In order to choose the right hand tool, you need to have experience with it, at least short, but versatile. Choosing a good hammer is simple, it only takes a week to work with the tool to understand what a professional quality hammer should be.

The content of the article:

- How and which hammer to choose

-

The best locksmith hammers

- Solid forged Krafttool hammer

- German metalwork hammer GROSS 10400

- Middleweight - Stanley 051908

-

The best straightening hammers

- A good tool for thin straightening - KING TONY 7842-28

- MasterDiamond

- Model JTC2530

-

The best hammers for a roofer

- Third place - Zubr 20203

- Second place - KRAFTOOL 20181

- First place - Stayer ProStrike 20205

-

The best hammers for a bricklayer

- Third place - stonemason's tool Startul ST2008

- Second place - ZUBR 20155-400 best hammer in the light category

- First place - middle hammer NEO TOOLS 25-105

-

The best carpentry hammers

- Third place - FISKARS hammers 20oz/13.5”

- Second place - carpentry tool Stanley FMHT1-51276

- First place - TOP TOOLS 02A205

How and which hammer to choose

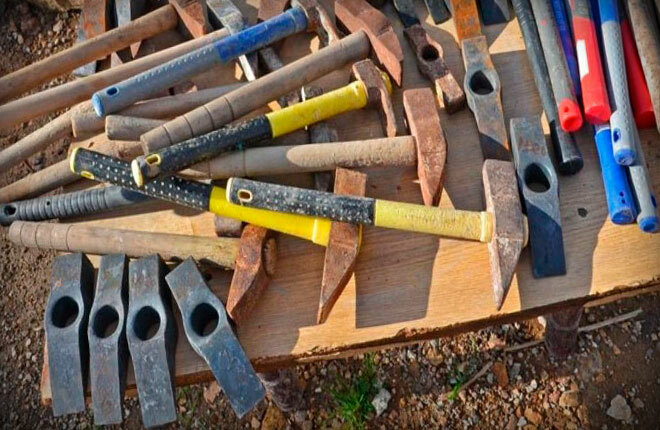

Long gone are the days when there was one hammer in the house for all occasions. With one tool they hammered nails and pricked bricks. In the workshop of a modern homeowner, at least 2 types should be present - for a locksmith and for carpentry or joinery work. Although in general the number of models is greater, however, they are not always present in the house.

Most often used by professional builders and locksmiths:

- For straightening metal, for example, for car bodies, fence sheathing, repair of metal containers.

- In roofing works - when laying the roof, for stuffing battens and counter battens.

- For work on laying brick or block walls.

All this is a specialized tool and it is always present in the ranking of the best hammers. Without them, nowhere. You can also remember a universal hammer, usually heavy - up to 800 g in weight. It was mainly used for repairs, where you need to hit hard, or as a substitute for a sledgehammer. All operations can be performed with such hammers, however, the quality will greatly depend on the skills of handling the tool.

The best locksmith hammers

This is a complete percussion instrument. You have to hit with a metal hammer more often and harder than with any other models. Therefore, when choosing, you need to consider:

- Striker weight (front) in grams. For a locksmith, 500 grams is enough. But for strong hands and unforeseen circumstances, you can choose a heavier metalwork hammer - up to 900 g.

- Balance or grip is largely determined by the shape of the handle.

- The presence of heat treatment of the impact surface.

- How to mount the striker on the handle.

Everything else - color, design, tool manufacturer can be ignored.

We bring to your attention the article: The best hammer axes.

Solid forged Krafttool hammer

Third place for model 20070-05. All-metal forged metal construction with a rubber grip on the handle.

Characteristics:

- Weight 900 g. Of these, the impact head accounts for 500 g.

- The shape of the striker is close to optimal with beveled vertical edges and a blunt wedge.

- The grip is covered with oil-resistant rubber with additional notches to prevent slipping.

In general, the hammer looks like a full-fledged working tool for an automotive mechanic.

It's too heavy for home use. Plus, the use of a metal handle and oil-resistant rubber make the hammer reliable, but not too comfortable for small plumbing jobs.

German metalwork hammer GROSS 10400

Sure first place. The design of the locksmith's hammer is better than the previous model.

