Expanded clay blocks are in demand in the construction of residential, utility and public buildings. Expanded clay concrete is classified as lightweight concrete. The popularity of the material is due to the low price and low weight with high strength, ease of wall construction.

In order to obtain high-quality and safe material that meets all building codes, it is important to learn how to distinguish factory products from handicraft fakes.

The content of the article:

-

What is expanded clay concrete blocks

- Production technology

- Technical characteristics of expanded clay blocks

- Main manufacturers

- Spheres of use of expanded clay blocks

- Block marking

-

Types of expanded clay concrete blocks for their intended purpose

- Wall

- Partition

- Facing

- Types of expanded clay blocks by design

-

Tables with the dimensions of expanded clay concrete blocks

- For walls and partitions

- Non-standard dimensions

- large format

- Weight of expanded clay concrete blocks

- How many expanded clay concrete blocks in 1 m3 of masonry

- How many blocks in a pallet

- Material cost

- Quantity calculation

-

Pros and cons of a house made of expanded clay blocks

- thermal insulation

- Durability

- Frost resistance

- Vapor permeability and moisture resistance

- Environmental friendliness

- Ease

- Labor intensity and cost

- Noise isolation

- Chemical inertness of expanded clay concrete

- The main disadvantages of expanded clay concrete blocks

- Myths about the danger of expanded clay blocks

- Comparison of expanded clay blocks with other materials

- Reviews of real owners of houses from expanded clay concrete blocks

- What to look for when choosing blocks before buying

What is expanded clay concrete blocks

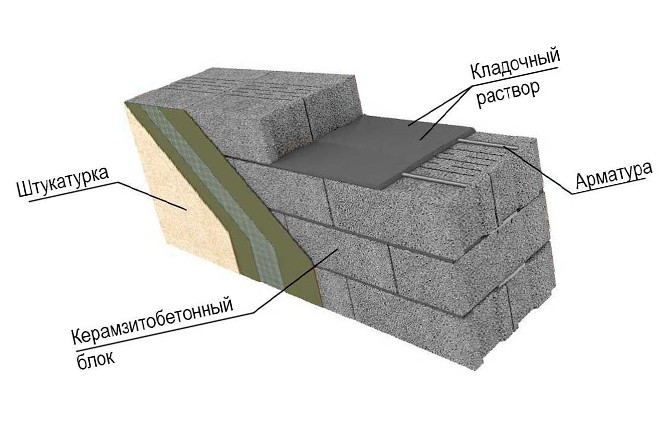

Expanded clay blocks are made of lightweight concrete. They are used as a building material for internal partitions and external facades.

They are blocks with dimensions exceeding the parameters of ordinary bricks. The material is lightweight and porous.

Production technology

Expanded clay concrete block is made from sand, expanded clay, cement.

Consumption of ingredients to kg per m3 for the production of claydite block 200 grade:

- cement component (GOST 10178-85, not lower than M-400) - 300;

- sand (GOST 8736-93, coarse or medium fraction) - 300;

- expanded clay granules (GOST 9757-90, fractions of 5-10 mm are more often used) - 1100;

- liquid (GOST 23732-79, water without impurities) - 195.

But this ratio is not standard. The manufacturer has the right to change the proportions to change the characteristics of the product. The amount of water depends on the moisture content of the remaining components. It is allowed to add fillers and plasticizing impurities.

The components are loaded into concrete mixers and mixed. A quality mixture resembles thick sour cream in consistency. Then it is molded (poured into molds). Bring to normal strength. The factory uses two methods:

- In an autoclave. Expanded clay blanks are placed in an autoclave, in which they are treated with hot steam under high pressure.

- Vibrocompression. For the procedure, a special machine (vibropress) is used. The mixture in the molds is affected by vibration with simultaneous pressure.

Both methods allow you to get rid of voids, improve the characteristics of expanded clay concrete blocks.

The last stage is drying. The material is dried directly in the forms in a natural way (from 2 days) or in a special chamber by steaming (up to 12 hours).

In handicraft production, blocks in molds are left to “ripen” in natural conditions, bypassing the procedure of vibrocompression or autoclaving. This takes approximately a month, but usually this time is reduced in order to speed up the production process. Such products are characterized by low strength.

Technical characteristics of expanded clay blocks

Expanded clay blocks - parallelepipeds with even ends or with grooves and ridges on them. Their corners are smooth and rounded, and the supporting surfaces are flat or with grooves.

The strength of the brand of expanded clay concrete blocks is from 35 to 100 kg / cm². Density - from 500 to 1800 kg / m³.

The main characteristics dictate the proportions of substances in the composition of expanded clay concrete blocks, the presence of impurities in it.

