Buying a power tool for driving screws into your home workshop is just a matter of time. You just need to choose the model and scheme of the tool. But most future tool owners cannot choose a power system: a cordless or cordless screwdriver. Why is one scheme better than another and is there any point in overpaying for a rating and batteries.

The content of the article:

-

Brief description of corded screwdrivers

- Advantages of corded screwdrivers

- Disadvantages of corded screwdrivers

-

Brief description of cordless screwdrivers

- Benefits of cordless screwdrivers

- Disadvantages of cordless screwdrivers

-

When is a cordless drill best suited?

- home renovation

- Summer cottage construction

- Non-standard situations

-

In what situations is a corded screwdriver best suited

- Home use network tool

- Screwdriver in the garage and workshop

- Results

Brief description of corded screwdrivers

The design is very similar to the device of an electric drill. For the home, you can use a screwdriver or drill, everything is one. Difference between corded screwdriver and an electric drill just in the gearbox.

With a corded screwdriver:

- big torque;

- it is possible to adjust the speed;

- reverse - change the direction of rotation to the opposite.

The drill has only one rotational speed. Since the drill shank is always cylindrical, the chuck is of increased accuracy, turnkey clamping.

Corded screwdrivers usually have a keyless chuck that can be easily screwed by hand without any additional tools. Its accuracy is lower, but it is not intended for precise drilling. The ability to install small diameter drills is necessary in order to make a hole and then wrap a self-tapping screw into it.

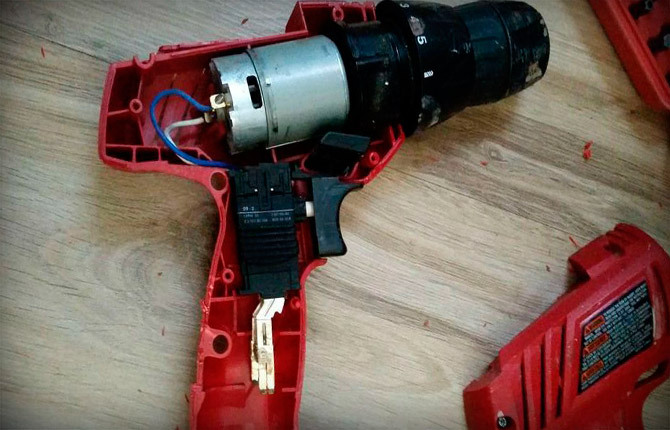

The mains screwdriver is based on a 220 W motor with a small current consumption. In fact, this is a housing with a reduction gear and a high-speed collector motor. About the same as in mixers or coffee grinders.

The engine is designed for short-term switching on within 5-10 seconds. Approximately how much is required in order to wrap a self-tapping screw. Then a pause for the installation of the next screw in the bat, during which the gearbox and motor cool down. Therefore, problems with overheating, as a rule, do not happen, even if you work with the tool all day.

If you try to drill like a drill, for several minutes, then the brushes will burn out first, then the bearings of the gearbox and at the end the winding of the screwdriver motor. Few corded screwdrivers can work under heavy load for a long time, so you need to take breaks.

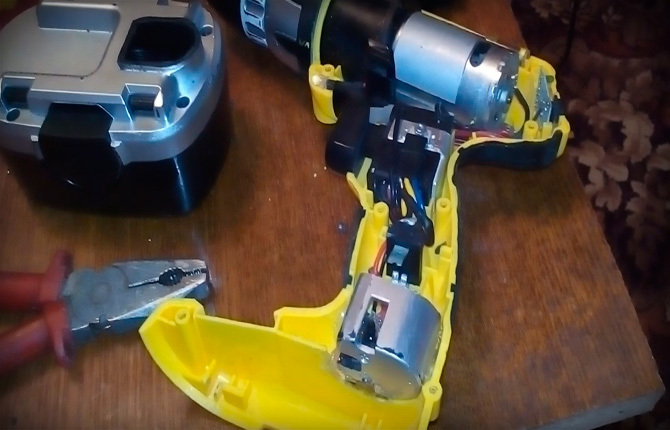

In a battery tool, the gearbox is much larger, almost always made of wear-resistant cast iron and steel. The motor is usually commutator, with a massive copper winding of 10-15 A. A replaceable battery is installed at the bottom, it can be in the form of a flat block or clip.

