A bed with a lifting mechanism solves one big problem that occurs in standard rooms. It's not enough free space. Often by setting bed in such rooms, there is no room for other pieces of furniture.

A berth with a lifting mechanism is not just a sunbed, but a large storage area, which is located under the mattress. And to get to it, you need to lift the grate. For this, a lifting mechanism is installed.

The content of the article:

- Features of the design of beds with a lifting mechanism

- Bed sizes

- What mechanisms can be

- Schemes and drawings

- What tools and materials will be needed

- Step by step instructions for creating

- Where is the best place to install a bed with a lifting mechanism

Features of the design of beds with a lifting mechanism

In furniture stores, beds of this type are widely represented. But they are not cheap. You can make a bed with a lifting mechanism with your own hands, although it is not so simple. The design is not so complicated, but it requires skills to work with a certain type of tool. In addition, it is not easy to connect the lifting part with the stationary one using a mechanism.

Speaking about the design features, several important points should be noted:

- The lifting mechanism can connect 2 parts of the bed both in a horizontal position and in a vertical one. It all depends on the chosen model.

- The lifting device is selected based on the dimensions of the bedroom furniture. The larger the bed, the heavier it is. Accordingly, for it it is necessary to buy a more powerful lifting mechanism, with a greater carrying capacity.

- The higher the height of the bed, the more storage space under the mattress.

- In the design with legs, the storage box is smaller in volume than in the design without legs.

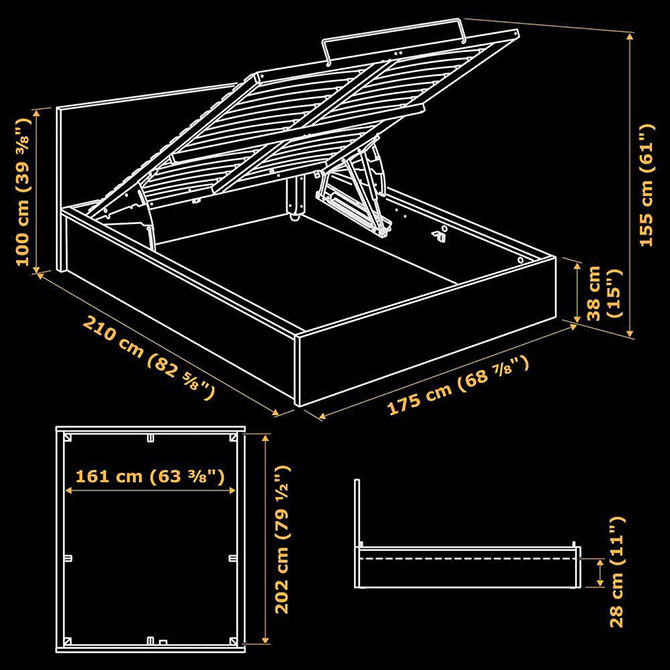

Bed sizes

Classification based on the dimensions of the place to sleep:

- One or two bedrooms. This applies to models used by adults. And here the main size is the width. For single beds it is 90 cm, for doubles it is 160-180 cm. The length in both cases is 2 m.

- Adults and children. The width of the last 60-90 cm, the length is selected taking into account the growth of the child, to which 20-50 cm is added. This is for growth.

The height of a bed with a lifting mechanism is limited only by common sense. The minimum is 40 cm.

What mechanisms can be

Manufacturers produce 4 types of lifting devices.

- Manual. There are no additional energy storage devices in the design, which help to raise the sunbed with the mattress. Therefore, it is difficult to carry out this action, especially if the bed is double. It is heavy, and the entire burden falls on the hands. Children, the elderly and fragile women cannot cope with such a mechanism. In addition, a heavy mattress with a frame is a serious load on the lifting device, which is why it quickly fails. But this is the cheapest model.

- Spring. Here, the installed springs take on part of the load. When lowering the frame with the mattress, they stretch, so a compressive force is created. When the sunbed is raised by hand, the springs spontaneously compress, lifting the entire structure behind them. But their efforts are not enough to carry out this action on their own. As an assistant, they perform the functions assigned to them.