Table of vapor permeability and thermal conductivity, taking into account density:

| Density kg \ cu. m. | Thermal conductivity coefficient (W\(ms)) | Vapor permeability mg\(m h Pa) |

| 500 | 0,14 | |

| 600 | 0,16 | 0,256 |

| 800 | 0,21 | 0,187 |

| 1000 | 0,27 | 0,138 |

| 1200 | 0,36 | 0,108 |

| 1400 | 0,47 | 0,094 |

| 1600 | 0,58 | |

| 1800 | 0,66 |

Main manufacturers

The safety and durability of expanded clay concrete products depends on their quality. Therefore, it is worth choosing the material of trusted manufacturers. Here are some of them:

- Cheboksary building complex.

- Smolegkoe enterprise "Monolith".

- "Premium brick plus" company.

- Company "Stroy Pavement".

- Enterprise "Stena Blok".

- Klinstroydetal.

- CJSC "Keramzit"

All products of these factories are subject to mandatory certification. Enterprises have SES conclusions on environmental safety. Their product complies with state standards, is safe for humans and the environment.

Spheres of use of expanded clay blocks

Expanded clay blocks are intended for construction of houses. Expanded clay bricks are used for:

- load-bearing elements of the structure;

- construction of partitions;

- wiring communications (for example, the construction of a chimney);

- exterior wall finishes.

Block marking

Claydite blocks, as well as other building materials, are marked. With its help, they indicate the characteristics, type and class of the product. Reading the label is easy if you know the basic notation.

| Letters | Numbers |

| K - a kind of artificial stone | The first is the length in cm |

| L - front | The second is the strength factor |

| C - wall | Third - frost resistance |

| P - partition | Fourth - density |

| PS - hollow | |

| PZ - for dressing seams | |

| P - private | |

| UG - angular | |

| PR - ordinal |

Using the table, it is easy to decipher any marking. For example, the designation KSR-PR-PS-39-100-F100-1500 is:

- KSR - ordinary wall stone;

- PR - ordinal;

- PS - hollow;

- length 39 cm;

- strength 100 kg per 1 sq. cm;

- frost resistance 100 cycles;

- density 1500 per cubic meter kg.

Types of expanded clay concrete blocks for their intended purpose

Expanded clay blocks are classified according to their purpose. The following options are distinguished:

- wall kremsite blocks;

- facing products;

- partition elements.

Wall

Wall claydite-concrete blocks are designed for laying load-bearing walls. Differ in high strength and density characteristics.

Solid expanded clay blocks are suitable for the construction of load-bearing walls of residential buildings. They are the most durable, but have a high price compared to hollow ones. For outbuildings, it is possible to use hollow ones.

Partition

Such expanded clay blocks are bought for the arrangement of internal walls. They are not suitable for load-bearing structures. An exception is buildings with one floor.

Partition blocks are released with voids inside. They are thinner than wall tiles. This allows you to build fairly thin, but at the same time durable and with good soundproofing walls inside the building.

Facing

Such expanded clay blocks are distinguished by precise geometry, have a decorative coating on one or both sides. Designed for external walls, therefore, they meet all the requirements for such building materials

Their advantage is that additional cladding of the walls erected from them is not needed. Decorative coating can be of various shades and textures.

And why do you want to use expanded clay blocks?

Wall construction

50%

The erection of a partition

50%

Facing

0%

I'll post my version in the comments.

0%

Voted: 2

Types of expanded clay blocks by design

According to the type of construction, expanded clay concrete blocks are divided into corpulent and hollow. Their differences:

- Hollow. Inside each block there are evenly distributed voids. This makes the product lighter, increases its thermal and sound insulation characteristics. When laying, the voids must lie on the cement mortar. Hollow expanded clay blocks are designed for the construction of one-story buildings.

- Full bodied. Products with high strength and density characteristics. There are no voids in such blocks. Material for buildings with different number of floors.

Tables with the dimensions of expanded clay concrete blocks

Dimensions of building materials are regulated by GOST standards. However, in the case of expanded clay concrete blocks in size, some nuances and errors are permissible.