With such a tool, you can drill without problems, but also with interruptions. If you need to constantly drill metal, then it is better to take a model with a brushless motor. Such a screwdriver will cost more, but its capabilities are much greater than those of conventional models.

Advantages of corded screwdrivers

Using a circuit powered by a 220 V household network has pros and cons. There are more advantages, and they clearly outweigh the negatives:

- the design of the screwdriver is simpler and more reliable;

- the tool can be used for an unlimited time;

- the performance of the screwdriver is not affected by the temperature and type of fasteners;

- in the event of a breakdown, repairs will be cheaper than with battery models.

The mains screwdriver also has less weight due to the lack of batteries. After purchasing the tool, you will need to purchase an extension cord and a set of bits. There will be no other costs.

In addition, corded power tools are much safer than cordless ones. If the wiring remains intact, then you can work with a screwdriver even in rain, severe frost, heat, and high humidity. A corded screwdriver can be dropped from a roof or a ladder and this minor incident will not affect the performance of the tool in any way.

Another significant plus is that the mains power tool is much easier to repair. Moreover, some operations, such as replacing an electric motor, can be performed independently.

Disadvantages of corded screwdrivers

Of the minuses, only a relatively small torque should be noted. On average, it is 18-20 N * m. That is, only small and relatively short self-tapping screws can be wrapped with a network screwdriver. For facing walls with drywall, the capabilities of a screwdriver will be enough, but for filing boards on the ceiling or roof sheathing - no.

In addition, many owners of screwdrivers who previously used cordless versions of the tool are often annoyed by the power cord. In their opinion, this is the biggest drawback of network models.

The cord is not just uncomfortable to use. It significantly limits the possibility of using a screwdriver. The tool cannot be taken to the country if the house does not have electricity and a generator. Connecting a mains screwdriver through an extension cable longer than 20 m leads to a voltage drop on the wiring, and, accordingly, the motor turns the gearbox not as powerfully as if you turn on the screwdriver directly in socket.

According to many owners, a corded screwdriver is just a “younger” version of a cordless one. It costs less and can be used for any operations, and in everyday terms - even to replace a conventional electric drill.

Brief description of cordless screwdrivers

Hand tools powered by batteries appeared quite a long time ago, since the active development of nickel-metal hydride and lithium batteries. The use of Li-Ion batteries to power screwdrivers ensured a minimum operating time of 20-25 min., fast charging of replaceable batteries (30-60 min.) and the ability to work for several hours without connecting to the network 220 V.

Design features of a cordless screwdriver:

- low-voltage (6-40 V) DC motor, collector or brushless type;

- a powerful gearbox, as a rule, is heavier and more massive than that of network models;

- huge torque on the chuck, about 2-3 times more than that of 220 V screwdrivers.

The range of torque and speed control is much larger. The standard for battery models is 18 adjustment steps, advanced models can have up to 20.

Complete with cordless screwdriver must be charging and at least one spare battery. If the cordless tool is often stored and transported without a case or box, then the cordless screwdriver should be stored in the case along with a spare battery and charger.

Benefits of cordless screwdrivers

Thanks to the batteries, the tool has become a little heavier, but much more convenient to use. Especially if you need to constantly move around in the work area with a screwdriver, climb stairs or move along scaffolding.

But the most important advantage of a cordless screwdriver is more torque. You can easily screw a self-tapping screw with a length of 100-120 mm. Moreover, to do this with a small blow, when the head of the screw enters the tree completely and crushes the fibers. Such fasteners are considered the most reliable.

