One of the conditions for a comfortable microclimate in the house is sufficient air circulation. Equipping the climate system of the room, it is desirable to provide for the possibility of smooth adjustment of the intensity of air jets.

Anemostats cope with this task. Before choosing an air distributor, one should understand what a ventilating anemostat is and how to choose a model based on the specific operating conditions.

These questions are studied by us and set forth in detail in the article. In addition to the selection of recommendations, we have prepared an overview of popular brands and popular modifications of ventilation aemostats.

The content of the article:

- The use of anemostat in the ventilation system

- Typical device and principle of operation

- Constructive and functional features

- Anemostat and diffuser: similarities and differences

-

Criteria for selection of the air distributor

- Production material: which is more practical and durable

- Evaluation of the technical characteristics of anemostat

- Type of control ventilating "ceiling"

-

Overview of popular brands and modifications

- Vents - a wide range of anemstat

- Dospel - air distributors of Polish production

- Blauberg: VPR and VMR series models

- Exhaust and supply anemostatis Lessar

- Systemair - European quality ventilation devices

- Conclusions and useful video on the topic

The use of anemostat in the ventilation system

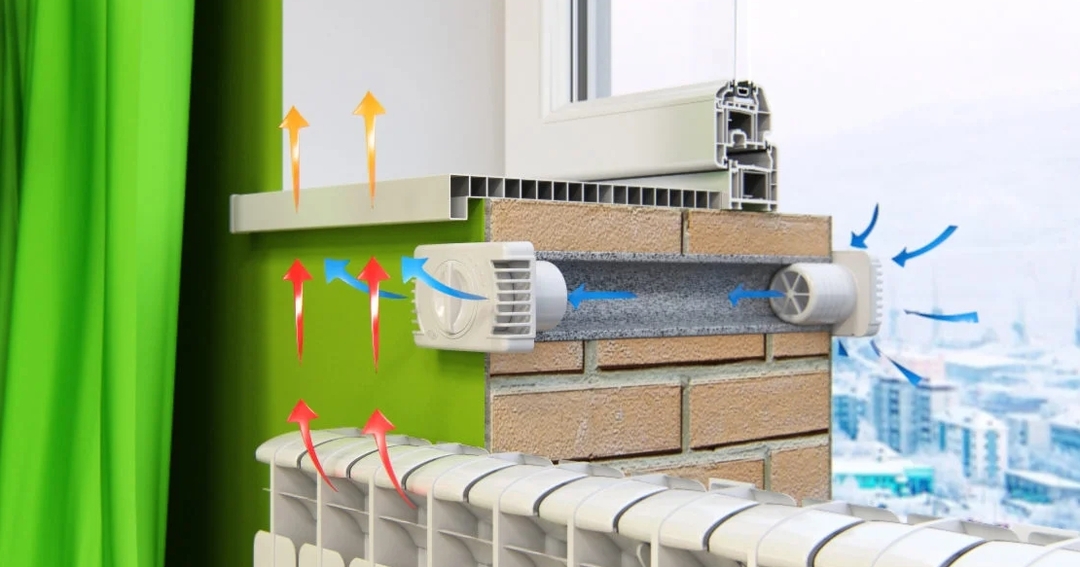

Anemostat is the final element of the ventilation system, which is responsible for the uniform distribution of air masses in a closed room. In fact, this is an alternative version of the diffuser or the usual ventilation grille.

The device is actively used in air heating systems, air conditioning and ventilation, both household rooms, and buildings of production appointment.

Image Gallery

A photo of

Anemostat is designed to control the supply of air supplied by a mechanical ventilation system.

The aerodynamic configuration of the valve is responsible for the uniformity of the air flow in the design of the anemostat;

Anemostats with air ducts connected to them are installed behind suspended ceilings, internal lining of frame walls, behind false walls

Smooth adjustment of the air flow is carried out by rotating the central part of the valve.

Anemostat supply and exhaust ventilation

Aerodynamic valve shape

Ceiling installation

Device for smooth flow control

The main task of the anemostat is the formation and distribution of the air flow entering the room from the outside or vice versa, directed into the exhaust pipe.

