Drywall - an indispensable material in the repair. It is used to implement bold design ideas - to make an arch, decorate a niche or other decorative elements. They cut it out, construct anything from it, only the finish remains. There are many recommendations on how to paint drywall correctly. Before starting work with this material, carefully study its characteristics.

The content of the article:

- How to prepare drywall for painting

- What paint to choose for covering drywall

- What tools and materials to prepare

- The technology of applying paint to drywall

How to prepare drywall for painting

Drywall is an economical material that allows designers to realize even incredible renovation ideas. Due to the fact that it is easy to use, to make it, for example, an additional storage cabinet, you do not need a huge amount of tools and accessories. Even a person who first encountered this material will design it.

Among the options for drywall constructions, there are several main ones that are easy to upgrade into something new:

- Cabinets. We are talking not only about ordinary cabinets that are sold in furniture stores, but also about entire dressing rooms (due to the nature of the rooms, not particularly large, but certainly functional). Every woman dreams of a wardrobe, with the help of this material, they make their dream come true even in a small apartment, while spending a relatively small amount.

- Niches. Additional illuminated shelves, plasterboard niches for TV - such interiors will help to competently organize the space in the apartment, create additional comfort.

- Arches. A great option if the use of an interior door is impractical. It is supplemented with niches, creating new storage spaces.

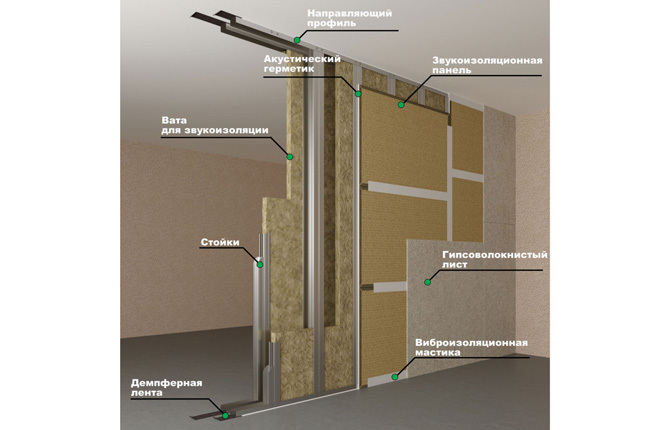

- Partitions. They are popular in one-room apartments, studios, as they are a great way to divide space. When constructing partitions, niches are added, or simply additional storage space, decorated with glass, lighting.

- Communication boxes. When repairing, many are faced with the problem of protruding ventilation, water and gas pipes. They stand out from the interior, attract attention. In this case, the box will be the perfect solution, because it is decorated for decoration.

- Fireplace. It is impossible to install a real fireplace in an apartment, but it is difficult in a private house. A cozy artificial false fireplace is made of drywall, next to which it will be cozy, like with a real one.

- Column. It is decorative and functional. The column itself is supplemented with niches or hidden inside the communication.

As when working with any other materials, there are subtleties, nuances that are studied before starting work. Depending on the choice of the product, where it will be located, choose the material. In almost any specialized hardware store, drywall is found:

- GKL. A simple material that is suitable for normal humidity conditions.

- GKLV. Moisture resistant, used in bathrooms, showers, and other rooms with a high level of humidity.

- GKLO. Flame retardant is used in rooms where there is an increased level of ignition.

- GKLVO. Moisture-resistant drywall. Resistant material at the same time to moisture, fire.

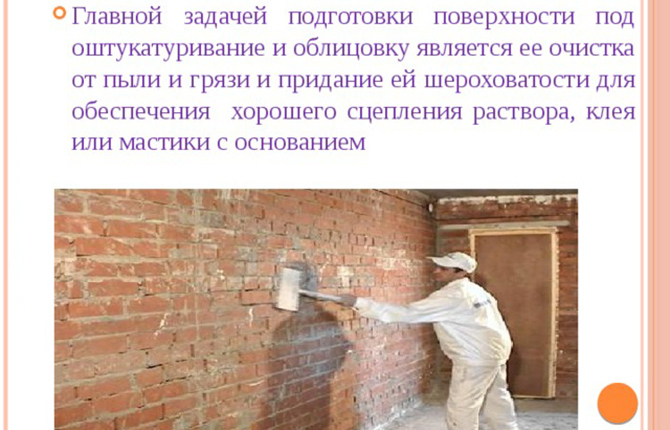

After completing the stages of choosing drywall, designing, they begin to prepare the material before painting. The main goal is to obtain a perfectly even and smooth surface on which the coating will lie well. When preparing drywall for painting, it is necessary to remove excess, clean the surface of excess dust, dirt.

