Almost 90% of connections, both amateur and professional designs, are made electric welding and gas burners. Until recently, the quality of welding directly depended on the experience and skills of the electric and gas welder. Today, a good welding inverter can be mastered in a few hours of practice, and the quality of the seam will be satisfactory, since the device “forgives” many mistakes in working with metal.

The content of the article:

-

What to look for when choosing

- Design features to look out for

- Manufacturers of welding inverters

-

Rating of the best budget welding inverters

- SPECIAL IMMA160PN-3

- Cedar MMA-200

- ZUBR Compact SA-190K

- Wert SWI 190

- FUBAG IR200

-

Rating of the best high-quality and reliable welding inverters

- WESTER MMA VRD 200

- Solaris MULTIMIG-224

- Aurora OVERMAN 180

- FUBAG IQ200

- BLUEWELD Starmig 210 Dual Synergic

-

Rating of the best universal welding inverters

- Cedar MultiARC -2000

- BRIMA TIG200P AC/DC

- Svarog TECH ARC 205 B (Z203)

- BLUEWELD Prestige 186 PRO

- Quattro Elementi B 225

What to look for when choosing

Usually related to welding machines inverter type somewhat idealized. It is believed that any inverter welding works without problems even at low voltage in the network, while providing a high-quality arc and good penetration of the metal. In fact, only the best welding inverters are capable of this. At the same time, there are many models on the market that cause owners more trouble than they really help in their work. It happens that such devices even fall into the ranking of the best welding inverters.

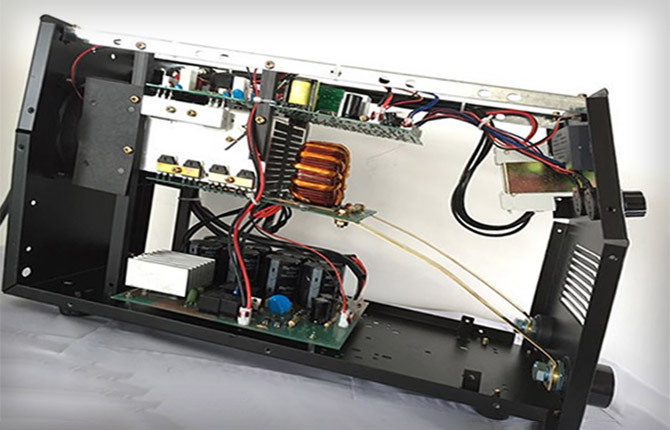

A modern welder is a complex technique. Most of the inverter consists of electronic components, so the work is largely dependent on the quality of parts, the level of assembly and commissioning. Moreover, under the guise of a branded device, you can find a homemade or handicraft welder.

Therefore, when choosing a welding inverter, you need to pay attention to:

- Type - professional, household or universal.

- Maximum welding current and range of its regulation.

- The presence of service functions, such as anti-sticking or automatic retention of the welding arc.

- manufacturer and build quality.

- Existence of protection against an overheat.

- The maximum time of continuous welding by the machine.

In advertising, you can find a lot of interesting opportunities, but most often these are marketing techniques aimed at raising the rating of a welding inverter of a certain model or brand.

Usually parameters such as maximum continuous operation time, as well as additional features such as hot start or automatic selection of welding current, are necessarily present in all ratings of the best welding inverters. In fact, neither the maximum welding time nor the “hot start” can be checked at the time of purchase of the inverter.

Moreover, all of them have a certain meaning only for an amateur mastering the welding process. For a professional, continuous welding time will always be limited, and it is selected not by the capabilities of the welding machine, but by the working conditions.

Indirectly, the brand or country of assembly can speak about the quality of the device. German inverters assembled in China have long become standard. They are inexpensive, and the attitude towards them is appropriate. But the original devices from Japan or Italy enjoy authority even at a high price for the inverter.

This will come in handy!Welding kits - what is included in the package, how to choose a good one.

Design features to look out for

Before the advent of inverter type machines, one of the characteristics indicating good quality was the heavy weight of welding. First of all, because of the massive transformer iron and thick winding wire.