Anemostat is represented by a small piece of pipe with a movable "cap". The air distribution element cuts into the vent outlet from the side of the room

“Ceiling lamp” is responsible for a number of additional, but equally important functions:

- adjustment of the air supply;

- elimination of drafts - the device provides aero-convection, due to which the probability of air turbulence is leveled;

- effective airing of the room - fresh air streams fill all the inner space of the room;

- overlapping duct openings.

Some models of air distributors are equipped with a filtering element that holds dust particles from incoming outside air.

Anemostats are available in different colors, which allows decorating the ventilation duct to the tone of finishing materials and making the duct less noticeable

Typical device and principle of operation

The design of anemostat is extremely simple.

Standard equipment includes:

- round case;

- mounting coupling;

- adjustable flange partitions;

- disk with a threaded rod.

A spacer with an adjusting screw and a movable plate is inserted inside the ventilation channel.

The shield moves perpendicularly relative to the duct through the pipe anemostat. The mode of operation of the air distributor is selected independently and controlled by the position of the valve (+)

When moving the cover counterclockwise, the throughput gap increases, respectively, the inflow or output of air increases. The permeability of the device increases when the ceiling is rotated clockwise.

Some anemostats have two plates: one - a concave of larger diameter, the second - a standard form. This modification distributes the air better.

Constructive and functional features

Depending on the nature of the distribution and direction of air jets, there are three types of anemostats: supply, exhaust and universal.

The fresh-type air distributor is completed with a shield concave inside. The shape of the plate has minimal aerodynamic resistance, so that air masses are distributed evenly. This anemostat is installed in the ducts ventilation.

The divider is mounted in the intake ventilation system and redirects air flow along the surface of the ceiling or wall - depending on the installation method

In the exhaust anemostat, the outer lid has a round, smooth shape to effectively eliminate exhaust air.

The universal supply and exhaust anemostat is equipped with two caps-dividers.

The nuances of the combined model:

- when installing into an exhaust system, it is permissible to use two cracks simultaneously formed by the plates;

- work in the intake ventilation system involves the opening of a single gap created by a concave shield; exhaust hole in this case must be closed.

The choice of the appropriate mode is carried out manually - the technological gap of the necessary size is established.

If the supply air duct is equipped with a universal anemostat and the exhaust mode is set, then the flow of fresh air will be blown vertically down rather than distributed under the ceiling.

Anemostat and diffuser: similarities and differences

Despite the fact that both devices perform similar tasks, the principle of operation of air distributors varies. By itself, the diffuser is not designed to adjust the bandwidth.

The angle of inclination of the lamellae of the supply and exhaust diffuser is fixed, and various modifications of the manual control flaps are provided for adjusting the volume of the air flow.

Unlike the anemostat, the diffuser housing is round, rectangular or square. High throughput are distinguished by linear oblong models.

Criteria for selection of the air distributor

The determination of the optimal model of the anemostat should be based on the evaluation of a number of parameters: the material of manufacture, the dimensions of the device, the working range of the plate and the area of the slot. All criteria are selected based on operating conditions.

Production material: which is more practical and durable

Lightweight materials are used in production: aluminum, plastic or galvanized steel. Exclusive options are made of wood. Each product has pros and cons.

Metal. Feature of metal products - durability and durability. An additional advantage is the beautiful exterior design that blends well with different styles in the interior.

The disadvantages include: high cost and complicated installation due to the large weight.

The metal anemostat is optimally suited for difficult production conditions - for the removal and supply of heated air. Heat-resistant models are used in smoke removal systems.

Products from a stainless steel are established in baths, saunas or furnace chambers.

Plastic. Plastic aemostatis are commonly used in household, commercial, office and public buildings. Products are well proven in wet areas (shower, laundry, kitchen, swimming pool, bathroom).

Competitive advantages of polymer anemostats:

- resistance to moisture - do not corrode like metal, and do not rot, like wood;

- light weight and easy installation;

- variety of sizes and colors;

- unpretentiousness in care and maintenance;

- low cost.

