid inside and on top of combustible structures, therefore, aluminum analogues should also be excluded.

To choose cable for wiring in a wooden house, you need to pay attention to the type of insulation. The best options for a wooden house recognized VVGng and NYM.

The transition from SIP to the house wire according to the standards should be carried out from the outside of the building - under the roof, on the facade or inside a metal shield

If the metering panel is fixed on the facade, for example, at the request of the service company, then the CIP is connected inside it to the machine, and then, before MSB - the distribution house billboard - is pulled VVGng.

What to consider when laying the cable underground:

Image Gallery

A photo of

The cross section of the conductors is selected taking into account the design load, from 10 mm² and more. According to the norms, splicing a cable into a trench is prohibited, that is, it must be integral from the support to the shield in the house

To protect the electrical cable at a depth of 0.8 m, HDPE pipes are used, but if the line passes under the roadway, then the requirements are different: depth - 1 m, laying is carried out in the asbestos-cement pipe

The HDPE pipe is optimal for protecting the cable in a closed area (underground), and for connecting to the switchboard on a support or for entering a wooden house in open areas wiring is carried out in steel pipes

When placing a cable into a house (wall, foundation) in the ground or above the ground, metal shells are used to protect the flammable material (wood) and the cable itself. They are made of thick-walled pipes.

For installation under the ground suitable cable VVGng

Cable trench depth - not less than 0.8 m

The use of HDPE and metal protection

Sleeve in the foundation for the cable

It is worth mentioning that the underground method of entering the electric cable into the building is more expensive and more complicated than using CIP.

Features of the device electrical panel

Externally, the switchboard is a plastic or metal (preferably) a box with a door with fasteners for machines and an electricity metering device.

It has no size limits, and when a new box is installed, they always leave some free space for further connections.

Inside is a counter (sealed), the main automatic shutdown device (RCD), which also they seal, and single-pole automatic machines for protection of various groups of electrical wiring (lighting, socket and etc.)

Automatic protection mounted on the prescribed for this DIN-rail. Nominal value of automata directly depends on the parameters of the connected line: if the permissible limit of the socket group is 16 A, then the machine should correspond to this value.

In the presence of automatic installation UZO optional, but installation should not be neglected. Additional protection is triggered at the time of leakage current. Manually UZO disconnect, when it is necessary to block the flow of electricity into the house.

Despite the expensive cost of equipment, the responsible electricians insist on installing protection by zone, which increases the safe use of electricity in a wooden house.

The nuances of connecting RCDs and automata in the panel are described in this article.

Open wiring rules

Ways of open wiring should not contradict the requirements of the OES.

Therefore, the following products can be used to fasten cables to the wooden surface of walls, partitions or ceilings:

- ceramic or porcelain insulators;

- floor plinth with built-in cable channel;

- corrugated and rigid PVC pipes;

- PVC box;

- metal box and pipe.

Specific product names are specified in the project documentation, and in relation to wooden structures they must be accompanied by a fire safety certificate and be marked with “NG”, as not supporting burning.

Installation of cable channels and other mounting elements must be thought out in advance, as protruding parts can interfere with the placement of furniture or other interior issues.

WITH cable channel selection There are no questions, since in hardware stores you can pick up products both in color and width, and with a set of related accessories - plugs, turning elements, adapters.

It is better to choose thick-walled, fairly wide products with a single lock, as the double-lock box is more difficult to maintain.

Requirements and recommendations for installation:

- The cable, as well as protective fittings, must not sustain combustion, that is, be marked “ng”. The best option for wooden houses - VVGng-ls (with reduced smoke emission).

- The presence of a metal platform for installation - fireproof base, increasing the safety of the use of electrical appliances.

- Switches and sockets - only overhead, external.

- The use of metal sleeves to organize the transition of the cable through the wooden walls, floors, partitions.