For a modern inverter, weight also matters. The large but light body of the welder indicates an incorrect layout. The device overheats a lot, so we had to leave more free space for high-quality cooling of parts.

The device should not be small or too light. The small body and light weight indicate that the manufacturer has saved well on the margin of safety (reliability) or tightly packed all the parts in a small volume.

The case is metal with a powder coating, the front and back sides can be plastic. None of the welders install the inverter near the metal welding site. Therefore, you can not be afraid that flying splashes and drops will melt the outer lining.

The most important characteristic is the welding current. Budget and simple amateur models usually have a range from 20 A to 170 A. In fact, amateur class inverters are not brewed with a current of 150 A. Therefore, the maximum current can be ignored. But the minimum current is important, since the welding inverter is most often used for welding parts with a thickness of 1.5-2 mm, sometimes with a current of up to 10-15 A.

For a professional class, the regulation range should be from 10A to 200A. Usually, regulation is performed manually, but there are models with automatic increase and decrease in welding current.

Another characteristic is the electrical power of the inverter. Usually it is indicated in the range of 3.5-7 kilowatts. In practice, the device develops the declared power level only in a cold state at the time of launch. In this sense, state employees are, as it were, more honest, they are not designed for long-term work, and they give out the declared 4-5 kW for 30-90 seconds, which are required for a beginner to weld. For professionals and generalists, power usually drops in all models, no matter how well they are made.

Manufacturers of welding inverters

All electronic components used in inverters are manufactured in Southeast Asia and the European Union. Therefore, manufacturers are usually divided into 3 groups:

- Inverters manufactured entirely in the EU using original parts.

- Welding machines, inverters manufactured in China under a Chinese brand. As a rule, these are large corporations that have an interest in maintaining the image of their brand.

- Welders, the design of which was developed in Germany - Italy, but produced at the enterprises of the PRC and the Russian Federation.

This does not mean that domestic inverters are of poor quality. They are cheaper, easier to repair, as a rule, all the characteristics correspond to the declared ones. Welders made in the European Union are expensive and work reliably.

We should also mention welding inverters made in Japan. A real dream of any welder. You can buy any model. Japanese inverters are not always rated for 220V, usually 110V and 127V. But they are distinguished by high survivability and good arc quality. Many "Japanese" do not even have additional features.

When choosing a model, you need to pay attention to the presence of a quality certificate from the manufacturer. The design of the inverter allows you to produce them even in artisanal conditions, so you can easily buy a device in gray or black assembly.

This will come in handy! welding machine for polypropylene And polyethylene pipes

Rating of the best budget welding inverters

This category includes low-cost MMA machines designed exclusively for manual welding with a conventional electrode. They are mainly designed for amateurs who need an inexpensive device to brew a broken assembly or part a couple of times a year. Approximately 70% of the volume of purchased welders for the home workshop falls on MMA machines.

SPECIAL IMMA160PN-3

The most inexpensive option for a welding inverter with a relatively satisfactory quality of the device. The price of a welder is 3400 rubles. This does not mean that the device is of poor quality. It's just that its capabilities are below standard.

Characteristics of the welding inverter:

- Power 4.9 kW, welding current 20-160 A.

- The maximum electrode diameter is up to 4 mm.

- Weight 3 kg, dimensions - 34x22x14 cm.

- There is a standard set of auxiliary functions: "anti-sticking", "afterburner" and "hot start".

Useful time is only 30%. This means that out of 10 minutes of working time, only 3 minutes can be cooked with maximum power. During the rest of the time, the inverter will cool down.

This is a classic version of a budget device for those who need to make minor repairs to home belongings, household appliances or furniture from time to time. In general, the device is praised for its low price and simple design. The manufacturer provides a 2-year warranty.

Cedar MMA-200

One of the most massive Chinese inverters. Well-known brand hand tool welder manufactured in China. Very simple in design, case material - stamped steel, front panel - Bakelite and heat-resistant polypropylene. Everything points to the fact that the inverters are manufactured on industrial equipment, and not just assembled with a screwdriver in the basement.

Main characteristics:

- Power 5.2 kW.

- Electrode diameter from 2 mm (even 1.5 mm) to 4 mm, it is possible to work with 5 mm for a short time.