Main characteristics:

- The weight of the striker without a handle is 300 g, the total weight is 0.769 kg.

- All-metal forged construction, rubber-grip handle is orthopedic shaped for improved grip.

- The impact surface of the striker is hardened to a hardness of 52 HRC.

For a locksmith's hammer, the last point is more of a disadvantage than an advantage. A hardness of 52 units means that with a strong impact, a metal chip will occur, and it is not known where the fragment will fly. Therefore, the best metalwork hammers should have moderate hardness, up to 40-45 HRC.

In general, the hammer can be considered successful due to the light weight of the striker. This means that it will be easier to dose the impact force. The rating is spoiled by a metal handle and an overheated striker.

Middleweight - Stanley 051908

First place - a typical American hammer for plumbing work around the house. Expressive design and practical shape of the handle. The weight of the impact striker is 500 g, the total weight is 700 g.

In this model, unlike most metalwork hammers, the handle is made of composite, and this is very important:

- Approximately half as much return to the hand upon impact.

- The balance changes, the main weight falls on the end of the tool, which means that it will be easier to work, the impact accuracy is higher.

The shape of the striker is perfect, the design provides for reinforcement of the handle on the mounting hole. This is a sign of a good locksmith's hammer that will last a long time, and most importantly - such a tool is safer to use than all-metal constructions.

The best straightening hammers

A good tool for straightening metal should not be heavy; a handle with a profiled surface must be used. The main difference between a good straightening hammer and a conventional tool is that the worker by the handle must feel and correctly assess the position of the striker relative to the workpiece surfaces.

Unlike a carpenter's or metalworker's hammer, you need to hit lightly with a straightening hammer, the main thing is to hit the right place exactly and dose the blow correctly.

A good tool for thin straightening - KING TONY 7842-28

The tool does not impress with modern design. In fact, this is a good, if not the best form for straightening thin-walled metal at the final stage.

KING TONY is a rattle hammer. The weight of the striker is 165 g, it is hollow from the inside, the body is machined from aluminum. Inside is a shotgun charge. This is a good solution if you need to straighten metal that springs under impact.

Durable polyurethane plugs provide contact with the treated surface. The lacquered wooden handle provides good grip. Even if the coating wears off, the wood provides grip on the skin of the palms.

MasterDiamond

This is a heavy version of the straightening hammer for initial leveling of the surface and processing of thick plate blanks. The weight of the steel head is 450 g. The tool differs in good quality of metal of a striker. In addition to the traditional straightening of car bodies, a hammer can be used as a common household tool.

It is worth noting a good layout:

- The optimal weight of the head is 450 g, while the shape of the striker makes it possible to work with any materials without the risk of splitting or breaking the surface.

- The handle is made of fiberglass, but its shape is optimized for a good grip with the palm, even in a short grip, even in a long one.

The only negative is that for straightening you will need to additionally buy a set of overlays for the spherical head of the striker. They are not included with the hammer.

Model JTC2530

The classic version of a good straightening hammer. Used for pulling out small deformations and bends on thin metal. The main purpose is body repair, but the straightener provides good quality for extracting small defects, so any thin-walled metal can be repaired with it. For example, a corrugated board bent by the wind on the fence of a house.

The 300mm wooden handle provides a good swing, while the relatively wide heel with a diameter of 41mm provides even impact force. It is clear that the striker is not hardened, all good straightening nozzles have a soft surface, so it will not work to chop a brick or hammer nails.

The good quality of the hammer is confirmed by a lifetime warranty from the manufacturer.

The best hammers for a roofer

The tool for roofing works differs from the usual plumbing or carpentry. Oddly enough, when laying a roof on the roof of a house, the most common operation is carpentry - you need to drive small and large nails into the rafters, battens and counter-battens. But since it takes place on the roof, you have to work with one hand, the second roofer most often holds on to the stairs.

At the same time, you still need to somehow hold the nail, otherwise you won’t be able to hit it with a hammer correctly. Therefore, a specialized roofing tool differs from a conventional one:

- Less weight and handle length.

- There is a spike or awl with which you can make a hole in a sheet of metal or simply hook the tool on the rail to temporarily free your hand.