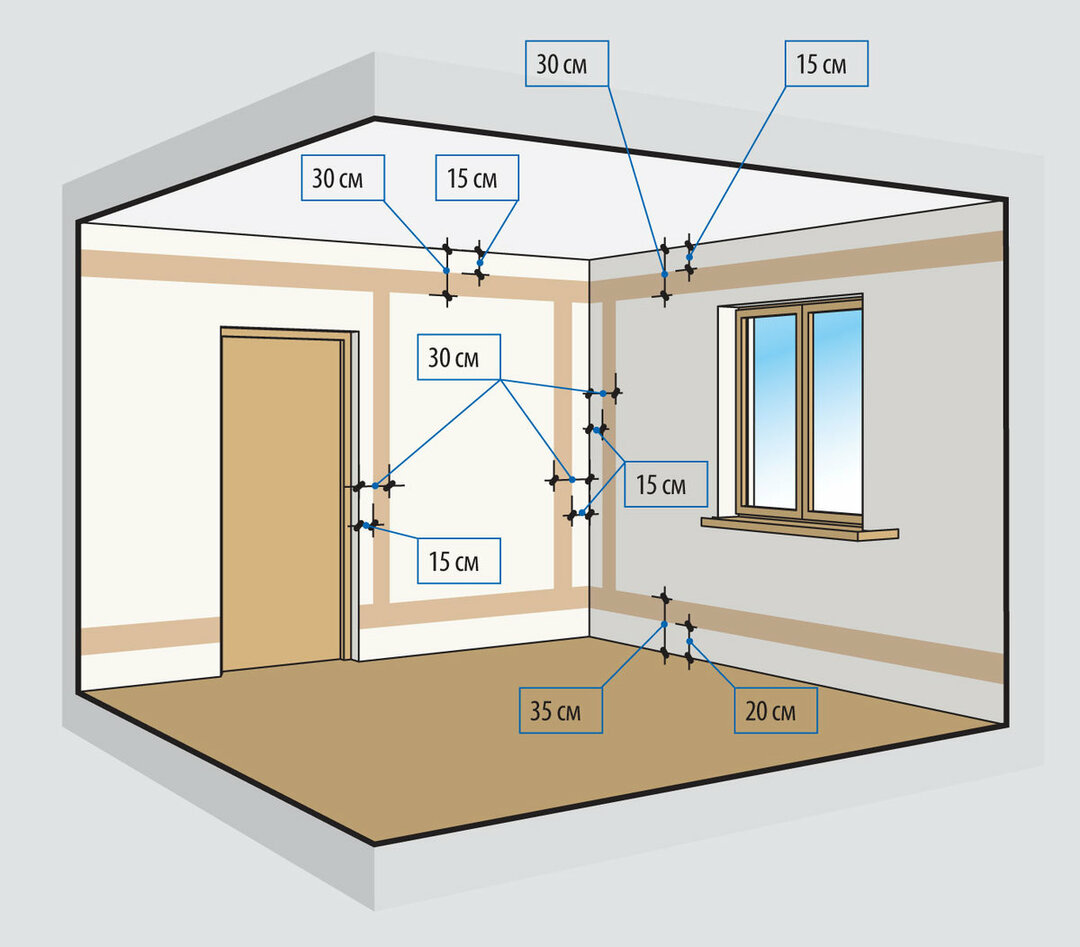

Sleeve sleeves are sections of a thick-walled metal pipe that should protrude 1 cm from each side of the combustible structure. To prevent the cable from deforming, the edges of the sleeves are protected with plastic overlays.

According to the rules of the open area wiring between the sleeve and the box should not remain. The end of the sleeve coming out of the hole must go inside the box

When choosing a cross section of an electric cable for laying in a wooden house, they are guided by the generally accepted norms:

- 3 * 2.5 mm - for sockets;

- from 6 mm² - for powerful electrical equipment, for example, electric stoves;

- 3 * 1.5 mm - for lighting group, etc.