- Welding current from 20 A to 200 A. According to reviews, Cedar easily holds even more, up to 220 A, but it won’t work for them to cook even for half an hour.

- Duration of work - 60%, that is, 15 minutes of welding, 10 minutes of rest. Option for giving.

- Dimensions 32x12x20 cm, weight - 5 kg.

There are functions "anti-sticking" and "hot start". On the front panel there are couplings for fastening welding cables and a current regulator knob. Hot air is blown out by a fan from the back.

ZUBR Compact SA-190K

Produced in China, the quality of the welding inverter is quite high. Good inexpensive machine. The price of a welder is on average 6000 rubles.

Model Features:

- The high idle voltage is 65 V, which means that there will be no problems with the start.

- There are standard functions "hot start", "afterburner", anti-sticking.

- Maximum power 5.4 kW.

- The diameter of the electrodes is 1.6 - 4 mm.

- Maximum current 190 A.

In practice, the Zubr-Compact is often praised for its ability to withstand overcurrent or welding times. Given the massive use of aluminum winding wires, it is better not to experiment with overloads. In general, a fairly easy-to-use and practical Chinese-made welding inverter.

The manufacturer gives a 5-year warranty.

Wert SWI 190

A popular, lightweight device of a budget class. The weight of the welding inverter is only 2.4 kg. Passport power - 3.7 kW, maximum current - 190 A, but in reality you can only count on 3.5 kW and 170 A, respectively.

According to reviews Wert SWI 190 confidently pulls an electrode with a diameter of 4 mm. So with its help you can easily eliminate the leak on the pipe, or weld a massive bracket, any part with a seam thickness of 4 mm.

Inverters are massively used by repair teams serving water pipes and heat communications inside high-rise buildings. The rugged die-cast metal housing withstands the most brutal handling of the inverter, and the recessed panel control with two sleeves for welding cables and the current adjustment knob remains intact even if the welder falls on concrete floor.

FUBAG IR200

One of the most popular home models of the welding inverter. If someone in a conversation recommends buying a FUBUG for a workshop, then they usually mean this particular model of an MMA welder. The cost of FUBAG IR200 is slightly higher than the level of the budget class. The average price is 8600 rubles.

The design of the FUBAG IR200 was developed in Germany, but production is deployed in China. Therefore, in the market, in addition to the classic models of the welding inverter, you can find clones that, in appearance and in name, strongly resemble the classics, FUBAG IR200.

The main characteristics of the inverter:

- Power - 8.6 kW.

- Operating current from 10 A to 200 A, electrode diameter 1.6-5 mm.

- The minimum mains voltage is 150 V.

- The design provides for three standard auxiliary functions - "hot start", "anti-sticking" and "arc afterburner". Useful time is only 40%.

In the reviews, you can often find complaints that the welding inverter cooks very high quality, stably with a soft arc, but it is clearly not suitable for long-term operation.

Rating of the best high-quality and reliable welding inverters

This category includes models that have earned a reputation for being the best in terms of results of practical use according to 3 criteria:

- Trouble-free and reliable welding operation.

- Comfortable in using.

- High build quality.

The rating includes all inverter options, both conventional for manual welding and for general use, regardless of the price and manufacturer of welding equipment.

WESTER MMA VRD 200

The price of a welder is 10 thousand rubles. rub. In general, the device is worth its money. This is a fairly complex inverter. The built-in control microcontroller is programmed for intelligent performance control. For example, the controller will lower the open circuit voltage if the device has been turned on idle for a long time.

Characteristics:

- Idle voltage (XX) - 65 V. This is enough for confident ignition of the arc even on an oxidized metal surface.

- Electrode diameter 1.6 - 5 mm. In theory, it can cook with electrodes up to 6 mm.

- Useful time - 70%.

- Weight - 6.4 kg.

- Welding current from 10 to 200 amperes.

- Power 8.8 kW.

The body is stamped from thin metal, the sides are covered with plastic overlays. According to its design, the inverter should not allow dust and moisture to pass inside. But it is not recommended to work WESTER MMA VRD 200 in extreme weather conditions (snowfall or fog), as the fan will still draw in a small amount of atmospheric moisture.

