The basis for planning communications in private households has always been and remains the calculation of the flow rate of the transported medium and the cross section of the pipeline. Only on the basis of calculated data, it is possible to select the dimensions of polypropylene pipes from the existing range. Unlike steel, polypropylene differ both in polymer properties and in the recommended scope of application. What other features do they have?

The content of the article:

- What determines the size of polypropylene pipes

-

Dimensions depending on the material of manufacture

- PPR

- PPH

- PPS

- PPB

-

How to choose pipe sizes based on system pressure

- An important characteristic of dimensions

-

Dimensions according to application

- Dimensions of polypropylene pipes for ventilation

- Dimensions of polypropylene pipes for sewerage

- Dimensions of polypropylene pipes for water supply and heating

- Special cases

- How Pipe Sizes Are Considered When Welding

What determines the size of polypropylene pipes

Pipe blanks made of polypropylene were designed for a specific use case. Polypropylene pipes have never been universal - they were not brought together into a single assortment, as in the case of steel pipes. At best, you can find a size chart for the recommended type of communications. Therefore, it is not enough to know the optimal dimensions of polypropylene pipes in mm for a specific liquid or gas flow rate.

When choosing sizes, you need to consider:

- material, a type of polymer based on a polypropylene matrix;

- pressure and temperature of the working medium;

- type of medium being moved;

- method of joining tubular billets. With an increase in the transverse dimension, the number of technical problems proportionally increases.

There is one more nuance. The throughput and diameter of the pipeline obtained during the calculation for the project will always differ from the internal size of polypropylene pipes. The latter are produced with a certain diameter step. Therefore, you need to choose a workpiece with the closest, most suitable transverse dimension. For example, select from a table.

This is necessary so that the throughput does not decrease less than the critical one, and not to spend money on the purchase of more expensive large-diameter polypropylene pipes.

Dimensions depending on the material of manufacture

For the manufacture of pipelines based on polypropylene, several types of polymer compositions are used. Pure polypropylene is used to a limited extent due to low mechanical characteristics, low resistance to heat, active oxygen and ultraviolet radiation.

PPR

The most common material. It is a random copolymer of polypropylene with ethylene and polyethylene. Thanks to high-temperature directional polymerization, a dense, strong, heat-resistant structure is formed. This is the most durable grade of polypropylene.

Blanks marked PPR or PP-R are used for:

- heating;

- supply of hot and cold water;

- floor heating systems.

Standard size range - 16-250 mm. The material is perfectly processed and soldered by hand or machine tools.

PPH

It is practically pure polypropylene with additives that prevent secondary polymerization, aging and delamination. The ductility of the material is lower, the rigidity and strength are higher. Low density and high water resistance. Therefore, large-section pipes are made from homopolypropylene:

- pressure type with diameters 63, 90, 110, 200, 250, 315 mm;

- non-pressure type with diameters 200, 250, 315, 400, 500 mm.

Pipe blanks made of homopolypropylene are poorly glued and have low impact strength. Therefore, the assembly of large-diameter sections of free-flow conduits is carried out mainly mechanically on rubber seals.

| Characteristics/type of polypropylene | RR-N | RR-S |

| Density, g/cm3 | 0,915 | 0,910 |

| Modulus of elasticity, MPa | 1700 | 1200 |

| Operating temperature range, ℃ | from 0 to +100 | -20 to +80 |

| Thermal conductivity coefficient, W/m ℃ | 0,22 | 0,22 |

| Physiologically harmless according to BIR | Yes | Yes |

| Chemical resistance to acidic and alkaline media | inert | inert |

| fire resistance | Normally flammable, class B2 | Normally flammable, class B2 |

PPS

Copolymer of polypropylene and polyethylene. Unlike other brands of polypropylene matrices, it has a low thermal stability, heating up to a temperature of no more than 80 ℃ is allowed. It can be operated at negative temperatures, up to -20 ℃.

It is used mainly for medium-sized water pipes laid in unheated rooms and in open areas. The outer size of polypropylene pipes is 25-225 mm.

PPB

This type of material for polypropylene pipes is the result of the joint polymerization of ethylene and propylene. Only unlike PPS matrices, the structure is blocky. Individual microblocks of PPB-polypropylene, characterized by high strength and chemical resistance, are interconnected by a mixture of PP and PE with a lower degree of polymerization.

PPB polymer was developed as an effective replacement for PPH grade polypropylene pipes. Most manufacturing companies producing sewer pipes and fittings are switching from RPH to RRV. The dimensions of pipe blanks are 55-500 mm.