Preparation for painting consists of several stages:

- Wall seam finishing. Using putty, spatulas, smooth the corners, aligning the seams for painting. It is worth paying attention to this stage. Use a special reinforcing tape - it should not stick out, be visible after painting. It is important that before starting work, it is necessary to mix the putty composition, eliminating lumps.

- putty. To properly putty before painting, take a large metal spatula (30-50 cm). If there is doubt about evenness, then 2 layers are applied - this will not affect the quality of the coating, its durability.

- Grinding. Even if visually the coating looks even before painting, they pass with sandpaper or a special grinder. Thus, it will be possible to eliminate even the smallest flaws before painting. The main thing is to use only a fine-grained canvas so as not to damage the putty layer.

- Primer. The last step in preparation before painting. If the primer is a concentrate, then it is diluted according to the instructions, if not, then it is applied to the dried surface in an even layer. Exclude smudges due to uneven absorption of the composition into drywall.

Before painting, attention is paid to cleaning so that excess dust, dirt, and debris do not get into the compositions used. Not all the debris that got in when painting and entrenched in the coating is easy to clean. To remove large inclusions in drywall, you will have to remove a layer, for example, putty, and repaint.

What paint to choose for covering drywall

Before starting painting work, make sure that the layers of the previously applied compositions have dried out. The basis of preparing drywall is to level the surface with putty.

3 groups of putty compositions:

- Starting. Used for the first rough leveling layer of drywall before painting. Dries quickly. Suitable for additional reinforcement of walls, reinforcement of meshes and joint tapes.

- Finishing. This type of putty is applied to a dried starting layer with a thickness of not more than 3 mm.

- Universal. Such putties are used instead of starting and finishing. They both level and complete the preparation of drywall walls for surface painting.

Separation of compositions according to purpose:

- Cement putty. The main ingredient is cement. Because of it, this putty is resistant to temperature extremes, various levels of humidity. They are used for exterior or when finishing drywall in rooms with high humidity - kitchen, bathroom, shower room. The main disadvantage is the difficulty in processing after drying.

- Gypsum putty. It has a rich white color, in addition, one of the main properties of gypsum is plasticity, which makes filling with this material easier than with cement. Gypsum putty perfectly absorbs and releases moisture, which allows you to create an ideal microclimate in the room. One of the advantages is that they are used as a start and finish line. However, it is not suitable for outdoor work due to the fact that gypsum is sensitive to weather conditions and temperature changes.

- Acrylic putty. This material is easy to apply on drywall for painting, because it is plastic, easy to sand. Use as a starting and finishing layer. Putty is more expensive than gypsum and cement, but it is an environmentally friendly product, ideal leveling and finishing plasterboard, giving the surface a beautiful white color and a slight gloss after painting.

- Polymer putty. Suitable if you have doubts about your own abilities. In application, the material is simple, it is easily leveled even with the thinnest layer, it is not difficult to grind. Even a beginner will putty correctly. Polymer putty is vapor-permeable, the walls breathe, with a heat-insulating effect. The main disadvantage is the high price. However, with a competent calculation of the amount per application area, you will not have to buy extra.

It is important (when preparing drywall for painting) to apply a primer to the putty. This layer improves grip properties. What gives the application of a primer on drywall before painting:

- Additional reinforcement of previous layers.

- Reduced absorbency, which is an additional plus in high humidity.

- Reducing the consumption of the coloring composition due to uniform application.

- Protection against the formation of mold and fungi.

- Improved bonding properties between coatings.

Like plasters, primers for drywall for painting are sold in several types. They have various additional properties that are based on when choosing:

- Water repellent primer. For rooms with a high level of moisture, such as kitchens, showers and bathrooms. Surfaces treated with this composition are able to pass steam without retaining water.

- Anticorrosive primer. It is mainly used on metal surfaces subject to corrosion and rust. However, many advise using such a primer when processing plasterboard boxes for radiators and other communications before painting.

- Antiseptic primer. Often this type is also fireproof, so it is used in rooms where the level of fire hazard is increased. However, the main property of this primer is to prevent the formation of fungus and bacteria. It is used on already affected surfaces, as a preventive measure to avoid the appearance of mold.

- adhesive primer. Possesses the increased level of coupling with a covering. If the prepared drywall has a lot of roughness, other damage, painting will be perfect with this tool.

- Deep penetrating primer. This type is suitable for those who do not want to understand the difference between the starting and finishing layers, planning to reasonably save on materials. This tool penetrates deeply into the structure of the previous layers of drywall processing, impregnating them, increases the strength of the coating for painting.

After completing the stages of preparing drywall for painting, proceed to the final coating. However, there are nuances here, because the choice of paint is not limited to color. Before painting drywall consider:

- Moisture resistance. When working in rooms with high humidity, they choose means for preparing drywall with moisture-repellent properties, so the paint should also be with the same effect. Otherwise, the starting coating will stick, and the paint will stain or simply fall off.