High torque and reverse make the cordless screwdriver ideal for loosening old wood-wrapped screws with paint or linseed oil. There is no other way to remove the old fasteners.

A cordless tool is often used as a mixer drive if you need to mix paint or putty in a bucket. Battery powered screwdrivers are traditionally used for assembling home furniture. In this case, working with a network tool is quite troublesome and inconvenient. You have to constantly make sure that the cord does not get tangled.

Another use case is cordless screwdrivers with high torque, which are massively bought by ice fishing enthusiasts for drilling holes. Moreover, a type of screwdriver has already appeared, designed taking into account the specifics of use as a drive for an ice drill.

Disadvantages of cordless screwdrivers

This is not to say that battery-powered power tools are the most convenient. If you take a tool for professional work, then the battery option may be a good choice. All costs and inconveniences associated with using the battery are compensated by the technical capabilities of the screwdriver.

The most important disadvantages:

- Batteries lose their charge quickly at low temperatures. It is also impossible to store in the sun or near open sources of fire.

- Batteries last for a couple of years of intensive use. If you have to work with a screwdriver far from the 220 V network, you will have to buy additional batteries.

In addition, battery-powered screwdrivers are afraid of moisture and water condensate. Many models use electronic speed controllers. If the tool has been stored in the cold for a long time (even without a battery) and was moved to a warm room (car interior), then the water condensation that has fallen out can cause a short circuit and even a fire.

The tool on batteries is noticeably heavier than network models with similar characteristics.

As practice shows, when falling on the floor, the screwdriver most often hits the surface with the battery. The tool will withstand a single fall, but if the screwdriver falls off the roof or stairs a couple of times, the battery can be hopelessly damaged.

When is a cordless drill best suited?

Battery-powered power tools, with all the shortcomings, remain the most popular version. If a tool is purchased for a home workshop, it is almost always the battery version.

Sometimes it's just conventional wisdom, but a cordless screwdriver is indeed more suitable for household chores than a mains one. True, we are talking about well-known brands with high-quality electric motors and gearboxes.

Important! In addition, when choosing a specific model, you need to carefully study the complete set of a screwdriver. Often such giants as Bocsh or DeWalt supply their tools without batteries.

Article for you: 12 best screwdriver bits.

home renovation

According to statistics, brushes, a hammer, a cordless screwdriver and a saw are considered the most used tools in the process of apartment renovation of any complexity. Therefore, all private teams that undertake the repair of apartments and private houses use the battery version of the screwdriver.

Moreover, battery-powered tools are preferred by everyone who likes to work with their own hands, build and craft around the house, and make furniture on their own. In the case of constant use, the battery version is much more convenient to use.

The gearbox of the cordless tool can be adjusted so that the chuck revolutions will be even less than if you tighten the self-tapping screw with a screwdriver in your hand. At first glance, a trifle, but sometimes this feature helps if you need to wrap a self-tapping screw in a hard-to-reach place.

Summer cottage construction

For work in the summer cottage, a cordless screwdriver really becomes indispensable. Often in the country there is no light at all or it is served only in the evening. It is also useful for the construction of the house itself and buildings on the site.

Today, there are already entire lines of cordless power tools - saws (chain and saber), electric hammers, planes, drills, with which you can perform any joinery and carpentry work. There are cases when craftsmen, for the purpose of advertising, erected log cabins using only a battery tool. Moreover, washing down into the bowl was carried out with chain saws with a power of 300-400 watts.

Many craftsmen purchase several powerful 18V or 24V lithium-ion universal batteries and use them for their entire fleet of tools, including cordless screwdrivers. More and more manufacturing companies are producing universal batteries that can be used on all power tools of a particular brand.

That is, the purchase of a battery option becomes even more profitable if most of the home arsenal is battery-powered. Moreover, modern lithium-ion ones with built-in protection are able to work in conditions of intensive use for at least 5 years, and the tools themselves - up to 10 years.