The formation of groups produced by the principle of "as little as possible", that is, a block of 4-5 outlets emit as a separate line and equip a separate machine.

Those wishing to get rid of cables use open wiring on insulators. According to the standards of PUE, it is allowed to have insulated wires in the open form at a distance of 10 mm or more from a wooden surface.

The way that was actively used in the middle of the 20th century is again coming into fashion, so we will pay attention to the retro wiring.

Image Gallery

A photo of

Cable laying on porcelain or plastic insulators is allowed in log houses, buildings from laminated veneer lumber, in lined buildings, as well as in panel and frame constructions

Retro wiring consists of stranded wires with insulation made of synthetic materials or PVC, which may have different colors. Wire material - copper

When purchasing consumables, products of reputable brands are preferable: GI Gambarelli, Mezzanine, Villaris, Salvador, BLF, Aldo Bernardi, Retrica, Bironi, Fontini

In addition to wires, insulators will be required (porcelain is preferable to plastic), conductive sleeves, stylized switches and sockets, terminal boxes, installation decorative frames

When installing, cable cutters, pliers, wire cutters, stripping tools, tape measures, levels, pencils or markers, screwdrivers, drills, drills, extension cords will be required.

Initially, it is necessary to draw on paper the layout of the individual lines - lighting and rosettes, and also indicate the location of switches / sockets (including for low-voltage lines), distribution shield

More than 3 wires usually leave the board, so in this area you have to abandon retro-style wiring and use plastic boxes to match the wall color (to the nearest junction box)

The first insulator is installed at a distance of 5 cm from the socket / switch, the rotation angles are 90 degrees (option - 2 x 45 degrees through 2 insulators), at the intersection of the lines - terminal boxes, the distances between the insulators are the same, not more than 40 cm

Using retro style wiring in wooden buildings

What type of wiring is called "retro"

Quality products companies

Consumables and installations for electrical work

Electrical installation tools

Input data - installation project

Features of connecting switchboard

Rules for pulling lines from wiring accessories

For several years after the construction of a wooden house, its shrinkage occurs, therefore, the sagging of wires is inevitable. To maintain the pleasant appearance of the lines without braces, the wires are fastened with ties above and below the insulators.

Additional information on the installation of open wiring is given in the article - Installation of open electrical wiring: a review of the technology works + analysis of basic errors

Wiring methods for closed wiring

The main difference between hidden wiring is a restriction on the use of laying methods. According to the standards of PUE, it is strictly forbidden to use metal sleeves, plastic boxes and PVC corrugation for concealed wiring. All products must necessarily have localization ability.

There are several reasons for this:

- PVC products do not protect wires from rodents;

- even the slightest damage to the insulation during installation can further provoke a plastic burnout and inflammation as the load increases;

- The metal hose is a spiral-shaped product that does not have localization characteristics, which means that even wood dust can easily penetrate inside the protection.

The rules of fire and electrical safety state that only two types can be used for concealed wiring. products - a metal pipe and a box of similar material specifically designed for this purpose.

From the inside, metal elements must be galvanized or painted so that they are not covered with corrosion during operation.

For a strong connection is not enough bell-shaped or similar method, so they use soldering, electric welding, coupling and threaded connections.

Option hidden wiring in metal pipes - in the future, the ceiling will be closed suspended structure. This solution is acceptable for cable laying in wooden floors, inside walls and partitions

The use of metal hoses, corrugations and boxes of PVCNG is also permissible, but on condition that the equipment is made of a lining made of a material that is not amenable to burning: concrete, alabaster, plaster.

The main stages of laying a closed electrical wiring:

- Track layout. It is necessary to calculate the broach lines so that the number of turns and intersections was minimal.

- Preparation of walls and floors. It includes gouging strobe, drilling holes.

- Metal pipe laying. The size of the product is chosen so that the cable takes up no more than half of the internal space.

- Installation of metal boxes under switches and sockets. Copper pipes are attached to the boxes flaring, steel - with the help of nuts.