The negative side of plastic: low strength and the inability to use for "pumping" of hot air masses.

Tree. Such specimens are rarely met, they are mainly used, if required by the design of the room. Anemostats organically look in the interior of a wooden house, bath or sauna.

As a rule, the upper plate of the air distributor will play the decorative role. This element is made of wood, and the rest of the "stuffing" of the device is made of plastic or metal.

Evaluation of the technical characteristics of anemostat

After selecting the type of distributor (exhaust or inflow), assess the operating conditions and determine suitable material, you should choose a model according to three parameters: diameter, size of the slotted hole and stroke valve.

Diameter. The cross section of the anemostat head should be compared with the size ventilation system channel. For example, an appropriate 100 mm distributor will fit under a 100 mm air duct.

Standard diameter of anemostat varies in the range of 80-200 mm. If necessary, close the ventilation pipe of a larger cross section and apply diffusers.

Slot hole. The parameter determines the bandwidth of the device. The run-up of indicators - adjustment of the gap with the help of the flange. In small models with a diameter of 80 mm, the boundary area of the living section is 0.002 square meters, in anemostats with a size of 200 mm, the figure reaches 0.009 square meters.

Power reserve. The indicator characterizes the maximum opening - moving the “ceiling” along the normal. The larger the valve stroke, the wider the range of operation of the anemostat. The boundary value in different models reaches 8-30 mm.

Type of control ventilating "ceiling"

Most models are designed for mechanical adjustment of the position of the plate. The operation mode of the air distribution valve is set manually - just scroll the “cover” clockwise or vice versa.

In this case, the convenience of control depends on the location of the anemostat. With ceiling mounting, changing the position of the dish is difficult. To simplify the task, it is better to choose an automatic device with a control unit.

Opening and closing of the ventilation channel is carried out using a conventional switch on the type of ignition of the light bulb. In addition to the installation of an anemostat, the supply of electrical cable and the installation of a wall control unit

Overview of popular brands and modifications

On the ventilation system market, anemostatis are represented by various manufacturers. The leader among sales is products Vents. Worthy competition they are air distributors Dospel, Blauberg, Lessar and Systemair. Consider the proposed modification of popular manufacturers in more detail.

Vents - a wide range of anemstat

The company realizes six series of anemostats:

- A * BP - combined plastic;

- A * VRF - universal with plastic flange;

- A * PR - inlet plastic;

- A * PRF - stitched with an assembly flange, production material - plastic;

- AM * VRF - universal metal with a flange;

- AM * VRF N - forced-air and exhaust from stainless steel.

The combined anemostatas A * BP and A * VRF are made of polystyrene or ABS plastic. Both models are suitable for wall or ceiling mounting.

Series A * BP / A * VRF are available in six standard sizes - from 80 mm to 200 mm. Throughput and channel travel in different versions of the same diameter are (+)

The difference is that anemostatas А * ВРФ are equipped with a flange and a limiting ring, which make it possible to quickly and easily fix the air distributor in the ventilation channel.

The A200VR, A200VRF and A200 / 150VRF models are equipped with two regulating elements - this ensures a better redistribution of air masses.

Air supply aerostats A * PR and A * PRF are available in two diameters: 150 mm, 200 mm.

Corresponding characteristics of air distributors:

- cross-sectional area - 0.011 and 0.012 square meters;

- the maximum course of the plate along the normal is 21 and 22 mm.

The cost of plastic air distributors Vents without flange is 4-9 USD, depending on the size and availability of the flange.

Metal models of combined anemostats (AM * VRF and AM * VRF N) are presented in four standard sizes: 100, 125, 150 and 200 mm.

The diagram shows air flow at different positions of the internal plate of the AM200VFM device. Valve stroke range is 2-22 mm (+)

The price for steel products with a polymer layer is 9-12 cu, for stainless steel anemostats - 25-100 cu

Dospel - air distributors of Polish production

Company Dospel (Poland) specializes in the manufacture of ventilation equipment and accessories.