For walls and partitions

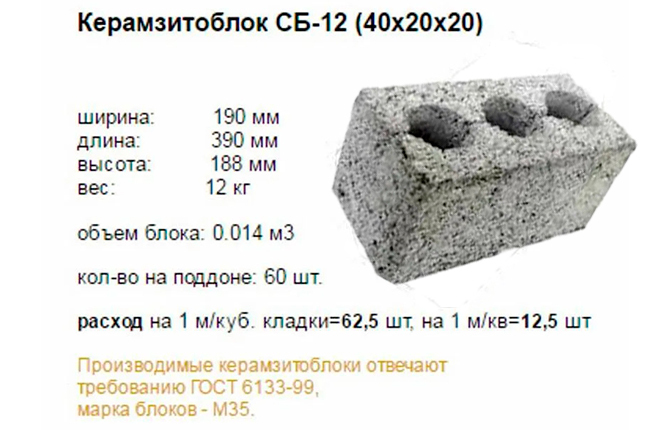

Most manufacturers use standard sizes of expanded clay concrete blocks. Materials for walls and partitions according to GOST 6133-2019 are produced with the following parameters (in mm).

| block type | Height | Length | Width |

| wall | 138 | 288 | 288 |

| 138 | 288 | 138 | |

| 188 | 390 | 190 | |

| 188 | 290 | 190 | |

| 188 | 288 | 190 | |

| 188 | 190 | 190 | |

| 188 | 90 | 190 | |

| Septal | 188 | 590 | 90 |

| 188 | 390 | 90 | |

| 188 | 190 | 90 |

If you are building walls or a partition in the animal shed, then do not forget about ventilation.

Non-standard dimensions

Expanded clay blocks are also available in non-standard sizes. They are usually made to order.

Also, some manufacturers produce blocks not according to GOST, but according to TU. These standards are individual for each enterprise. Therefore, if the product is not GOST, but TU marking, it is also worth studying.

large format

Large-sized blocks of expanded clay concrete are produced according to specifications. Their size range is wide. Popular dimensions (in mm):

- 192x390x400;

- 200x200x400;

- 200x400x400;

- 400x400x200;

- 600x300x200;

- 400x400x1200;

- 1200x400x400.

Manufacturers are constantly releasing products in new non-standard sizes to increase their own competitiveness. The increased size of building materials allows you to speed up the construction of the walls of the building.

Weight of expanded clay concrete blocks

The weight of KB-blocks depends on their size, the presence of voids inside the product, purpose and other characteristics. The average weight of different types of claydite blocks with a size of 390x190x188 mm:

- full-bodied wall expanded clay concrete product M75 -18 kg;

- full-bodied expanded clay blocks M100 - 19 kg;

- hollow M35 weigh 11 kg;

- hollow KBB M 50 - 12 kg;

- the mass of the hollow KBB M75 is 14 kg;

- hollow products M100 weigh 16 kg.

The weight of large-sized products is much greater.

How many expanded clay concrete blocks in 1 m3 of masonry

The number of expanded clay concrete blocks that fit in 1 cu. m masonry, depending on their size. To make calculations, it is necessary to multiply the length, width and height of one unit in meters with each other. Then divide the unit by the resulting value. The result will be the answer.

For example, let's take the most popular size - 390x190x188 mm. To calculate the number of blocks, taking into account the seams, the parameters must be rounded - 400x200x200 mm. The calculations look like this:

- 0,4*0,2*0,2 = 0,016;

- 1\0,016=62,5.

It turns out that in 1 cu. m fits 62.5 blocks with a size of 390x190x188 mm.

How many blocks in a pallet

Blocks of expanded clay concrete have a variety of dimensions. GOST does not establish the amount of material for one pallet.

On the market, packages of 72, 84, 90, 105, 120-160 pieces are most often found. in one pallet. But this number may change.

Material cost

The price of expanded clay concrete blocks depends on the dimensions, purpose, type of product.

Quantity calculation

To calculate the required number of blocks for the planned construction work, it is necessary to subtract the area of door and window openings from the total wall area. The resulting number is multiplied by the number of blocks in 1 square. m (1 divided by the area of one block in meters). The material must be taken with a small margin.

It is easier to make calculations using an online calculator. The specified dimensions are entered into the windows and the program displays the finished result.

Pros and cons of a house made of expanded clay blocks

Expanded clay blocks have their pros and cons. Before dwelling on this building material, it is worth familiarizing yourself with them.

Pros:

- high-quality thermal insulation;

- durability;

- frost resistance;

- vapor permeability and moisture resistance;

- environmental friendliness;

- light weight;

- ease and speed of laying;

- price;

- soundproofing;

- fire safety;

- chemical inertness.

thermal insulation

Expanded clay in the composition of the blocks provides high thermal insulation qualities. This property is also provided by the porosity of the material.

Durability

The minimum service life of expanded clay blocks is 50 years.

Frost resistance

The material is not afraid of even extremely low temperatures. Withstands at least 75 freeze and thaw cycles. It is often purchased for use in areas with an extremely frosty climate (subject to high-quality heat and moisture insulation).

Vapor permeability and moisture resistance

The porous structure of expanded clay concrete materials provides high vapor permeability and hygroscopicity. Such walls take moisture from the air and dry quickly.

Moisture does not provoke the destruction of walls made of expanded clay concrete, does not contribute to the appearance of fungus and mold.