- Installation of terminal boxes. Ideally, they should be connected to the pipes by a welded method or by soldering to ensure 100% grounding.

- Electrical measurements. All metal elements of installations must be connected to the PE bus (without exception, the lines must be with a grounding conductor).

- Cable pulling into pipes. To place the wires inside the metal pipes, use special pull-through cables.

- Installation of sockets and switches. When cutting the cable, it is necessary to make a small margin of wires in case of repair or replacement of equipment.

After the wiring of the hidden wiring is completed, you must contact the representatives of the electrical laboratory. Many people forget that a technical report on the status of the wiring and the quality of installation is a mandatory document.

Fire safety regulations regulate the parameters of steel pipes for hidden wiring. Pipes and ducts made of steel with a wall thickness of 2 mm (or less) should not be installed in rooms with a high degree of humidity and with condensation on the walls (ceilings)

It should be understood that the installation of hidden wiring in steel, and even more so in copper pipes - an event disadvantageous from the material point of view.

In addition to expensive material, it is necessary to spend part of the money on good specialists, since it is far from wiring a person with the design of hidden wiring can not cope, and for the installation need a qualified specialist.

What is the ground loop for?

The design of electrical networks for a wooden house necessarily includes a section on the installation of a ground loop, without which the entire system of energy supply to the building is considered unsafe. There are several methods of grounding devices, and, despite the prohibitions, all of them are still used.

It is necessary to refuse assembly of a contour from improvised materials - it is dangerous. The traditional way of arranging a “triangle” of metal corners and tires requires free space on house territory, moreover, since 2013 it has been banned as non-conforming to modern standards (GOST R 50571.5.54-2011).

It is reasonable to apply a modular-pin earthing method in a suburban area, according to which the earthing switches are installed in a line or along the perimeter of the house.

It does not require the allocation of impressive free space on the site, because all elements are located along existing objects. Only a punch is needed to place the pin in the ground.

The length of one mounting pin is 1.5 m. To create one vertical element, several pins are interconnected by a coupling method. For horizontal grounding equipment, the pins are connected with a copper strip or copper wire

To increase current carrying capacity, factory-made electrodes are coated with copper, and all connections, threads and couplings are smeared with conductive paste during assembly.

As a rule, anti-corrosion additives are also included in the paste. As a protection against aggressive external environment, all connections are also wrapped with waterproofing material.

The advantages of the ready grounding systems of the pin type are efficiency, low labor costs, space saving, the main disadvantage is high cost.

It is precisely because of the high cost that many owners of wooden cottages and country houses still use segments of metal corner or fittings for ground loop devices instead of factory products.

Fire Protection Measures

If we analyze the whole process of electrical work in a wooden house from the point of view of security, we can distinguish the main rules:

- correct selection and installation of the RCD;

- installation of a grounding circuit modular pin method (with a resistance of 4 ohms);

- equipotential bonding system;

- ensuring continuity of grounding throughout the network;

- installation of overhead outlets only;

- the hidden installation - in metal boxes and pipes.

Upon completion of electrical work, the risks of accidental fire should be completely eliminated. or electric shock, as well as damage to household appliances due to poor condition wiring.

Conclusions and useful video on the topic

In the process of laying routes and installing electrical installations, there are many nuances that only professional engineers and electricians can help.

How to install the socket using a wooden lining:

Rules for hidden wiring:

General information about electrical installation in a wooden house:

The installation of electrical networks in wooden structures that are considered to be combustible requires special attention, experience, knowledge of technical nuances and compliance with regulatory requirements.

For drawing up and coordination of the project documentation, input of an electric cable to the house, and also installation of the hidden conducting we recommend to address specialists. This does not interfere with working independently - for example, installing an outlet.

If you have any questions, or have a desire to share your personal experience in electrifying a wooden house, please leave comments on the article. The feedback box is located below.