Most users rate the welding inverter as a real hard worker, reliable and hardy.

A relatively good inverter can be recommended for those who are just learning the art of welding.

Solaris MULTIMIG-224

Expensive inverter, the minimum price for today is at least 22 thousand rubles. rub. The welder is able to work both in manual MMA welding mode and in semi-automatic welding mode (MIG / MAG) in a protective environment of carbon dioxide. If necessary, you can cook metal simply with points, without gas, with one wire. This mode is called FLUX.

Solaris is the apparatus that in a professional environment is called blue welding. The inverter is very popular not only because of the large number of functions and 4 different built-in welding systems. Solaris earned a high rating due to the reliable operation of all systems.

Design features:

- Reliable, albeit outdated, IGBT brand transistor switches are installed in the power control boards. They are hardy, easily withstand current overload and work in off-design modes.

- The system uses double protection against overload and overheating.

In general, the device turned out to be reliable, but heavy. Inverter power - 6.5 kW, with a mass of 14.5 kg. Most budget welding inverters have about the same power, but they weigh 3-4 times less. This suggests that the design uses full-fledged copper wires, and not aluminum ersatz.

Supply voltage 160-220 V, maximum current - 220 A. Welding electrode diameter 4 mm, for wire 1.0 mm.

Aurora OVERMAN 180

This is a MIG / MAG type welding inverter, with relatively low power, as for a professional, only 6.6 kW. The main function of the Aurora is to work in semi-automatic mode, welding with metal wire in a protective gas environment. Inside the housing there is a gas reducer with heating, as well as a wire feed mechanism. Therefore, the weight of the inverter turned out to be large - 15 kg. Current at maximum - 175 A.

The design was developed in Russia, but the production of the welder is deployed in China.

There are 3 adjustment knobs on the panel. You can reset the minimum current, gas-wire flow and inductance. That is, you can manually select the optimal welding mode for any material.

A feature of Aurora is the use of special transistors (assemblies) from Toshiba. It is believed that Aurora's microelement base is one of the most reliable.

The only disadvantage of Aurora is the high price of the inverter, today the welding machine costs from 30 thousand rubles. rub.

FUBAG IQ200

This model can be called the best option in terms of price-quality ratio. A good choice for a garage. The welding inverter of the MMA system for manual welding is one of the few devices that are noted for good welding quality, the absence of unnecessary and useless functions. The inverter is often used as mobile equipment for welding work of various levels of complexity.

Features FUBAG IQ200:

- Power - 7.7 kW.

- The inverter conversion system is assembled on IGBT transistors. The welding machine can work up to 40% of the working time at a current of 200 A.

- The maximum current is 220 A.

- The optimal electrode diameter is 5.0 mm.

- Weight 5.2 kg.

The device can work even with a supply voltage of only 150 V. The price of a welder is 7800 rubles.

BLUEWELD Starmig 210 Dual Synergic

One of the most popular welding inverters used in the professional repair of cars, refrigerators, transport equipment. It can be used for welding aluminum, stainless steel, carbon steels of all grades.

This is a full-fledged MIG-MAG semi-automatic welding machine, it can work both on a conventional copper-plated wire with a thickness of 0.8-1 mm, and using a special wire electrode with flux coated.

Characteristics:

- Power - 5 kW.

- Welding current up to 200 A.

- Weight - 11.5 kg.

The welding inverter is equipped with an electronic processor. You can select 17 different programs with template modes for different materials. According to the reviews of the masters, it is comfortable to work as a welder, the load on the hands is minimal, so you can cook metal for at least a whole day.

But the main feature of the device is the “indestructible” design. Many welder owners note that the Italian inverter can withstand the load where Chinese and German machines burn out in a few hours.

Rating of the best universal welding inverters

This review includes the best universal devices with the minimum necessary functionality for different operating modes.

Cedar MultiARC -2000

Universal inverter for welding with a consumable electrode or a tungsten rod torch in a protective argon atmosphere. Initially, the device was designed for heavy loads in semi-industrial and industrial production. Developed by a Russian manufacturer, produced in China.