- Many models have a nail holder.

This is such a groove on the heel of the striker, where you can insert a nail with one hand, and then hammer it into a tree with a strong blow (shallow). That is, all operations with a roofing hammer can be performed with almost one hand.

Third place - Zubr 20203

The manufacturing company classifies this tool as a professional one. The design is quite attractive, although simple in form. Hammer head weighing 600 g is made of forged metal, fiberglass handle with additional lining of silicone.

The length of the handle is 270 mm, this is enough to drive in all nails up to and including the “weave”. Due to the use of fiberglass, the tool turned out to be light, so the hand practically does not get tired.

The only minus of the ZUBR is the place where the handle is attached to the striker. It has no reinforcement, therefore, if a novice roofer regularly misses and hits the crate not with a head, but with a handle, then the hammer mount will quickly fall apart.

This model can be considered more successful due to the well-thought-out instrument scheme. The axis of the striker is deflected at a small angle in the direction away from the worker. It is much more convenient to drive nails on the roof with such a tool in conditions when the worker is forced to stand on the stairs or work on the roof with a large slope angle.

Second place - KRAFTOOL 20181

The design and overall construction is one of the most successful for a roofing hammer. The tool is made by forging from two parts - the handle and the striker. Drummer weight - 600 g, total weight - 800 g. The impact part was carburized and hardened, after which it was forged welded with a handle.

This is one of the few models of a specialized tool, in which the handle is made of chrome vanadium steel. The place of grip is tightened with dense silicone rubber. The color is chosen well, if you drop such a hammer from the roof into the grass, you won’t have to look for a long time. The design of the handle itself makes it possible to intercept the tool with one hand. For example, take the hammer by the striker, place the nail into the groove of the holder with the other hand, then simply lower the hand with the hammer down and let it slide in the palm of your hand to the rubberized lining on the handle.

The striker has a special groove and a magnet to hold the nail on the first hit on wood or roofing. But the main advantage is that the axis of the striker is deflected by a small angle on the worker. This makes work easier if, for example, you have to hammer nails while sitting on your knees or squatting.

The only disadvantage of KRAFTOOL 20181 is its high price, for 2400-2500 rubles. you can buy a few hammers easier. Although the service life of KRAFTOOL 20181 will be rather big, 20-25 years, no less.

First place - Stayer ProStrike 20205

It is relatively inexpensive, but it is completely all-metal, forged from tool steel. That is, in terms of strength, such a tool is only slightly inferior to heavy hammers for masons. The weight of the striker is 600 g, the total weight is up to 1000 g. It is somewhat heavier than models with wooden and plastic handles, but its resource is about three times higher. And if it is really made of tool steel, as the manufacturing company declares, then the tool has every reason to outlive its owners.

Stayer ProStrike Benefits:

- Well balanced, the center of gravity is behind the head, so there will be no strong recoil in the hand, even if you hit metal or stone.

- The convenient handle with protrusions under fingers of a palm. More comfortable grip, less miss on the nail.

- Correct design of the nail puller and spades.

The shape of the point and nail puller is large enough to pull out the most “weave”, but at the same time does not disturb the balance of the tool.

For many roofing models, especially those made in China, the nail puller is made very large, forgetting that that the lever arm is reduced, and only a very physically strong person can use the device roofer.

The best hammers for a bricklayer

There are 2 types of tools for working with stone. Firstly, in order to prick a but, a natural stone of hard rocks, heavy hammers with a striker weighing up to 1.5 kg are used. For such a tool, a strong handle is selected, up to 60 cm long. The top of the striker and the impact surface must be hardened to a hardness of 50-55 HRC. The rest should be viscous and soft, otherwise, with strong blows, the hammer can be easily split.

Secondly, for cutting ordinary bricks, a relatively light hammer with a sharp and hardened head and a short handle is used. The weight of the striker is up to 0.7-1 kg. This tool does not chop, but chip off the material in small pieces.

Third place - stonemason's tool Startul ST2008

A good option for manual pruning of bricks. Startul ST2008 differs from most Chinese and German models in manufacturing technology. The hammer is cut from one continuous forging of metal. This makes it strong and durable.