- Breathability. This factor is taken into account to avoid the accumulation of moisture under the coating.

- Washing surface. This is important to take into account on coatings in the kitchen, such as rooms where drops of fat and other contaminants can get on the drywall product.

- Safety. An important point, especially for interior decoration. Non-toxicity is needed for the safety of children, pets. The composition should have a minimum odor. If you use a coloring composition intended for external work, which has a strong chemical the smell in the room, then dizziness, nausea are possible, you can get poisoned, asthma symptoms will increase, allergies.

- Abrasion resistance. If the drywall to be painted is in a place where there will be frequent contact with any other objects, then this item is taken into account. After a while, the paint will rub off and a stain will appear, this will be especially noticeable on bright, dark surfaces.

- Consistency. Too thick or vice versa, the liquid coloring composition will lie unevenly when stained. The problem is easily solved with a solvent in the case of density. However, before buying a large volume of coloring compositions, they study reviews or purchase a small tester.

- Hiding power. It depends on this factor how many layers of the coloring composition will be applied, because, depending on the color, consistency, the coating will lie evenly, in a dense layer the first time, and in some it will take 2-3 painting.

Drywall itself is not picky about the type and composition of the coloring composition, which is why it is considered a universal material for painting.

2 large groups of paints for finishing:

- Organic. This type is created on the basis of alkyd varnish, and white spirit is used as a solvent.

- Waterborne. This type is used for finishing both internal and external walls, the solvent for it is ordinary water.

Each of the species with separate subspecies, which have nuances and features.

Organic:

- Oil. The advantage of this type of coverage is the cost. There are more cons. The first and obvious one is that it has a pungent odor. Therefore, it is not recommended to use when working indoors. The second disadvantage is that this coating does not allow air to pass through, it dries for a long time. Another disadvantage is that the service life of this coating is relatively short - about 3 years. Exposure to direct sunlight accelerates this process. Using the oil composition for external work, the service life is reduced even more, it will be a year and a half.

- Alkyd. As with oil, this type has a strong odor due to the fact that gasoline or turpentine is used as a solvent. Therefore, it is not recommended to perform internal work with this tool. Often chosen because of the low cost. Resistant to direct sunlight, temperature extremes, moisture.

Waterborne:

- Water emulsion. The basis of this type of coating is an aqueous solution with the addition of oil particles. There are many advantages, so it is the “water emulsion” that is chosen when finishing drywall products. One of the obvious advantages is the cost. It is slightly higher than that of oil or alkyd, but not critical. The absence of an unpleasant odor and the speed of drying are the arguments when choosing the final coating. Due to the consistency of the "water emulsion" lay down in a dense, even layer. However, there is one drawback here - they are washed off with water, therefore they are not recommended in kitchens, where frequent wiping of coatings from dirt, and in showers and bathrooms.

- Water-dispersed. This type is popular when used for painting drywall products. Their composition is based on an aqueous dispersion of polymers. Of the nuances, only one is distinguished - it cannot be stored at temperatures below 0 ˚С. Plus in service life. This type of coating is resistant to moisture.

- Acrylic. This coating is well tinted in any shade, dries quickly. Does not have a strong unpleasant odor, cheap. It tolerates temperature changes, changes in humidity levels. There is another type - acrylic latex compositions. They additionally level the surface, hiding even small imperfections.

They are chosen according to the composition, but in the water base they distinguish not only the absence of smell, the speed of drying, but also other factors, including a long service life. In the manufacture of various products from drywall with your own hands, "water emulsion" is a favorite.

What tools and materials to prepare

At the very beginning, prepare the inventory that will be required for painting and working with drywall:

- Brushes. Take several sizes, including thin ones, to work with corners.

- roller. An ordinary one will do, but with a large amount of work, you will need several pieces.

- Putty. Choose based on the type of drywall.

- Priming. Take acrylic.

- Spatulas. Just like brushes, you will need different sizes.

- Paint bath.

- Sandpaper. Several types with different grain size from 80 to 180.

- Ladder. If the work will be carried out at height.

- Additional lighting. When preparing the material and working with it, it is sufficient light that will help to see even small flaws and quickly correct them.

- Respirator. When working with paint and other similar substances.

- Masking tape. For markup, if required.

When performing the final stage of work (painting), they are determined with the tool:

- roller. It is not recommended to use foam rubber, because they leave strong stains.

- Professional spray gun. With this method of application, the coating will be even, and the application process itself is simple and fast.

- Brush. A simple method, a long one, and at the same time there is a high probability of leaving texture stains.