Air distributors are represented by three subcategories:

- AN * - plastic inlets;

- ANM * EV - exhaust metal anemostaty;

- ANM * SV - inlet distributors of metal.

"Ceiling" series AN are available in diameters of 100, 125 and 150 mm. The maximum opening of a shutter reaches - 16, 13 and 21 mm.

Comparison of the aerodynamic characteristics of AN125 and AN150 in various ranges of the opening of the plate and the dependence of throughput on the diameter of the anemostat (+)

Dospen metal inflow and exhaust distributors are made of stainless steel and powder coated. Both series (ANM * EV and ANM * SV) are available in five sizes: minimum - 100 mm, maximum - 250 mm.

Estimated cost of plastic models - 4 USD, metal - 6-19 USD

Blauberg: VPR and VMR series models

German corporation Blauberg ventilatoren offers two types of supply and exhaust air distributors:

- VPR - plastic with mounting flange. They are made of polymers that are resistant to UV rays and temperature effects, antistatic additives are present in the plastic. Overall dimensions are suitable for air ducts of 80-200 mm. The maximum cross-sectional area is 0.009 square meters.

- VMR - metal anemostats. Material production - steel, on top - a layer of white polymers. The model range has four positions from 100 to 200 mm.

High strength characteristics of both models determine their wide scope of application: residential, utility, office, retail space, kindergartens and medical facilities.

Blauberg Anemostats are designed for wall and ceiling mounting. For reliable fixation with the air duct, sealing rings are provided in the VPR and VMR models

Exhaust and supply anemostatis Lessar

Firm Lessar It has manufacturing facilities in China and various European countries. The company's products are in demand due to decent quality and affordable prices. Anemostats are available in a limited range - metal exhaust and intake type.

Distinctive features of air distributors Lessar:

- the lineup: LV-DCP - for intake ventilation systems, LV-DCV - for exhaust air ducts;

- channel cross section: 100, 125, 160 and 200 mm;

- bandwidth anemostats - 10-500 cubic meters / hour;

- the cost - 5-10 cu (depending on the size of the product).

Anemostats Lessar compared with similar metal models from other manufacturers are much cheaper.

Air distributors are made of steel and coated with white powder paint - according to the tinting color matching system RAL №9010

Systemair - European quality ventilation devices

Swedish brand Systemair implements a standardized line of ventilation equipment: fans, air handling units and air distributors.

Types of Systemair Anemostats:

- Balance-E. Exhaust type device made from regenerated polypropylene. The material withstands high temperatures (up to + 100 ° C) and chemical compounds in moderate concentrations. Four variations are designed for air ducts of 100, 125, 160 and 200 mm. The maximum air gap is 20 mm.

- Balance-S. Inlet anemostat made of the same plastic as the previous model. Available in three sizes: 100, 125 and 160 mm.

- EFF. Universal steel distributor, capable of operating in the "exhaust" and "inflow" of air. EFF modifications have a diameter from 63 to 200 mm, the stroke of the central cone is up to 28 mm.

- Tff. Inlet anemostat made of steel. The design includes an inlet cone and a flat sound-proofing disc. Available in diameters of 80-200 mm.

The Balance-E, Balance-S and EFF models are installed using a mounting ring or directly into the duct. TFF is fixed in the ventilation channel by spacer springs or in the mounting frame.

Adjustment of the gap and directional distribution of air flow at 180 ° in the Systemair TFF anemostat is carried out by a screening element

Conclusions and useful video on the topic

Typical device universal adjustable "diffuser":

Work automatic anemostat:

Technology of installation of the air distributor in a plasterboard box:

Anemostat is a simple and effective solution for improving the microclimate. The device is responsible for a uniform flow of fresh air in the injection ventilation system and regulates the release of "testing" in the exhaust channels. Important plus of the air distributor - reasonable cost.

Looking for an effective ventilating anemostat? Or have experience using such installations? Please leave comments on the article, participate in discussions and share your impressions about the use of anemostats.