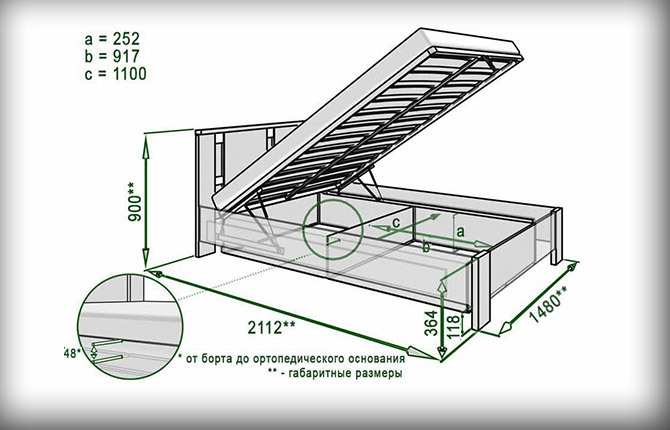

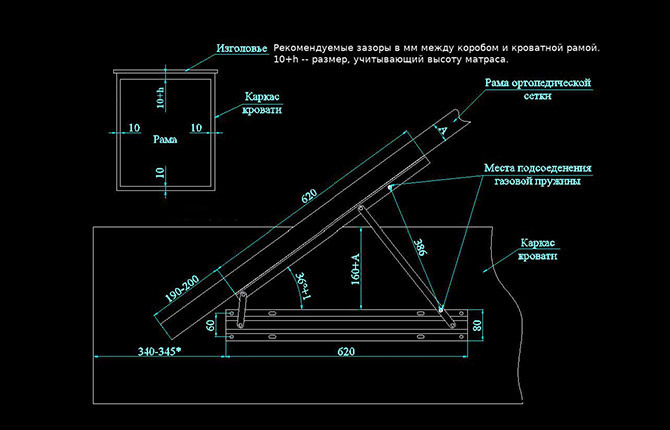

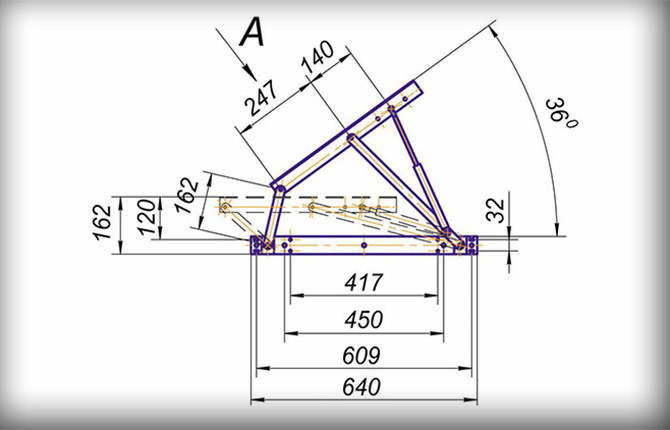

When making a bed with a lifting mechanism yourself, you must choose the right spring device. Its length and stiffness are chosen taking into account the weight of the mattress and the frame on which it fits. Structurally, you can change both parameters of the mechanism with your own hands due to the fact that through holes are made on the rods of the device as places for fastening the springs. By changing these places, you can increase or decrease the length and stiffness. - Gas. A steel cylinder filled with compressed gas is installed in the design of the lifting mechanism for the bed. A rod is inserted into it, at the end of which a piston is attached. When the mattress is in a horizontal position, the rod is completely inside the cylinder. He squeezes the gas with his piston to the maximum. When the frame is lifted, the gas pushes out the piston rod, thereby creating energy that helps to carry out the lift. This lifting mechanism has a big plus - it is more efficient than the previous 2. And 2 minuses - high price, the cylinder cannot be repaired. Therefore, the advice is to buy a gas analogue only from well-known manufacturers that guarantee a long service life. Fakes don't last long.

- Auto. This lift has an electric motor. The mechanism is volatile. The principle of operation is based on a device that converts the rotational movement of the motor shaft into translational. You can control the mechanism with a button installed on the bed, or remotely using the control panel. It all depends on the chosen model. This option is convenient in that no effort is needed here. Therefore, it is recommended to install them on large and heavy beds, as well as on children's beds.

The gas lift cylinder indicates how much force it can generate. This should be taken into account when choosing a model, commensurate this indicator with the weight of the lifting part of the bed along with the mattress.

Schemes and drawings

In the manufacture of a bed with a folding mechanism, the dimensions of the structure are mainly taken into account. Sleeping area will be single or double. From this calculation, you need to sketch out a sketch of the future piece of furniture with exact dimensions on a clean sheet of paper.