Applying paint with a roller is a budget way. In this case, the work itself will be easier and faster than coating with a brush. However, when choosing a roller, pay attention to some nuances. The use of foam rubber when painting is not recommended.

In any building mass market there are rollers:

- Polyamide. These rollers come in different lengths of artificial pile, from 8 to 20 mm, for a certain type of paint and coating texture. They allow you to apply a thin and even layer without streaks.

- Natural. With sheepskin. Both water-soluble and solvent-based paints are perfectly applied, distributing them evenly over the surface.

- Velor. Their cover is a fabric base with a plush pile. With such rollers, even a thin layer of coating is applied, while leaving no marks or streaks.

The rollers differ in the length of the pile, which you should pay attention to when performing the finishing stage of the work:

- Short - up to 4 mm. Suitable for glossy finishes.

- Medium length - from 4 to 8 mm. This look is well suited for matte paint.

- Long - more than 8 mm. A roller with such a pile is more convenient to create textures at the final stage of work.

The rollers differ in the width of the treated surface:

- Mini rollers. The width of the working surface is 50 to 100 mm. This type of roller is used for painting hard-to-reach places, embossed surfaces with many small details.

- Midi cushions. From 100 mm to 150 mm. Otherwise, they are called standard, because. sold in any building mass market. They are used for their versatility.

- Maxi rollers. In another way they are called professional. Used for painting large areas, since the size of the working surface is from 180 to 270 mm.

The technology of applying paint to drywall

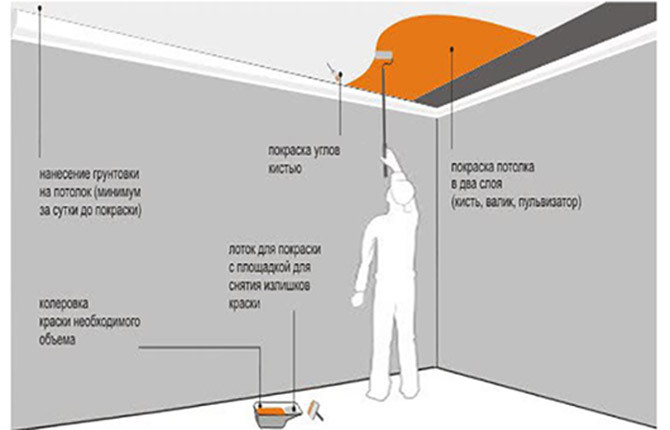

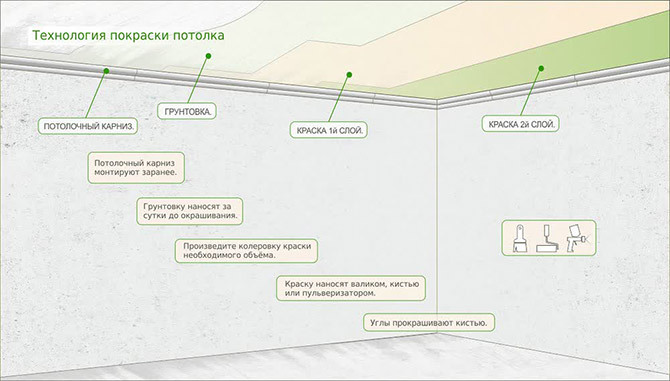

After preparing the tools and materials, the surface, proceed to the final stage - painting. To ensure that the result is the same as expected, carefully follow the instructions for applying the final coat of paint.

The tool for applying paint is a roller. Following the recommendations, select the material and size.

Step-by-step instructions for applying paint to a prepared drywall surface:

- Prepare the paint by mixing it thoroughly so that there are no streaks, and the color is even. Pour into a special bath.

- Gain paint on the roller without excess, to eliminate smudges and streaks. To do this, the working surface of the tool is rolled several times along a special slope on the container.

- Apply paint in an up and down motion.

- Do not try to apply more paint at a time on the wall. This will lead to leaks. They also make sure that the drops are rolled out, excluding the creation of a relief.

- When painting walls, it is recommended to first apply paint to corners and other hard-to-reach places, and then to the rest of the surface.

- Monitor the uniformity of the coating and avoid streaks. Change the roller, if necessary.

- When applying the second layer, wait for the first to dry, and only then proceed to re-painting.

After completing the painting of the surface, it is necessary to protect it from external damage before drying. It depends on the chosen paint, but on average it is about a day. For oil, you need a little more.

Having carefully studied the nuances when working with drywall, to make a visually complex niche or arch from it is even a beginner who is not privy to the intricacies of finishing work. And the painting technology is simple, if you follow the recommendations and correctly prepare the surface.

How do you paint drywall, what do you use in preparation? Share the link on social networks and bookmark the article.