It is possible to perform welding in MMA and LIFT TIG modes In addition to the standard set, afterburner, hot start, Kedr has a VRD function. With its help, you can achieve a very high quality of welding, work for a long time at maximum current, regardless of the direction and position of the seam.

Characteristics:

- The electrical power of the inverter is 8.2 kW.

- Welding current regulation range 10-200 A.

- The recommended electrode diameter is from 2 to 4 mm.

You can cook metal for a long time. The manufacturing company recommends limiting the operating time at maximum power to 20 minutes, but in practice Cedar is able to work longer without losing the quality of the seam.

The price of the model is 42,000 rubles.

BRIMA TIG200P AC/DC

One of the best models of welding inverters of the German brand of the same name, which produces professional electric tools. In addition, it is also the heaviest version of the welder. Its weight is more than 25 kg, although the power is only 5 kW.

A feature of BRIMA TIG200P AC/DC is the ability to weld metal with both alternating and direct current, which is especially valuable when working with stainless steels, cast iron, aluminum alloys.

All elements and components in inverters are of high quality, there are practically no problems with the operation of the welder. The only difficulty is mastering the settings of the inverter, and he has a lot of them. There are already 9 pieces of welding parameters control knobs on the front panel of the case.

In general, such a device can be used in any workshop, in car repair, in production.

Svarog TECH ARC 205 B (Z203)

Welding machine with two modes of operation - manual MMA welding and argon-arc torch with a tungsten electrode. The developers of the inverter tried to do everything to ensure that the electronics are protected from negative factors. Such as overheating, power surges and the wrong choice of welding scheme.

Basic Features:

- Power - 9 kW, current regulation range - from 10 to 200 A.

- The open circuit voltage is 73 V, which means that the welding arc will start very easily.

- The weight of the apparatus is 8 kg.

- The recommended electrode diameter is 1.5-5.0 mm.

The input circuit of the device is supplemented with a stabilizer, thanks to which it is possible to reduce voltage fluctuations up to 15%. Accordingly, the quality of the weld is improved.

If you work with an inverter in TIG mode with a welding current of 170 amperes, then the welding time can be long. The design of Svarog has a special module. It controls the temperature of electronics, primarily transistors. If even when the fan blows the temperature rises, then the overheating indication will be displayed on the panel, and after 30 seconds the automation will turn off welding.

BLUEWELD Prestige 186 PRO

Universal welding inverter, designed for manual operation with a consumable MMA electrode, as well as in a shielding gas environment with a tungsten tip. You can cook steel, stainless steel, cast iron, certain grades of aluminum alloys.

Italian engineers managed to combine two opposite qualities in one model - high power and compactness of the device. Electric power - 5 kW, current ceiling - 160 amperes. At the same time, the weight of the welding inverter is only 4.7 kg.

BLUEWELD Prestige 186 PRO is assembled in Italy, so the build quality is the highest. The welding inverter is valued for its reliability, both among professionals and amateurs. The only negative is the overpriced price of the device - 40,000 rubles.

Quattro Elementi B 225

A relatively simple welding inverter from the Italian company Quattro. Can be used for TIG welding or used as manual MMA welding. Produced in China.

Characteristics:

- Power 7.8 kW, maximum current up to 225 amperes.

- Operating voltage 170-220 V.

- Recommended electrode diameters are 1.6-5.2 mm.

- There are built-in functions of "anti-sticking", "hot start" and "strengthening of the welding arc".

A feature of the model is the high reliability of the entire inverter path. If you choose a device for long-term work with metal throughout the working day, then the Quattro Elementi B 225 is best suited. The indicator of working time of this model is as much as 80%. That is, you still need to try to burn the welding inverter, since the design provides protection against constant overheating.

The price for this model is only 10 thousand rubles. rub.

Choosing which welding inverter is better is not easy. First of all, you need to understand the tasks for which welding is purchased. The second factor is the quality of the device. You quickly get used to all the features in the process of work, so they are of secondary importance.

This is useful!TOP 12 best soldering irons for pipes: review, photo, pros, cons, price.

Tell us about your device - how did you choose the inverter, and how well did the welder live up to expectations? Bookmark this article so you don't lose it.