Next, decide on additional structural elements. They will be present or not. For example, the storage will be in the form of drawers or it will be just a common niche. If boxes, what sizes, how many there will be. Because for each you need to purchase mounting and retractable mechanisms. Under each box, load-bearing elements are added to the bed structure, to which the sliding devices will be attached.

But the basis of the entire drawing will be the mattress, or rather, its dimensions. First, choose it, and then around to form the bed itself. You can not do the latter, and then buy a mattress. There's a good chance something won't match up somewhere.

It is better to make a detailed drawing with the details of each element. This will not only simplify the layout of the assembly process. This is necessary to purchase the required materials and fasteners. In addition, it will become clear which tool needs to be prepared.

What tools and materials will be needed

From the tools you will need:

- a wood saw or a circular saw - the latter cuts smoothly, which is important when making a bed with a lifting mechanism;

- drill with drills;

- screwdriver;

- long steel ruler;

- roulette;

- pencil;

- furniture stapler with metal staples.

From materials:

- a wooden block with a section of 25x50 mm - for assembling a lattice for a mattress;

- laminated chipboard or boards - to assemble the frame of the bed itself;

- plywood 6-8 mm thick - for the bottom of the storage place;

- if a headboard is being built, then you still have to buy a furniture board or laminated chipboard;

- self-tapping screws, confirmations (these are furniture screws), corners and ties;

- decorative tape for finishing chipboard edges;

- upholstery fabric, if provided;

- legs, if they are also planned in the design of the bed;

- lifting mechanisms.

It is easy to cut out all the elements of the bed with your own hands. But it will take a long time. And there is always a high probability that some of the elements will be cut inaccurately or incorrectly. Mistakes in this difficult matter cannot be avoided.

Therefore, advice - sawing boards or chipboard can be ordered in furniture workshops. In the same place, decorative tapes will be professionally glued to the chipboard elements. The same services are now offered by large stores selling furniture or building materials.

Step by step instructions for creating

A step-by-step instruction for making a bed with a lifting mechanism consists of 4 operations:

- Assembling the bed frame. It is he who forms the place of storage. Lifting mechanisms will be attached to it and a lattice for the mattress will lie. This is a rectangular design with the dimensions of a bed.

- Assembling the lattice under the mattress.

- Installation of lifting mechanisms with fastening to the base frame.

- Fastening the grate to lifting mechanisms.

The base is assembled first. In fact, this is a rectangle of boards or sawn sheets of laminated chipboard. If the bed is single, then nothing is added to the design.

If double, then you need to install another longitudinal element, which will be an additional support for the lounger grill. The installation location is in the middle of the rectangle. This additional element should be smaller in width than the other main ones (in the design of the bed, it will be lower than others), because the lattice under the mattress is laid so that it does not go beyond frame. Its surface should be flush with the edges of the sidewalls.

All elements of the frame are connected to each other by perforated corners on self-tapping screws. This is the easiest and most reliable way. There are many others that are equally reliable, but for many of them you need to prepare, which takes some time. For example, in order to use furniture bolts for connection, you need to drill holes for them, make grooves for nuts, and so on.

You can use a different bed model. Here, one of the load-bearing parts of the structure is the headboard. It can be cut from furniture board, chipboard or plywood. The width of the headboard corresponds to the width of the bed, the height is not limited by anything, only common sense. Any form is chosen. It is to the headboard that the sidewalls of the base frame are attached.

The frame is ready, now you need to attach the legs to it, if any are planned. If not, then neither the lower edges are attached to furniture stands made of plastic or aluminum.

And the last thing related to the assembly of the frame is the installation of bars with a section of 50x50 mm along its perimeter. These are the supports on which the lattice of the lounger will be laid. The place of their installation is below the upper edges at a distance equal to the thickness of the lattice under the mattress. Fastening method - self-tapping screws.

The next stage is the manufacture of a lattice for the mattress, which is also the lifting part of the bed. There are many options here, but everything is based again on a wireframe basis. You need to make a rectangular frame with your own hands, the external dimensions of which should be 8-10 mm smaller than the internal dimensions of the assembled base frame. The grille should fit freely inside the finished frame structure.

Strictly according to the dimensions from the drawing, a rectangle is assembled from wooden bars with a section of 50x50 mm. The corners that are formed by the bar elements are verified. They must be straight. The connection is made by perforated corners on self-tapping screws.