Non-standard situations

Battery-powered screwdrivers often become the basis for all sorts of DIY and useful devices that have no obvious relation to tightening self-tapping screws. The first and easiest option is to use a cordless hole puncher. Moreover, both for ice fishing and for the installation of supports in the construction of fences.

A screwdriver with a mixing nozzle mixes wallpaper glue, water-based paint, and mixtures for self-leveling floors. At the same time, network models are clearly not suitable for such work due to the small torque.

If you install a tap in the chuck of a cordless screwdriver, then the tool can be used for cutting internal threads. In a similar way, external threads are cut on studs with a diameter of up to 8 mm and a length of up to 20 cm. To do this, the workpiece is inserted into the chuck, and the mandrel with the die is fixed in a vice. It is clear that the part of the workpiece clamped in the chuck will have to be cut off.

Battery-powered tools are often used as a drive for manual car winches. True, for this you have to put a pair of pulleys and a belt drive.

There is even a cordless screwdriver attachment that can be used to cut holes in metal tiles. Moreover, the sheet firmware occurs without damage to the protective film and paintwork. Bulgarian or with a jigsaw, it is almost impossible to make a cut as accurately as with a cordless screwdriver.

In what situations is a corded screwdriver best suited

A 220 V power tool is often purchased for specific jobs. It is cheaper for the contractor to buy a few simple corded screwdrivers that will be used for cladding drywall walls in new-build apartments than to purchase more expensive and difficult to repair battery tools.

Home use network tool

Mains powered models will cost less than the battery version. Moreover, for the home, a corded screwdriver is much more practical. Usually the owner, after 2-3 days of intensive testing of the power tool, sends it to the workshop shelf. From time to time, usually no more than a couple of times a month, a screwdriver is taken out to wrap or unscrew a screw. After that, he is sent back to the shelf, where he can lie for six months or a year until the next case.

If the tool were on batteries, then before wrapping one or two self-tapping screws, you would have to charge the battery for at least an hour. In addition, the constant deep discharge of batteries dramatically reduces their life. Therefore, if there are no homemade lovers in the house, then the network option will be a more suitable solution than the battery one.

Screwdriver in the garage and workshop

Network tools work great where you need to tighten a huge amount of fasteners. If furniture is assembled in the workshop, simple drilling of holes of small diameter is performed, then it is easier to do this with a network model.

If you engage in individual repair of household appliances in the garage, then again, the network option will be more convenient to use, since it does not have a heavy appendage in the form of a battery.

The network tool is convenient:

- Collect containers. For example, wooden boxes, plywood boxes for postal parcels. All work is done in one place, usually on a carpentry workbench.

- Sew lining with a rail or clapboard on the walls inside the room. Each bar takes at least two self-tapping screws; there can be up to a hundred attachment points per meter of length.

- Sewing fiberboard or OSB boards on the floor for future parquet or laminate. You have to tighten a huge number of fasteners, so even a low-powered network tool will be enough to work.

The battery version is too heavy for the hands. In addition, a powerful engine and a large torque on the cartridge hit the wrist pretty hard. If you wrap a dozen or two self-tapping screws with a cordless screwdriver, then there will be no discomfort from a strongly jerking tool. But if you need to wrap several hundred screws, then the hand will hurt after half an hour of work.

The only exceptions are car repairs and furniture assembly. This type of activity requires constant movement, so the power cord will cause a lot of inconvenience.

Results

Choosing which is better: a cordless or corded tool, without having practical experience, is quite difficult. If you buy a tool for constant use, perhaps the battery option will be a better solution. In other cases, you can use a mains power tool for the home.

Usually the brand of the tool is not critical, since almost all hand-held power tools are made in China. An exception may be mains and battery models made in Taiwan or Malaysia. This equipment may be of higher quality, but its design is not always suitable for a European user.

Tell us about your experience with screwdrivers. What schemes do you think look more convenient for a home workshop? Bookmark the article and share it on social networks.