What pipe material did you choose for the plumbing?

Metal.

0%

Plastic.

0%

Metallic.

0%

I do not understand this.

0%

Voted: 0

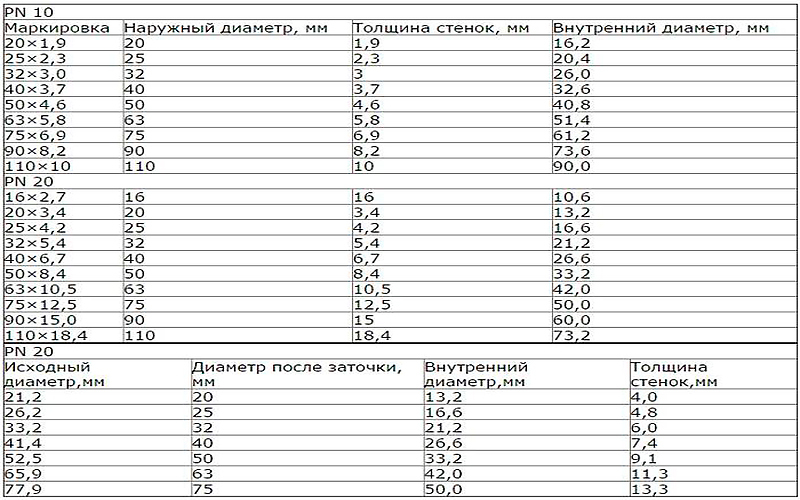

How to choose pipe sizes based on system pressure

With rare exceptions, pipe blanks are purchased blind. The customer, the master or the owner of the house simply tell the manager what they need polypropylene pipes "for soldering" or for the assembly of plumbing, heating, sewerage. The seller offers a product that is in stock with his comments. None of the participants in the process even tries to understand the labeling.

The first thing to pay attention to is that the grade of polypropylene must be PPR - a random copolymer. There may be several options for marking - PPR, PP-R, PP-RCT, all of which are practically the same material.

For lines with increased internal pressure, a random copolymer is used. Therefore, the presence of one of the marking options on the workpiece indicates that it is exactly suitable for highly loaded pipelines, no matter whether it is a size of 16 mm or 250 mm.

Next, you need to check the pressure limit - it is indicated on the marking in the form of a combination of letters and numbers:

- PN10;

- PN16;

- PN20;

- PN25.

The numbers indicate the maximum pressure (Bar) at operating temperature. The first three are used for non-hot water. The last two are for transporting hot water or liquid media under pressure, at temperatures up to 95 ℃. Working conditions are more difficult, so the walls are made multi-layered and reinforced. Their thickness increases, the outer size of the pipe billet increases.

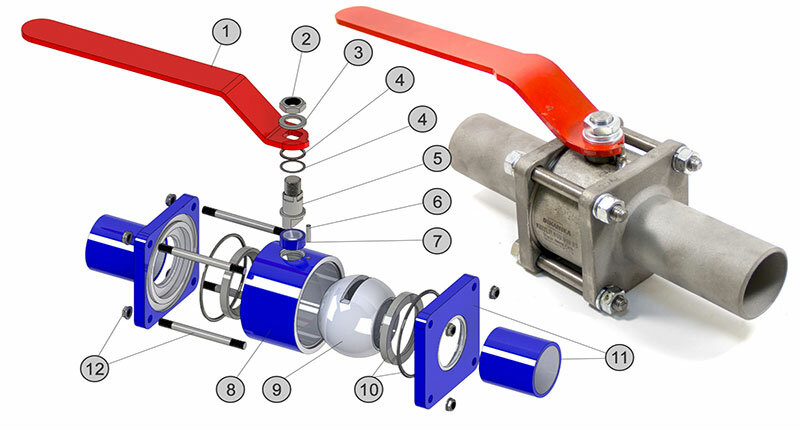

An important characteristic of dimensions

Another parameter is called the SDR index. It characterizes the ratio of the outer diameter of a polypropylene pipe to the wall thickness. Usually indicated as a number on the outer surface of the workpiece, next to the marking. If there is nothing, then the index can be calculated independently. It is enough to measure the diameter and wall thickness of the workpiece with a caliper, and then divide the first value by the second.