Environmental friendliness

High-quality factory-made expanded clay products contain only safe components in their composition. They do not emit substances hazardous to the environment or human health.

Ease

Despite their large dimensions, expanded clay concrete blocks are lighter than bricks. This allows you to reduce the cost of arranging the foundation. Light weight makes it easier to work with building material.

Labor intensity and cost

High speed and low labor intensity of masonry is ensured by large dimensions, low labor intensity of cutting and processing, light weight of expanded clay concrete (compared to brick).

Expanded clay blocks are relatively inexpensive.

Noise isolation

Walls made of expanded clay concrete will protect the home from extraneous noise, as the material has high sound insulation. This applies to both blocks for the construction of load-bearing structures, and for the construction of partitions.

Chemical inertness of expanded clay concrete

Expanded clay blocks are not sensitive to chemicals, fungus, mold, bacteria. The composition does not contain lime, so they will not cause corrosion of the reinforcement.

The main disadvantages of expanded clay concrete blocks

The ease of handicraft production is not the only disadvantage of expanded clay concrete blocks. The material has other disadvantages:

- The need for facade cladding made of expanded clay concrete. Bare walls do not look aesthetically pleasing (with the exception of facing blocks).

- Not suitable for arranging a monolithic foundation.

- Decreased thermal insulation properties when using handicraft blocks.

- Not suitable for the construction of unheated buildings.

- Expanded clay blocks are not suitable for areas with high air humidity due to porosity and hygroscopicity (this reduces their service life).

- Fragility. In case of inaccurate transportation, it is easy to damage expanded clay concrete blocks.

How to reduce the impact of negative factors

To reduce the severity of negative aspects, you can:

- When erecting buildings with more than 2 floors, tie the walls and lay a reinforcing mesh in 3-4 row increments. This will increase the structural strength and load-bearing capacity.

- To prevent the accumulation of moisture inside the walls and reduce the risk of freezing of the building, additionally provide high-quality thermal insulation and waterproofing.

Myths about the danger of expanded clay blocks

There is an opinion that expanded clay blocks are radioactive and emit harmful compounds. The danger is only materials from radioactive clay.

Expanded clay blocks manufactured at the factory undergo mandatory certification. They use environmentally friendly ingredients. Blocks made in artisanal conditions cannot boast of this.

Comparison of expanded clay blocks with other materials

Expanded clay blocks are not the only building material for laying walls. The list provides a brief comparison of expanded clay concrete with other options:

- Foam concrete blocks. They are easier to cut, retain heat better, but have a lower density compared to CBB.

- gas silicate blocks. Produced on the basis of lime and concrete. Due to its brittleness and ability to quickly draw in liquid, it is not recommended for load-bearing elements.

- Blocks of ceramic concrete. They are made from siliceous substances, flint sand, white cement. They are aesthetically pleasing and durable. Facades do not need decorative cladding.

- Sawdust concrete blocks. Made from sawdust, cement, sand. These blocks need additional cladding due to high fluid absorption.

- Cinder blocks. Various materials are used as a filler, for example, waste obtained during the combustion of fuel. Cinder blocks are less environmentally friendly. Thermal insulation characteristics are low.

- silicate brick. Made on the basis of lime and sand. Approved for use in areas with extremely cold climates.

Reviews of real owners of houses from expanded clay concrete blocks

Irina, 30 years old:

We built a house of expanded clay concrete 10 years ago. Speaking about the advantages, I can name a quick construction process due to the lightness, large dimensions of the material. During this time, the walls were not covered with fungus or mold, no cracks appeared on them. However, we did not have enough funds for facade cladding, and for the first 3 years the walls of the building were ugly (you can see in the photo). They also say that such houses are cold, but we immediately made high-quality thermal insulation, so we did not encounter such a problem.

Victor, 55 years old:

For a long time they chose between silicate brick and expanded clay concrete blocks. We settled on the second option because of the large dimensions. We built the house ourselves and wanted to finish the construction as soon as possible. We are satisfied. The only thing you should not choose such material because of the price. It will not be possible to save on it, since, unlike brick, expanded clay concrete walls need mandatory decorative cladding.

What to look for when choosing blocks before buying

Expanded clay concrete blocks are an environmentally friendly material with a long service life for the construction of low-rise buildings. It is chosen for its low cost, low weight, ease of installation, resistance to fungi, mold.

In order for the material to be of high quality and safe, it is better to buy factory products. Before that, make sure that there are certificates for expanded clay concrete products.

Do you think expanded clay concrete blocks are suitable for the construction of a residential building? Or maybe a brick is better? Write in the comments. Save the article to your bookmarks or repost it on social networks.