Inside, 2-3 bars are installed along the frame. They will give the structure rigidity and strength. Now boards with a section of 25x100 mm are stuffed on top of the resulting structure in increments of 15-20 cm. Instead, you can lay plywood with a thickness of 8 mm.

Now we need to check whether the lifting part of the bed will freely enter the stationary one. It is necessary to put the grate inside the base frame. If this action did not cause difficulties, then you can proceed to the installation of lifting mechanisms.

They are first attached to the stationary part. The installation location depends on the type of bed being made. If it is single, then lifting devices can be mounted next to the headboard. If a double bed, then closer to the middle of the structure. Fastening is made to the sidewalls.

Lifting mechanisms should not be fixed with self-tapping screws. They just can't handle the heavy load. Therefore, it is better to use bolts for which you need to drill through holes. It is done like this:

- apply the mounting plate of the lifting mechanism to the side of the bed;

- through the mounting holes with a simple pencil are placed on the last mark;

- holes are drilled through them;

- the folding device is again applied at the installation site and fastened to the sidewall with a bolted connection;

- the head of the bolt should be on the outside, the nut with the washer inside, it is better to use bolts with a rounded or flat head.

Now it is necessary to lay the grate under the mattress on top of the base frame and lifting mechanisms. From below, through the upper mounting strips of the folding devices on the lattice frame, marks are made with a pencil. The latter is removed, and through the marks on it, through holes are made. It is again placed at the place of installation and bolted to the lifting devices. The bolts must be installed so that their caps are on top, the nuts and washers are on the bottom.

Manufacturers of furniture lifting mechanisms in the instructions attached to them clearly and in detail describe how to install these devices. The installation scheme is painted, as well as the dimensions of the indentations for the holes. If you strictly follow these instructions, then assembling the bed will not be problematic.

Before you screw the grille to the folding products, it is recommended to experiment. Screw it temporarily, but securely, for example, with wire. Then raise the lifting part of the bed and make sure that everything works, the elements do not touch each other, the lifting height is required. Be sure to make sure that even the lift is enough to unlock the hinged part. Because when the lattice with the mattress is raised to the maximum, it is blocked by latches on the lifting mechanisms. You have to lift it up to unlock it.

The last operation is laying the plywood sheet at the very bottom of the bed structure. The plywood will form the bottom of the storage space. It can be attached to the underside of the base frame. It is possible to break through the bars along the lower edges, as if under a grate. Only use a bar with a section of 20x20 mm. If the bed is double, then 2 plywood sheets are laid. They will be separated by a longitudinal jumper.

On this, the assembly of the bed with a lifting mechanism can be considered complete. It remains only to decorate. If the assembly is carried out with laminated chipboard, then finishing is not needed. If boards, chipboard or plywood were used, then all wood finishing technologies can be applied here: painting, varnishing, staining, upholstery with fabric, stencils, and so on.

Where is the best place to install a bed with a lifting mechanism

There are no strict conditions that regulate the installation site. You just need to understand that the folding model in height will occupy a certain space. This is when the bed lift will be raised. And if it is installed in the attic, where the roof slopes form the walls of the room, then you should not install it under the slopes. The raised part will rest against them, which will prevent the bed from opening completely. The same situation will arise if you install the bed under the stairs.

The same applies to areas near the wall. It is better not to put the bed against the wall. It is highly likely that over time, a backlash will appear in the fasteners, which will lead to displacement of the elements relative to each other. This means that the hinged part at some point will begin to touch the surface of the wall.

A bed with a lifting mechanism is best placed where there is a lot of free space. And even in small rooms, its installation site is in the middle. It is possible against the wall, but so that the headboard is located there. If drawers are used in the design, then it must be installed so that these drawers can be freely opened completely.

In fact, a bed structure with a folding lattice under the mattress is an ideal piece of furniture. In fact, this is a wardrobe bed that occupies one small area and performs 2 functions: a place to sleep and storage. It is not recommended to store heavy objects in it. Plywood installed from below may not withstand heavy loads. It obviously will not crack or break, it can simply separate from the frame.

Who has already tried to assemble such a bed model with his own hands - respond. Write in the comments what materials were made of, what lifting mechanisms were used, were there any difficulties or not? Bookmark the article so that useful information is available at any time.