Why is this needed? This is the most important indicator of the load capacity of a polypropylene pipeline. For example, most pipes of the PN20-25 class have an index of no higher than 7.4. Conventional PN10 pipe billet - as many as 11 units. The higher the SDR index, the lower the mechanical strength of a product of any diameter.

| Outer diameter of PP-R pipe, in mm | Wall thickness (mm) for SDR=5, for PN25 | Wall thickness (mm) for SDR=6 for PN25 | Wall thickness (mm) for SDR=7.4 for PN25 |

| 20 | 4,1 | 3,4 | 2,8 |

| 25 | 5,1 | 4,2 | 3,5 |

| 32 | 6,5 | 5,4 | 4,4 |

| 40 | 8,1 | 6,7 | 5,5 |

| 50 | 10,1 | 8,3 | 6,9 |

| 63 | 12,7 | 10,5 | 8,6 |

| 75 | 15,1 | 12,5 | 10,3 |

| 90 | 18,1 | 15 | 12,3 |

| 110 | 22,1 | 18,3 | 15,1 |

| 125 | 25,1 | 20,8 | 17,1 |

| 140 | 28,1 | 23,3 | 19,2 |

| 160 | 32,1 | 26,6 | 21,9 |

Dimensions according to application

Good machinability of cast polypropylene, simple production technology are the reason for the gradual displacement and replacement of polyethylene pipes with polypropylene. In addition, polymers of the PPB, PPH, PPR brands are considered safer in comparison with the closest competitors - polyvinyl chloride and polyethylene.

Dimensions of polypropylene pipes for ventilation

The standard diameter of ventilation ducts is 110-200 mm. This is enough to remove polluted air through the hood in the kitchen, in the bathroom, in any residential or non-residential premises of a house or apartment. Ventilation systems of office premises are completed with pipes up to 250 mm.

Installation is carried out by mechanical assembly pipe-socket. It will not work to replace ventilation based on PRV pipes with polyethylene or PVC.

Polyethylene air ducts are prone to electrification, accumulation of dust plugs that clog filters and recuperators. PVC cannot be used on air ducts for fire safety reasons.

In addition, PPB pipes are more rigid than vinyl or polyethylene blanks. For example, it is almost impossible to crush the walls of a standard 16x2.2 mm polypropylene pipe billet with your fingers. Whereas similar products made of polyethylene or vinyl are easily wrinkled.

So ventilation made of polypropylene with a diameter of up to 1200 mm with an SDR index of tens of units. Under load, the walls do not crumple, withstand any pulsations and fluctuations in the air flow.

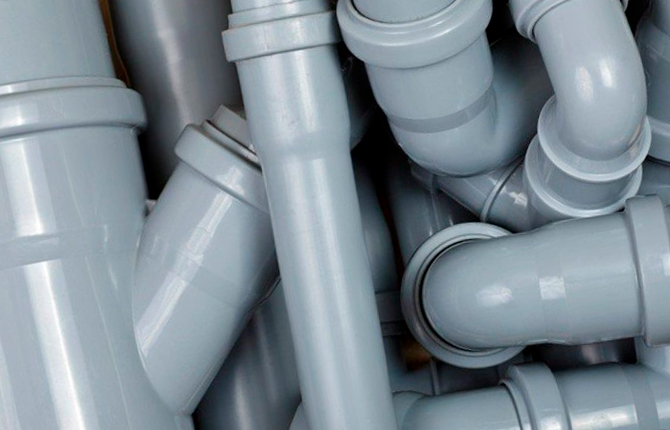

Dimensions of polypropylene pipes for sewerage

For waste and sewer systems, pipes made of PPH polymer are used. The material is practically equal to PVC in terms of chemical resistance, while it has higher water resistance, and most importantly, wall rigidity.

This means that propylene sewer pipes can be produced with a high SDR index:

- the weight of the pipe billet is less, which means that sewage will be cheaper;

- the joint on the rubber seal will not leak;

- locks at the joints of polypropylene pipes practically do not have such defects.

For domestic sewers, PPH blanks with a diameter of 25, 50, 110 mm are used. To drain sewage from the house, pipes measuring 300-550 mm are used.

Dimensions of polypropylene pipes for water supply and heating

For piping a boiler or distributing a centralized heating system, hot water pipes of the PPR brand are used, class PN20, SDR index 6-7 units. Dimensions - 20-40 mm.

On the return line, feeding the main or water supply, put PPR - PN10 with an SDR index of more than 10. The dimensions of the cross-section of pipelines are determined by the second flow of water. For the hot section, pipes reinforced with fiberglass or aluminum foil are installed. Otherwise, the brazed joint between the fitting and the hot pressurized propylene wall may leak.