At competitors, in order to save metal, the blank is pre-cast, released, and then only subjected to forging. As a result, the hammer looks spectacular, but due to internal casting defects, such hammers break and crack more often.

Design features:

- Optimized heel and stabbing head shape.

- The handle is made flat. It is based on a steel rod in a fiberglass sheath with a rubberized lining.

In addition, the hammer is well balanced, the center of gravity is shifted to the front, which is an important condition for the correct distribution of force when hitting a stone.

Second place - ZUBR 20155-400 best hammer in the light category

By design, this is a classic tool of good quality, made according to the scheme of the Soviet construction hammer. The model is composite - the striker itself, weighing only 400 g, is mounted on a fiberglass handle.

This is a good decision:

- The composite structure dampens the vibrations that appear when a hammer strikes a stone.

- The handle is made with a reverse wedge. That is, on the front there is a thickening that will not allow the striker to break off the handle even with the strongest blow.

- Consistent forging quality. Single head is easier to forge, good working depth and hardening.

The only negative is that for such a scheme, a good handle must be made of oak or ash. Fiberglass or fiberglass wears out faster.

First place - middle hammer NEO TOOLS 25-105

The weight of the head is only 600 g, so the tool works well only on chipping with metal quality, moderate hardening of the chisel. A good mason's hammer should not give a strong rebound on impact, so the cutting edge should not be overheated.

The handle with a rubberized pad, you can not be afraid of swelling if you forget the tool at a construction site in the rain. Convenient to store on the waist belt while working.

A good option for a construction hammer for every day.

The best carpentry hammers

For a joiner or carpenter, the weight of the tool is not as important as a good butt handle. Typically, a carpenter's hammer is used either for tamping (downsetting) wooden parts, or in order to hammer a nail. Therefore, the best hammers have a "shoe" striker configuration. It is believed that with this shape of the tip, even if you miss the cap, the nail does not bend, but simply ricochets along the round heel.

Third place - FISKARS hammers 20oz/13.5”

Attractive tool design with stylish orthopedic handle (390 mm). 570 g striker made of forged steel, which increases the life of the carpenter's hammer. Total weight up to 1000 g.

If you hammer a nail-weave with it, then the tool is too heavy, ideally, for carpentry, you need a drummer of 300-450 g, and the handle should be twice as light. Here, only half a kilo is allocated to the handle. Moreover, a metal handle is not needed for carpentry work, wood is not a stone, it softens the shock load. Only an experienced carpenter or carpenter can strike correctly.

Second place - carpentry tool Stanley FMHT1-51276

One of those tools that are commonly called indestructible. Made of all-metal with a plastic overlay in the grip area. It is valued not for the quality of the metal (and it is very high), not for the shape and weight of the striker (500 g), but for the design of the nail puller. Paradoxically, this is the best carpenter's hammer you can think of for pulling fasteners and disassembling wooden packaging.

Hammering nails is not so convenient for them, many users note the presence of strong vibrations on the handle when hitting a hard surface.

First place - TOP TOOLS 02A205

Medium weight hammer. The shape of the impact striker is rectangular, without any fashionable "boot" heels. This makes the carpenter's hammer safer to use. The weight of the striker is 550 g, which is heavier than that of all-metal competitors.

The main feature of this model is a flat wooden handle 32 cm long, without any rubber or silicone pads. Thanks to the successful shape of the handle, the position of the hammer in the hand is much better controlled if the manufacturing company sealed the handle in a silicone shell.

The balance of a carpenter's hammer with a wooden handle and a heavier striker is shifted to the end of the tool. This means that less force is required to strike, and the hand will work in more comfortable conditions.

The only negative of the model is that the developers sealed the place where the handle was attached to the striker in epoxy. For any hammer, the use of epoxy does not make sense, the resin will fly off after a few hours of work, but the tool will still remain operational.

The best hammer can be unpretentious in appearance, as long as it fits well in the hand, is easy to control when struck, and is reliable. If you have to repair the handle or striker more often than work, then it is better to get rid of such a tool immediately.

Tell us about your choice, which hammer model, in your opinion, can be considered the most successful. Which model would you choose for your home workshop?