There are many models of PPR pipes on the market. Despite the fact that pressure polypropylene pipes of different brands are made of almost the same material, and there are differences between them in terms of size. Any of the manufacturing companies has its own catalog of polypropylene pipe sizes, it will help you make a choice.

We can recommend the following models as an option:

- Pipes marked PVPP-RCT UNI are easy to distinguish by a characteristic longitudinal green stripe. Transverse dimensions - from 16x2.2 mm to 250x22.7. It is believed that hydraulic losses in small-section water pipes are less than those of analogues.

- Pipe blanks marked PVPP-RCT FASER with an orange longitudinal stripe, section 20x2.8 mm are most popular for supplying hot water under pressure up to 25 bar. It features a thermal expansion coefficient reduced by more than three times.

- PVPP-RCT is designed for high temperature and pressure environments. Dimensions from 20x2.8 mm, PN index can exceed 25 units. Marked with a red stripe.

- For the main water supply, pipe blanks PVPP-R CT FASER are used. The diameter at the input can be 40x3.7 mm or more.

- At the entrance to the apartment, polypropylene pipes of the PP-RCT brand, with a diameter of 25x4.2, are used. HOT series for hot water and CLASSIC for cold water.

You can assemble the water supply with propylene pipes of any type and size. But it is still better to put pipe blanks of the appropriate size and section. This will save money, and the plumbing will not make noise or buzz due to fluid fluctuations in the stream.

Special cases

Polypropylene pipes are widely used as a substitute for aluminum or steel profiles. From pipe blanks with an outer diameter of 25 mm, you can easily solder the frame of a small greenhouse with a base size of 200x400 cm. It is better to use polypropylene segments with an SDR index of at least 5, the wall thickness is 5.1 mm. This is enough to bend the arched vault, and screw self-tapping screws into the wall to fasten the crossbars or fix the stretched film.

From polypropylene scraps left after assembling the heating circuit, it is possible to make floor heating for a loggia or balcony. The room itself will need to be thoroughly insulated along the walls, ceiling and floor. Foiled polyethylene foam is laid under the pipes. For the heating circuit, we use polypropylene blanks of the PPS brand, 25 mm in size and with an SDR index of 10. Thin walls conduct heat well, and the material is not afraid of freezing down to -20 ℃.

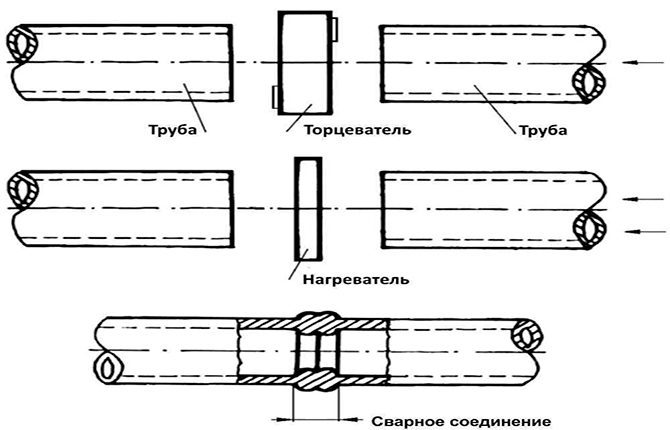

How Pipe Sizes Are Considered When Welding

Pipe material with a transverse dimension up to 63 mm is soldered using a hand soldering iron. Any brand of polypropylene for pressure water pipelines is spliced using polypropylene couplings heated on the nozzles of an electric soldering iron. The quality of the connection in all cases is high.

The only thing is that care must be taken when soldering pressure pipelines from PPR blanks with an outer diameter of 20 mm and an SDR index of 5. The wall thickness is 4.1 mm, the distance between them in the light is only 12 mm. If you overheat the material, apply too much force, then the flash or flash can completely block the passage inside the pipe.

There are industrial soldering irons that can weld fittings up to 110 mm in size and more.

The soldering of the aluminum-reinforced polypropylene contour has to be additionally prepared by trimming the outer and aluminum layers. Otherwise, the diameter of the pipe will be too large to fit into the hole of the coupling or valve.

The range of sizes of polypropylene pipes allows you to choose the appropriate diameter for water pipelines any performance. The soldering technology has been worked out even for large cross-sections, therefore, as a rule, there are no problems with the assembly of heating and water mains.

Polypropylene pipes for water supply and heating systems. Types and benefits: video.

Share your experience - have you ever had to change sections on an already assembled polypropylene water pipe to new pipes of a different diameter? Bookmark this article so you don't lose the latest information.